Patents

Literature

74results about How to "Improve appearance visual effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

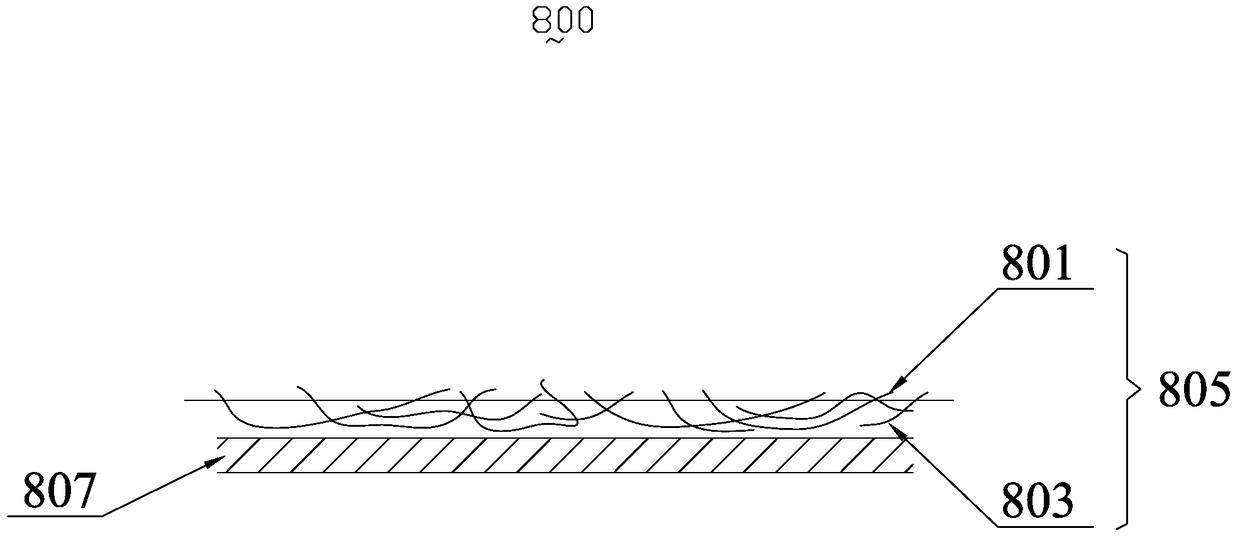

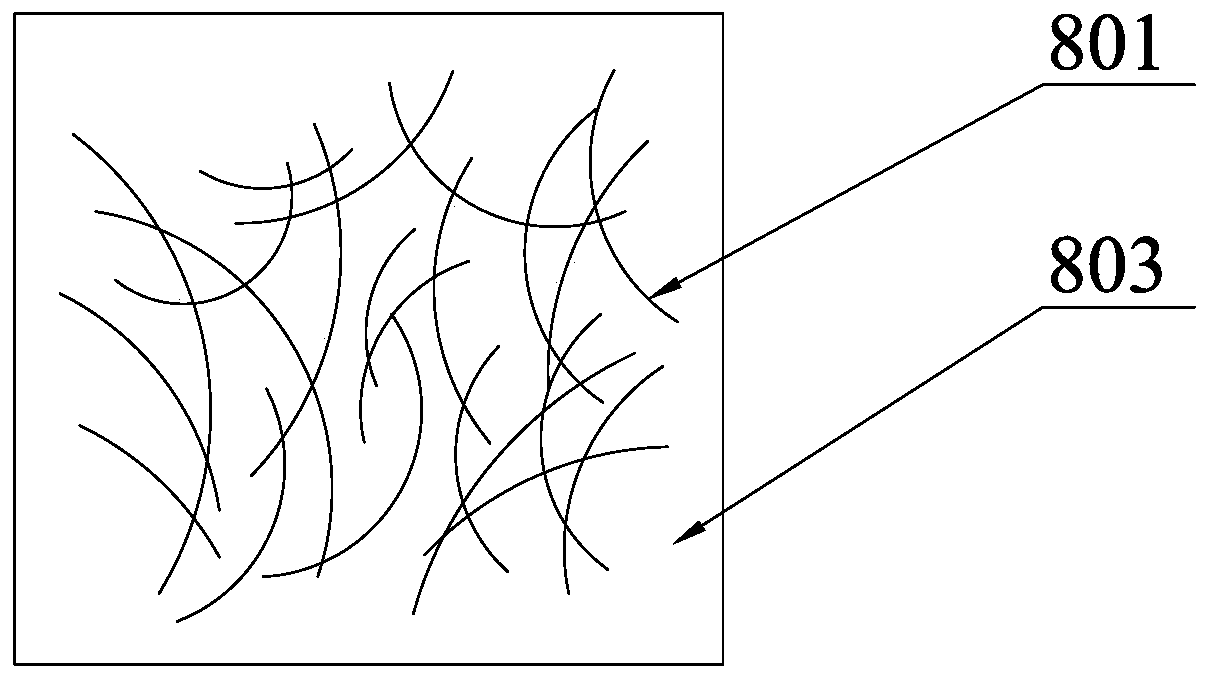

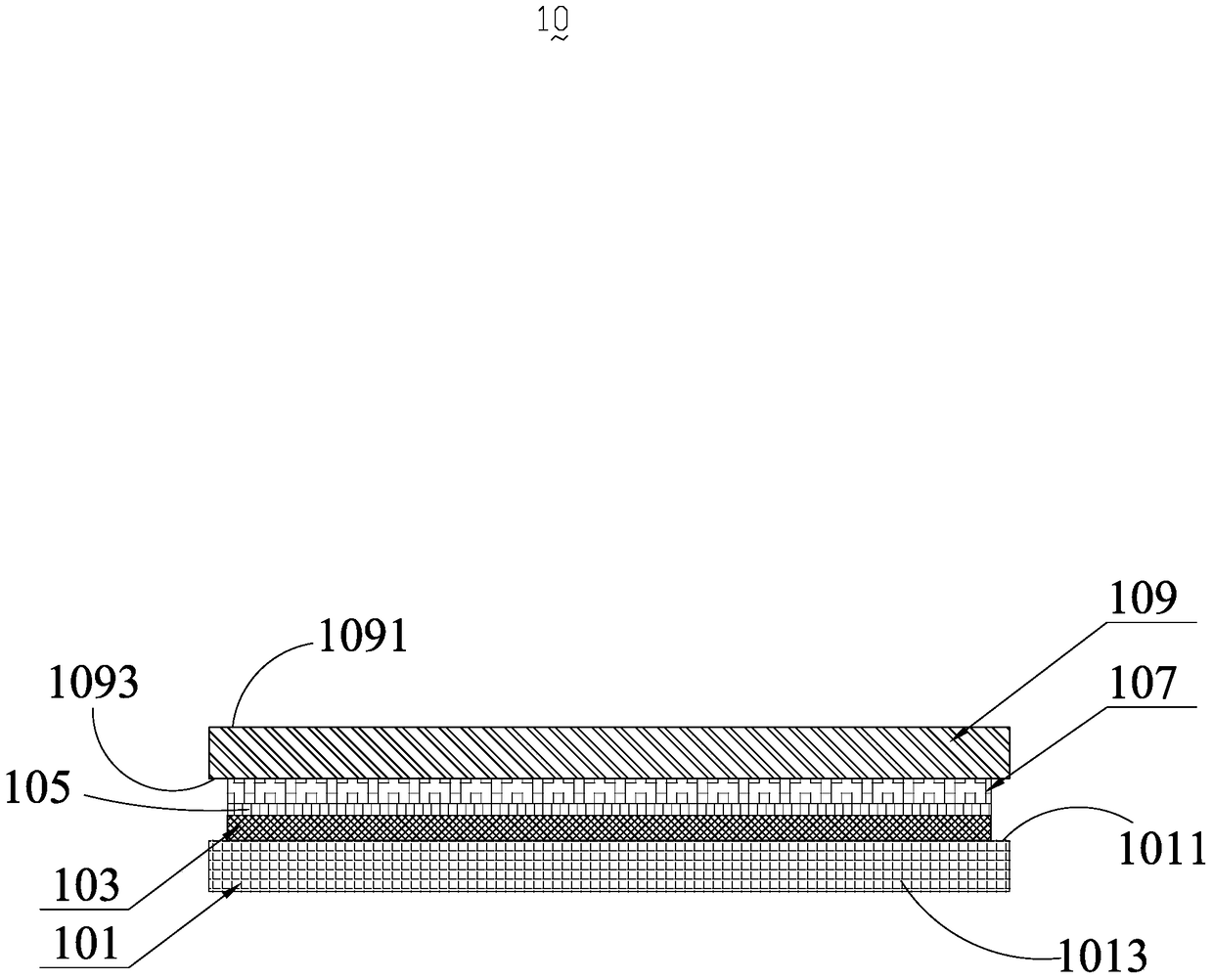

Touch panel and touch display module

InactiveCN105425992AImprove visual effectsEliminate gridline outlines and Murray moiré issuesNon-linear opticsInput/output processes for data processingPolarizerTouch panel

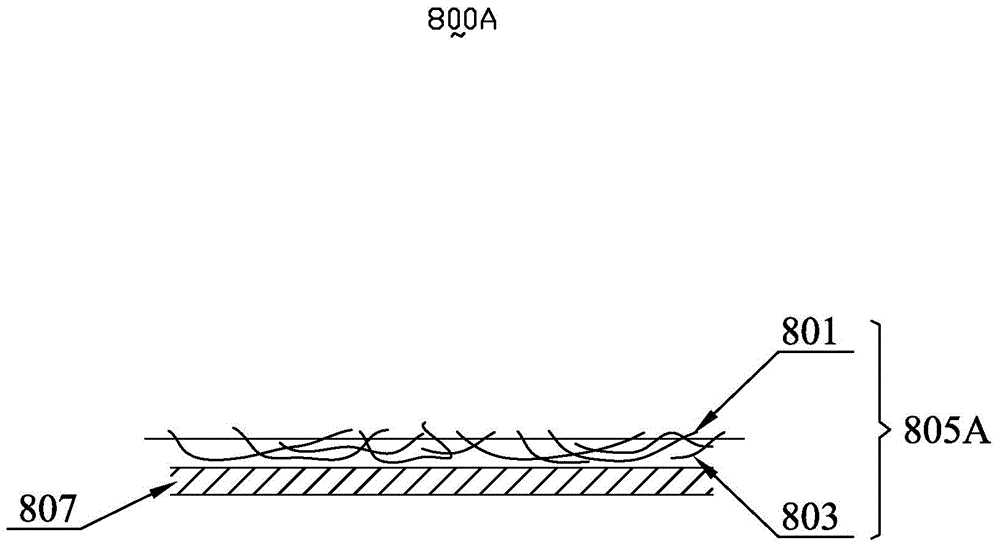

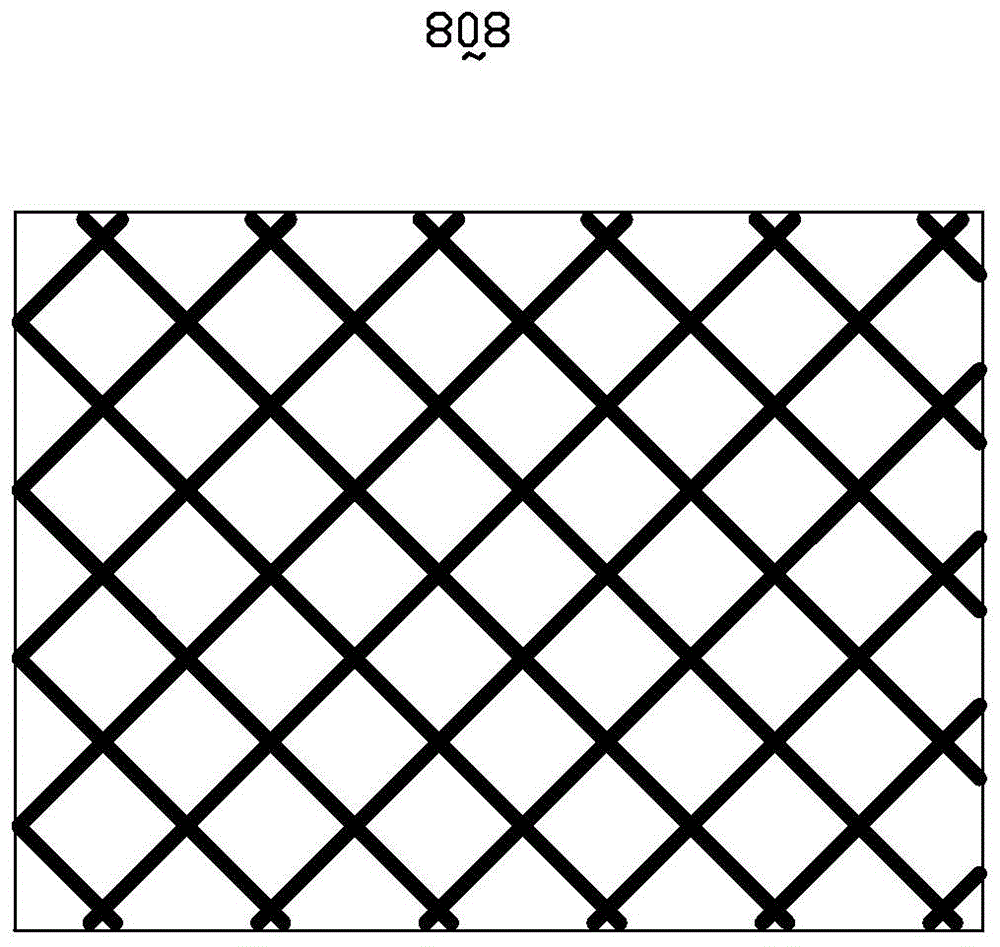

The invention relates to a touch panel. The touch panel comprises a first substrate and a first silver nanowire electrode layer, wherein the first silver nanowire electrode layer is formed on a surface of the first substrate and comprises a plurality of first electrode pads and a plurality of first connecting wires conductively connected with the electrode pads; each first electrode pad is a conductive grid pattern; two first non conductive regions are formed on two sides of a connection direction of the two adjacent first electrode pads; and a plurality of wire segments insulated from the first electrode pads are arranged in the first non conductive regions. The invention furthermore provides a touch display module. The touch display module comprises the touch panel and a display unit, wherein the display unit comprises a display substrate, a liquid crystal layer and a polarizer; and the first silver nanowire electrode layer is arranged on any one of the upper surface of the display substrate, the lower surface of the display substrate, the upper surface of the polarizer and the lower surface of the polarizer.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

