A kind of air-entrained concrete block using sanding powder as raw material and preparation method thereof

A technology of aerated concrete and sanding powder, applied in the field of building materials, can solve the problems of low compressive strength and high processing cost of sanding powder, and achieve the effects of reducing processing cost, low density and improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

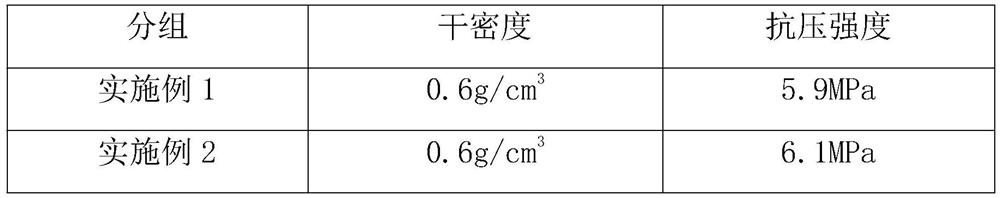

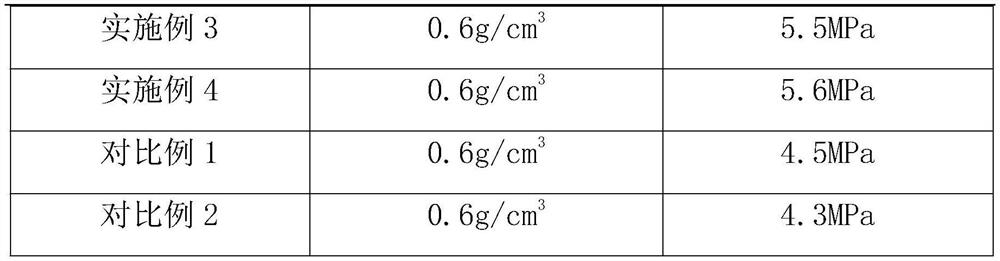

Examples

Embodiment 1

[0025] The present embodiment provides a kind of aerated concrete block with sanding powder as raw material, comprising the following components by weight: 10 parts of sanding powder, 45 parts of quartz sand, 20 parts of cement, 25 parts of quicklime, 3 parts of gypsum, 0.1 part of aluminum powder. Among them, the main components of sanding powder are tobermolite, quartz, calcite and wood pulp fiber; ordinary Portland cement is used for cement; and medium-speed ash is used for quicklime.

[0026] The preparation method of the aerated concrete block using sanding powder as raw material, the specific process is as follows:

[0027] (1) Sieve the sanding powder so that the residue on a 200-mesh sieve is no more than 1 wt%.

[0028] (2) Weigh 10 parts of sanding powder, 45 parts of quartz sand, 20 parts of cement, 25 parts of quicklime and 3 parts of gypsum after the above sieving, mix and stir evenly.

[0029] (3) Mix the powder obtained in step (2) with water, the ratio of wat...

Embodiment 2

[0032] This embodiment provides a kind of aerated concrete block with sanding powder as raw material, including the following components by weight: 20 parts of sanding powder, 40 parts of quartz sand, 20 parts of cement, 20 parts of quicklime, 4 parts of gypsum, 0.2 parts of aluminum powder. Among them, the main components of sanding powder are tobermolite, quartz, calcite and wood pulp fiber; ordinary Portland cement is used for cement; and medium-speed ash is used for quicklime.

[0033] The preparation method of the aerated concrete block using sanding powder as raw material, the specific process is as follows:

[0034] (1) Sieve the sanding powder so that the residue on a 200 mesh sieve is no more than 1wt%;

[0035] (2) Take by weighing 20 parts of sanding powder after the above-mentioned sieving, 40 parts of quartz sand, 20 parts of cement, 20 parts of quicklime and 4 parts of gypsum and mix and stir;

[0036] (3) Mix the powder obtained in step (2) with water, the rat...

Embodiment 3

[0039] The present embodiment provides a kind of aerated concrete block with sanding powder as raw material, comprising the following components by weight: 15 parts of sanding powder, 55 parts of quartz sand, 10 parts of cement, 20 parts of quicklime, 3 parts of gypsum, 0.15 parts of aluminum powder. Among them, the main components of sanding powder are tobermolite, quartz, calcite and wood pulp fiber; ordinary Portland cement is used for cement; and medium-speed ash is used for quicklime.

[0040] The preparation method of the aerated concrete block using sanding powder as raw material, the specific process is as follows:

[0041] (1) Sieve the sanding powder so that the residue on a 200 mesh sieve is no more than 1wt%;

[0042] (2) Take by weighing 15 parts of sanding powder after the above-mentioned sieving, 55 parts of quartz sand, 10 parts of cement, 20 parts of quicklime and 3 parts of gypsum and mix and stir;

[0043] (3) Mix the powder obtained in step (2) with water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com