Nucleating agent, copper tailing autoclaved aerated concrete product, preparation method and application

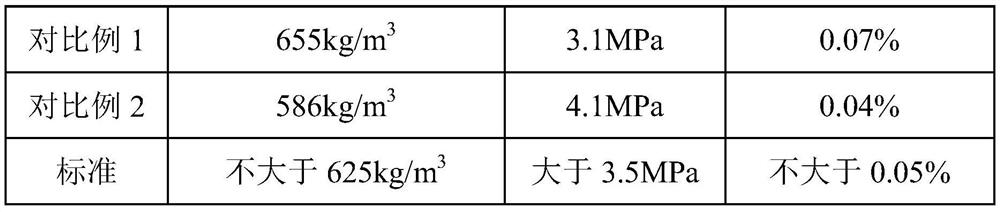

A concrete product, autoclaved aerated technology, applied in the field of preparation, copper tailings autoclaved aerated concrete products, crystal nucleating agent, can solve the problems of large shrinkage, high bulk density, low compressive strength, etc., to reduce product shrinkage , Low dry density, and the effect of improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a preparation method of the above-mentioned crystal nucleating agent, the preparation method of the described crystal nucleating agent comprises the following steps:

[0028] 1) Weighing (grinding) blast furnace slag, nano-calcium carbonate, fly ash, polycarboxylic acid (water reducer) and triterpene saponin in proportion, and mixing them uniformly to obtain a mixture;

[0029] 2) Weighing the acicular wollastonite powder and sodium bicarbonate in proportion, adding them to the mixture obtained in step 1), and mixing evenly to obtain the crystal nucleating agent.

[0030] Preferably, the preparation method of described crystal nucleus agent comprises the following steps:

[0031] 1) Weighing (grinding) blast furnace slag, nano-calcium carbonate, fly ash, polycarboxylic acid (water reducer) and triterpene saponin in proportion, and stirring with a mixer for 2-3 minutes to obtain a mixture;

[0032] 2) Weighing the ac...

Embodiment 1

[0045] A preparation method of a crystal nucleating agent, comprising the following steps:

[0046] Weigh (ground) 10 kg of blast furnace slag, 8 kg of nano-calcium carbonate, 12 kg of fly ash, 1 kg of polycarboxylic acid (water reducer), 0.01 kg of triterpene saponin, and stir for 2 minutes with a mixer to obtain a mixture;

[0047] 2) Weigh 25 kg of acicular wollastonite powder and 1 kg of natron, add them to the mixture obtained in step 1), and continue stirring for 2 minutes to obtain the crystal nucleating agent, which can be packaged and applied.

Embodiment 2

[0049] A preparation method of a crystal nucleating agent, comprising the following steps:

[0050] Weigh (grind) 30 kilograms of blast furnace slag, 22 kilograms of nano-calcium carbonate, 36 kilograms of fly ash, 5 kilograms of polycarboxylic acid (water reducer), 0.05 kilogram of triterpene saponin, and stir for 3 minutes with a mixer to obtain a mixture;

[0051] 2) Weigh 65 kg of acicular wollastonite powder and 6 kg of natron, add them to the mixture obtained in step 1), and continue stirring for 3 minutes to obtain the crystal nucleating agent, which can be packaged and applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com