Inorganic/organic composite casing layer nanometer phase-change capsule cool-storage fluid and preparation method thereof

A nano-phase and shell technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of rarely mentioned, difficult cooling energy transfer, brittle performance, etc., to ensure excellent performance and good thermal stability. , the effect of high phase change enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

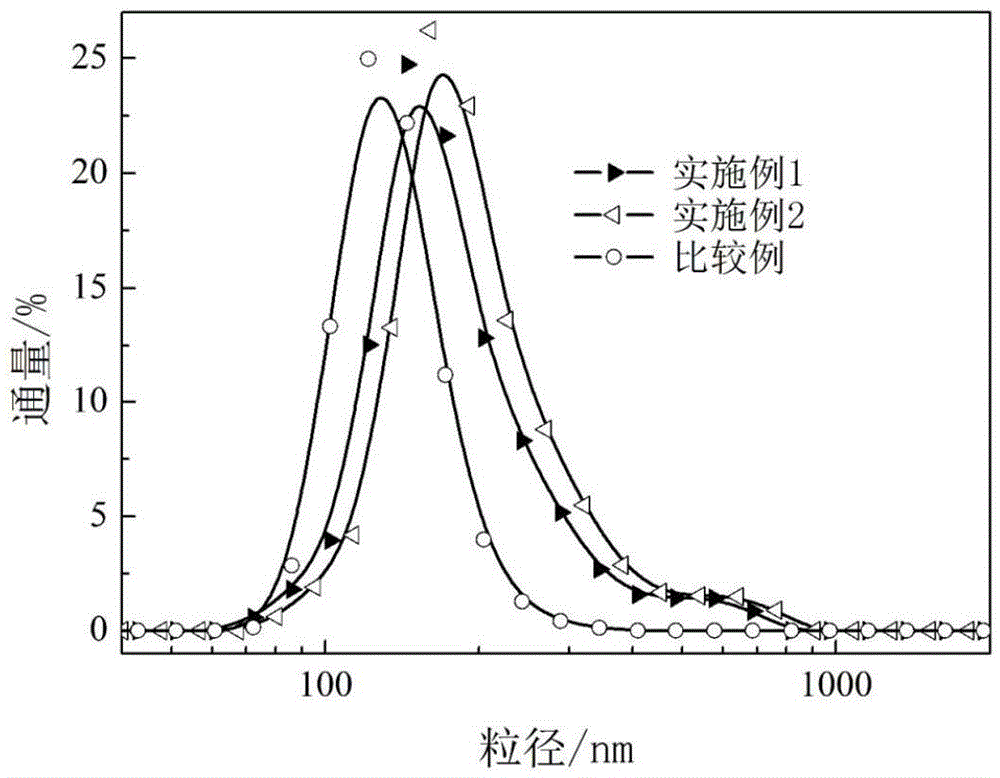

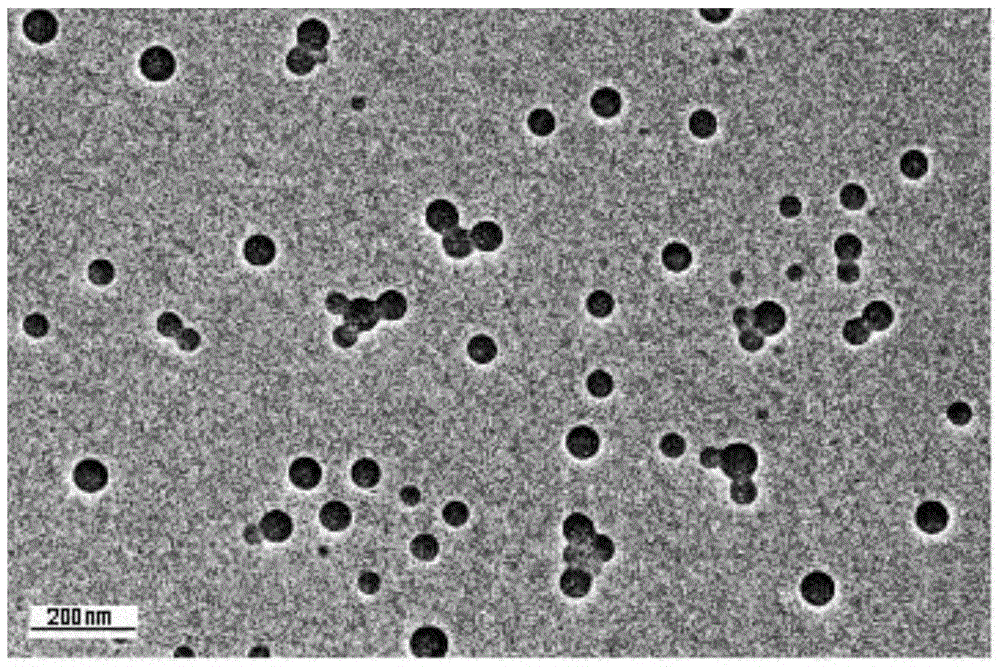

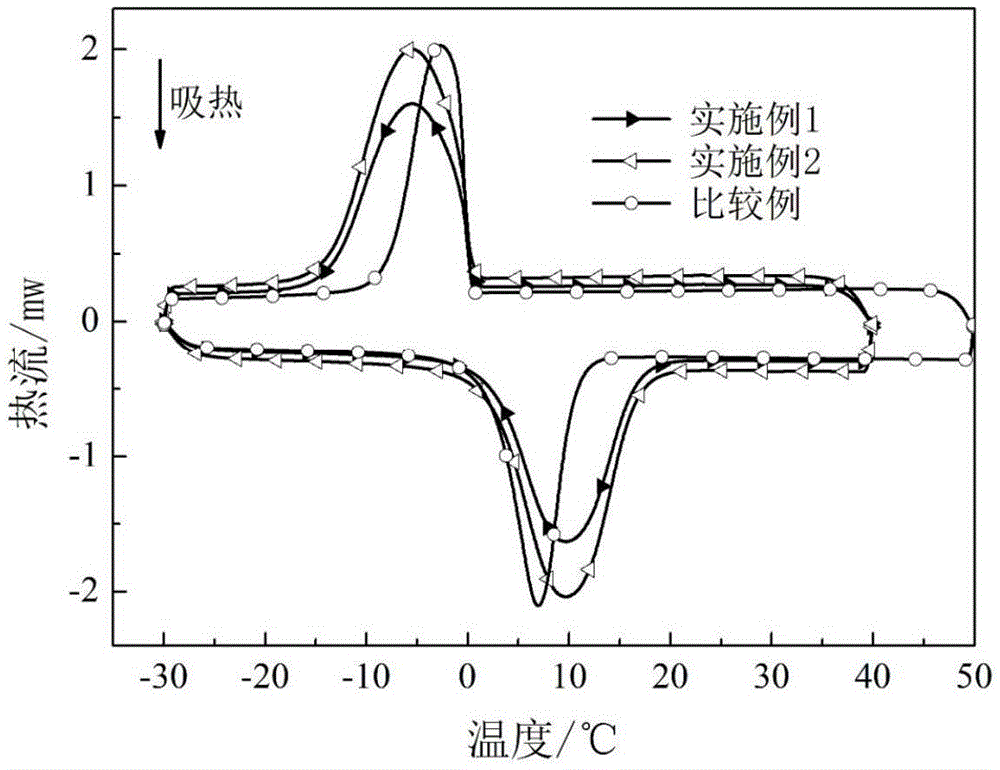

Embodiment 1

[0049] (1) Dissolve 5ml of tetraethyl orthosilicate in 30ml of absolute ethanol in a constant temperature water bath at 60°C, add 0.008mol of ammonia water dropwise, add 0.06g of KH-570 after 0.5h of reaction, continue to react for 2.5h, and cool naturally to Modified silica sol was prepared at room temperature. Neglecting other components, its solid content is theoretically calculated to be 16.7% (the same below).

[0050] (2) 10g of styrene, 12g of n-tetradecane, 0.4g of ethyl acrylate, 0.2g of dodecanethiol and 0.05g of azobisisobutyronitrile were formulated into an oil phase liquid, and 0.3g of emulsifier (SDS :OP-10=1:1) in 100g of water, emulsified with a homogeneous emulsifier for 10min to obtain an emulsion.

[0051] (3) The emulsion is transferred to a 250ml four-necked flask equipped with a reflux tube, nitrogen inlet, dropping funnel and mechanical stirring, and the first 15min of nitrogen gas is used to remove the oxygen in the system, and then under the condensat...

Embodiment 2

[0054] (1) Dissolve 5ml of tetraethyl orthosilicate in 30ml of absolute ethanol in a constant temperature water bath at 60°C, add 0.008mol of ammonia water dropwise, add 0.06g of KH-570 after 0.5h of reaction, continue to react for 2.5h, and cool naturally to Modified silica sol was prepared at room temperature.

