Method for producing cryolite

A technology of cryolite and ammonium fluoroaluminate, which is applied in the direction of aluminum fluoride, aluminum halide, etc., can solve the problems of severe equipment corrosion, high equipment requirements, and difficult operation control, and achieve high production safety, reduce production costs, and respond The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

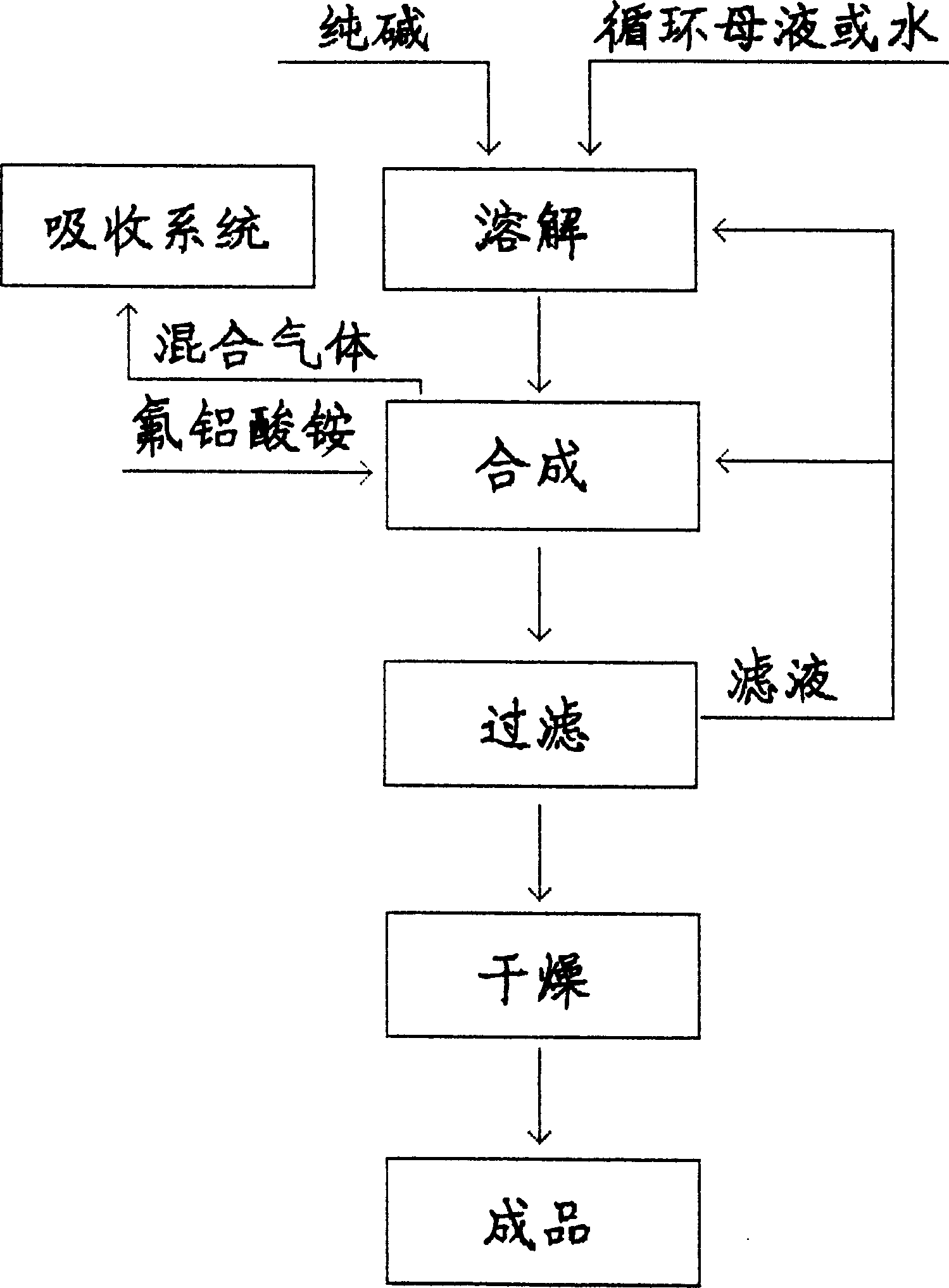

Image

Examples

Embodiment 1

[0014] Embodiment 1, a kind of method for producing cryolite, comprises the steps: (1) preparation soda ash aqueous solution, adds soda ash with deionized water or the circulation mother liquor in the reaction process and is made into the soda ash solution of soda ash content 20%; (2) ice crystal Stone synthesis, after adding deionized water or part of the mother liquor into the synthesis tank, add aluminum profile surface treatment waste residue - ammonium fluoroaluminate (purity 98%) under constant stirring, so that the concentration reaches 20%, open the steam valve, and pass the steam Make its temperature rise to 90°C, slowly add the sodium carbonate solution from the metering tank to the synthesis tank for reaction, the feeding time is 40 minutes, the molar ratio of ammonium fluoroaluminate to soda ash is 2:3, and cryolite slurry is obtained after the reaction is completed; (3 ) The cryolite slurry is filtered with a horizontal spiral centrifuge to obtain an ointment (less...

Embodiment 2

[0015] Embodiment 2. In this embodiment, the concentration of soda ash is 15%, the concentration of ammonium fluoroaluminate is 15%, the reaction temperature of cryolite synthesis is 95°C, the feeding time is 50 minutes, and the drying temperature of ointment is 200°C. Others are the same as embodiment 1.

Embodiment 3

[0016] Embodiment 3 In this embodiment, the concentration of soda ash is 25%, the concentration of ammonium fluoroaluminate is 25%, the cryolite synthesis reaction temperature is 95°C, the feeding time is 45 minutes, and the ointment drying temperature is 300°C. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com