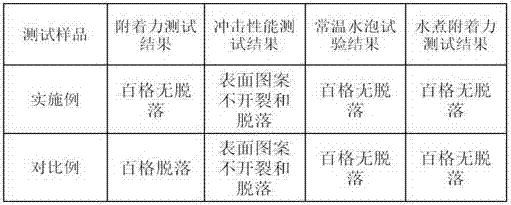

Glass cover plate surface color gradient printing process

ActiveCN108357224AGradient colors are uniform and naturalClear gradient colorOther printing apparatusScreen printingGlass cover

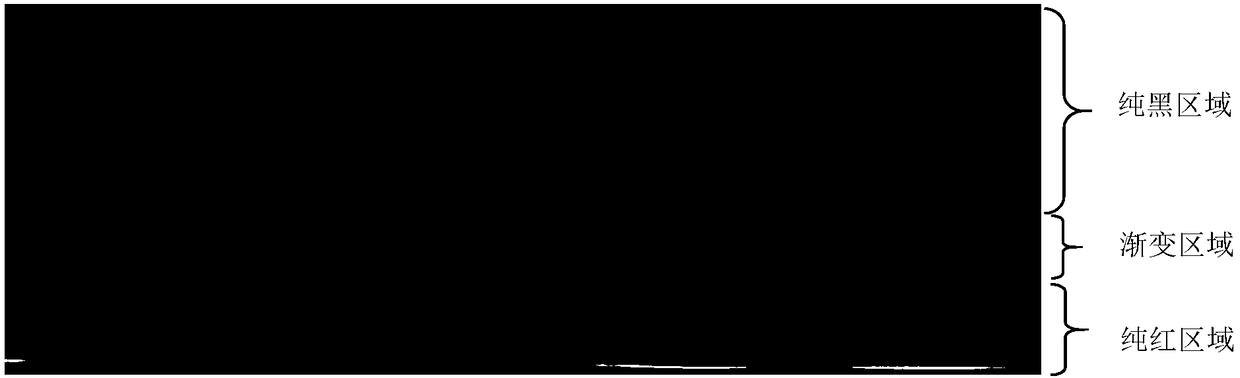

The invention discloses a glass cover plate surface color gradient printing process and relates to the technical field of cover plate surface processing. The printing process comprises the steps of (1) manufacturing a five-layer screen printing plate; (2) conducting screen printing through A-color printing ink; (3) conducting screen printing through B-color printing ink; (4) conducting screen printing through white semi-transparent ink; (5) conducting screen printing through white ink; and (6) conducting screen printing through black ink, wherein the color A and the color B are different colors. According to the glass cover plate surface color gradient printing process, the structure of the screen printing plate is designed, and multiple layers of ink in colors is printed on the surface ofa cover plate through the screen printing plate; through mutual overlapping and permeation of the multiple layers of the ink, the natural gradient effect of the colors in a printing region is achieved; the gradient colors are uniform, natural, clear and not dull, and the appearance visual effect is good. Through the glass cover plate surface color gradient printing process, there is no need to purchase expensive equipment, the cost is low, the preparation process is simple, and the process meets the requirements for industrial production.

Owner:JIANGXI HOLITECH TECH

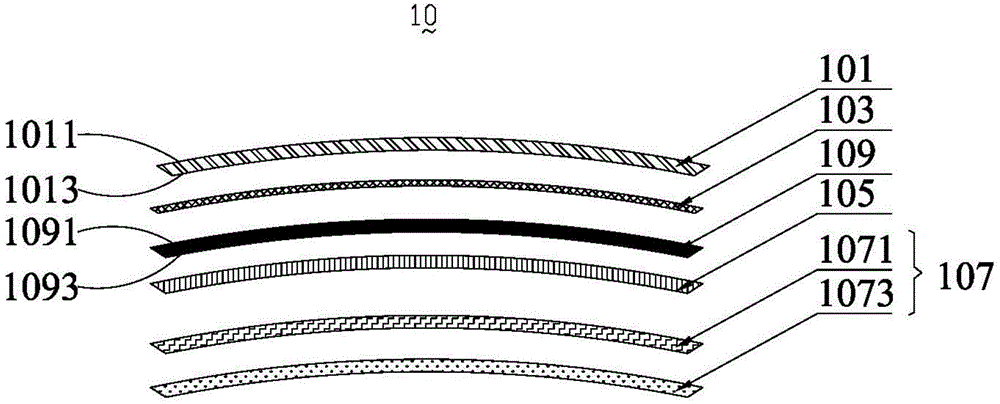

Curved surface touch panel and wearable device

ActiveCN105224115AGood electrical conductivityLow costInput/output processes for data processingTouch panelSurface plate

The invention relates to the technical field of touch, in particular to a curved surface touch panel and a wearable device adopting the same. The curved surface touch panel comprises a cover plate with a first surface and a second surface, a flexible substrate and a silver nanowire conductive layer arranged on the flexible substrate, wherein the first surface is a touch surface; the flexible substrate is positioned between the second surface and the silver nanowire conductive layer; and after the flexible substrate deforms, the curvature of the flexible substrate and the silver nanowire conductive layer is greater than 0, and the silver nanowire conductive layer is compressed. The wearable device comprises a driving control module and the curved surface touch panel, wherein the driving control module is electrically connected with the curved surface touch panel.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

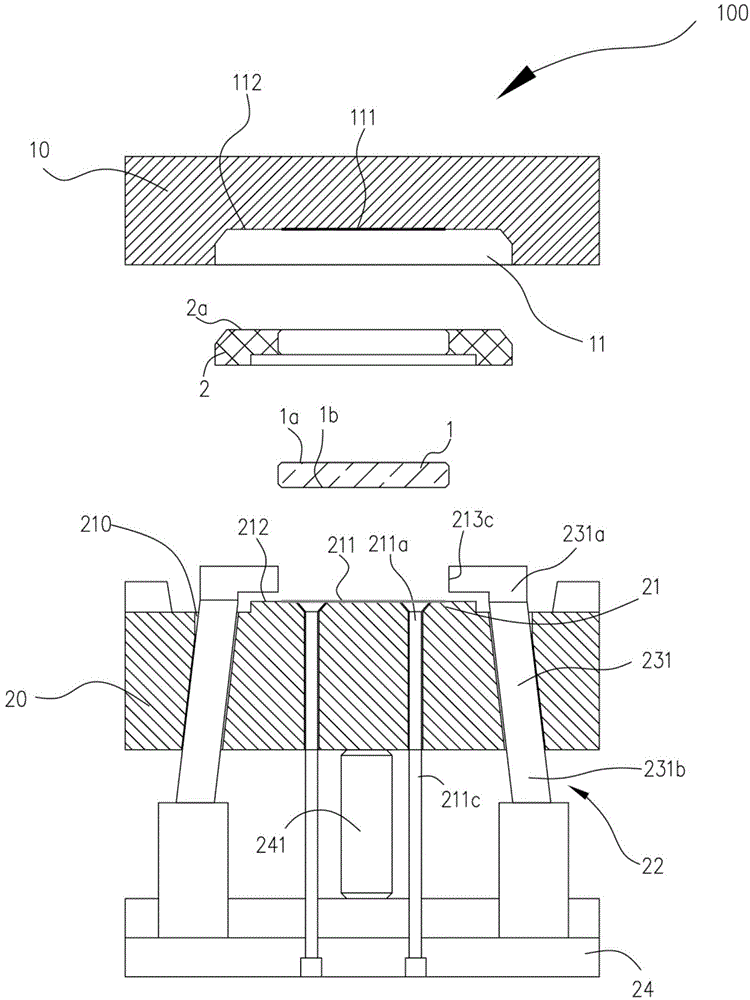

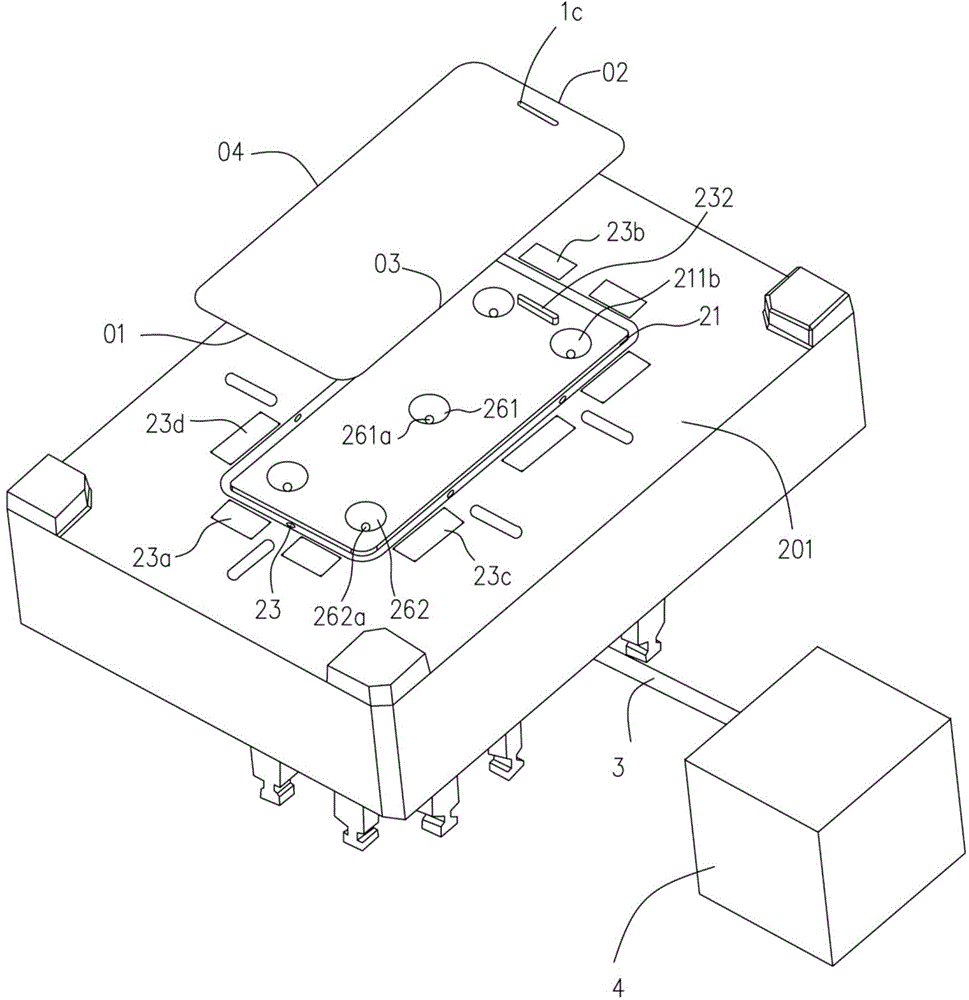

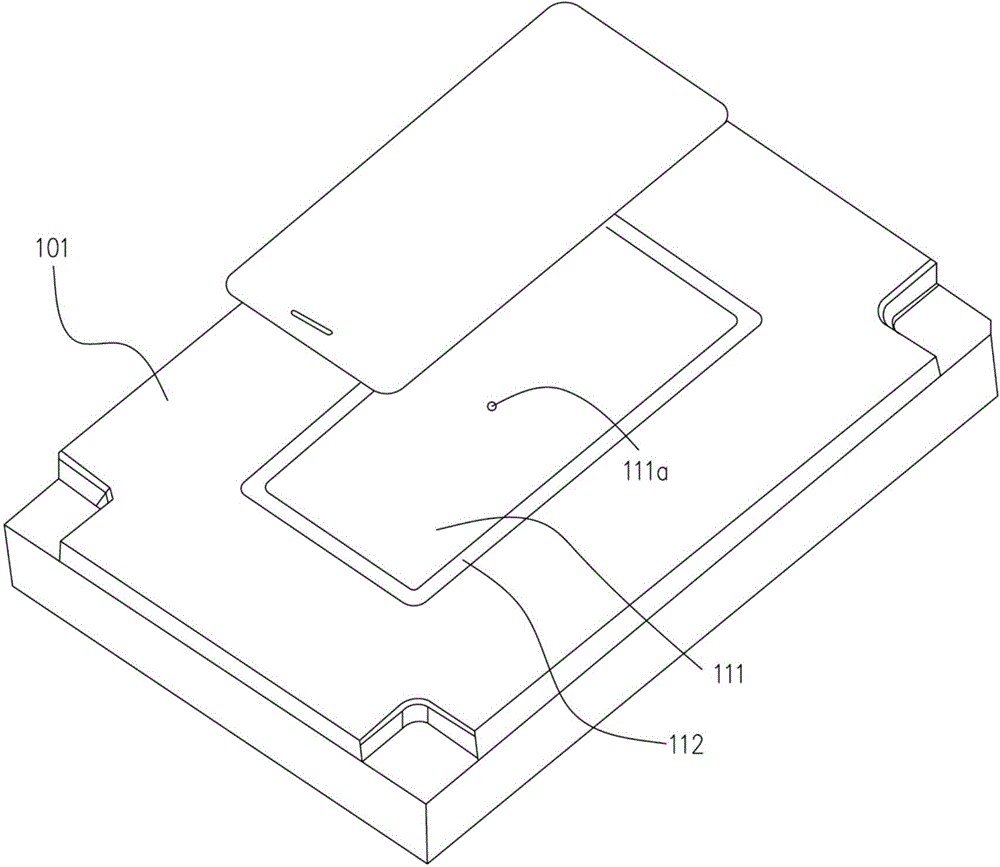

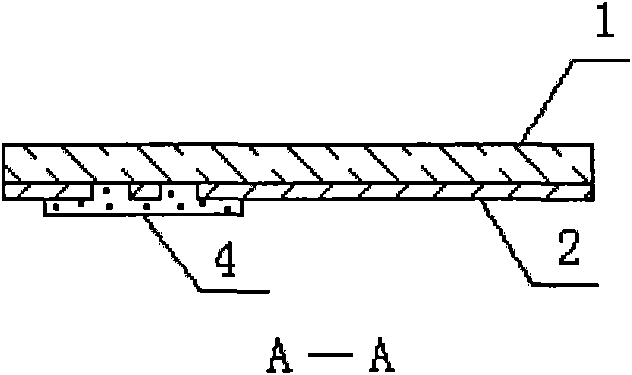

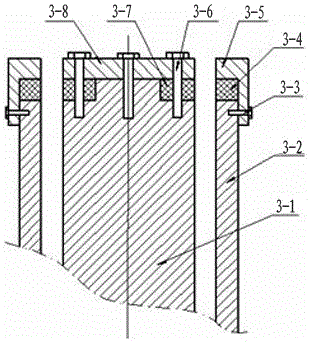

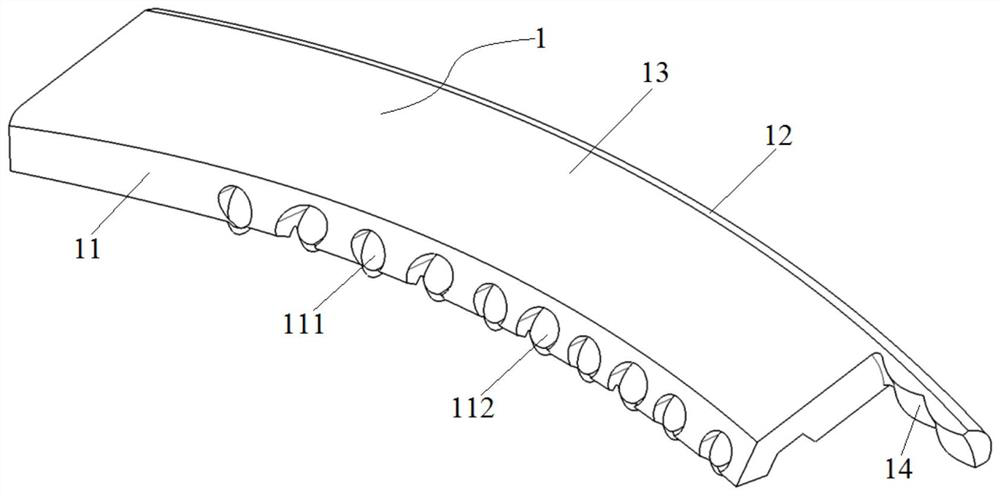

Forming mold of front cover component and manufacturing method of forming mold

InactiveCN104859098AImprove appearance visual effectImprove efficiencyCoatingsGlass sheetFront cover