[0055] (2) 10g of styrene, 12g of n-tetradecane, 0.4g of ethyl acrylate, 0.2g of dodecanethiol and 0.05g of azobisisobutyronitrile were formulated into an oil phase liquid, and 0.3g of emulsifier (SDS :OP-10=1:1) in 100g of water, emulsified with a homogeneous emulsifier for 10min to obtain an emulsion.

[0056] (3) Transfer the emulsion into a 250ml three-necked flask equipped with a reflux tube, a nitrogen inlet, and a mechanical stirrer. First pass nitrogen gas for 15 minutes to remove oxygen in the system, and then heat up to 60°C under the condensation of the reflux tube. After 30 minutes of polymerization reaction at a constant temperature, 0.8 g of modified s...

Embodiment 3

[0059] (1) Dissolve 5ml of tetrabutyl titanate in 30ml of absolute ethanol in a constant temperature water bath at 60°C, add 0.008mol of ammonia water dropwise, add 0.06g of KH-570 after 0.5h of reaction, continue to react for 2.5h, and cool naturally to The modified titanium sol was prepared at room temperature.

[0060] (2) 10g of styrene, 12g of n-pentadecane, 0.4g of ethyl acrylate, 0.2g of dodecanethiol and 0.05g of azobisisobutyronitrile were formulated into an oil phase liquid, and 0.3g of emulsifier (SDS :OP-10=1:1) in 100g of water, emulsified with a homogeneous emulsifier for 10min to obtain an emulsion.

[0061] (3) Transfer the emulsion into a 250ml three-necked flask equipped with a reflux tube, nitrogen inlet, dropping funnel and mechanical agitation. First pass nitrogen gas for 15 minutes to remove the oxygen in the system, and then heat up to 60°C under the condensation of the reflux tube. ℃, keeping the temperature of the water bath constant, after the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com