Cetylamine/ silicon dioxide composite phase-change energy storing material and preparation method thereof

A silica and composite phase change technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of polymer material rupture and low thermal conductivity, and achieve high phase change enthalpy and coating amount. And the effect of improved dispersion and good encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

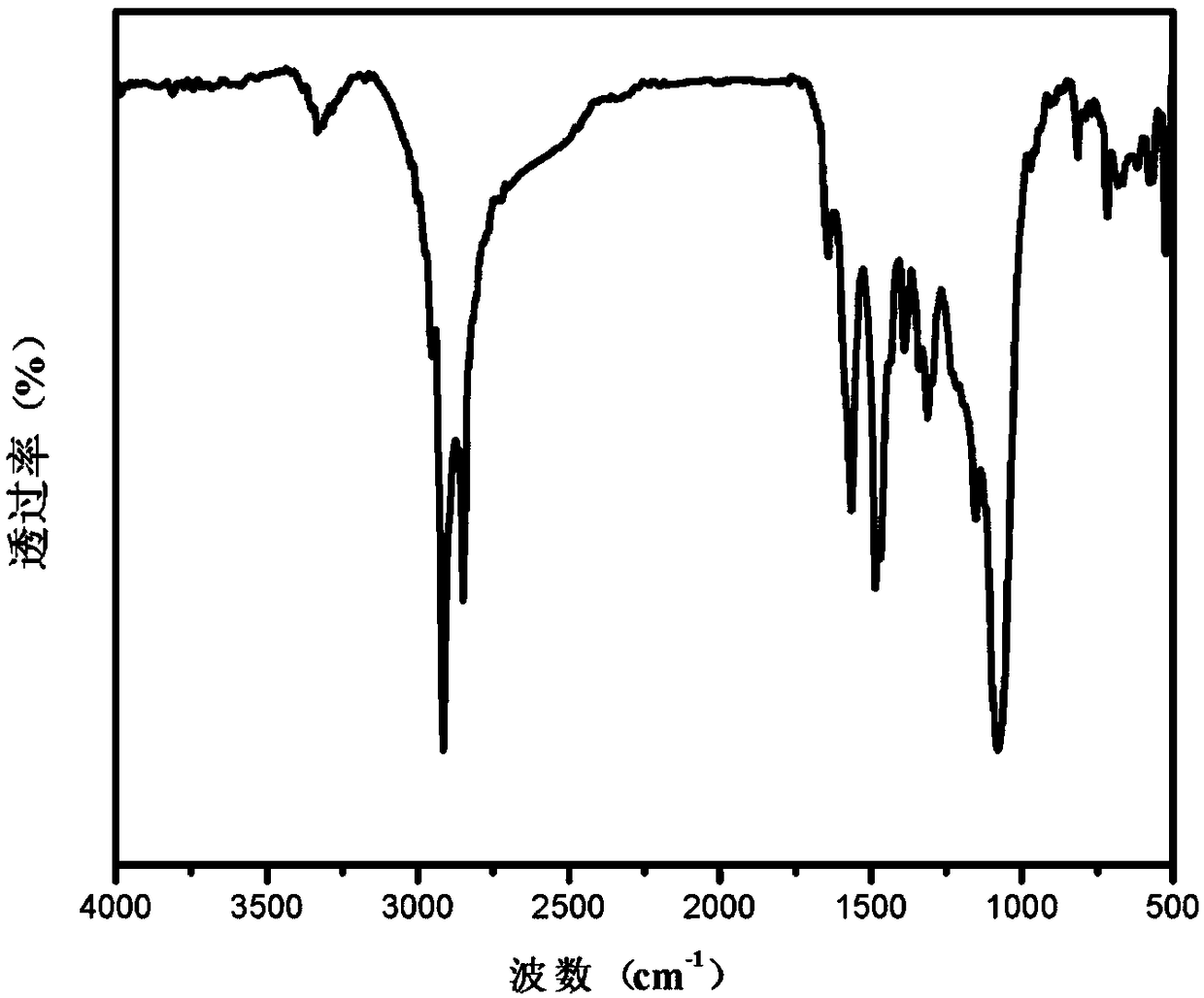

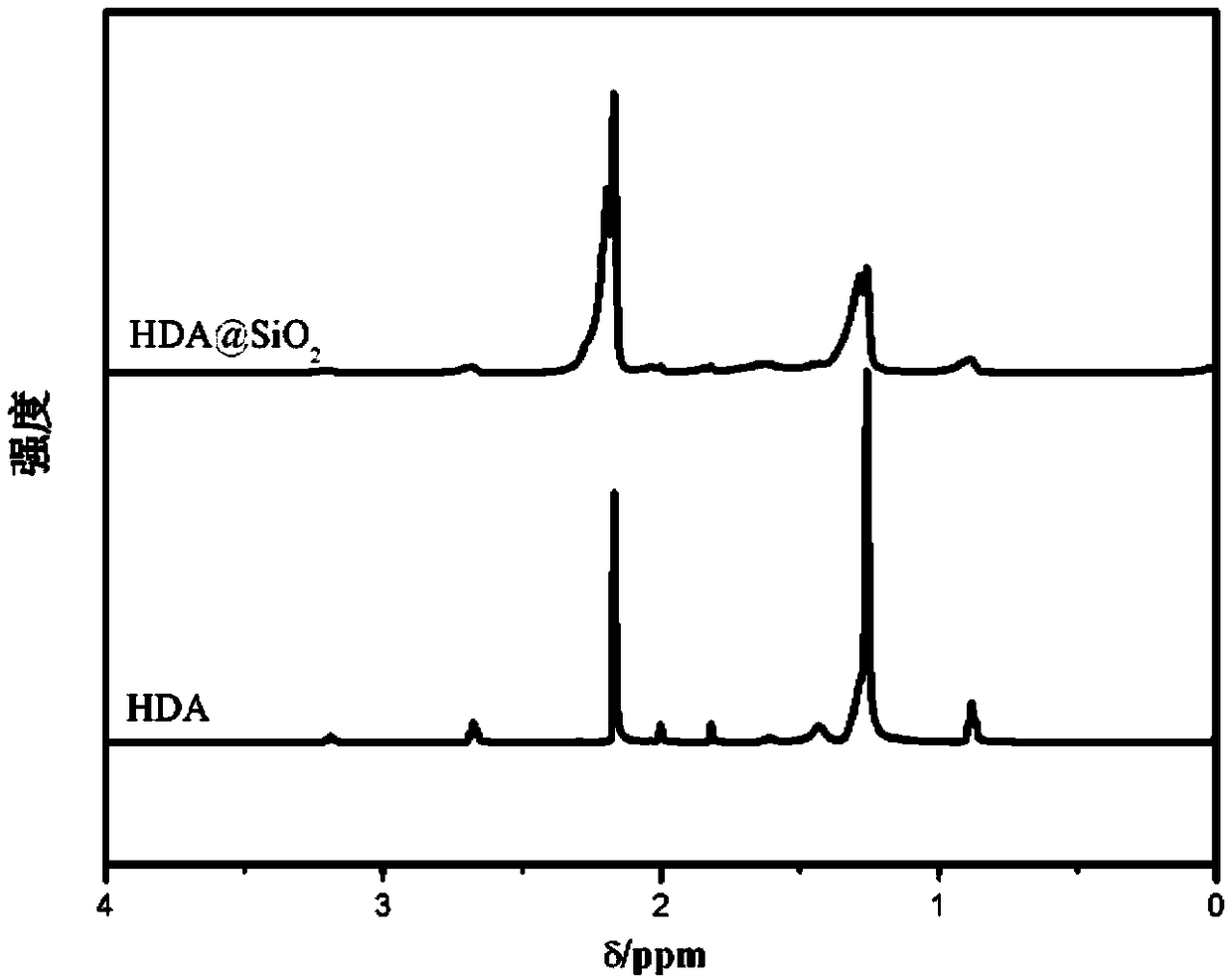

[0041] (1) Measure 80 milliliters of isopropanol (IPA) in a 100 milliliter beaker, weigh 7 grams (29.0 mmol) hexadecylamine (HDA) and join in the isopropanol solvent, at a temperature of 50 ° C, a rotation speed of Stir uniformly for 15 minutes under the condition of 500r / min to form a uniform colorless and transparent mixed solution.

[0042] (2) Take 1 milliliter (4.5 mmol) tetraethyl orthosilicate (TEOS) and add it to the above-mentioned homogeneous colorless and transparent mixed solution. The measured pH value is 7. Stirring was continued for 30 minutes under the same conditions to obtain a mixed solution.

[0043] (3) Measure 10 ml of deionized water (H 2 O) Slowly add 1 drop / second (using a 5mL disposable plastic dropper) dropwise to the mixed solution obtained in the above step (2), and continue to stir evenly at a temperature of 50°C and a rotation speed of 500r / min After 24 hours, it was dried in a drying oven at a temperature of 50° C. for 24 hours to obtain the f...

Embodiment 2

[0069] (1) Measure 60 milliliters of isopropanol (IPA) in a 100 milliliter beaker, weigh 5 grams (20.7 mmol) of hexadecylamine (HDA) and add it to the isopropanol solvent at a temperature of 80 ° C and a speed of Stir evenly for 30 minutes under the condition of 750r / min to form a uniform colorless and transparent mixed solution.