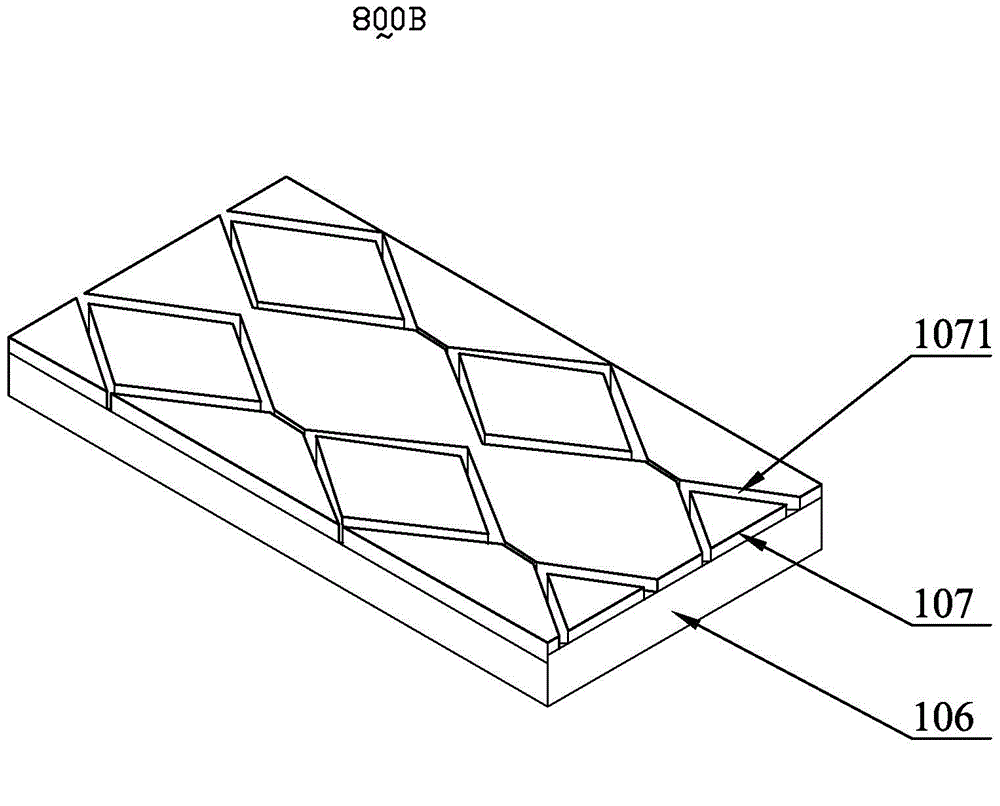

The invention discloses a forming mold of a front cover component. The forming mold of the front cover component integrally molds a glass plate and a frame surrounding the glass plate, and comprises a fixed mold and a movable mold, wherein the inner surface of a molding cavity of the fixed mold comprises a fit surface and an appearance molding surface; the movable mold is provided with a molding core extending to the molding cavity; the end surface of the top end of the molding core comprises a bonding surface and an inner side molding surface; the bonding surface is bonded with the lower surface of the glass plate; the inner side molding surface molds a shielding surface of the frame; and the shielding surface shields a non-display area. The inner side of the front cover component saves an ink layer, so that the front cover component and a display screen can be formed to an integrated terminal front cover, and the use efficiency of the front cover component is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

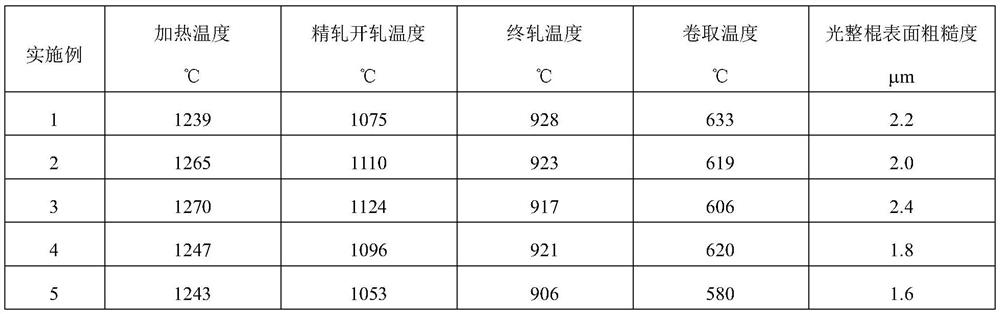

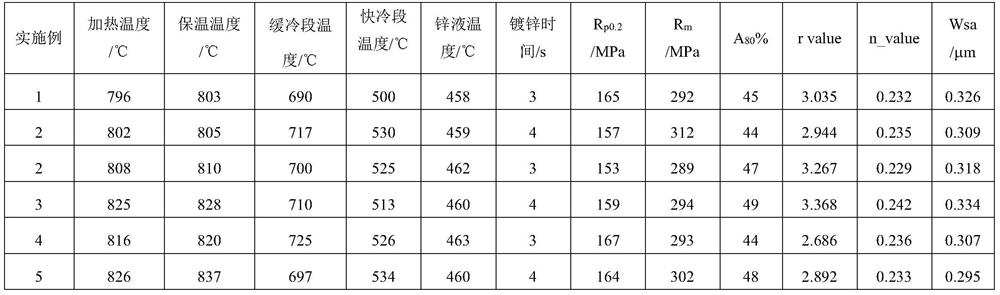

Hot-dip galvanized IF steel plate production method capable of controlling surface waviness

ActiveCN112538593AImprove uniformityImprove Wsa valueHot-dipping/immersion processesFurnace typesSteel platesChemical composition

The invention relates to a hot-dip galvanized IF steel plate production method capable of controlling surface waviness. The hot-dip galvanized IF steel plate is prepared from the following chemical components in percentage by weight: larger than 0 and less than or equal to 0.0030% of C, larger than 0 and less than or equal to 0.020% of Si, 0.04-0.15% of Mn, larger than 0 and less than or equal to0.010% of P, larger than 0 and less than or equal to 0.012% of S, 0.02-0.045% of Al, larger than 0 and less than or equal to 0.06% of Cr, larger than 0 and less than or equal to 0.005% of Nb, 0.05-0.09% of Ti, larger than 0 and less than or equal to 0.004% of N, larger than 0 and less than or equal to 0.06% of Ni and the balance of Fe and inevitable impurities. The production process of the hot-dip galvanized IF steel plate comprises the steps of smelting, external refining, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing and hot dipping. Through the comprehensive measures of reasonably designing the chemical components of the steel plate, adjusting the process parameters of the hot continuous rolling and annealing process, controlling the surface roughness of a finishing roller and the like, the surface texture of the stamped hot galvanized IF steel plate is finally improved, and the requirements of a 2C1B painting process are met.

Owner:鞍钢蒂森克虏伯汽车钢有限公司

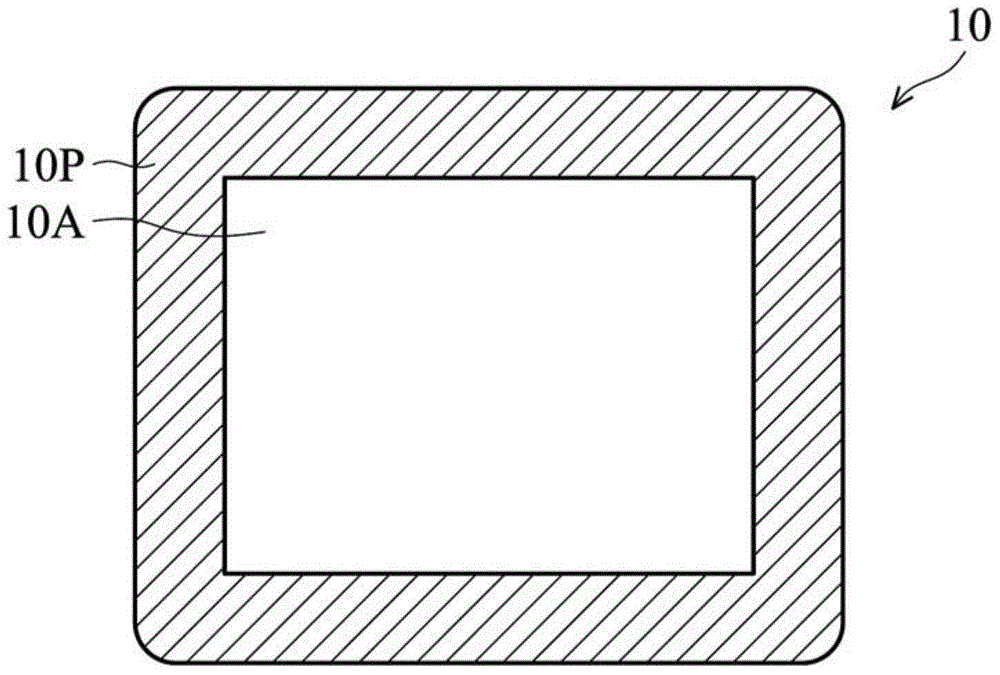

Light shield layer structure with infrared ray hole of flat plate display

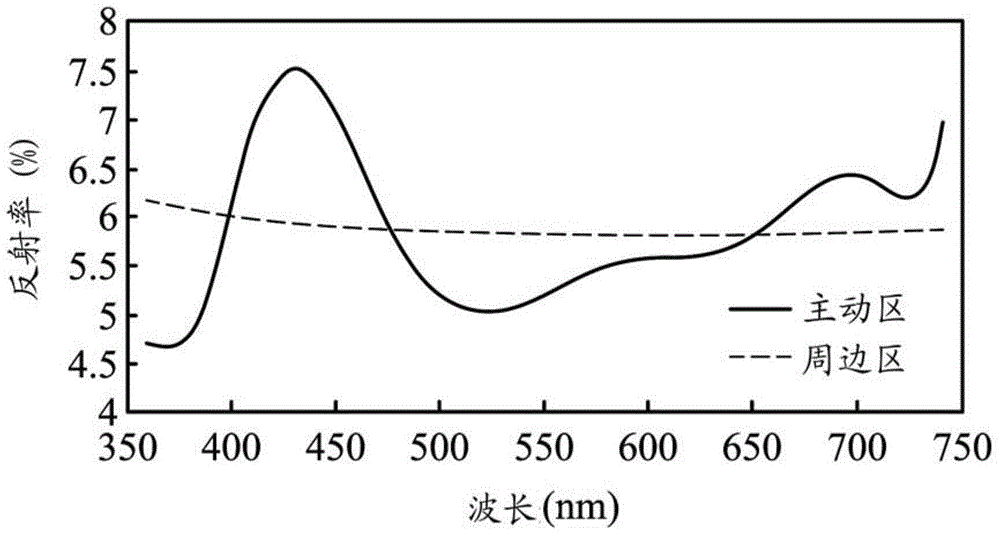

InactiveCN101727788AMaintain consistencyGood appearance and visual effectTelephone set constructionsIdentification meansFlat panel displayReflectivity

The invention discloses a light shield layer structure with an infrared ray hole of a flat plate display. The structure comprises a non-light tight substrate and a light shield layer with an infrared ray through hole on the substrate, wherein at least one layer of infrared non-light tight material is arranged between the non-light tight substrate and the light shield layer. Because the same plane is provided with the same infrared non-light tight material, the light shield layer structure not only can meet the requirement on the permeation of the infrared rays, but also can keep the consistency of reflectance, thereby achieving an excellent appearance visual effect. The infrared ray through hole positioned on the light shield layer behind the infrared non-light tight material cannot be seen from a viewing direction of a lens, so the disadvantage of inconsistent reflectances caused by two different materials existing on the same plane in the prior art is overcome. Simultaneously, the light shield layer structure with the infrared ray hole of the flat plate display can be manufactured by the same production equipment and process in the manufacturing process so as to achieve the purpose of simplifying the process and lowering the cost.

