Method for preparing active composite materials using materials containing tobermullite phase

A technology of tobermorite and active mixture, which is applied in cement production and other directions, can solve problems such as pollution of the environment, achieve the effects of high utilization rate, solving waste stacking, good hydrolysis ability and reaction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

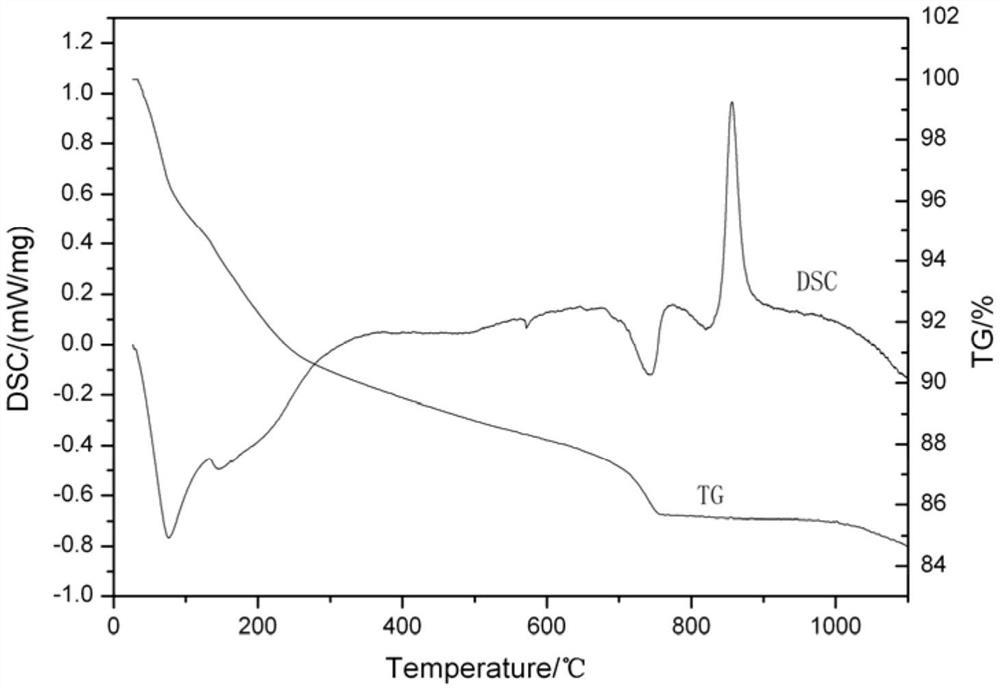

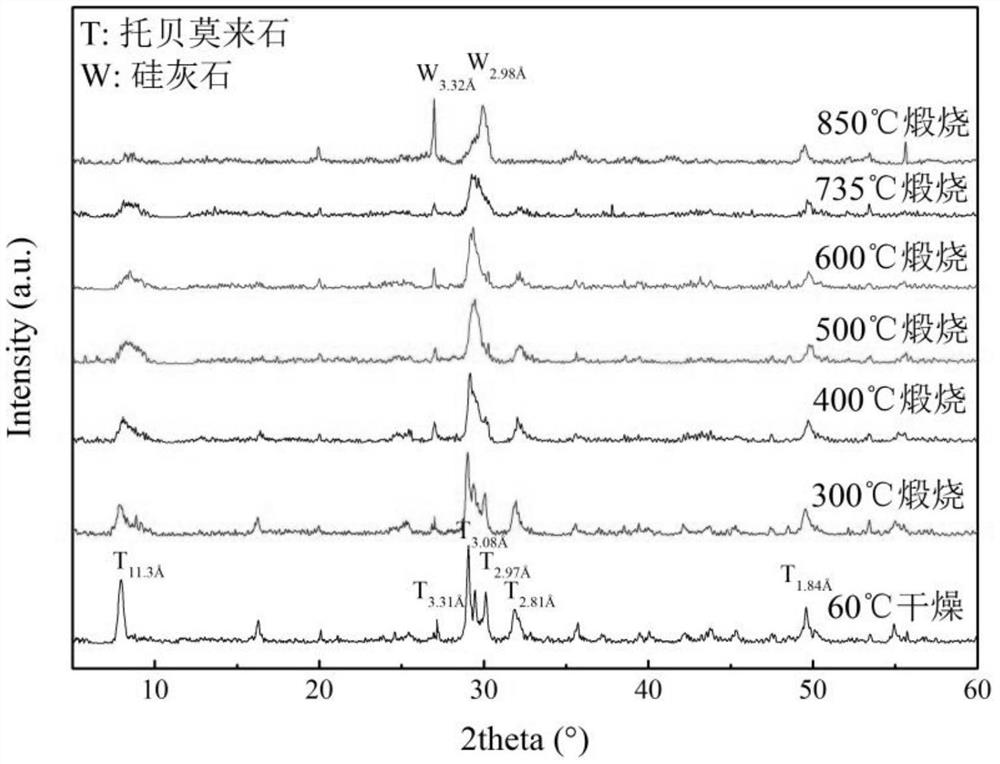

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: The method for activating waste aerated concrete block of the present invention comprises the following steps:

[0048] (1) Break the discarded aerated concrete blocks into aerated concrete fragments, the size of which is 1cm-5cm;

[0049] (2) Configure 20% aqueous solution of anhydrous sodium sulfate.