[0070](2) Take 1 milliliter (4.5 mmol) tetraethyl orthosilicate (TEOS) and add it to the above-mentioned homogeneous colorless and transparent mixed solution, add hydrochloric acid with a concentration of 12 mol / L to adjust the pH value to 7, and then , under the condition of rotating speed of 750r / min, continue to stir uniformly for 30 minutes to obtain a mixed solution.

[0071] (3) Measure 15 ml of deionized water (H 2 O) Slowly add 1 drop / second (with a 5mL disposable plastic dropper) dropwise to the mixed solution obtained in the above step (2), and continue to stir evenly at a temperature of 80°C and a rotation speed of 750r / min After 5 hour...

Embodiment 3

[0074] (1) Measure 40 milliliters of isopropanol (IPA) in a 100 milliliter beaker, weigh 9 grams (37.3 mmol) of hexadecylamine (HDA) and add it to the isopropanol solvent at a temperature of 65° C. Stir evenly for 30 minutes under the condition of 750r / min to form a uniform colorless and transparent mixed solution.

[0075] (2) Measure 1 milliliter (4.5 mmol) tetraethyl orthosilicate (TEOS) and join in the above-mentioned homogeneous colorless and transparent mixed solution, add ammonia water (mass percentage is 28%) to adjust the pH value to 10, then at a temperature of 65 ℃, under the condition of rotating speed of 750r / min, continue to stir evenly for 30 minutes to obtain a mixed solution.

[0076] (3) Measure 20 ml of deionized water (H 2 O) Slowly add 1 drop / second (with a 5mL disposable plastic dropper) dropwise to the mixed solution obtained in the above step (2), and continue to stir evenly at a temperature of 65°C and a rotation speed of 750r / min After 24 hours, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com