Owner:湖南普照爱伯乐平板显示器件有限公司

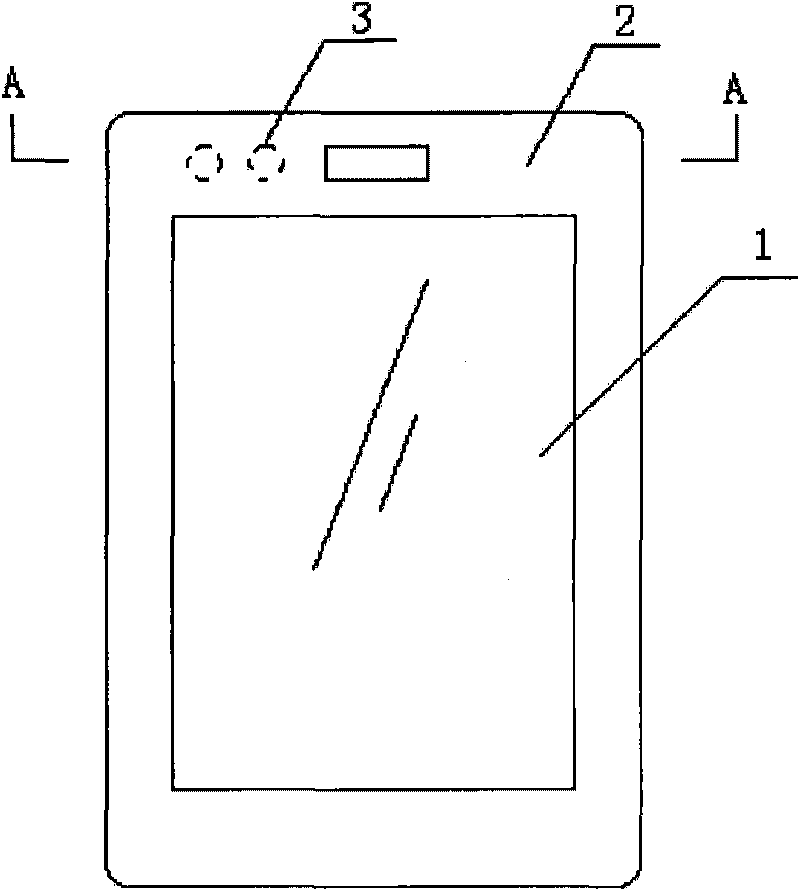

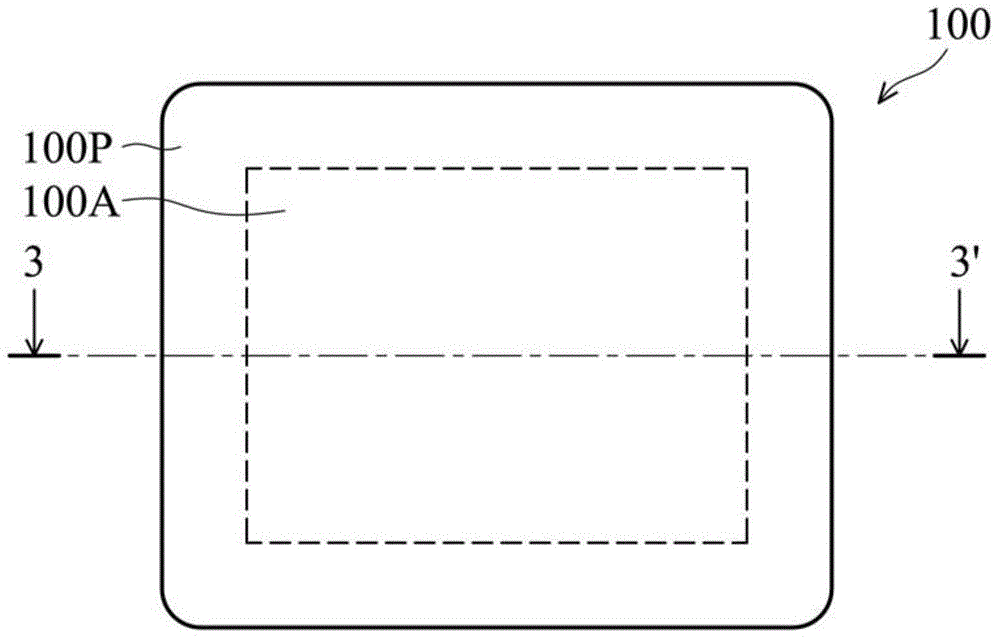

Touch panel

InactiveCN105005402AImprove appearance visual effectInput/output processes for data processingTouch SensesEngineering

The present invention discloses a touch panel, comprising a protective cover plate and a display element below the protection cover. A touch sensing layer is disposed in an active area of the touch panel, and between the protective cover plate and the display element. A decorative layer is provided in a peripheral region of the touch panel, and between the protective cover plate and the display element. The peripheral region surrounds the active area. The touch panel also comprises a dielectric material layer between the protective cover plate and the display element. A reflectivity difference between the active area and the surrounding region is between 0 and 0.5.

Owner:INNOLUX CORP

Glass printing technology with gradually-changing effect

InactiveCN106965579AStrong adhesionGood three-dimensionalPolyurea/polyurethane coatingsOther printing apparatusAdhesion forceIron powder

The invention discloses a glass printing technology with a gradually-changing effect. The glass printing technology includes the following steps that firstly, a UV coating is used for conducting silk printing on a glass material to form patterns; secondly, the material obtained after silk printing is placed on a magnet plate for 3 min to 5 min of standing; thirdly, the patterns on the materials are subjected to full curing through ultraviolet light; and fourthly, silk printing or brushing of thermosetting metal printing ink is conducted on the cured patterns, and baking is conducted for 5 min to 6 min under the temperature of 150 DEG C to 170 DEG C; and silk printing or brushing of sealing bottom paint is conducted on the surface of a cured metal printing ink layer, and baking is conducted for 7 min to 10 min under the temperature of 175 DEG C to 200 DEG C. In the above technology, a UV coating used in the above technology is the UV coating containing iron powder. The UV coating to which the iron powder is added and a matched technology are adopted in the technological method, so that the technology meets the requirement for industrial production; meanwhile, high-quality three-dimensional gradually-changing patterns conforming to the high-end market can be prepared as well, the adhesion force of the patterns to the surface of the glass material is good, the technology cost is low, and an existing multi-layer overprinting technology can be completely replaced.

Owner:FOSHAN CITY GREEND CHEM

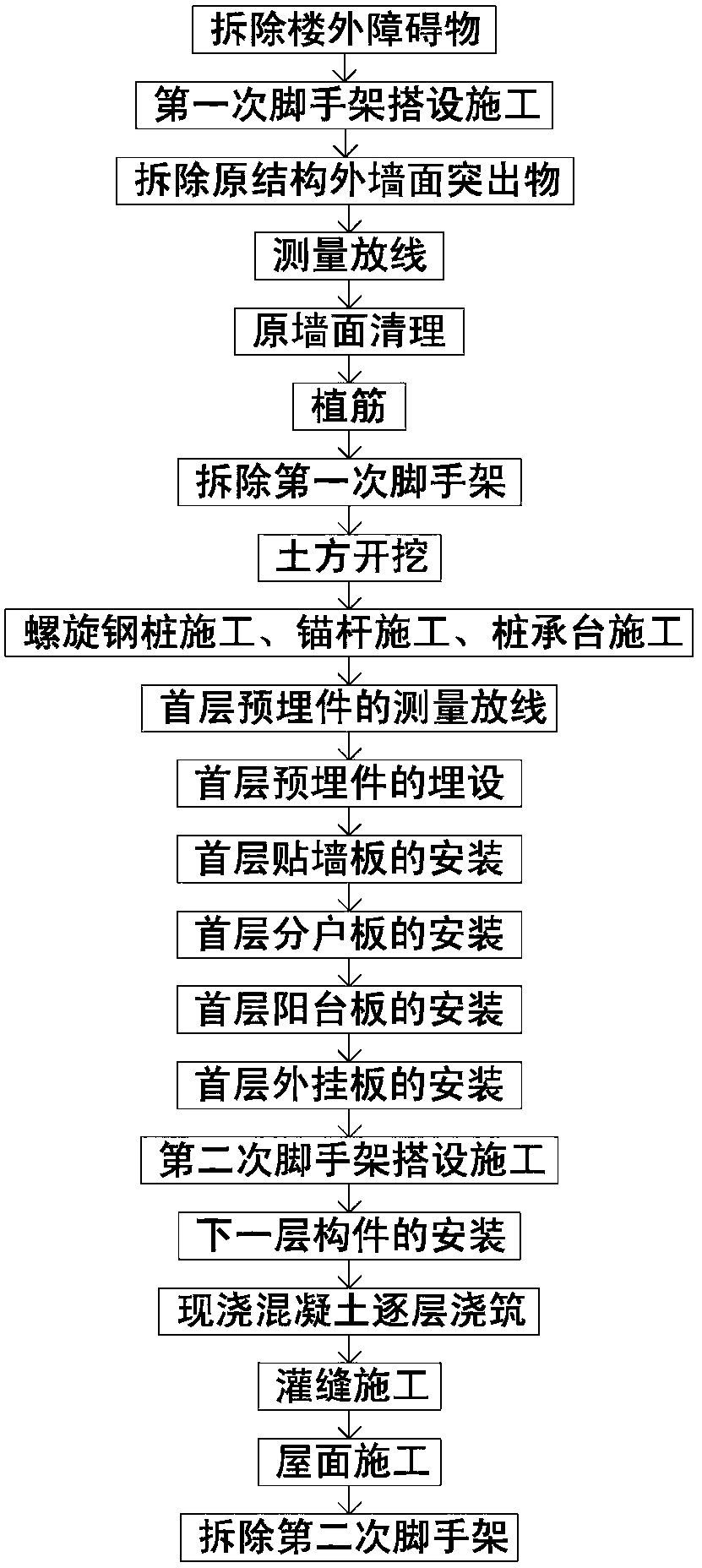

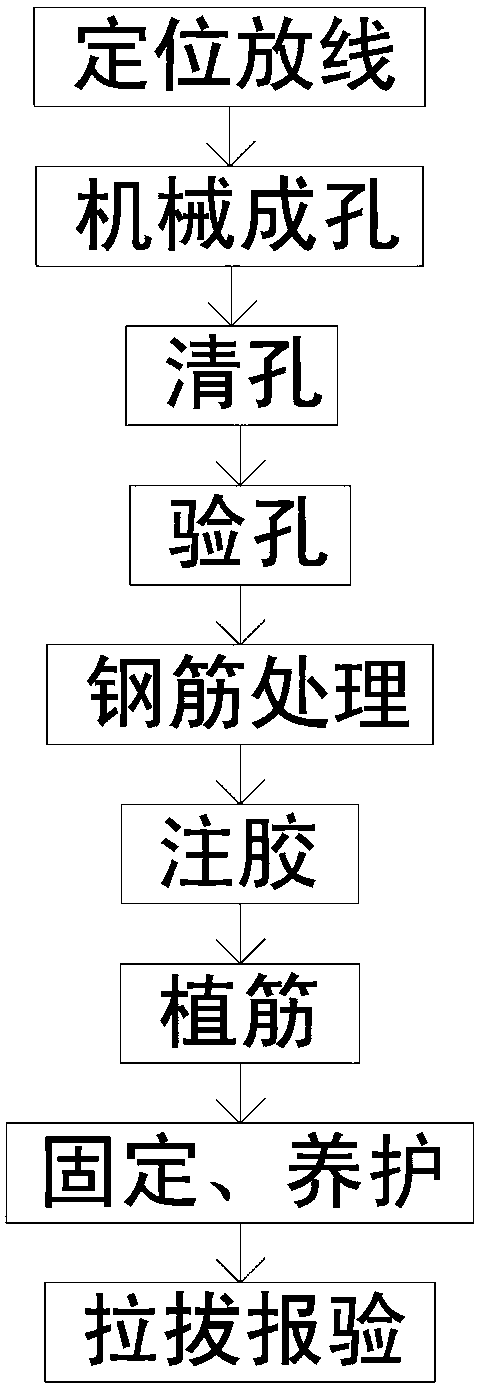

Shock prevention and strengthening construction method for existing brickwork dwelling house fabricated structure

A shock prevention and strengthening construction method for an existing brickwork dwelling house fabricated structure comprises the steps of demolishing barriers outside a building, constructing a scaffold for the first time, demolishing bulges on a wall surface, setting out, clearing the wall surface, embedding steel bars, demolishing the scaffold constructed for the first time, digging soil, performing spiral steel column construction, performing anchor stock construction, performing column supporting platform construction, performing the setting out of a foundation and the first layer of built-in fittings, embedding the foundation and the first layer of built-in fittings, mounting the first layer of household panel, mounting the first layer of balcony panel, mounting the first layer of cladding panel, back filling of the soil, constructing the scaffold for the second time, mounting the next layer of components, pouring and conserving on-site concrete layer by layer, joint grouting construction of a gap between each layer of wall panel and the wall surface of an original brickwork structure, performing roof construction, demolishing the scaffold for the second time and completing strengthening. The shock prevention and strengthening construction method solves the technical problems that an old brickwork dwelling house is poorer in anti-shock performance, external ornaments and internal components of the building are damaged, the living comfort is poorer, and energy consumption is great.

Owner:北京建工博海建设有限公司

Pearly luster coating membrane material of blasting beads for cigarette and preparation method of pearly luster blasting beads for cigarette

The invention provides a pearly luster coating membrane material of blasting beads for cigarette and a preparation method of the pearly luster blasting beads for cigarette. The pearly luster blasting beads for cigarette is obtained through the steps of adding 2-30 parts by weight of adhesive to 70-98 parts by weight of water at 25+ / -5 DEG C to be stirred for 0.5-2 hours and dissolved to form an adhesive water solution, being standing still for defoaming for 2-12 hours, putting the formed and dried blasting beads for cigarette in a granulating and coating machine, starting the device so that the blasting bead products can roll in the granulating and coating machine at constant speed, spraying the adhesive water solution and adding pearl luster powder at constant speed at the same time so that the adhesive water solution and the pearl luster powder can be completely added within 1-2 hours, and drying the blasting beads for cigarette where the adhesive water solution and the pearl luster powder are sprayed in the environment with temperature of 18+ / -2 DEG C and humidity of 40%+ / -5% for 2-12 hours. The problem that pearl luster powder is not dissolved in water and can not be applied in a water-soluble blasting bead system is solved, and the appearance visual effect of the blasting beads is well enhanced.

