Processing technique and device of antique relief wood door and furniture

A processing technology and wooden door technology, which is applied in the field of wooden doors and furniture, can solve the problems of many times of paint construction, lower environmental protection quality, high labor intensity, etc., achieve strong three-dimensional effect of wood grain, improve production efficiency, and have good environmental protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

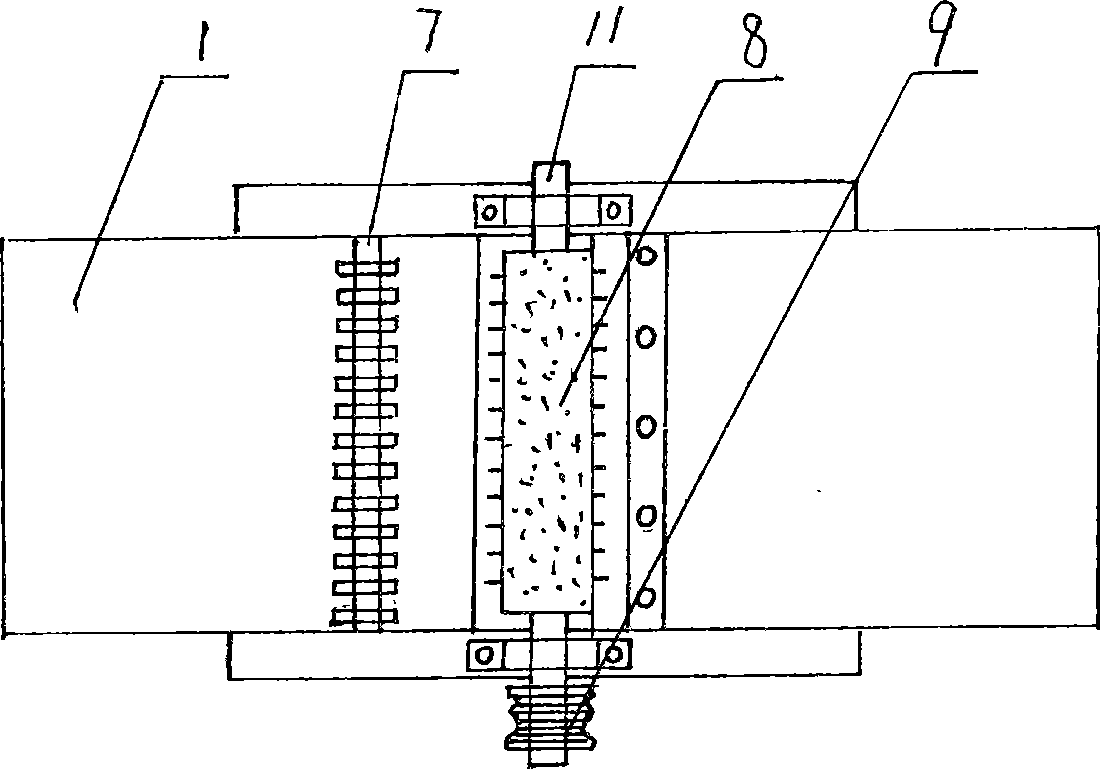

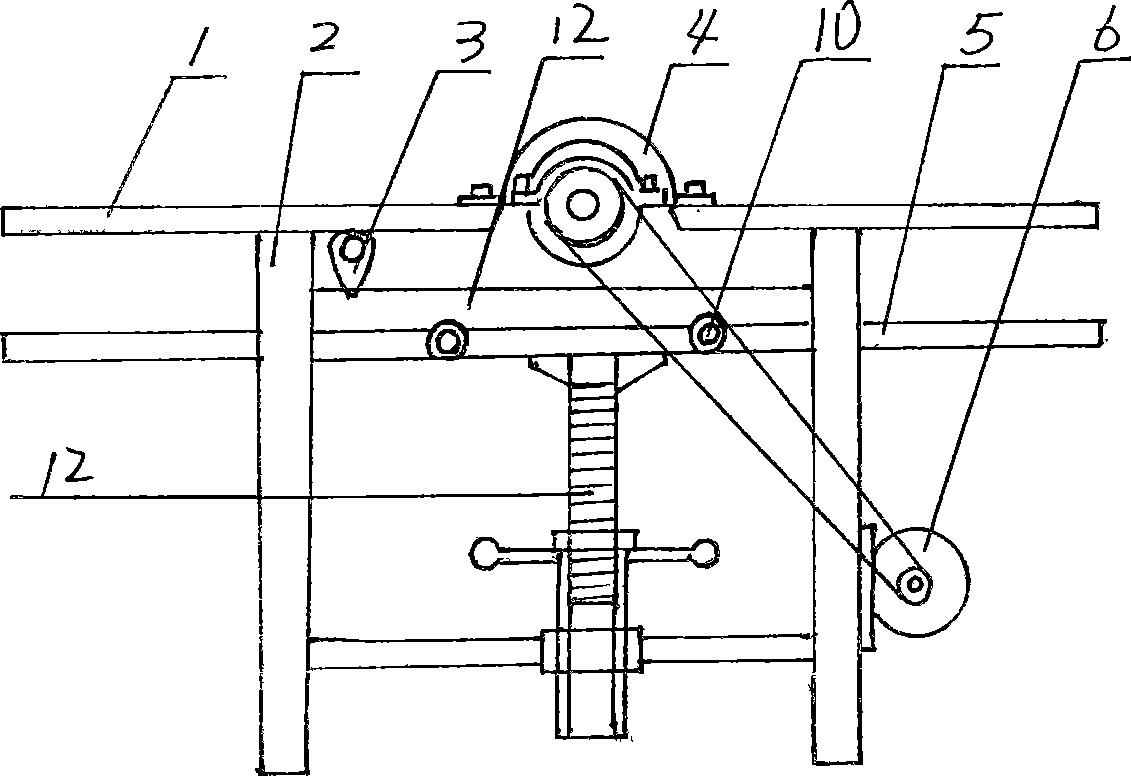

[0012] Such as figure 1 , 2 As shown, the wire drawing equipment includes: frame 2, upper workbench 1, lower workbench 5, wire brush body 8, resistance reducing device 10, bulletproof device and motor 6, steel wire brush main shaft 11 is fixed on the upper workbench, two ends The bearing is fixed on the frame, the wire brush body 8 is set on the main shaft, the safety cover 4 is arranged on the brush body, and the belt pulley 9 is installed on one end of the main shaft to connect with the motor, and the motor drives the wire brush main shaft to rotate, which plays the role of using the wire brush body. Rotate the wood grain on the plank 12 to process the three-dimensional effect. Positioning rod 12 is set below the lower workbench, and the depth and thickness of the three-dimensional wood grain and the thickness of the board are all determined by the lifting of the lower workbench regulated by rotating the positioning rod. The resistance reducing device 10 is arranged at int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com