Preparation method of polybutylene terephthalate/adipate butanediol copolyester

A technology of polybutylene terephthalate and butylene diacid copolyester, applied in the field of polyester synthesis, can solve problems such as adverse effects on product quality, and achieve shortened synthesis reaction time, high intrinsic viscosity and catalytic activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

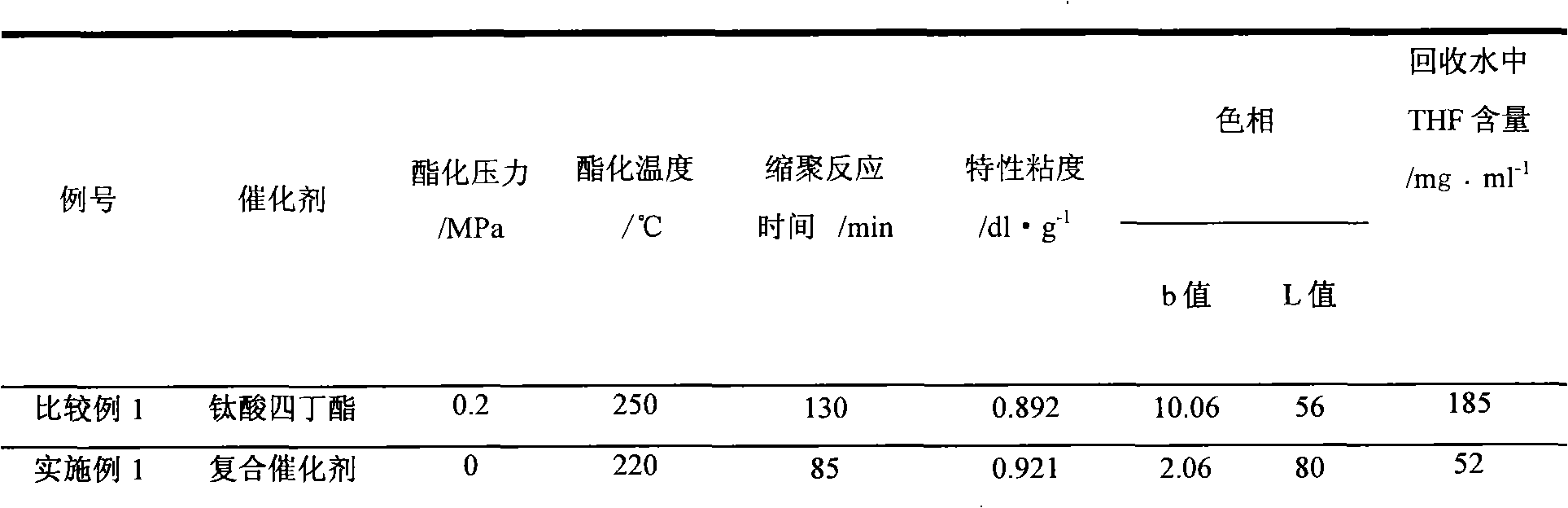

Examples

Embodiment 1

[0027] Add 820g terephthalic acid (PTA), 180g adipic acid (AA) and 383g 1,4-butanediol (1,4-BD) into a 5L stainless steel reactor equipped with nitrogen inlet, condensate outlet and stirrer. ), 0.2g tetrabutyl titanate (equivalent to 200ppm of the total weight of PTA and AA), 0.6g antimony acetate (equivalent to 600ppm of the total weight of PTA and AA). Keep the pressure in the kettle and stir at a constant speed. When the temperature in the reactor rises to 150℃, the water will be removed. Continue to increase the temperature and control the temperature in the reactor to not higher than 220℃. Wait until the amount of by-product water distilled from the reactor reaches the theoretical level. When the water output is reached, the esterification reaction ends. Continue to add 0.05g of trimethyl phosphate (equivalent to 50ppm of the total weight of PTA and AA) into the kettle, vacuum, reduce the pressure in the polymerization kettle to below 150Pa within 60 minutes, and react at ...

Embodiment 2

[0033] Add 630g terephthalic acid (PTA), 370g adipic acid (AA) and 686g 1,4-butanediol (1,4-BD) to a 5L stainless steel reactor equipped with nitrogen inlet, condensate outlet and stirrer. ), 0.2g of tetrapropyl titanate (equivalent to 200ppm of the total weight of PTA and AA) and 0.3g of antimony trioxide (equivalent to 300ppm of the total weight of PTA and AA). Keep the pressure in the kettle and stir at a constant speed. When the temperature in the reactor rises to 150℃, the water will be removed. Continue to increase the temperature and control the temperature in the reactor to not higher than 220℃. Wait until the amount of by-product water distilled from the reactor reaches the theoretical level. When the water output is reached, the esterification reaction ends. Continue to add 0.3g of tetrapropyl titanate (equivalent to 300ppm of the total weight of PTA and AA), 0.1g of antimony trioxide (equivalent to 100ppm of the total weight of PTA and AA) and 0.15g of trimethyl phos...

Embodiment 3

[0035] Add 532g terephthalic acid (PTA), 468g adipic acid (AA) and 806g 1,4-butanediol (1,4-BD) into a 5L stainless steel reactor equipped with nitrogen inlet, condensate outlet and stirrer. ), 0.3g tetramethyl titanate (equivalent to 300ppm of the total weight of PTA and AA) and 0.3g ethylene glycol antimony (equivalent to 300ppm of the total weight of PTA and AA). Keep the pressure in the kettle and stir at a constant speed. When the temperature in the reactor rises to 150℃, the water will be removed. Continue to increase the temperature and control the temperature in the reactor to not higher than 220℃. Wait until the amount of by-product water distilled from the reactor reaches the theoretical level. When the water output is reached, the esterification reaction ends. Continue to add 0.5 g of tetramethyl titanate (equivalent to 500 ppm of the total weight of PTA and AA) and 0.2 g of triphenyl phosphate (equivalent to 200 ppm of the total weight of PTA and AA) into the kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com