Owner:HUBEI CHINA TOBACCO IND

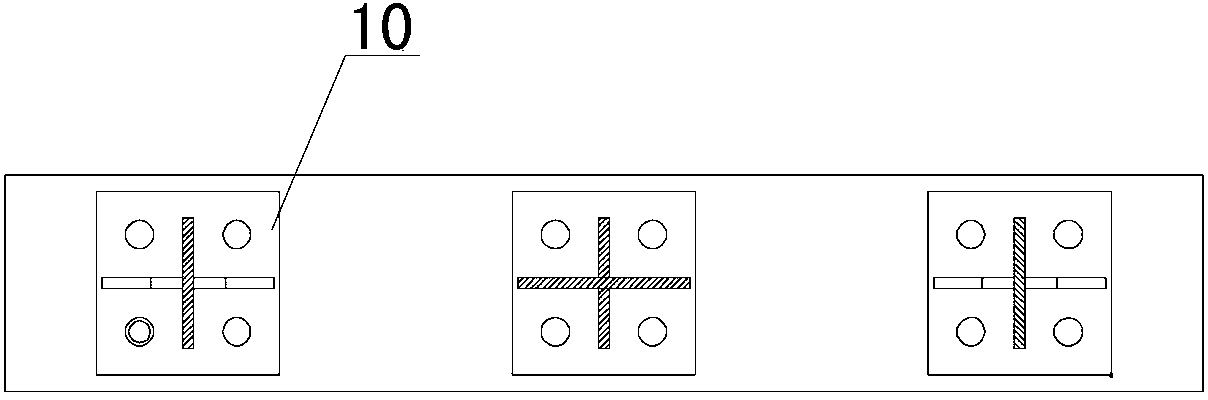

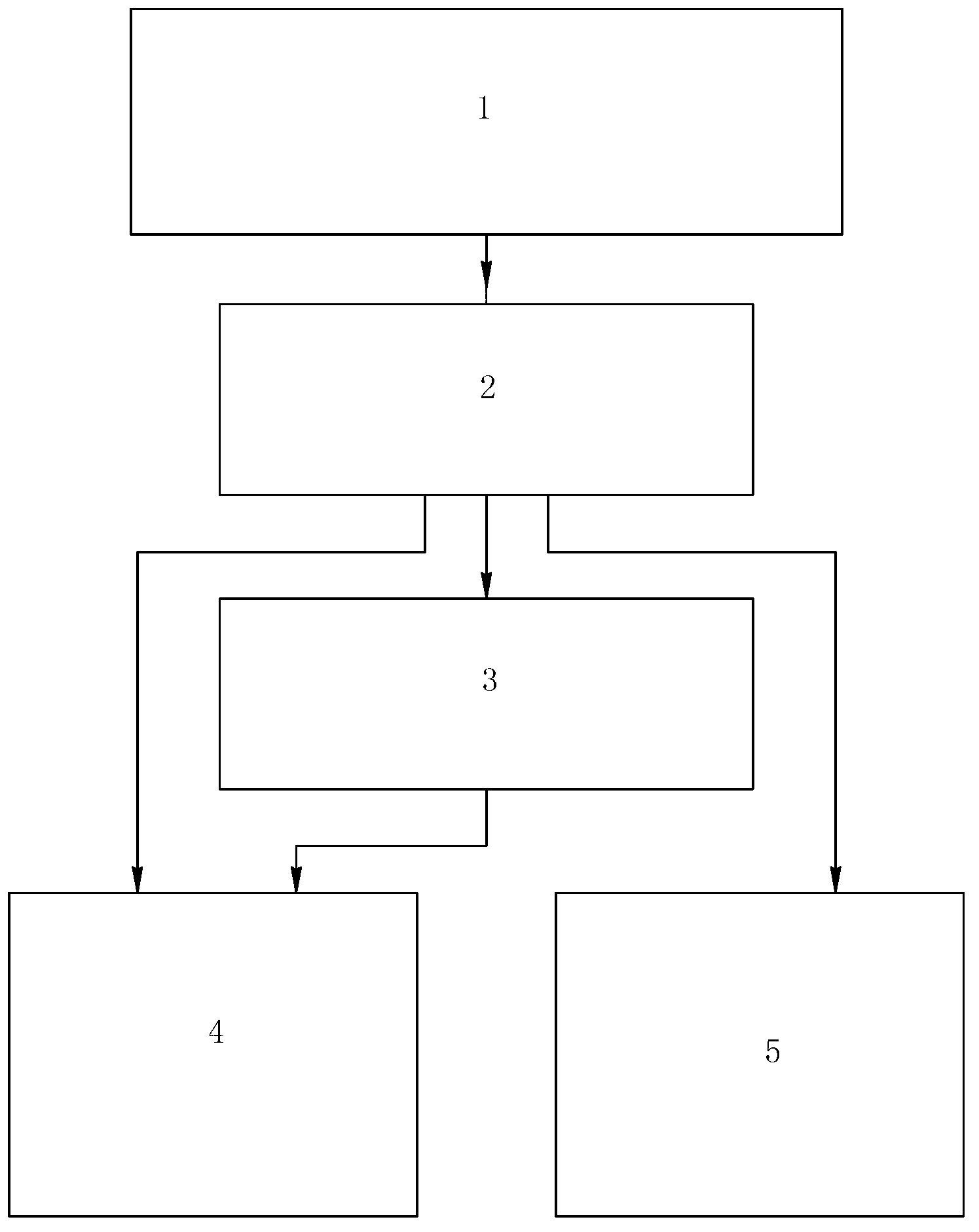

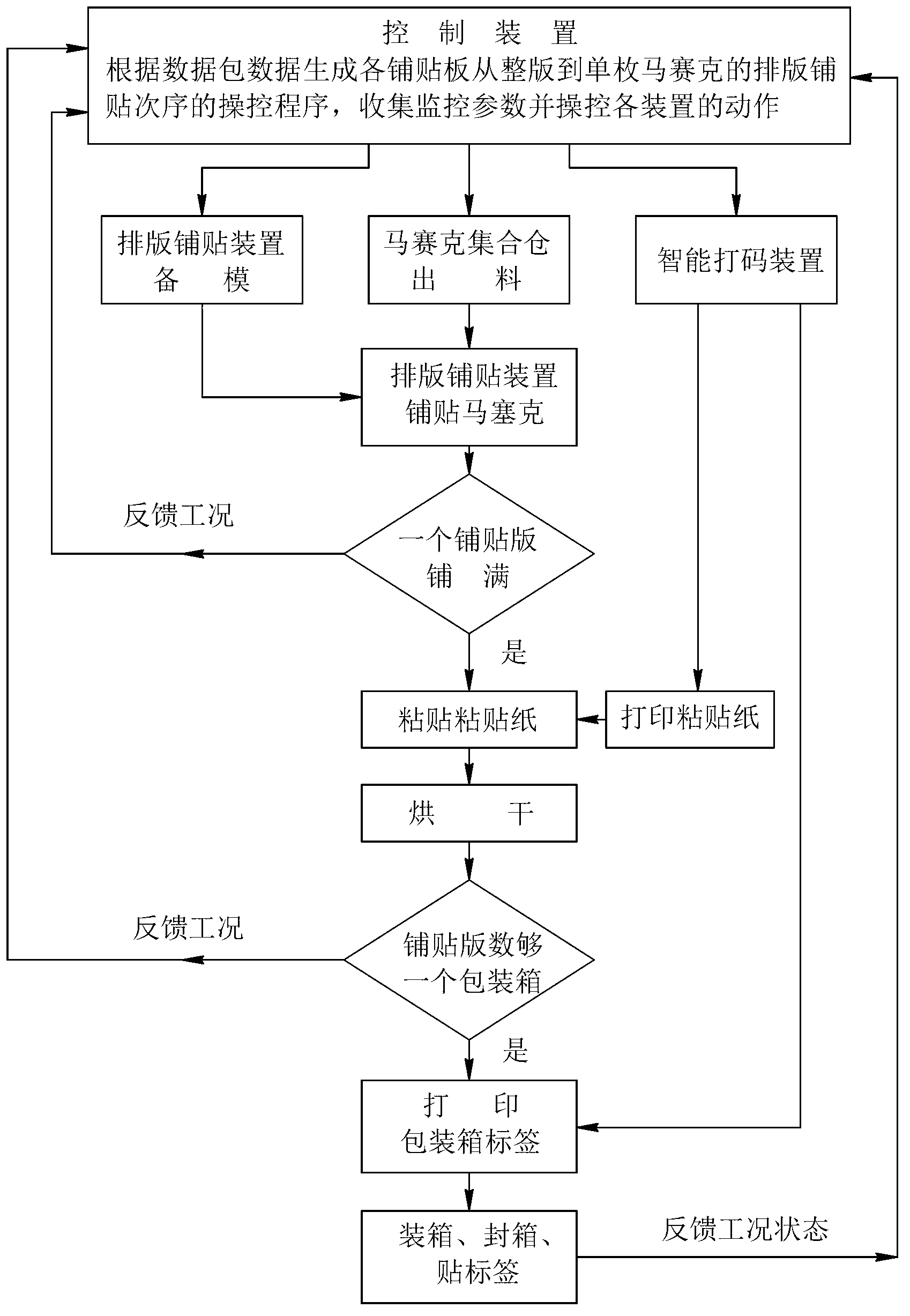

Picture splicing marking method and system for mosaic packaging

InactiveCN103268601AReduce labor intensityRestoration made easyImage enhancementGeometric image transformationNumerical controlNetwork packet

The invention discloses a picture splicing marking method and system for mosaic packaging. An original picture is precisely resolved into appropriate pixels through a computer system according to the overall size of an objective decorative face and the size of a selected mosaic, each pixel unit is replaced by a mosaic with a corresponding color number so that an effect picture of mosaic reappearance can be obtained, a mosaic paving and attaching plate is then used as a unit for conducting block separation on the effect picture of the objective decorative face, location coding is conducted on each separated unit, the code is named as an image bit code, and then construction instruction information is written according to the image bit codes to generate an operating data package. A mosaic collecting bin is used for conveying mosaics with different color numbers, a mosaic numerical control type setting device is used for placing the mosaics output by the mosaic collecting bin on the specified location of the paving and attaching plate, and at the same time, an intelligent marking device respectively outputs the image bit codes and the construction instruction information to the corresponding mosaic paving and attaching plate and a mosaic packaging box.

