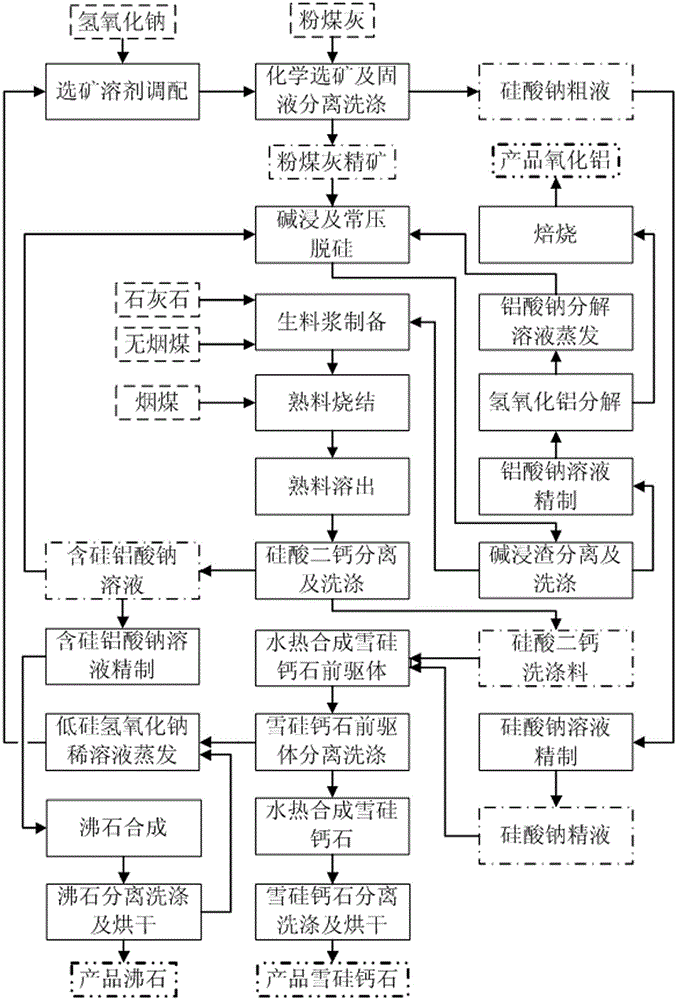

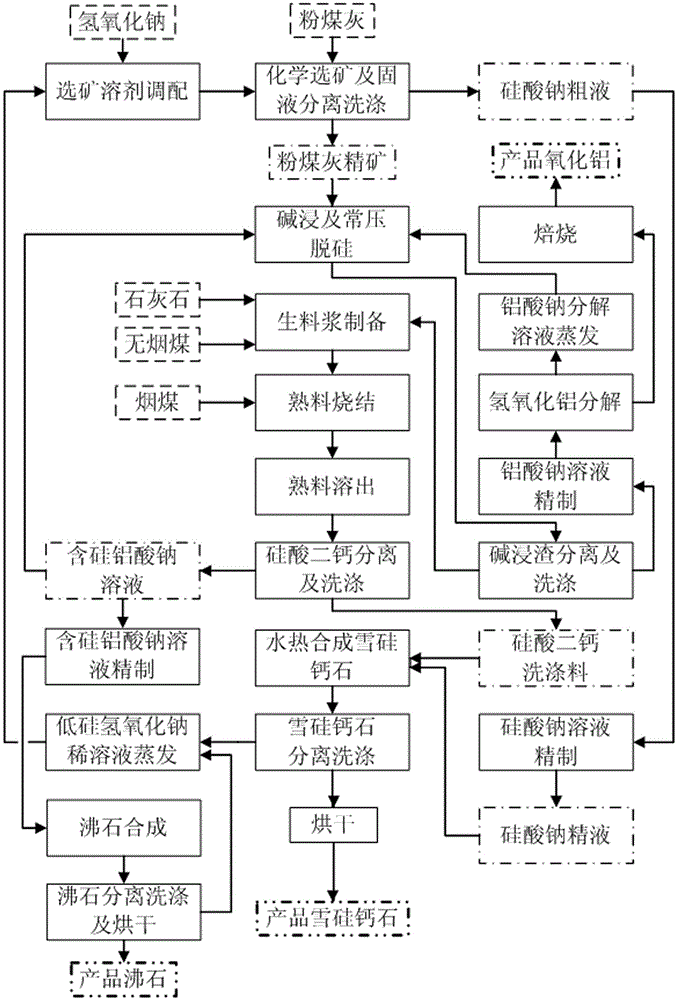

Method for producing tobermorite and aluminum oxide by using coal ash alkaline leaching sintering hydrothermal method

A technology of tobermorite and fly ash, which is applied in the field of comprehensive utilization of fly ash, and can solve problems such as large impact on resources and the environment, consumption, and shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Chemical beneficiation: Put the fly ash into the batching tank with chemical beneficiation solvent for batching. The chemical beneficiation solvent contains Na 2 O 30g / L, containing SiO 2 ≤5g / L; the proportion of ingredients is 3 according to the weight ratio of chemical beneficiation solvent and fly ash; then chemical beneficiation treatment, the reaction temperature is 70°C, and the reaction time is 600 min; the obtained chemical beneficiation slurry is continuously separated through a horizontal belt filter and washing to obtain the washing filter residue and crude sodium silicate solution; the washing filter residue is washed again to make a fly ash concentrate with a water weight content of 30%;

[0041] Na in the obtained crude sodium silicate solution 2 O concentration is 30g / L, SiO 2 The concentration is 15g / L; the crude sodium silicate solution is refined by leaf filtration to obtain a refined sodium silicate solution with solid floating matter less than ...

Embodiment 2

[0054] Method is with embodiment 1, and difference is:

[0055] (1) The chemical beneficiation solvent contains Na 2 O 80g / L, containing SiO 2 ≤5g / L; the proportion of ingredients is 6 according to the weight ratio of chemical beneficiation solvent and fly ash; then chemical beneficiation treatment, the reaction temperature is 90°C, and the reaction time is 200 min; the washed filter residue is washed again to make the water weight content 40% fly ash concentrate;

