Olefin composite shaping phase-change material and preparation thereof

A technology of shape-setting phase change materials and paraffins, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem of high proportion of support materials and additives, low percentage of main heat storage materials, and reduced phase change enthalpy, etc. problem, to achieve the effect of good application performance, low preparation cost, and high phase change enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

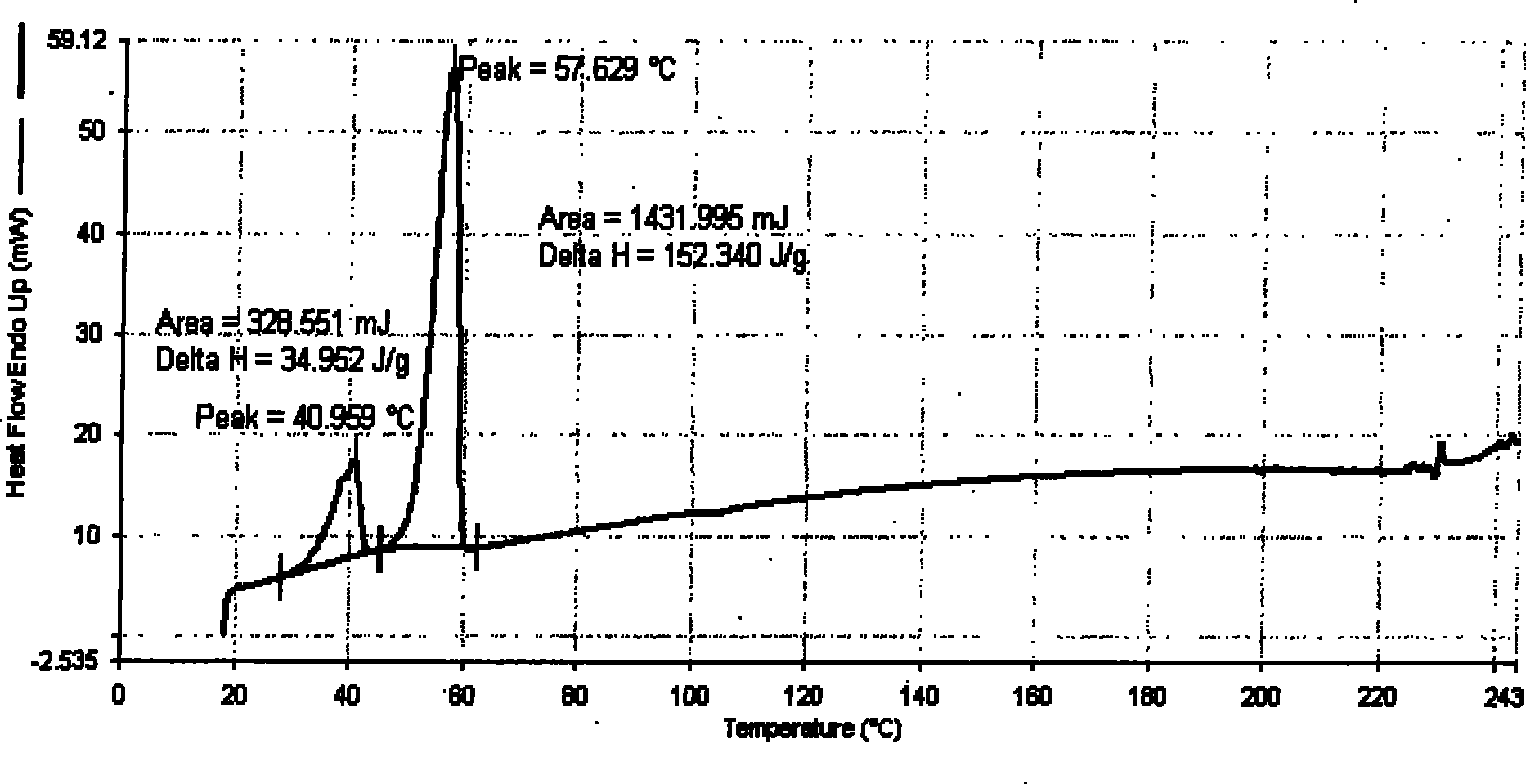

Embodiment 1

[0038] Take 54 with a melting point of 54-56°C and a phase change enthalpy of 187.29J / g # 90.00 g of solid paraffin was melted in a beaker, and (1,3; 2,4)-di(4-methylbenzylidene) sorbitol (MDBS) was added to make the mass percentage 0.5%, heated and stirred until completely dissolved, After the mixture is clear and transparent, pour it into an iron mold with a width of 3 cm, a thickness of 1 cm, and a height of 15 cm, let it cool and take it out to obtain a paraffin composite shape-setting phase change material. ((1,3;2,4)-bis(4-methylbenzylidene)sorbitol is a dicondensate of sorbitol and 4-methylbenzaldehyde)

[0039] The leakage rate of the paraffin-based composite shape-setting phase-change material prepared in this example is 4.23%. Its phase change enthalpy is 192.17J / g.

