Method for activating waste aerated concrete blocks

A technology of aerated concrete and blocks, which is applied in the direction of cement production, etc., can solve the problems of large economic losses, restrict the healthy development of aerated concrete blocks, and affect the normal production of enterprises, so as to increase profits, solve waste piles, and facilitate hydrolysis Effects on Ability and Responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of method for the activation of waste aerated concrete blocks of the present invention comprises the following steps:

[0026] (1) Break the discarded aerated concrete blocks into aerated concrete fragments, the size of which is 1cm to 10cm;

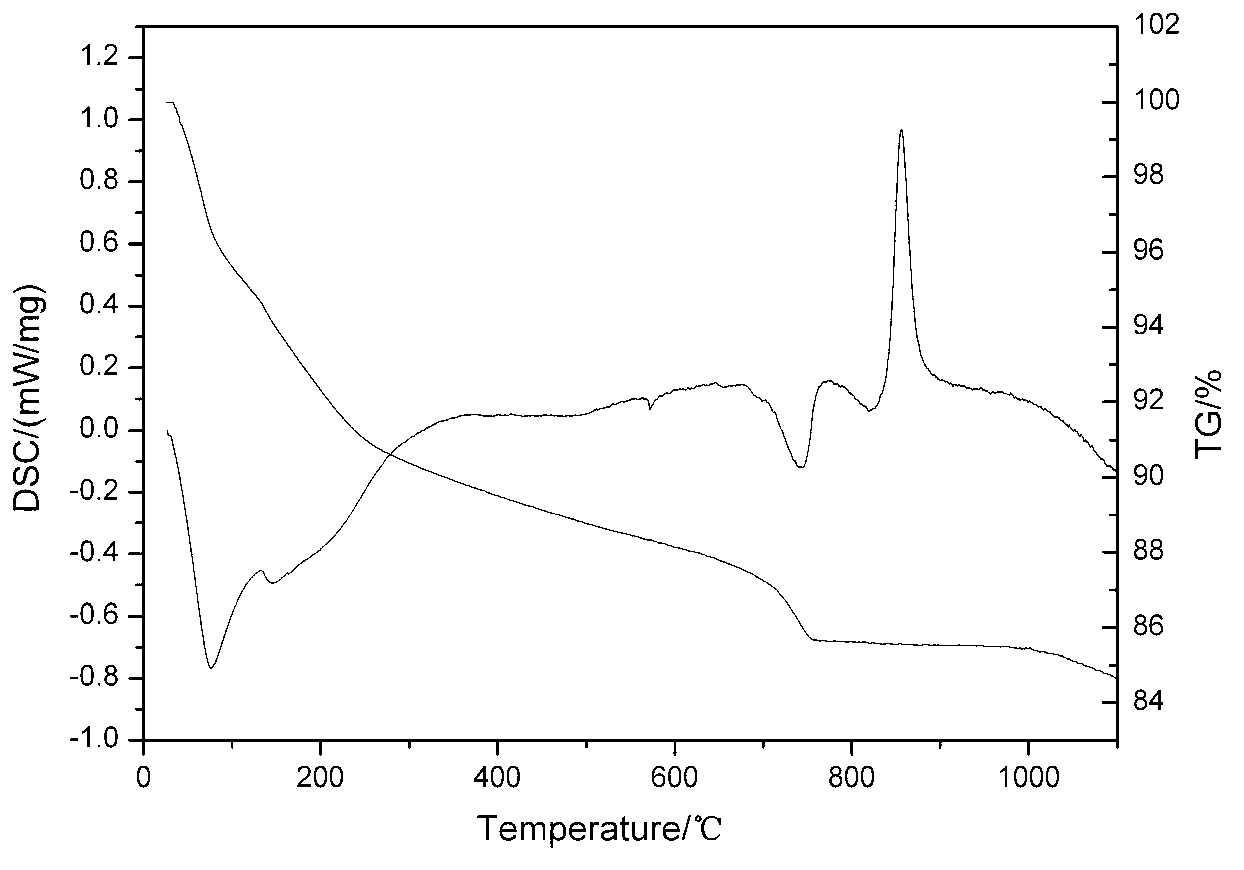

[0027] (2) Calcining the aerated concrete fragments, the heating rate is controlled at 10°C / min to 30°C / min, calcining at 600°C for 1.5 hours, and then cooling down to room temperature by air cooling or natural cooling;

[0028] (3) Put the above-mentioned aerated concrete fragments into a ball mill for ball milling, and the fineness is controlled at 180 mesh sieve ≤ 8%.

[0029] According to "GB / T 12957-2005 Test Method for Industrial Waste Residue Activity of Cement Admixtures", the test materials and requirements for the activity of industrial waste residues used in cement admixtures, as well as their potential hydraulic properties, pozzolanic activity and 28-day compression resistance of cement The streng...

Embodiment 2

[0032] Embodiment 2: A kind of method for the activation of waste aerated concrete block of the present invention comprises the following steps:

[0033] (1) Break the discarded aerated concrete blocks into aerated concrete fragments, the size of which is 1cm to 10cm;

[0034] (2) Calcining the aerated concrete fragments, the heating rate is controlled at 10°C / min to 30°C / min, calcining at 700°C for 1 hour, and then cooling down to room temperature by air cooling or natural cooling;

[0035] (3) Put the above-mentioned aerated concrete fragments into a ball mill for ball milling, and the fineness is controlled at 180 mesh sieve ≤ 8%.

[0036] According to "GB / T 12957-2005 Test Method for Industrial Waste Residue Activity of Cement Admixtures", the test materials and requirements for the activity of industrial waste residues used in cement admixtures, as well as their potential hydraulic properties, pozzolanic activity and 28-day compression resistance of cement The strength r...

Embodiment 3

[0039] Embodiment 3: A kind of method for the activation of waste aerated concrete block of the present invention comprises the following steps:

[0040] (1) Break the discarded aerated concrete blocks into aerated concrete fragments, the size of which is 1cm to 10cm;

[0041] (2) Calcining the aerated concrete fragments, the heating rate is controlled at 10°C / min to 30°C / min, calcining at 825°C for 45 minutes, and then cooling down to room temperature by air cooling or natural cooling;

[0042] (3) Put the above-mentioned aerated concrete fragments into a ball mill for ball milling, and the fineness is controlled at 180 mesh sieve ≤ 8%.

[0043] According to "GB / T 12957-2005 Test Method for Industrial Waste Residue Activity of Cement Admixtures", the test materials and requirements for the activity of industrial waste residues used in cement admixtures, as well as their potential hydraulic properties, pozzolanic activity and 28-day compression resistance of cement The streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com