Solid-solid phase-change energy-storage material and preparation method thereof

A phase change energy storage material and compound technology, applied in the field of intelligent polymer materials, can solve the problems of affecting heat storage effect, difficult recovery, long heat transfer time, etc., and achieve high overall phase change enthalpy and good thermal stability , the effect of high phase change enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

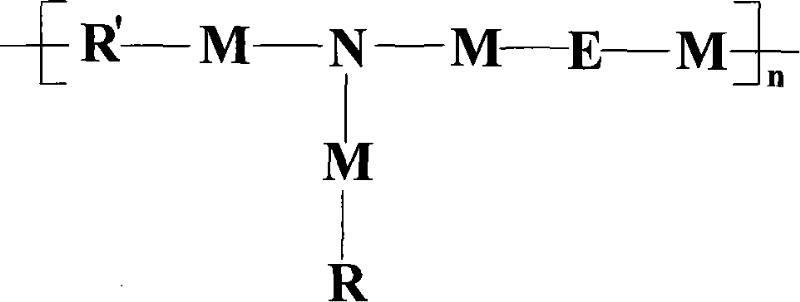

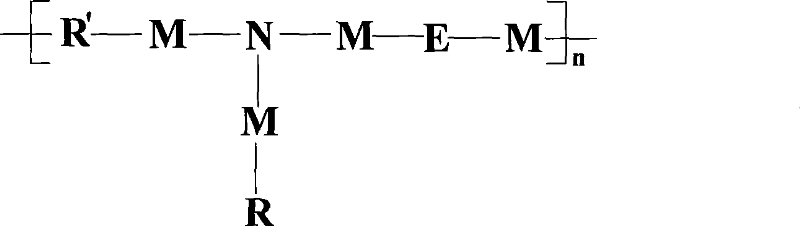

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of benzaldehyde glycerol acetal-TDI prepolymer

[0050] Use 1 mole of benzaldehyde glyceryl acetal and 3 moles of 2,4 toluene diisocyanate (TDI) in 50 milliliters of acetone solvent, under the protection of nitrogen, the temperature is 45 ° C, and the reaction time is 2 hours to generate benzaldehyde glyceryl acetal- Prepolymer of TDI.

[0051] 2. Preparation of benzaldehyde glycerol acetal-TDI-mPEG trimer

[0052] Use 1 mole of benzaldehyde glyceryl acetal-TDI and 1 mole of polyethylene glycol monomethyl ether (mPEG) with a molecular weight of 2,000 in 50 ml of acetone solvent, under the protection of nitrogen, the temperature is 40 ° C, the reaction time is 5 hours, and dry After that, benzaldehyde glycerol acetal-TDI-mPEG trimer is obtained.

[0053] 3. Hydrolysis of benzaldehyde glycerol acetal-TDI-mPEG trimer

[0054] Put the above 1 mole of benzaldehyde glycerol acetal-TDI-mPEG trimer into a round-bottomed flask in a hydrochloric acid solution wi...

Embodiment 2

[0058] 1. Preparation of Glycerol Methylal-IPDI Prepolymer

[0059] Use 1 mole of glycerol formal and 3 moles of isophorone diisocyanate (IPDI) in 50 ml of acetone solvent, under the protection of nitrogen, the temperature is 45 ° C, and the reaction time is 2 hours to generate glycerol formal-IPDI prepolymer.

[0060] 2. Preparation of Glycerol Methylal-IPDI-mPEG Trimer

[0061] Use 1 mole of glycerol formal-IPDI and 1 mole of polyethylene glycol monomethyl ether (mPEG) with a molecular weight of 5,000 in 60 ml of acetone solvent, under the protection of nitrogen, the temperature is 50 ° C, the reaction time is 5 hours, after drying That is, glycerol formal-IPDI-mPEG trimer was obtained.

[0062] 3. Hydrolysis of Glycerol Methylal-IPDI-mPEG Trimer

[0063] Put the above 1 mole of glycerol formal-IPDI-mPEG trimer into a round-bottomed flask in a hydrochloric acid solution with pH=4 at room temperature, stir for 3 hours for hydrolysis, and dry to obtain solid powder Glycero...

Embodiment 3

[0067] 1. Preparation of benzaldehyde glycerol acetal-MDI prepolymer

[0068] Use 1 mole of benzaldehyde glyceryl acetal and 3 moles of 4,4-diphenylmethane diisocyanate (MDI) in 50 ml of acetone solvent, under the protection of nitrogen, the temperature is 45 ° C, react for 2 hours to generate benzaldehyde glyceryl Aldehyde-MDI prepolymer.

[0069] 2. Preparation of benzaldehyde glycerol acetal-MDI-mPEG trimer

[0070] Use 1 mole of benzaldehyde glyceryl acetal-MDI and 1 mole of polyethylene glycol monomethyl ether (mPEG) with a molecular weight of 2,000 in 50 ml of acetone solvent, under the protection of nitrogen, the temperature is 45 ° C, the reaction time is 3.5 hours, and dry Afterwards, benzaldehyde glycerol acetal-MDI-mPEG trimer is obtained.

[0071] 3. Hydrolysis of benzaldehyde glycerol acetal-MDI-mPEG trimer

[0072] Put the above 1 mole of benzaldehyde glycerol acetal-MDI-mPEG trimer into a round-bottomed flask in a hydrochloric acid solution with pH=4 at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com