[0056] Na in the obtained crude sodium silicate solution 2 O concentration is 80g / L, SiO 2 The concentration is 40g / L;

[0057] (2) Na in sodium aluminate solution 2 o k The concentration is 220g / L, Na 2 O+K 2 O and Al 2 o 3 The molar ratio is 2.8, the mixing ratio of fly ash concentrate and sodium aluminate solution is based on the Na in all materials 2 O+K 2 O and Al 2 o 3 The molar ratio is 1.58, the leaching temperature is 270°C, and the reaction time is 60min; 2 o k The concentration is contro...

Embodiment 3

[0066] Method is with embodiment 1, and difference is:

[0067] (1) The chemical beneficiation solvent contains Na 2 O 120g / L, containing SiO 2 ≤5g / L; the proportion of ingredients is 9 according to the weight ratio of chemical beneficiation solvent and fly ash; then chemical beneficiation treatment, the reaction temperature is 120°C, and the reaction time is 30 minutes; the washed filter residue is washed again to make water with a weight content of 45%. fly ash concentrate;

[0068] Na in the obtained crude sodium silicate solution 2 O concentration is 120g / L, SiO 2 The concentration is 60g / L;

[0069] (2) Na in sodium aluminate solution 2 o k The concentration is 45g / L, Na 2 O+K 2 O and Al 2 o 3 The molar ratio is 3.2, the mixing ratio of fly ash concentrate and sodium aluminate solution is based on the Na in all materials 2 O+K 2 O and Al 2 o 3 The molar ratio is 1.6, the leaching temperature is 280°C, and the reaction time is 30min; 2 o k The concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com