Heat conduction enhanced heat energy storage shape-stabilized phase-change composite material and preparation method thereof

A technology of thermal energy storage and shape-setting phase change, which is applied in the fields of heat exchange materials, chemical instruments and methods, etc., can solve the problems of material phase change enthalpy drop, large addition of MXene nanosheets, etc., and achieves high phase change enthalpy value, excellent The effect of shape stability, enhanced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A thermal conductivity-enhanced thermal energy storage shape-changing composite material is made of the following components by weight percentage:

[0040] Organic phase change material 95%

[0041] Foam frame structural material 5%;

[0042] Among them, the foam frame structure material is made of polymer and two-dimensional sheet material;

[0043] In the present embodiment, polymer is polyvinyl alcohol (PVA);

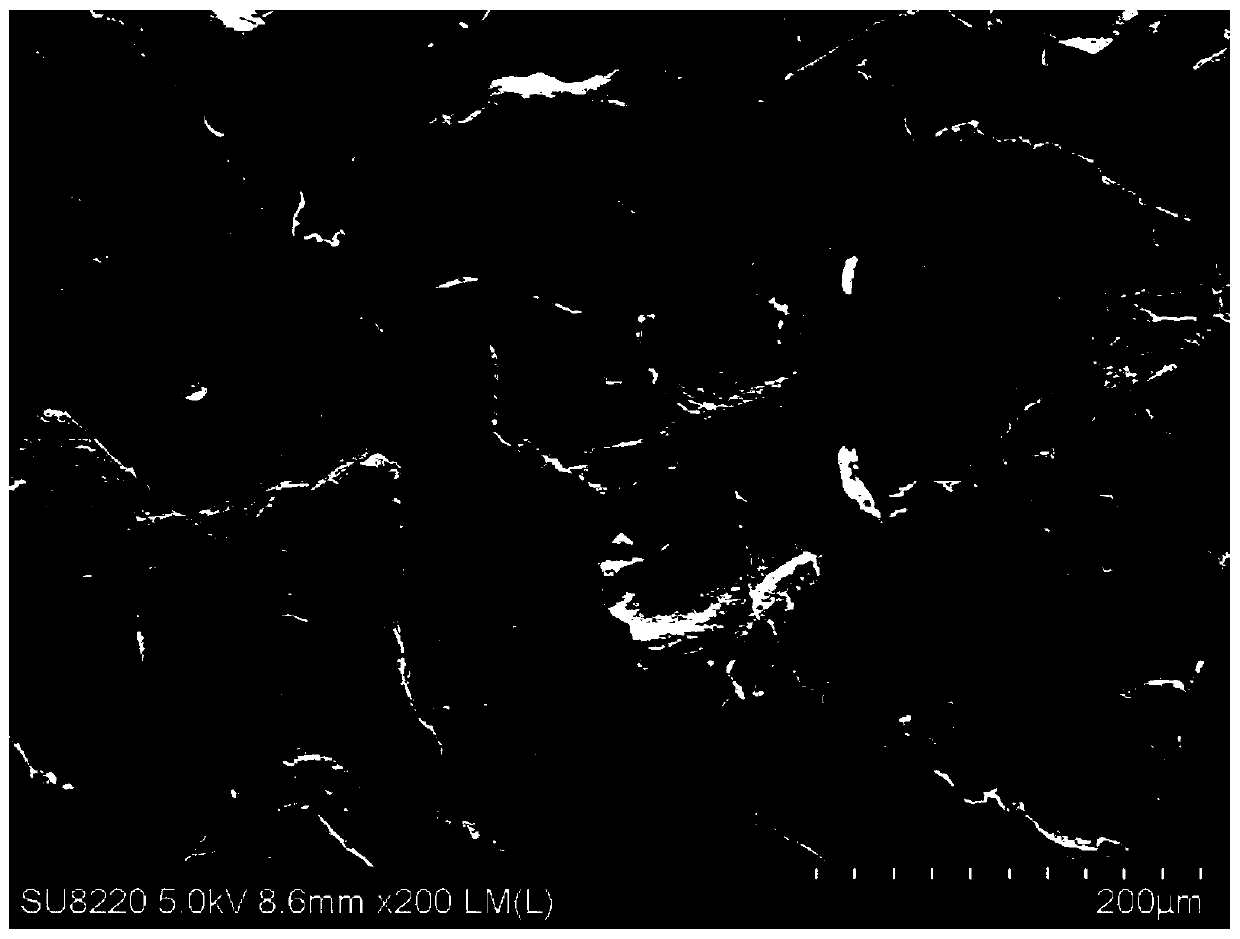

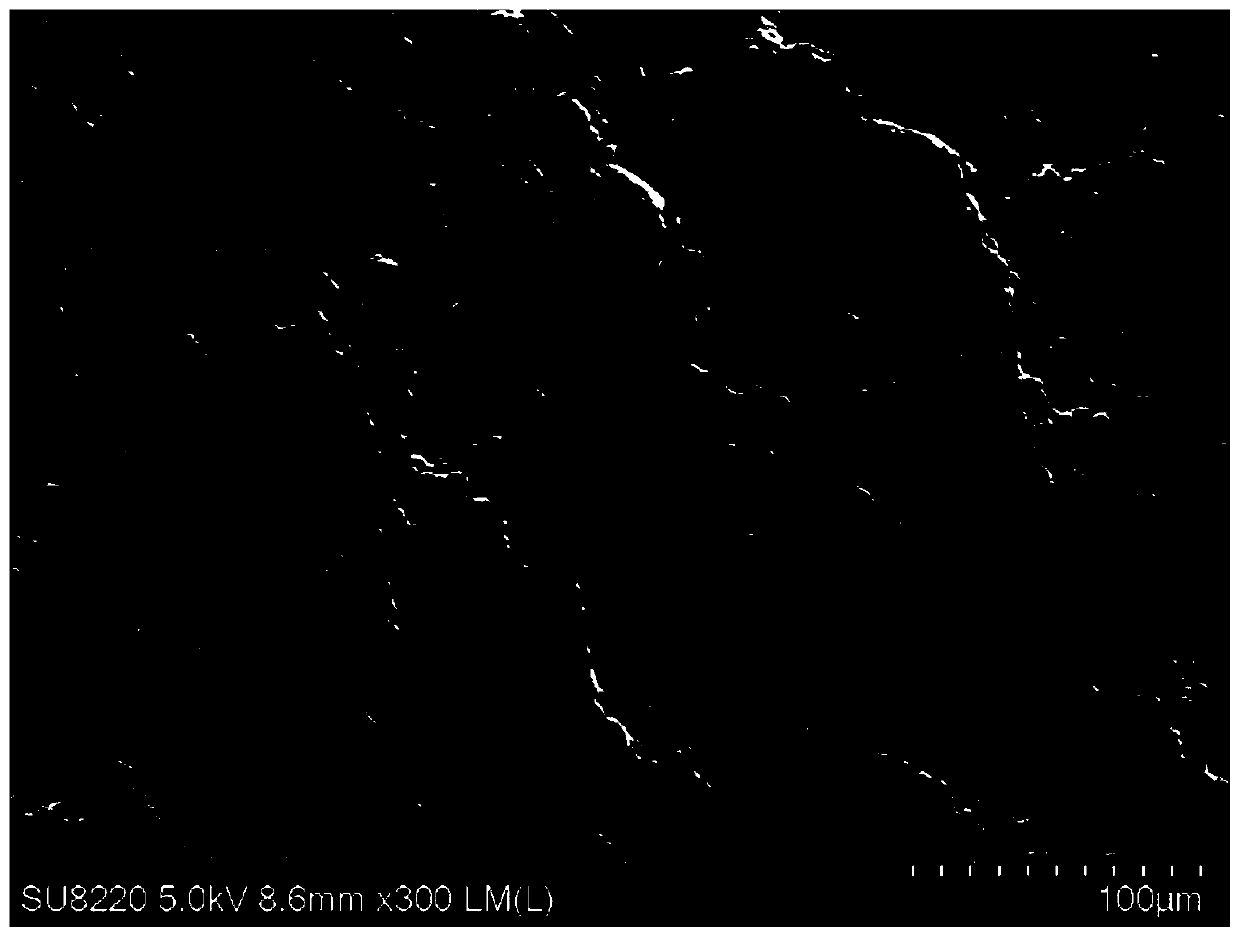

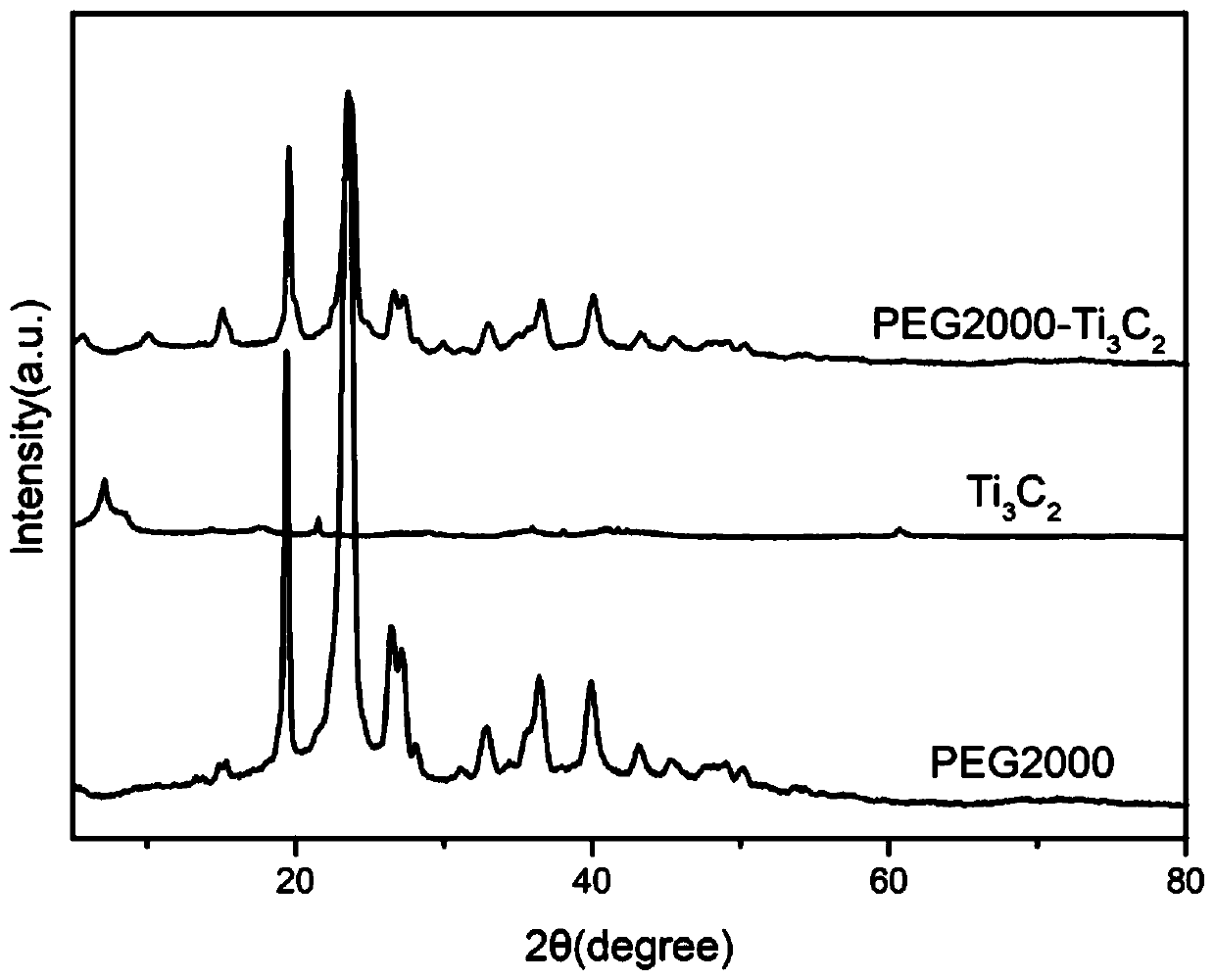

[0044] In this embodiment, the two-dimensional sheet material is Ti 3 C 2 nanosheets, where Ti 3 C 2 Nanosheets are 20mg.

[0045] Among them, the organic phase change material is fatty acid ester.

[0046] In this embodiment, the fatty acid ester is polyethylene glycol (PEG2000) with an average molecular weight of 2000.

[0047] In this embodiment, the mass ratio between the polymer and the two-dimensional sheet material is 3:20.

[0048] The above-mentioned preparation method of a heat-conducting enhanced thermal energy storage shape-changing compos...

Embodiment 2

[0054] Ti 3 C 2 The mass of is changed to 30mg, compounded to get Ti 3 C 2 Nanosheet composite shape-setting phase change material, other conditions are consistent with Example 1. Ti in the resulting composite shape-setting phase change material 3 C 2 The mass fraction is 5%.

Embodiment 3

[0056] Ti 3 C 2 The quality of the mass is changed to 50mg, compounded to obtain Ti 3 C 2 Nanosheet composite shape-setting phase change material, other conditions are consistent with Example 1. In the obtained composite shape-setting phase change material, Ti 3 C 2 The mass fraction is 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com