Owner:周万杰

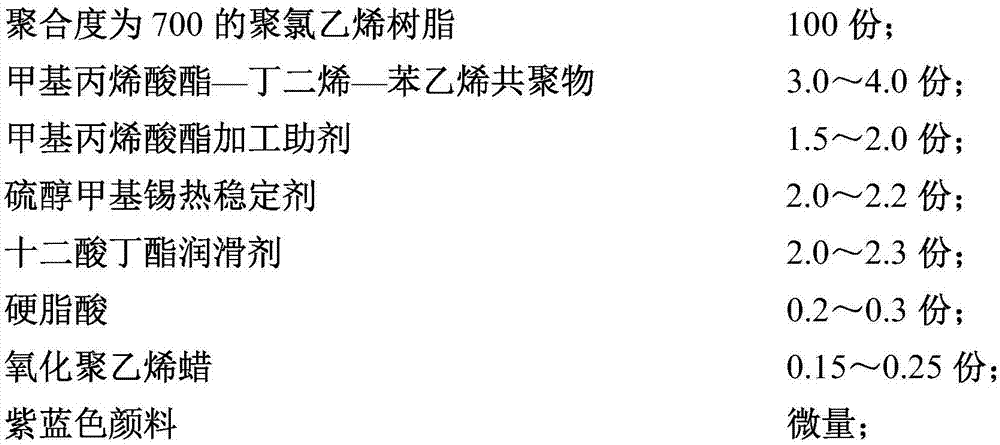

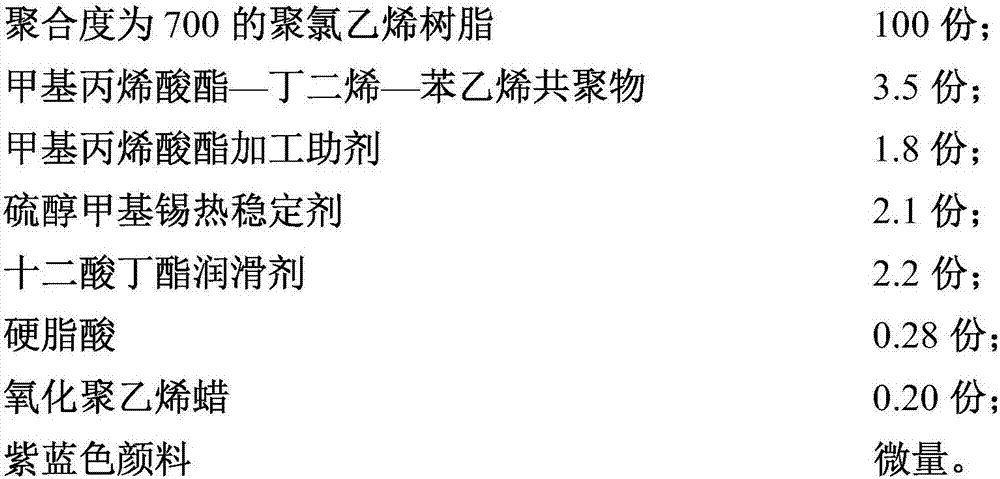

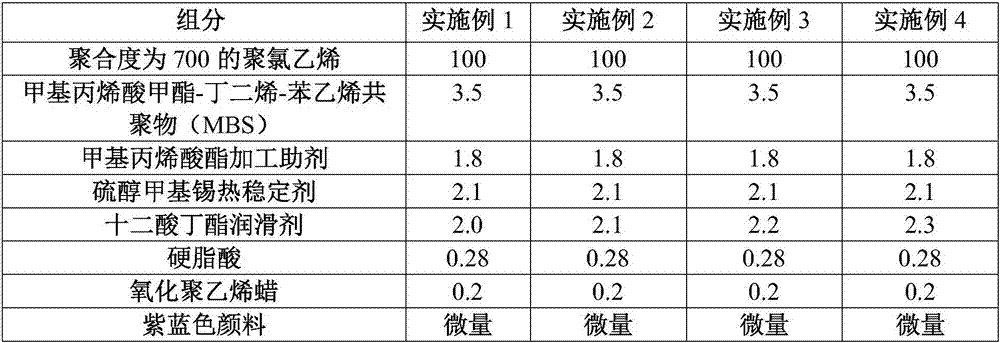

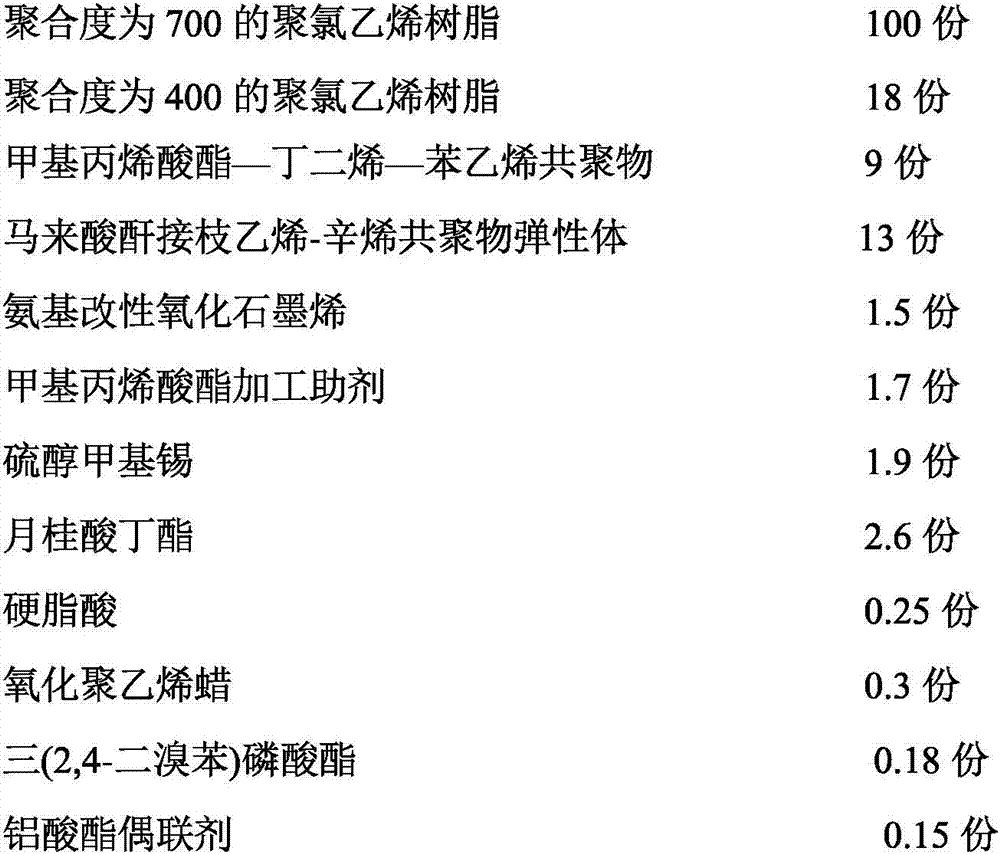

PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses

ActiveCN107141646AImprove thermal stabilityTransparency has little effectMethacrylateProcedure Agents

The invention discloses PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses. The PVC pallets comprise, by weight, 100 parts of polyvinyl chloride resin with the degree of polymerization being 700, 3.0-4.0 parts of methacryIate-Butadiene-Styrene copolymer, 1.5-2.0 parts of methacrylate processing aid, 2.0-2.2 parts of methyltin mercaptide heat stabilizer, 2.0-2.3 parts of butyl dodecanoate lubricant, 0.2-0.3 part of stearic acid, 0.1-0.25 part of oxidized polyethlene wax and trace indigo pigment. The finished products are prepared by means of feeding the components into a high-speed heating mixer according to the proportion for high-speed mixing, performing kneading to the temperature of 123-125 DEG C prior to discharging, putting the discharged material into a low-speed cooling mixer to be cooled to room temperature to obtain mixed powder, feeding the mixed powder into a pelletizer for pelletizing, and cooling the pellets to the temperature lower than 40 DEG C prior to packaging. The medical injection molding apparatuses made of the PVC pellets have ultrahigh transparency and surface glossiness.

Owner:WUXI JIAHONG PLASTICS TECH

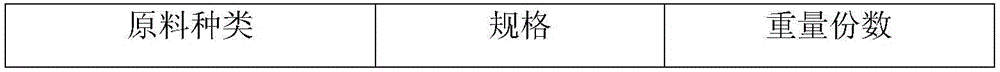

Cigarette bursting bead noctilucence coating film material, and production method of cigarette bursting bead

ActiveCN106519310AImprove solubilityImprove the problem of poor solubilityTobacco smoke filtersSolubilityMethyl cellulose

The invention provides a cigarette bursting bead noctilucence coating film material, and a production method of a cigarette bursting bead. The cigarette bursting bead noctilucence coating film material is prepared through the following steps: adding hydroxypropyl methyl cellulose to 20-30 DEG C water, and stirring hydroxypropyl methyl cellulose and the water to dissolve the hydroxypropyl methyl cellulose in order to form an aqueous solution; adding ethyl cellulose and noctilucence powder to 20-30 DEG C ethanol, stirring the ethyl cellulose, the noctilucence powder and the ethanol to dissolve the ethyl cellulose and the noctilucence powder in order to form an ethanol solution, uniformly mixing the dissolved aqueous solution with the dissolved ethanol solution according to a mass ratio of (4-7):(3-6), stirring the solutions, and standing the mixed solution for defoaming the mixed solution in order to obtain the material. The bursting bead noctilucence coating film material is sprinkled on a dry-molded bursting bead product in a normal temperature rolling manner at normal temperature by adopting a coating pan, and the sprinkled bursting bead product is dried to obtain the cigarette noctilucence bursting bead. The problem of poor dissolvability of the noctilucence powder is greatly improved, and the noctilucence powder is used to prepare the coating film material which coats the cigarette bursting bead, and the cigarette bursting bead is coated with the material to form a coating film with a noctilucence effect, so the waterproof property of the bursting bead is improved, the visual effect is increased, and the quality of the bursting bead is improved.

Owner:HUBEI CHINA TOBACCO IND

Environment-friendly water-proof packaging bag and manufacturing method thereof

ActiveCN101934880AStrong three-dimensional senseRich color changeSynthetic resin layered productsBagsWater basedHuman body

The invention discloses an environment-friendly water-proof packaging bag and a manufacturing method thereof, belonging to the technical field of packing materials. The packaging bag is manufactured by taking a chrome paper or a card paper as the base material, compounding a thin film with an environment-friendly water-based adhesive and combining a Glitter powder layer on the outer surface of the compounded thin film; drying and die-cutting the product; and making through a bag making machinery. The invention has the advantages of excellent effect for preventing water or vapour from being transmitted, environment protection and no harm to the human body and improved tensile intensity because of the combination of the base material, the thin film and the Glitter powder. The Glitter powder layer has strong three-dimensional effect, rich colour change and twinkling effect so that the visual impact of the packaging bag is improved.

Owner:常熟市双乐彩印包装有限公司

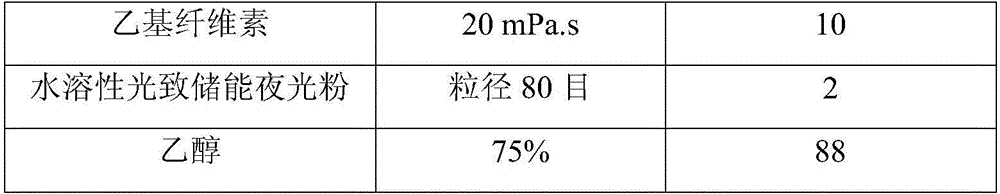

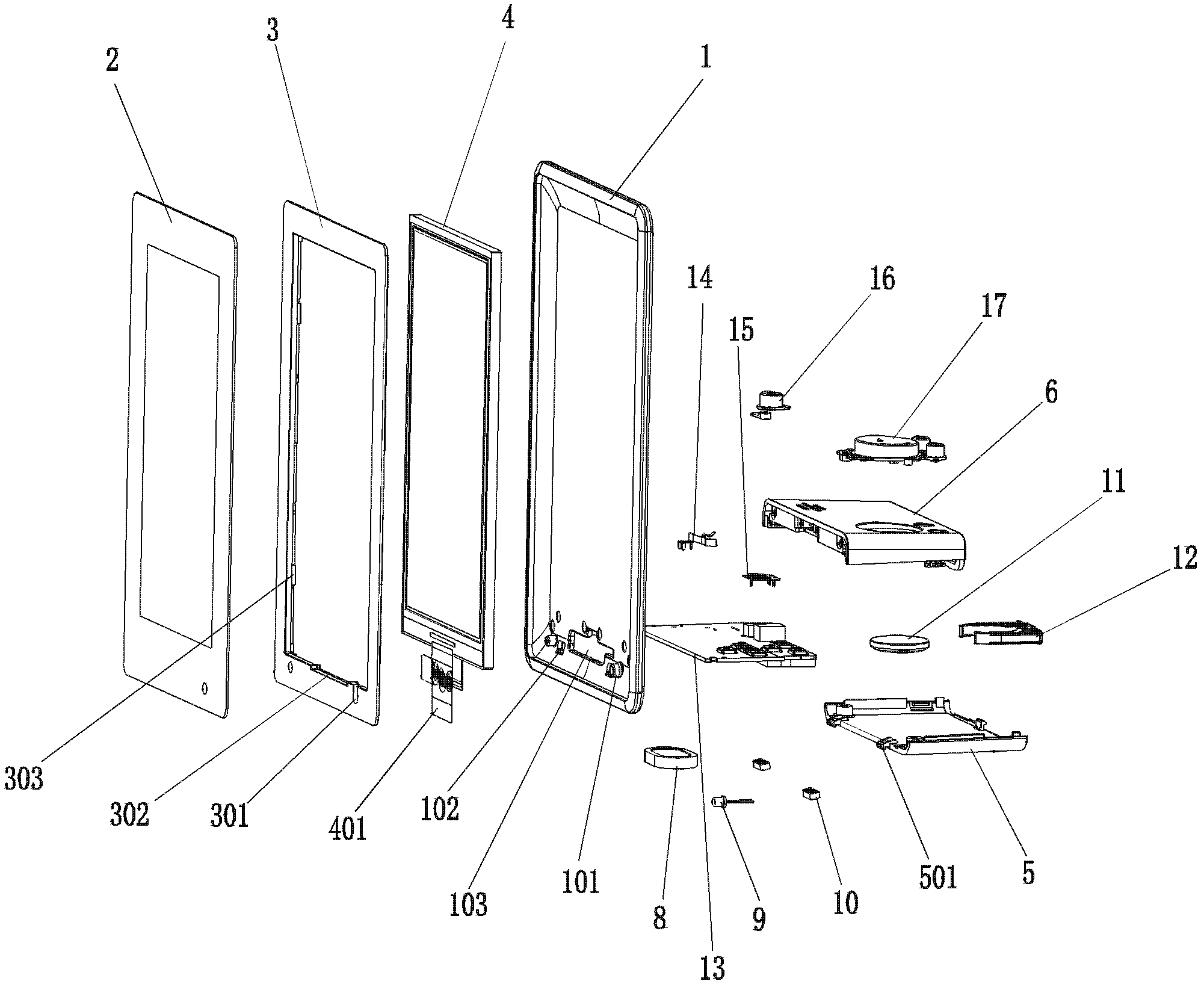

Ultrathin digital photo frame with spray paint in inside

InactiveCN102610174AReduce thicknessGood lookingPicture framesDomestic mirrorsFlexible circuitsEngineering

The invention discloses an ultrathin digital photo frame with spray paint in the inside. A circuit board is arranged outside a whole camera body, and simultaneously a displayer id connected with a main circuit board through a flexible circuit board so fix and clamp the whole displayer in a screen positioning frame, a protecting layer is utilized to protect a screen, and the screen positioning frame is bonded with the displayer so that the thickness of the camera body is reduced greatly. In addition, due to the facts that the screen positioning frame is connected with a rear cover through a clamping button and a clamping position and the whole camera body has no exposed button digit line, the appearance effect of a whole product is good. Compared with the prior art, the ultrathin digital photo frame with the spray paint in the inside solves the problem that an existing digital photo frame is complicated in assembling process and is not light and thin and enables the thickness of the whole product to be ultrathin, and the visual effect of the appearance of the whole camera is good.

