Foam concrete prepared from kitchen waste and construction waste as raw materials, and preparation method thereof

A technology of foam concrete and kitchen waste, which is applied to ceramic products, other household utensils, sustainable waste treatment, etc., can solve the problems of high consumption and achieve the effects of saving manufacturing costs, efficient integration, and huge market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

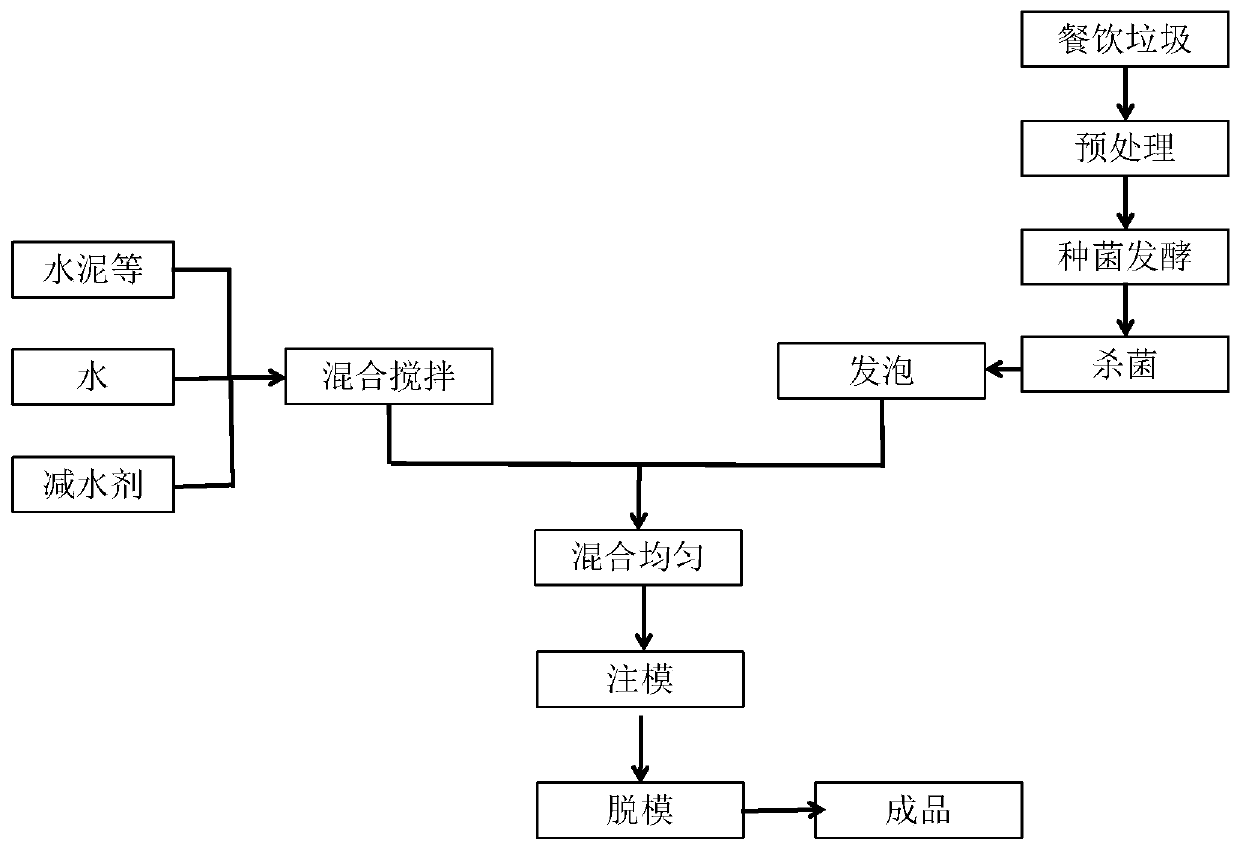

[0023] Such as figure 1 As shown, the collected food waste is sorted to remove metal, plastic, tableware and other sundries. Next, the kitchen waste and water are evenly mixed in a weight ratio of 1:1, then fully ground and pulverized, and the coarse residue and oil are separated to obtain a slurry. Transfer the slurry into the fermenter at 1kg / m 3 The added amount of the compound microbial flora (recipe a) was added and stirred evenly, and fermented for 48 hours at 37°C and slurry pH=8.5. After the fermentation is completed, a polyacrylamide foam stabilizer equivalent to 0.001% by weight of the fermentation liquid is added to the fermenter, and the obtained foam-making liquid is injected into a foaming device for physical foaming. The generated foam is evenly mixed with the concrete raw materials. The formula of the concrete raw materials is as follows: 200g of water, 1500g of Portland cement, 1.5g of water reducer, 3g of sodium sulfate, and 600g of foam. After the above m...

Embodiment 2

[0025] This example is basically the same as Example 1, except that the formula of concrete raw materials is: 240g of water, 1000g of Portland cement, 1.0g of water reducing agent, 5g of sodium sulfate, 1200g of recycled construction waste materials, and 700g of foam.

[0026] The compressive strength, water absorption and dry density of the obtained samples were: 3.6MPa, 15%, 0.71g / cm 3 . The foam concrete can be marked as FC A07-C4-W15-P-JG / T 266-2011.

Embodiment 3

[0028] This example is basically the same as Example 1, except that the formula of concrete raw materials is: 500g of water, 1500g of Portland cement, 1.0g of water reducing agent, 5g of sodium sulfate, 1400g of recycled construction waste materials, and 200g of fly ash , Foam 800g.

[0029] The compressive strength, water absorption and dry density of the obtained samples were: 4.7MPa, 10%, 1.05g / cm 3 . The foam concrete can be marked as FC A10-C5-W10-P-JG / T 266-2011.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com