Automatic edge-folding machine

An edge folding machine and automatic technology, applied in the direction of battery assembly, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as low efficiency, difficult to control welding quality, and high manpower and material resources, and achieve high efficiency, Good processing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

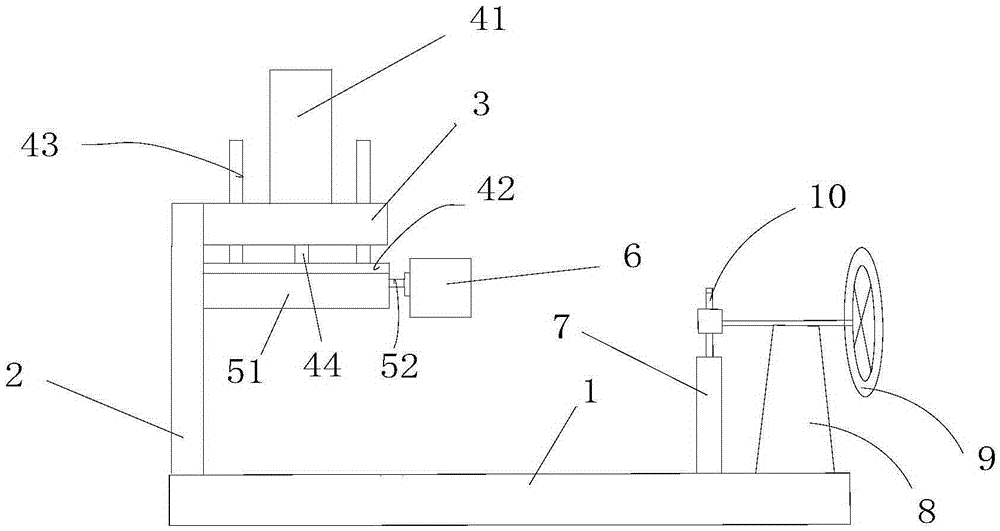

[0017] Such as figure 1 As shown, in the first embodiment of the automatic edge folding machine of the present invention, the automatic edge folding machine includes a workbench 1 for placing pouch batteries, a bracket assembly installed on the workbench 1, and a bracket assembly arranged on the bracket assembly. The horizontal drive mechanism, the horizontal slider 6 mounted on the horizontal drive mechanism and driven by the horizontal drive mechanism to reciprocate horizontally, and the baffle plate 7 opposite to the horizontal slider 6; the tab bending part of the pouch battery is located Between the horizontal slider 6 and the baffle 7 , the lug junction of the pouch battery is pressed against the lower end of the baffle 7 . Press the lug junction on the lower end of the baffle 7, when the horizontal slider 6 is driven by the horizontal drive mechanism to reciprocate horizontally, the tab bending part is clamped between the horizontal slider 6 and the baffle 7, and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com