Extrusion mold for high-strength magnesium alloy and magnesium alloy extrusion method

An extrusion die and extrusion method technology, applied in the field of alloy forging and extrusion, can solve the problems of complicated process, damage to the shape of the alloy, and low degree of refinement, and achieve the effects of simple operation, no damage to the shape of the material, and reduced segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

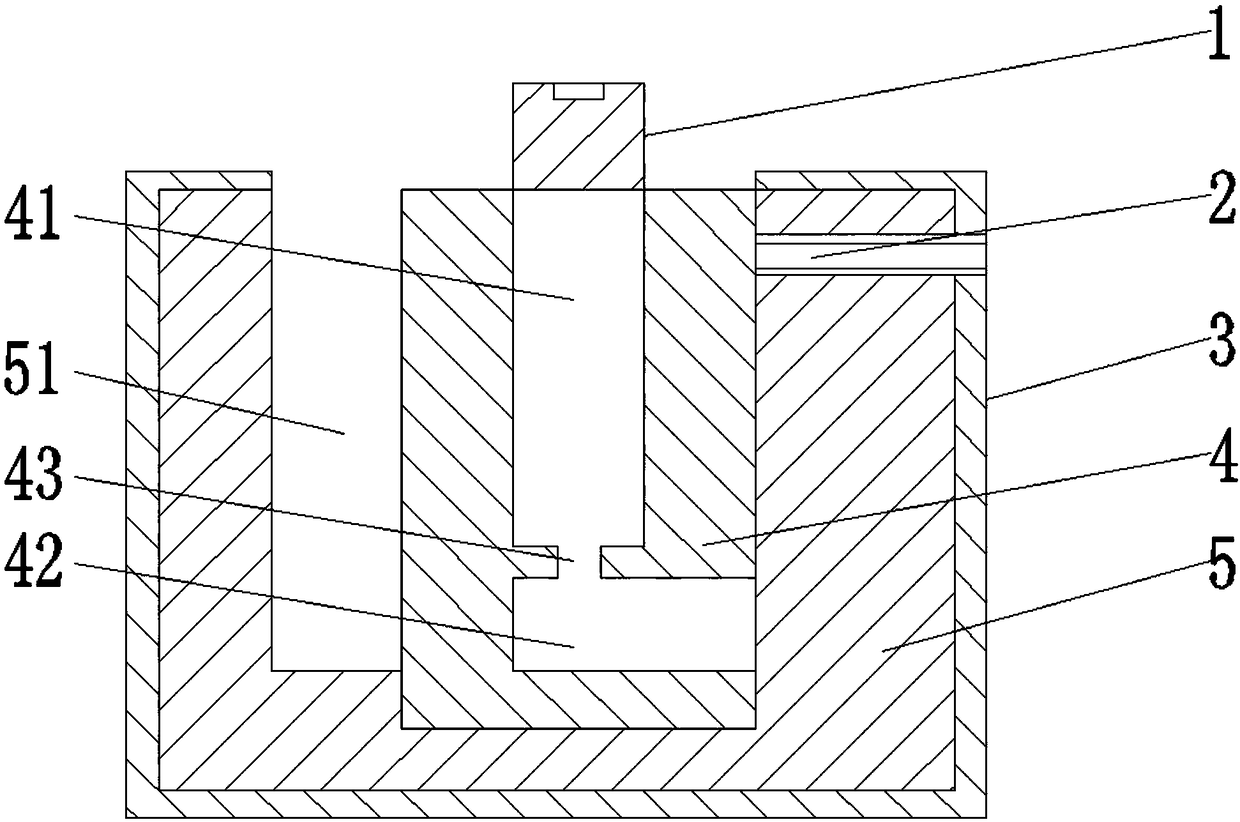

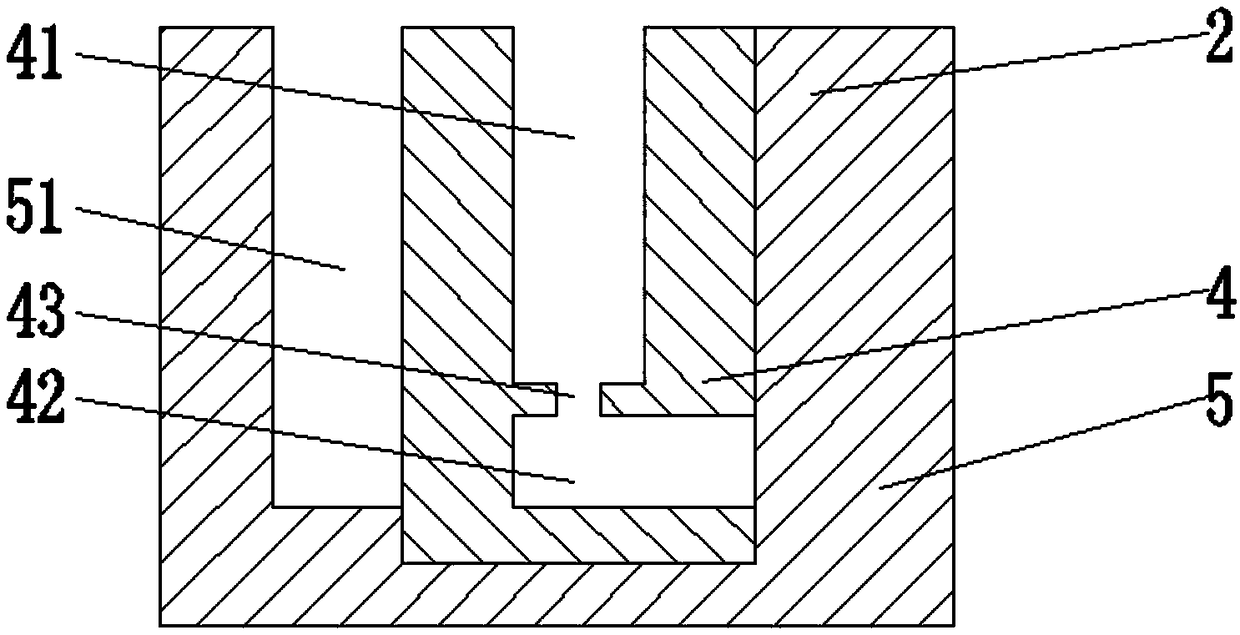

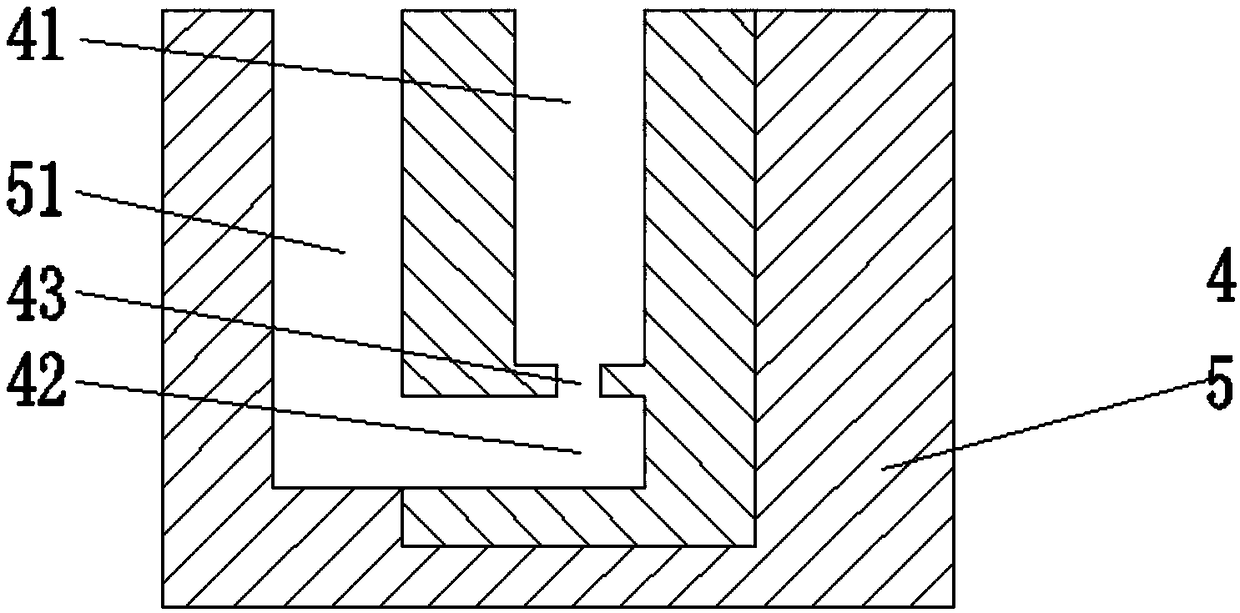

[0040] combine Figure 1-Figure 7 Shown, the extrusion die of a high-strength magnesium alloy disclosed in this embodiment includes a die punch 1, a heating device 2, a die sleeve 3, a rotatable inner mandrel 4 and an outer mandrel 5; the die sleeve 3 An external mandrel 5 is arranged inside, and a rotatable inner mandrel 4 is arranged inside the outer mandrel 5, and a magnesium alloy to be extruded is arranged inside the rotatable inner mandrel 4, and the upper end of the rotatable inner mandrel 4 is set There is a mold punch 1, and the upper end of the mold sleeve 3 is also provided with a heating device 2, and the heating device 2 supplies heat for the outer mandrel 5, the rotatable inner mandrel 4 and the magnesium alloy to be extruded respectively. 