Owner:GUANGZHOU JIASI INFORMATION TECH

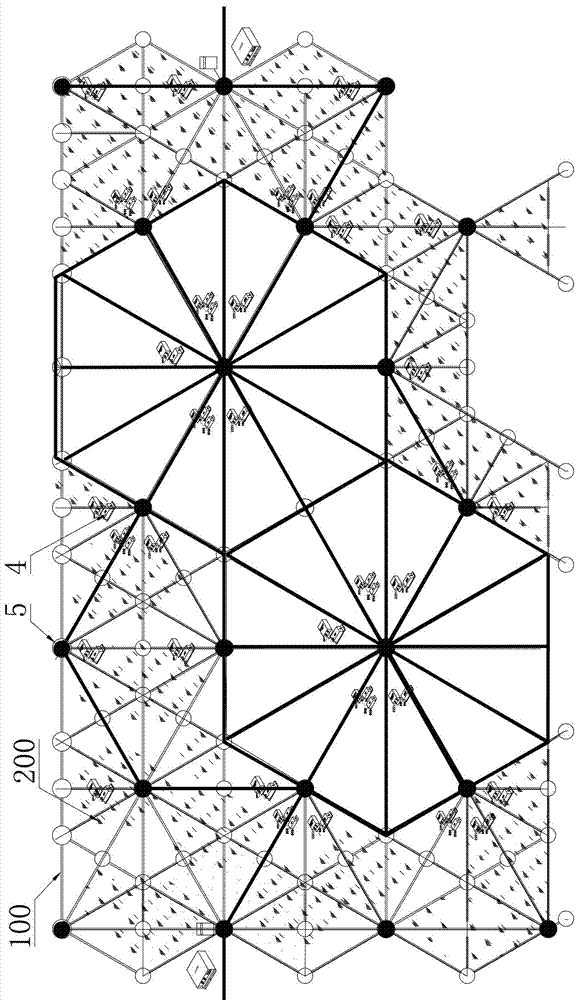

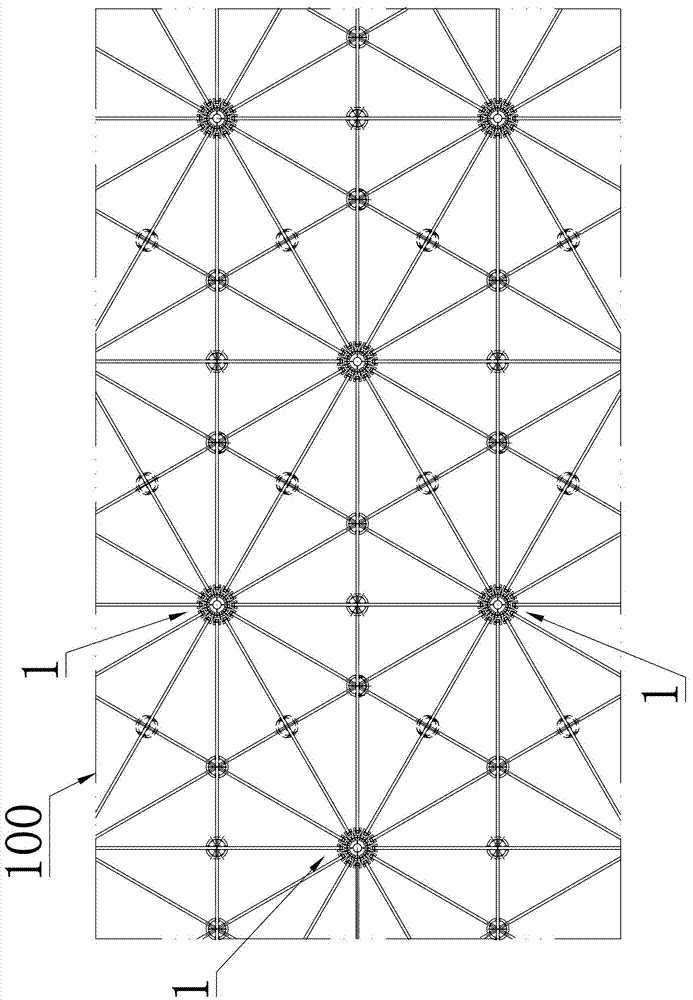

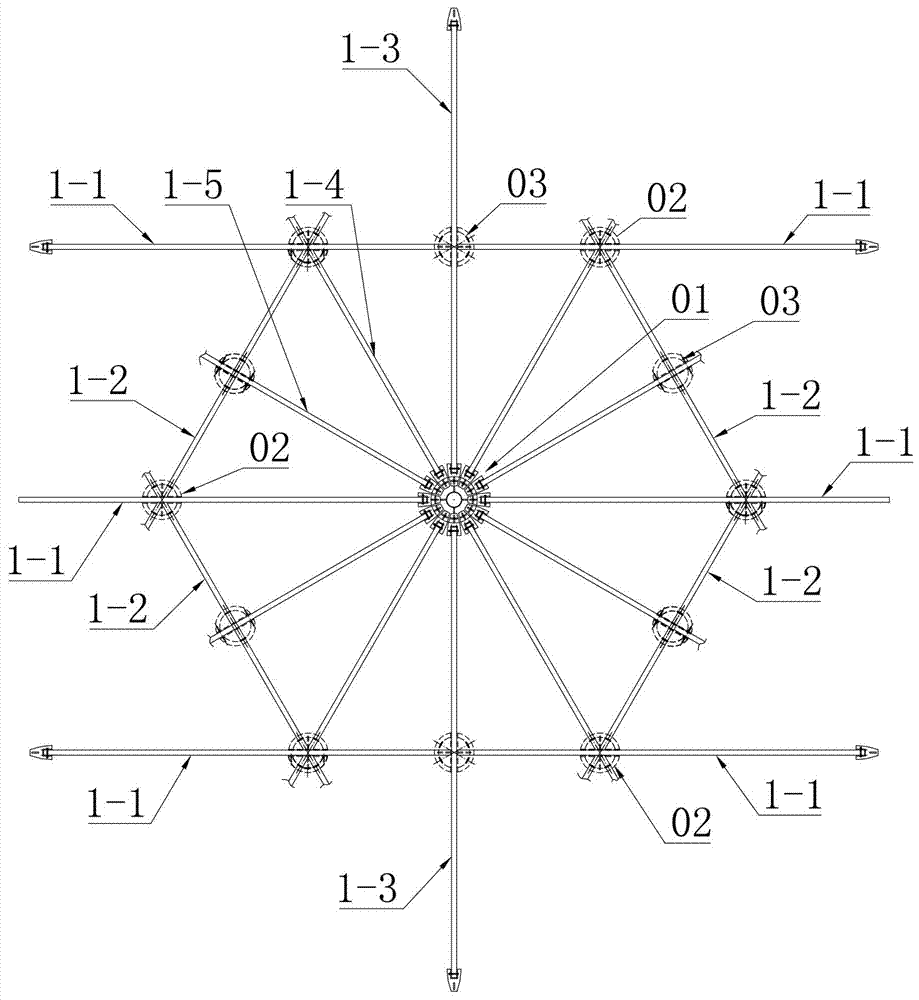

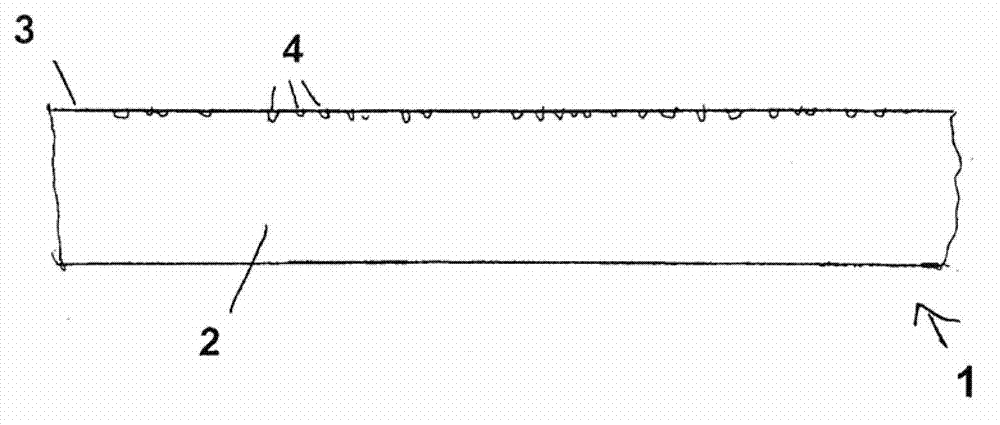

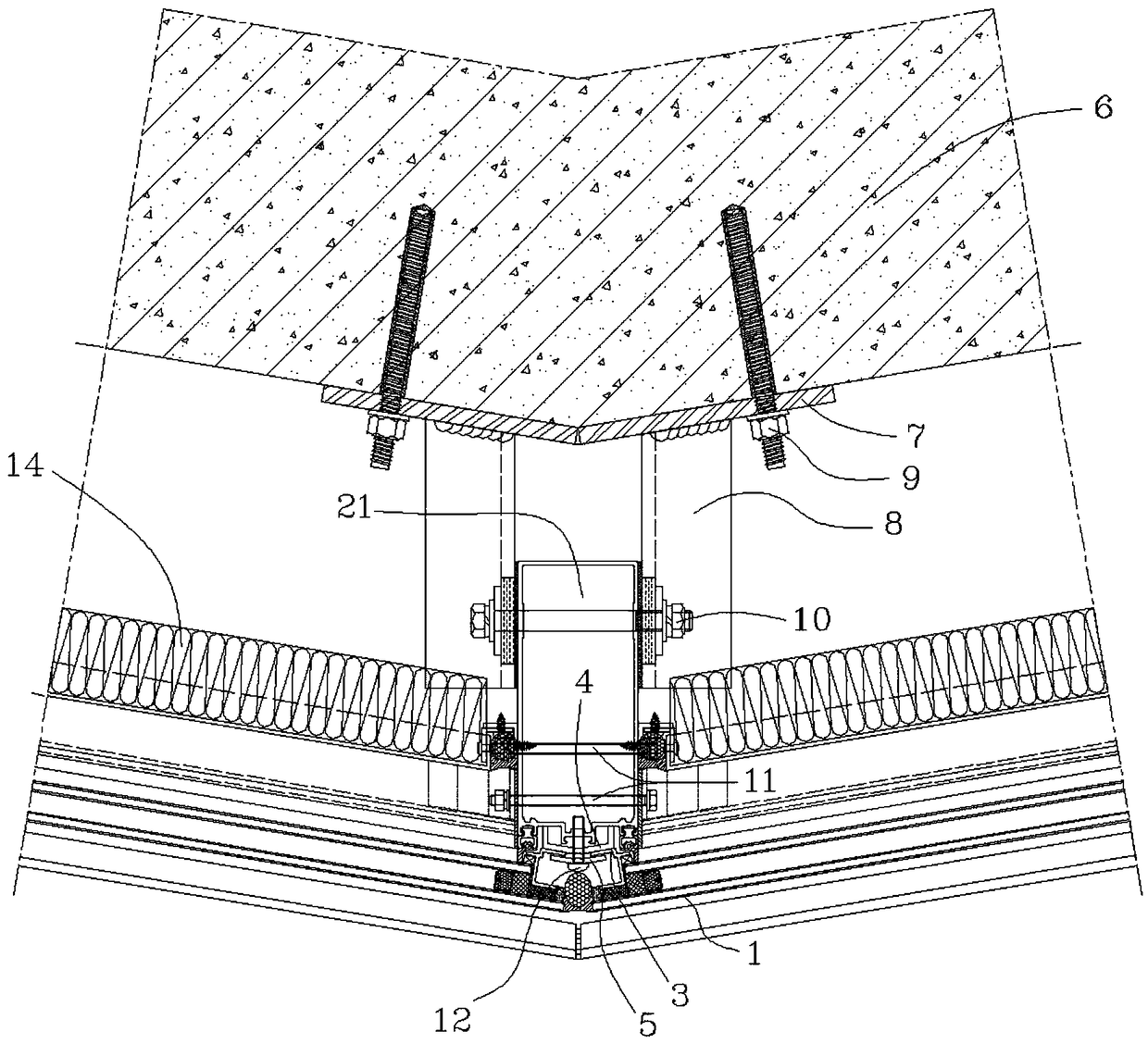

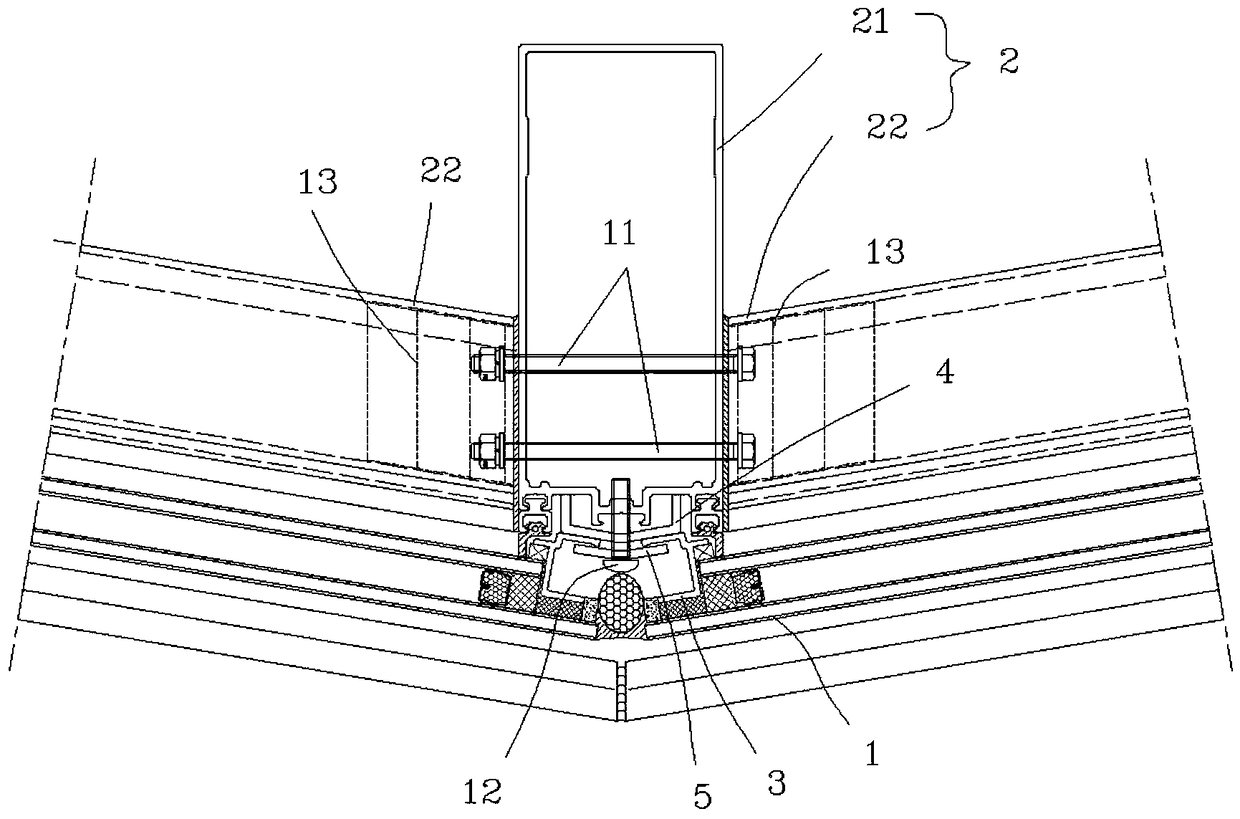

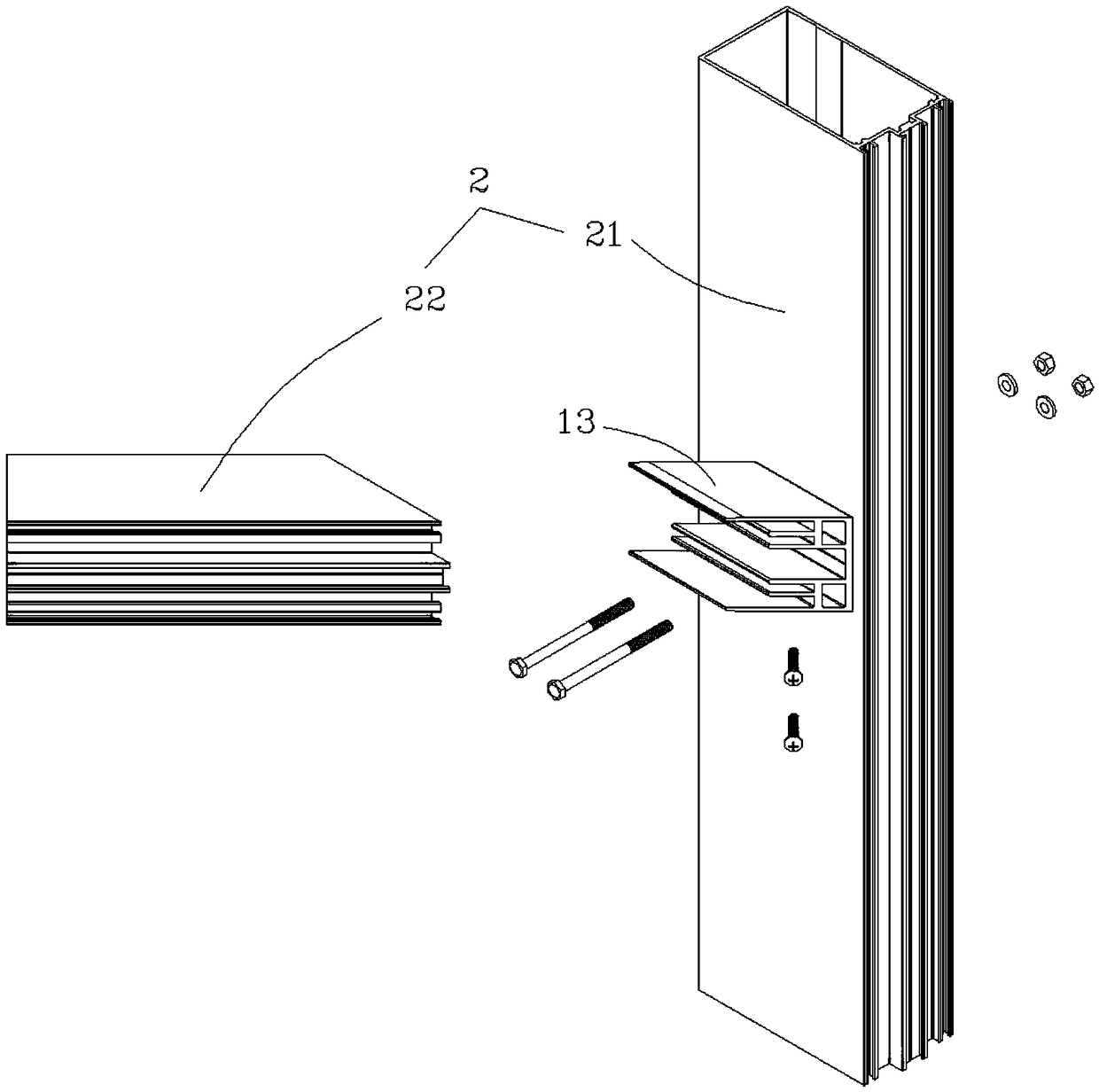

Unit type hexagonal combined rod and plate building external surface curtain wall structure

ActiveCN107035031AImprove integrityDoes not affect integrityWallsElectric circuit arrangementsKeelAngular point

The invention relates to a unit type hexagonal combined rod and plate building external surface curtain wall structure. The unit type hexagonal combined rod and plate building external surface curtain wall structure comprises a rod set frame formed by rod parts and connection parts, a glass curtain plate fixedly arranged on the rod set frame, and a landscape lamp system arranged on the rod set frame; the rod parts are a curtain wall keel; the rod set frame comprises a plurality of rod set part units which are connected with one rod set of a regular hexagon structure as the center; the rod part junction points of each rod set part unit are fixedly connected through a center rod part junction node, angular point nodes and edge vertical line nodes; the landscape lamp system comprises a main controller, a plurality of branch controllers connected with the main controller in parallel, decoders, a linear LED light source and a point type LED light source; an end port of each branch controller is provided with the multiple decoders in parallel; the decoders are connected with the linear LED light source and the point type LED light source; the linear LED light source is arranged along the rod parts; and the point type LED light source is arranged at the center rod part junction node.

Owner:NORTHERN ENG DESIGN & RES INST CO LTD

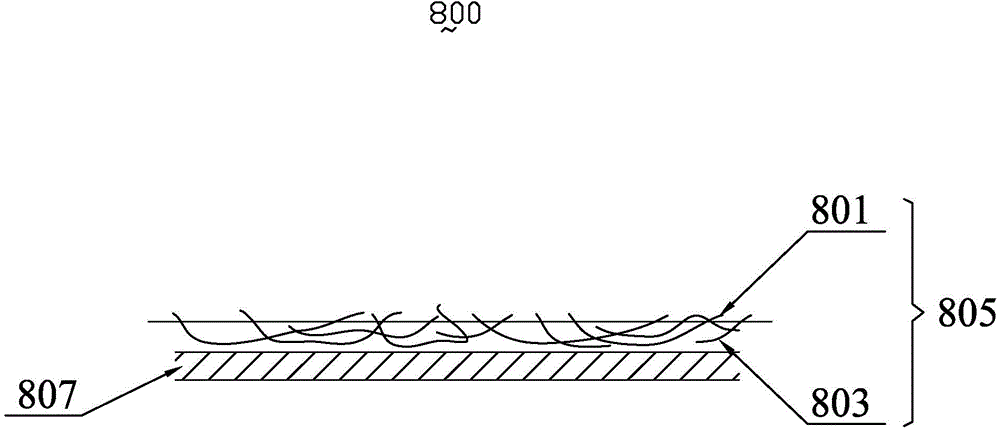

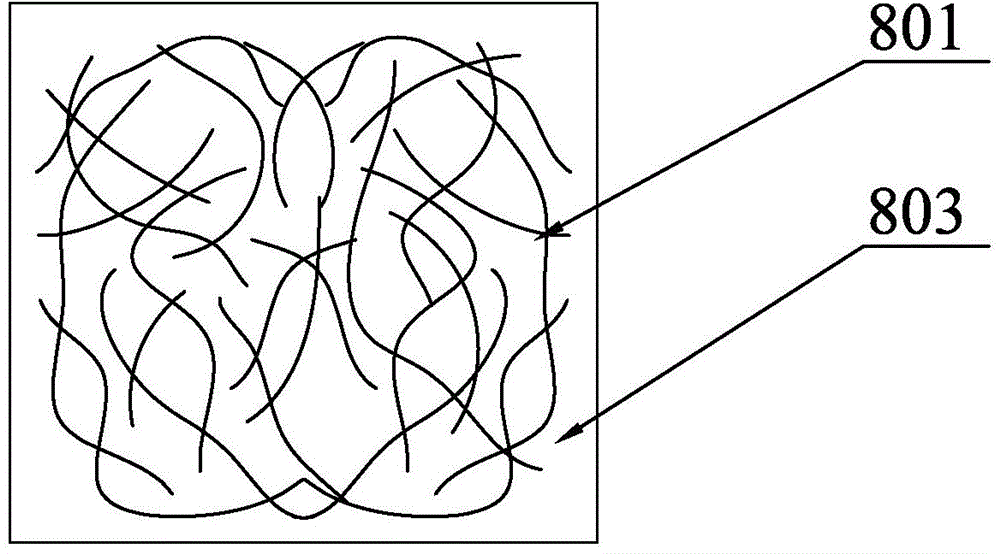

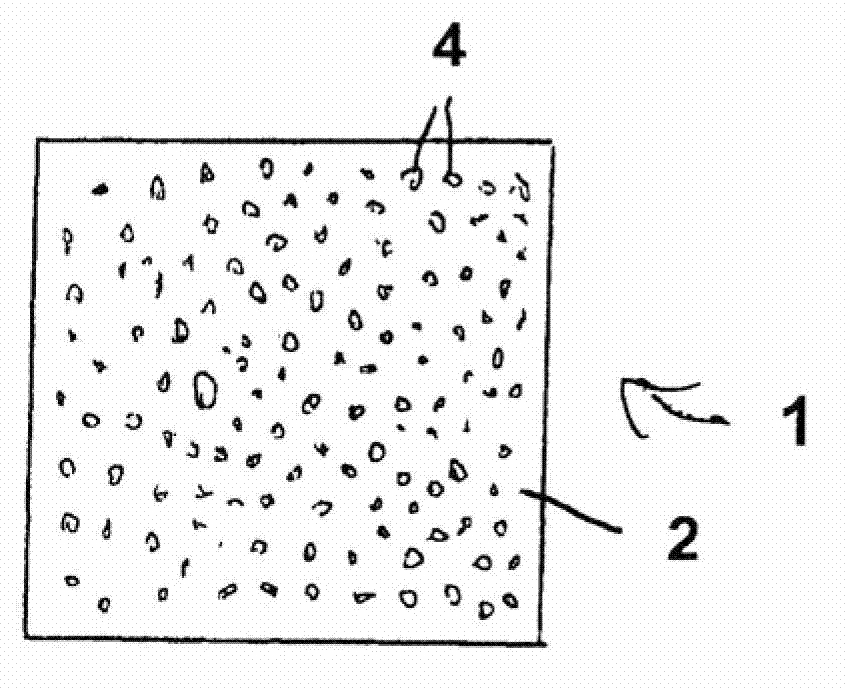

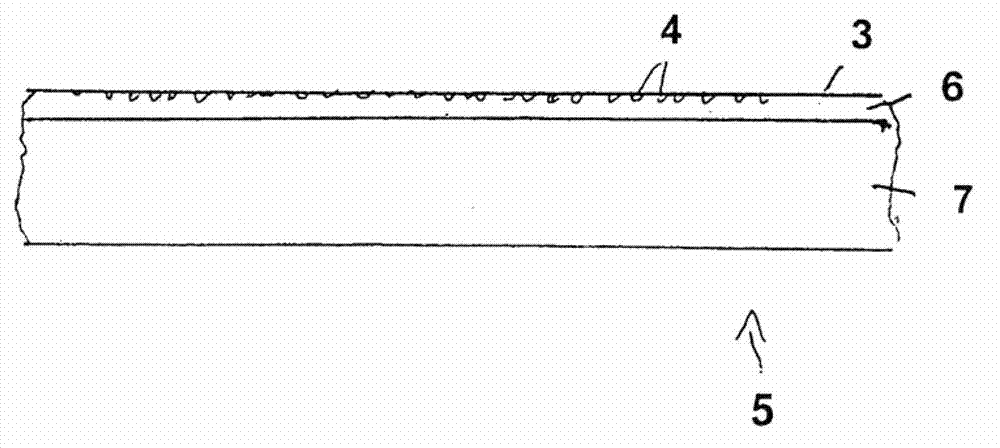

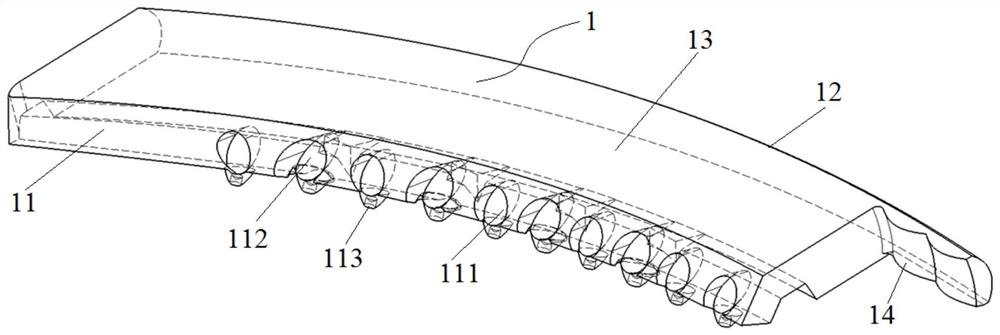

