Method for treating spent cathodes of spent potlinings of aluminum electrolysis cells

An aluminum electrolytic cell and treatment method technology, applied in chemical instruments and methods, aluminum fluoride, aluminum halide, etc., can solve the problems of secondary pollution sources, long process, inability to effectively realize comprehensive utilization of waste cathode resources, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

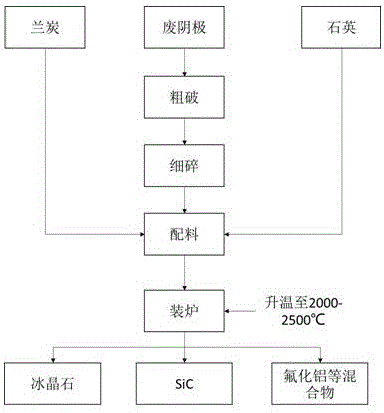

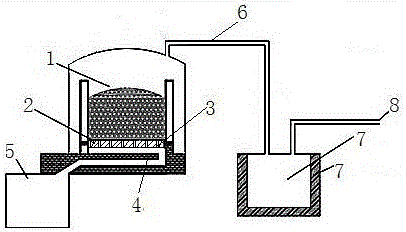

[0022] Crush the waste cathode and semi-coke, the particle size is 0.5-8mm; mix and mix the broken waste cathode, semi-coke and quartz sand in proportion, the ratio is: waste cathode 30%, semi-coke 20%, quartz 50% %. The above mixed raw materials were placed in a reaction furnace, the temperature was raised to 2000°C, and the heat treatment was carried out for 20 h to obtain the SiC product, and the cyanide was removed at the same time. During the heating process, the molten cryolite is separated from the raw material through the horizontal partition at the lower part of the furnace, and the fluoride-containing gas generated enters the fluoride collector through the exhaust pipe, and the fluoride in the gas is collected after cooling, and discharged through the lye. null.

Embodiment 2

[0024] The waste cathode and metallurgical coke are crushed, and the particle size is 1-3mm. Mix the crushed waste cathode, metallurgical coke and quartz sand in proportion and mix evenly, the ratio is: 40% of waste cathode, 15% of metallurgical coke, and 45% of quartz. Put the above mixed raw materials in the reaction furnace, raise the temperature to 2400 ° C, and heat-treat for 15 h to obtain SiC products, and remove the cyanide in them at the same time. During the heating process, the molten cryolite is separated from the raw materials through the lower partition of the furnace, and the generated fluoride-containing gas enters the fluoride collector through the pipeline, and the fluoride in the gas is collected after cooling, and emptied through the lye.

Embodiment 3

[0026] The waste cathode and petroleum coke are crushed, and the particle size is 1-3mm. Mix the crushed waste cathode, petroleum coke and quartz sand in proportion and mix evenly, the ratio is: 55% of waste cathode, 10% of petroleum coke, and 35% of quartz. Put the above mixed raw materials in a reaction furnace, raise the temperature to 2500°C, and heat-treat for 15 hours to obtain the SiC product, and remove the cyanide in it at the same time. During the heating process, the molten cryolite is separated from the raw materials through the lower partition of the furnace, and the generated fluoride-containing gas enters the fluoride collector through the pipeline, and the fluoride in the gas is collected after cooling, and emptied through the lye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com