3 The lower end is also provided with a set of thermocouple temperature measuring devices, the thermocouple temperature measuring devices are connected to a set of temperature control system data, and the temperature control sy...

Embodiment 2

[0056] A magnesium alloy extrusion method for an extrusion die of a high-strength magnesium alloy, the method comprising the steps of:

[0057] The magnesium alloy blank is selected as Mg-4Sn-3Nd-1Ti. After solution treatment, the magnesium alloy blank is made into the required size by wire cutting, placed in the mold mandrel, and the mold punch is placed above the blank.

[0058] Set the parameters of the temperature control system and then turn on the switch of the heating device. In order to promote the temperature stability of the device and reduce heat loss; wrap a layer of asbestos on the surface of the mold for heat resistance.

[0059] Adjust the position of the inner core and the outer core of the mold.

[0060] A magnesium alloy billet with a diameter of 25 mm and a length of 135 mm is put into the rotatable inner mandrel 4 .

[0061] The heating device 2 is connected in the mold sleeve 3, and the rotatable internal mandrel 4 and the magnesium alloy blank added ther...

Embodiment 3

[0070] A magnesium alloy extrusion method for an extrusion die of a high-strength magnesium alloy, the method comprising the steps of:

[0071] The magnesium alloy blank is selected as Mg-4Sn-3Nd-1Ti. After solution treatment, the magnesium alloy blank is made into the required size by wire cutting, placed in the mold mandrel, and the mold punch is placed above the blank.

[0072] Set the parameters of the temperature control system and then turn on the switch of the heating device, in order to promote the temperature stability of the device and reduce heat loss. Wrap a layer of asbestos on the surface of the mold for heat resistance.

[0073] Adjust the position of the inner mold core and the outer mold core of the mold, and the outlet of the outer core mold is exactly the same as the opening of the inner core mold.

[0074] A magnesium alloy billet with a diameter of 25 mm and a length of 135 mm is put into the rotatable inner mandrel 4 .

[0075] The heating device 2 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com