[0050] (3) The mass ratio of waste aerated concrete to sodium sulfate aqueous solution is 100:15.

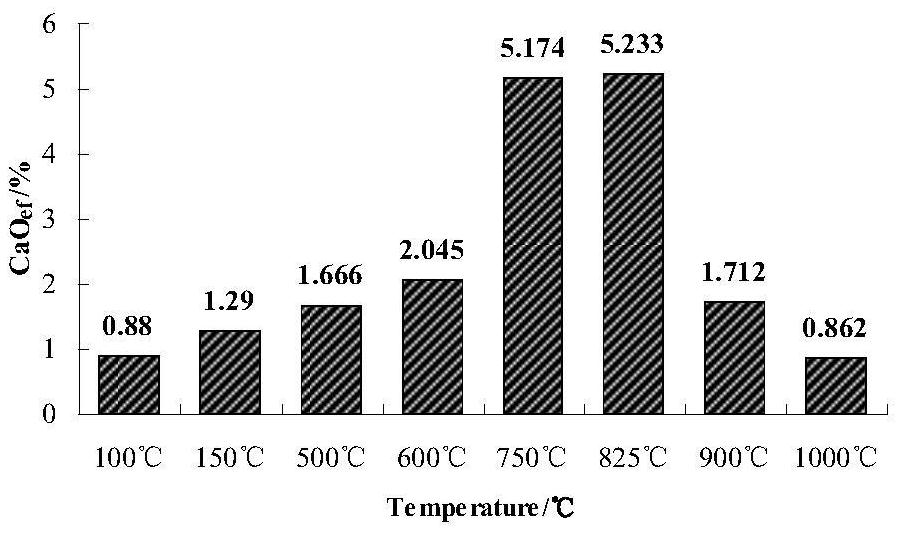

[0051] (4) Calcining the aerated concrete fragments, the heating rate is controlled at 5°C / min, calcined at 600°C for 2 hours, and then cooled to room temperature by air cooling or natural cooling;

[0052] (5) Put the above-treated aerated concrete pieces into a ball mill for ball milling, and the fineness is controlled at 200 mesh sieve ≤ 5%.

[0053] According to "GB / T 12957-2005 Test Method for Industrial Waste Residue Activity of Cement Admixtures", the test materials and requirements for the activity of industrial waste residues used in cement admixt...

Embodiment 2

[0057] Embodiment 2: The method for activating waste aerated concrete block of the present invention comprises the following steps:

[0058] (1) Breaking waste aerated concrete blocks into aerated concrete fragments, the size of which is 1cm to 5cm;

[0059] (2) Prepare 20% aqueous solution of anhydrous sodium sulfate, and the mass ratio of waste aerated concrete to sodium sulfate aqueous solution is 100:10.

[0060] (3) Calcining the air-entrained concrete fragments, the heating rate is controlled at 7.5°C / min, calcined at 700°C for 1.5 hours, and then air-cooled or naturally cooled to room temperature;

[0061] (4) Put the aerated concrete fragments after the above treatment into a ball mill for ball milling, and the fineness is controlled at 200 mesh sieve ≤ 5%.

[0062] According to "GB / T 12957-2005 Test Method for Industrial Waste Residue Activity of Cement Admixtures", the test materials and requirements for the activity of industrial waste residues used in cement admix...

Embodiment 3

[0066] Embodiment 3: The method for activating waste aerated concrete block of the present invention comprises the following steps:

[0067] (1) Breaking waste aerated concrete blocks into aerated concrete fragments, the size of which is 1cm to 5cm;

[0068] (2) Prepare 20% aqueous solution of anhydrous sodium sulfate, and mix according to the mass ratio of waste aerated concrete and sodium sulfate aqueous solution is 100:5.

[0069] (3) Calcining the aerated concrete fragments, the heating rate is controlled at 10°C / min, calcined at 825°C for 1 hour, and then air-cooled or naturally cooled to room temperature;

[0070] (4) Put the aerated concrete fragments after the above treatment into a ball mill for ball milling, and the fineness is controlled at 200 mesh sieve ≤ 5%.

[0071] According to the "GB / T 12957-2005 Test Method for Industrial Waste Residue Activity of Cement Admixtures", the test materials and requirements for the activity of industrial waste residues used in c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com