Hot-dip galvanized IF steel plate production method capable of controlling surface waviness

A steel plate production method and surface waviness technology, applied in hot-dip coating process, heat treatment furnace, manufacturing tools, etc., can solve problems such as the surface texture of galvanized steel plate without consideration, and achieve the effect of improving Wsa value and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is a production method of hot-dip galvanized IF steel sheet for controlling surface waviness. The chemical composition of the hot-dip galvanized IF steel sheet is: 0<C≤0.0030%, 0<Si≤0.020%, Mn 0.04% ~0.15%, 0<P≤0.010%, 0<S≤0.012%, Al 0.02%~0.045%, 0<Cr≤0.06%, 0<Nb≤0.005%, Ti0.05%~0.09%, 0<N ≤0.004%, 0<Ni≤0.06%, the balance is Fe and unavoidable impurities;

[0019] The production process of the hot-dip galvanized IF steel plate includes smelting, refining outside the furnace, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing, and hot dipping, wherein:

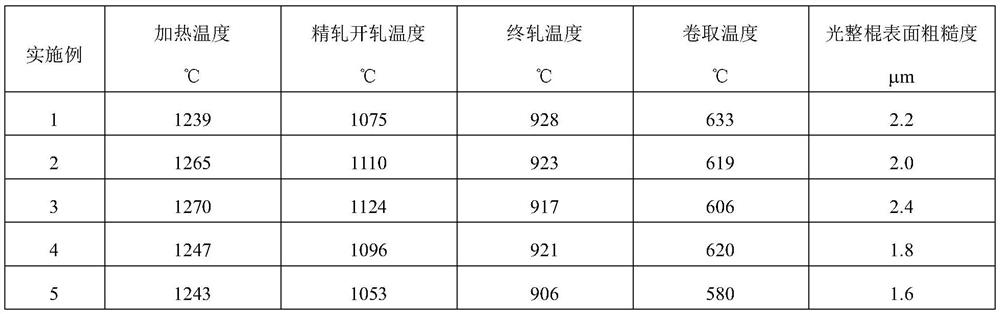

[0020] 1) During continuous hot rolling, heat the slab to 1200-1300°C, keep it warm for 120-180min, start the finish rolling at 1000-1150°C, finish rolling at 900-960°C, and coil at 580-640°C;

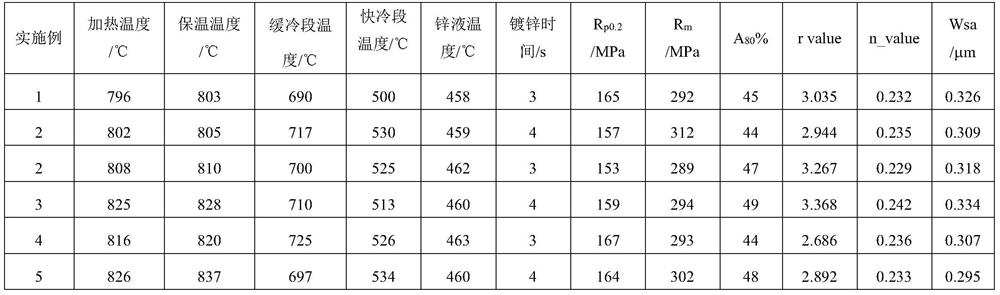

[0021] 2) During annealing, the temperature of the heating section is 790-840°C; the temperature of the holding section is 790-840°C, and the holding time is 30-90s; after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com