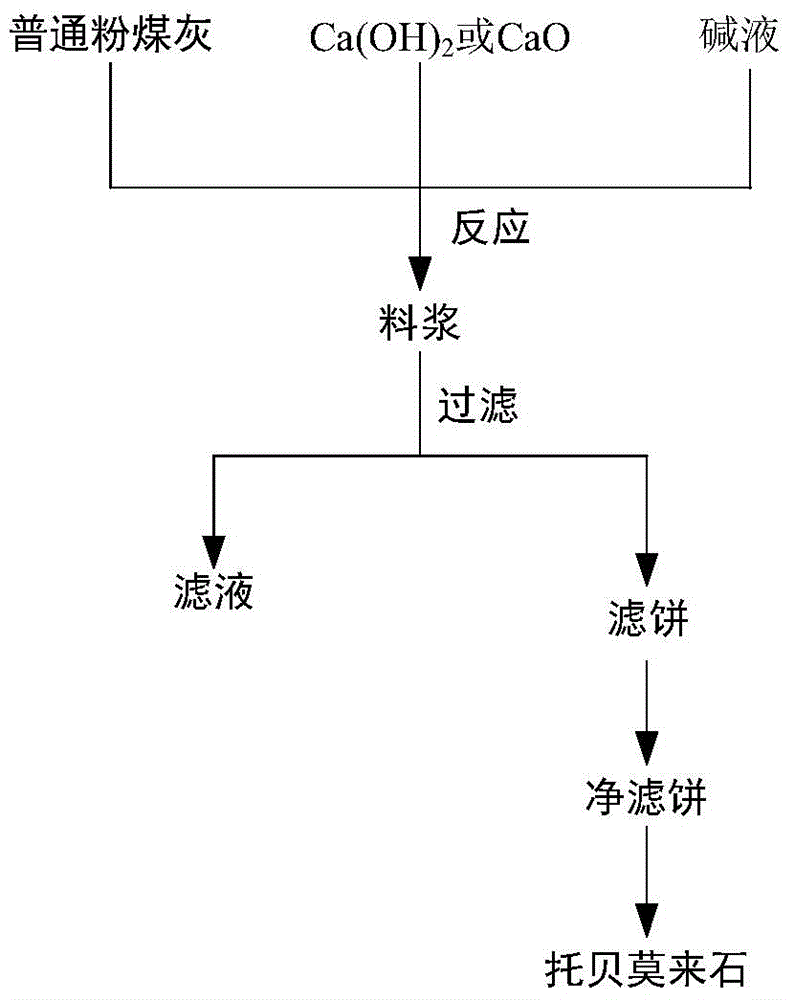

Method of preparing tobermorite from fly ash and application thereof

A tobermorite and fly ash technology, applied in the directions of alkaline earth metal silicate, silicate, etc., can solve problems such as environmental pollution, and achieve better mass transfer effect, better mass transfer effect and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