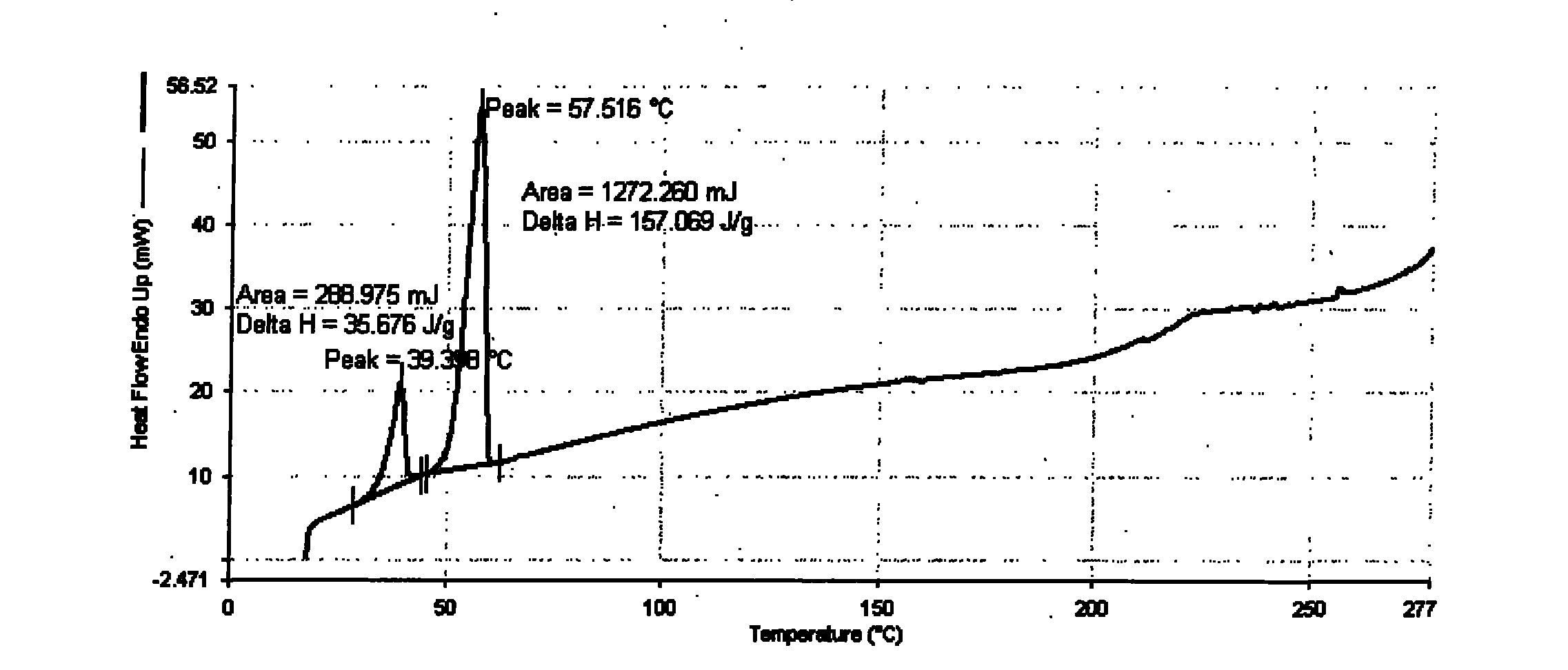

Embodiment 2

[0041] Take 54 with a melting point of 54-56°C and a phase change enthalpy of 187.29J / g #Melt 90.00g of solid paraffin in a beaker, add MDBS to make it 1% by mass, heat and stir until completely dissolved, pour the mixture into an iron mold with a width of 3cm, a thickness of 1cm, and a height of 15cm after the mixture is clear and transparent, let it cool and take it out , to prepare paraffin-based composite shape-setting phase-change materials.

[0042] The leakage rate of the paraffin-based composite shape-setting phase-change material prepared in this example is 2.56%. Its phase change enthalpy is 190.25J / g.

