Preparation method of modified paraffin

A paraffin and modification technology, applied in the field of materials, can solve problems such as poor processability, and achieve the effects of excellent phase change energy storage performance, good energy storage performance, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

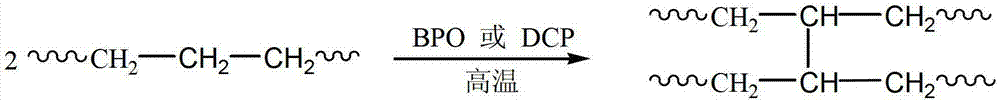

Method used

Image

Examples

Embodiment 1

[0021] Weigh 80 grams of paraffin, heat the paraffin to 80° C. to melt it, then add 4 grams of benzoyl peroxide to the paraffin under stirring, heat up to 110° C. to react for 24 hours after stirring evenly, and cool after the reaction to obtain Modified paraffin.

[0022] In the molten state, the apparent viscosity of the modified paraffin wax is significantly higher than that before modification. It was determined that the phase transition temperature of the modified paraffin wax was 64.1° C., and the phase transition enthalpy was 159 kJ / kg.

Embodiment 2

[0024] Weigh 80 grams of paraffin, heat the paraffin to 80° C. to melt it, then add 8 grams of benzoyl peroxide to the paraffin under stirring, heat up to 110° C. to react for 16 hours after stirring evenly, and cool after the reaction to obtain Modified paraffin.

[0025] In the molten state, the apparent viscosity of the modified paraffin wax is significantly higher than that before modification. It is determined that the phase transition temperature of the modified paraffin wax is 66.2° C., and the phase transition enthalpy is 162 kJ / kg.

Embodiment 3

[0027] Weigh 80 grams of paraffin, heat the paraffin to 80° C. to melt it, then add 5 grams of cumene peroxide to the paraffin under stirring, heat up to 130° C. to react for 20 hours after stirring evenly, and cool after the reaction to obtain Modified paraffin.

[0028] In the molten state, the apparent viscosity of the modified paraffin wax is significantly higher than that before modification. It is determined that the phase transition temperature of the modified paraffin wax is 65.6° C., and the phase transition enthalpy is 160 kJ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com