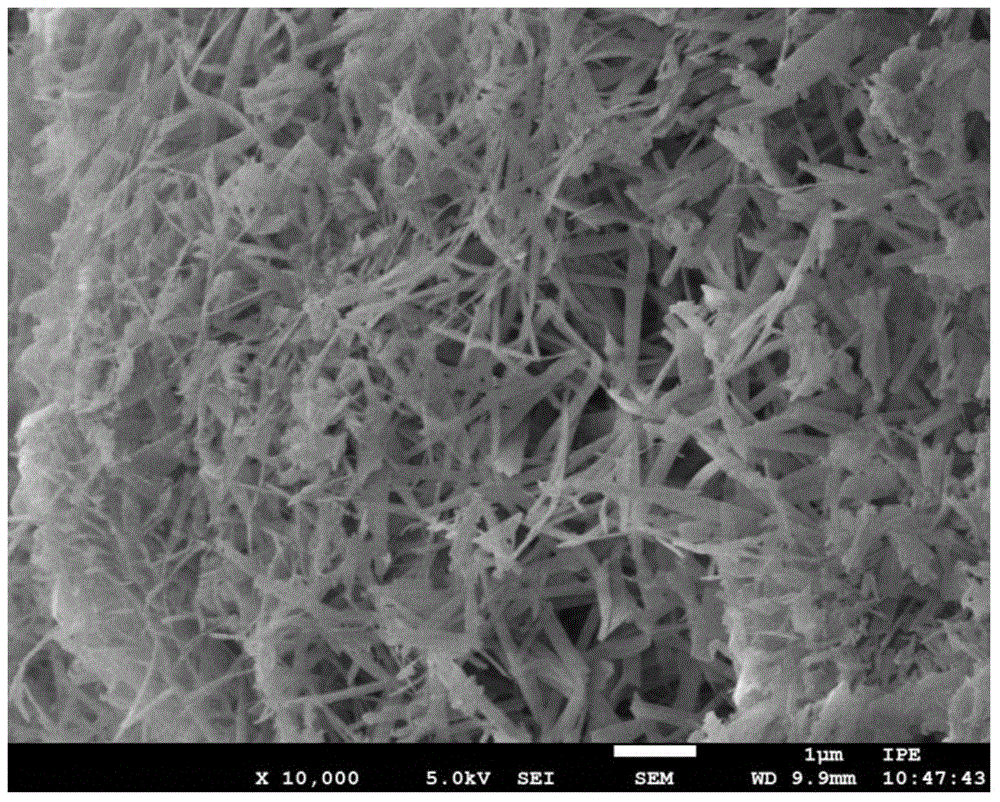

[0027] The raw material of this embodiment is ordinary fly ash, which contains 29.77% Al 2 o 3 and 43.66% SiO 2 . The above-mentioned ordinary fly ash and calcium hydroxide were combined by CaO / SiO 2 The molar ratio is 0.4 ingredients, soluble in Na 2 In the lye with an O concentration of 0.1g / L, the solid-to-liquid ratio is controlled to be 1:40, and the slurry is subjected to a synthesis reaction in a reactor at a reaction temperature of 250°C and a reaction time of 3 hours. After the reaction, the slurry is subjected to vacuum Suction filtration, tobermolite wet residue is obtained, its appearance is as follows figure 2 As shown; the slag phase obtained after suction filtration is pressed into shape with a selected mold; finally, the molded product is dried at 110°C for 3 hours, and the bulk density of the molded material is 349kg / m 3 , The compressive strength is 2.10MPa, and the linear shrinkage rate is 0.50%.

Embodiment 2

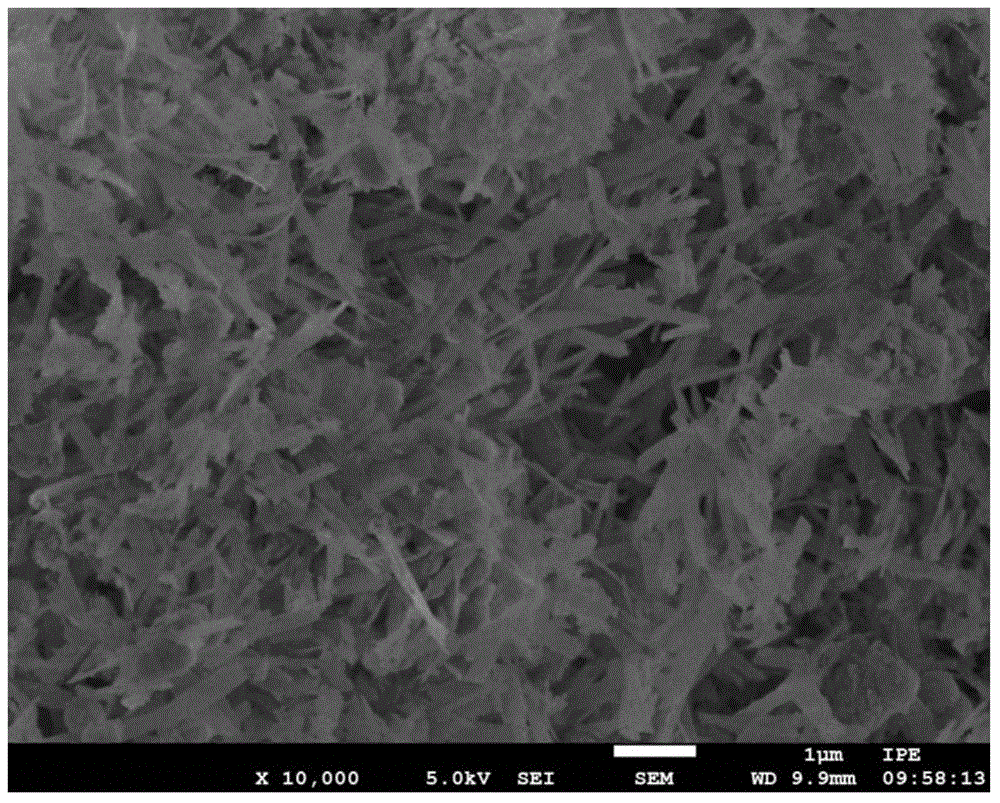

[0029] The raw material of this embodiment is common fly ash, which contains 20.85% Al 2 o 3 and 45.78% SiO 2 . The above-mentioned ordinary fly ash and calcium oxide were combined with CaO / SiO 2 The molar ratio is 1.0 ingredients, soluble in Na 2 In the lye with an O concentration of 88g / L, the solid-to-liquid ratio is controlled to be 1:20, and the slurry is synthesized in a reactor at a reaction temperature of 220°C and a reaction time of 10 hours. After the reaction, the slurry is vacuum pumped Filter to obtain wet slag of tobermolite; after suction filtration, the slag phase obtained is pressed and molded with a selected mold; finally, the molded product is dried at 100°C for 5 hours, and the bulk density of the molded material is 208kg / m 3 , the compressive strength is 1.38MPa, the thermal conductivity is 0.060W / (m·k), and the linear shrinkage is 0.58%.

Embodiment 3

[0031] The raw material of this embodiment is ordinary fly ash, which contains 27.05% Al 2 o 3 and 39.97% SiO 2 . The above-mentioned ordinary fly ash and carbide slag were combined with CaO / SiO 2 The molar ratio is 1.4 ingredients, soluble in Na 2 In the lye with an O concentration of 8g / L, the solid-to-liquid ratio is controlled to be 1:30, and the slurry is synthesized in a reactor at a reaction temperature of 220°C and a reaction time of 12 hours. After the reaction, the slurry is vacuum pumped Filtration to obtain tobermolite wet slag; the slag phase obtained after suction filtration was pressed and molded with a selected mold; finally, the molded product was dried at 50°C for 15 hours, and the bulk density of the molded material was 369kg / m 3 , The compressive strength is 2.01MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com