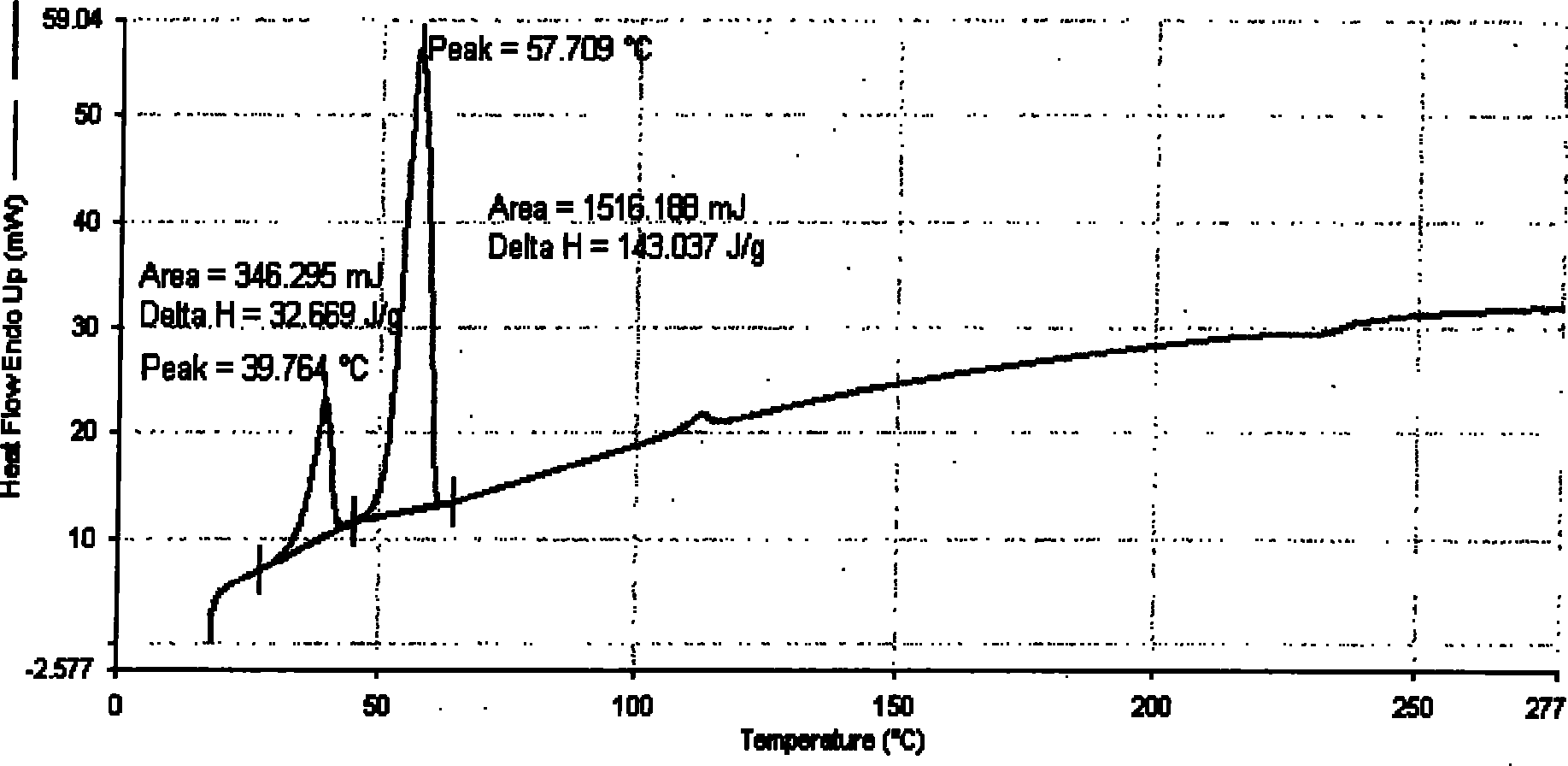

Embodiment 3

[0044] Take 54 with a melting point of 54-56°C and a phase change enthalpy of 187.29J / g # Melt 90.00g of solid paraffin in a beaker, add MDBS to make it 3% by mass, heat and stir until it is completely dissolved, pour the mixture into an iron mold with a width of 3cm, a thickness of 1cm, and a height of 15cm, let it cool and take it out , to prepare paraffin-based composite shape-setting phase-change materials.

[0045] The leakage rate of the paraffin-based composite shape-setting phase-change material prepared in this example is 1.75%. Its phase change enthalpy is 192.74J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com