Comprehensive recovery method of waste and old cathode charcoal block of aluminium electrolytic tank

A technology for waste aluminum electrolysis cell and cathode carbon block, which is applied in the directions of aluminum fluoride, aluminum halide, alumina/aluminum hydroxide, etc., can solve the problems that the process has not been industrialized, the valuable substances cannot be effectively recovered, and the processing cost is high. , to achieve the effect of low raw material price, shortened alkali leaching time and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

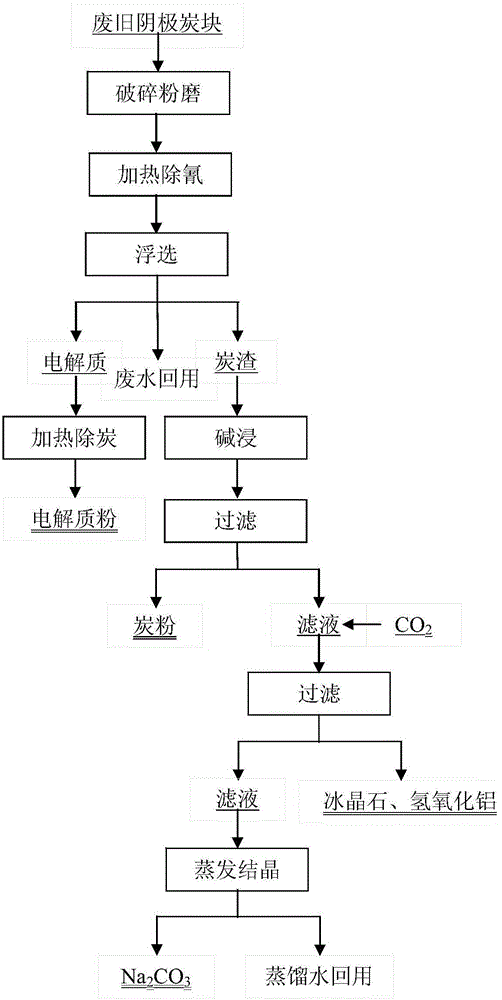

Image

Examples

Embodiment 1

[0044] Take 10g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, the main element content is (wt%): C70.9, Al8.23, O9.55, F5.38, Na2.57, Fe1.21, crushed to -200 Mesh accounted for 90%, tiled in a 9cm × 6cm flat-bottomed square porcelain boat.

[0045]Put the porcelain boat containing the waste cathode powder in a muffle furnace, heat it up to 400°C, and keep it warm for 60 minutes to remove cyanide; the waste cathode powder for cyanide removal is mixed with water at a mass concentration of 25% to form a slurry, and passed through single-cell flotation machine for rough selection. The inhibitor in the flotation process is water glass, the dosage is 320g / t waste cathode; the collector is kerosene, the dosage is 400g / t waste cathode; the foaming agent is No. 2 oil, the dosage is 40g / t waste cathode. The flotation foam and underflow were washed with water, dried and weighed to obtain 7.52 g of carbon residue and 2.26 g of electrolyte residu...

Embodiment 2

[0050] Take 30g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, the main element content is (wt%): C70.9, Al8.23, O9.55, F5.38, Na2.57, Fe1.21, crushed to -200 Mesh accounted for 90%, tiled in a 12cm x 8cm flat-bottomed square porcelain boat.

[0051] Put the porcelain boat containing the waste cathode powder in a muffle furnace, heat it up to 300°C, and then keep it warm for 70 minutes to remove cyanide; the waste cathode powder for cyanide removal is mixed with water at a mass concentration of 10% to form a slurry, and passed through single-cell flotation machine for rough selection. The inhibitor in the flotation process is water glass, the dosage is 200g / t waste cathode; the collector is kerosene, the dosage is 400g / t waste cathode; the foaming agent is No. 2 oil, the dosage is 40g / t waste cathode. The flotation foam and underflow were washed with water, dried and weighed to obtain 23 g of carbon residue and 6.62 g of electrolyte r...

Embodiment 3

[0056] Take 100g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, the main element content is (wt%): C70.9, Al8.23, O9.55, F5.38, Na2.57, Fe1.21, crushed to -200 Mesh accounted for 90%, tiled in a 12cm x 8cm flat-bottomed square porcelain boat.

[0057] Put the porcelain boat containing the waste cathode powder in a muffle furnace, heat it up to 400°C and keep it warm for 60 minutes to remove cyanide; the waste cathode powder for cyanide removal is mixed with water at a mass concentration of 30% to form a slurry, and passed through single-cell flotation machine for rough selection. The inhibitor in the flotation process is water glass, the dosage is 400g / t waste cathode; the collector is kerosene, the dosage is 200g / t waste cathode; the foaming agent is No. 2 oil, the dosage is 100g / t waste cathode. The flotation foam and underflow were washed with water, dried and weighed to obtain 77.25 g of carbon residue and 21.78 g of electrolyte r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com