Moulded skin and method for producing moulded skin

ActiveCN102712111AHigh-quality exterior visual effectsImprove appearance visual effectDomestic articlesCoatingsCuticleBiomedical engineering

The invention relates to a moulded skin, which contains a plastisol layer having a first colouring and a plurality of plastisol spatters that are introduced into a surface of the plastisol layer and have a second colouring, which is different from the first colouring. The invention also relates to a method for producing such a moulded skin. Because plastisol spatters are introduced into the surface of the moulded skin, a very durable optical effect is achieved in a simple manner.

Owner:FAURECIA INNENRAUM SYST

Air hole prevention production technique for colored PE pipe

ActiveCN106476243AShorten warm-up timeIdeal Extrusion Drying RequirementsTubular articlesPulp and paper industryTemperature and pressure

The invention relates to an air hole prevention production technique for a colored PE pipe. The air hole prevention production technique for the colored PE pipe comprises the following steps that materials are heated, stirred and mixed, heating and dehumidification are conducted, the pipe is extruded, and the pipe is subjected to vacuum calibration, cooling and traction cutting; according to the technique, before the production of the PE pipe, the steps of heating and stirring, and heating and dehumidification are added, so that the air hole problem caused by humid material during colored PE material production is well solved, and mechanized material feeding is achieved. The invention further provides the key parameters such as temperature and pressure of every process during air hole prevention production, and particularly, a plastic embedded extrusion mould and a spray type calibration sleeve are applied, so that the produced colored PE pipe can be uniform in texture, free of air holes, high in dimensional precision, smooth in pipe wall and good in appearance visual effect.

Owner:NANYANG SENYUAN PLASTIC

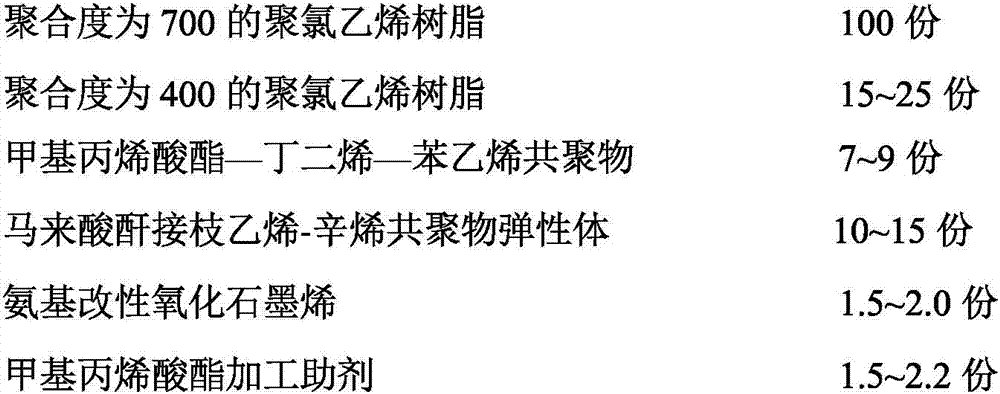

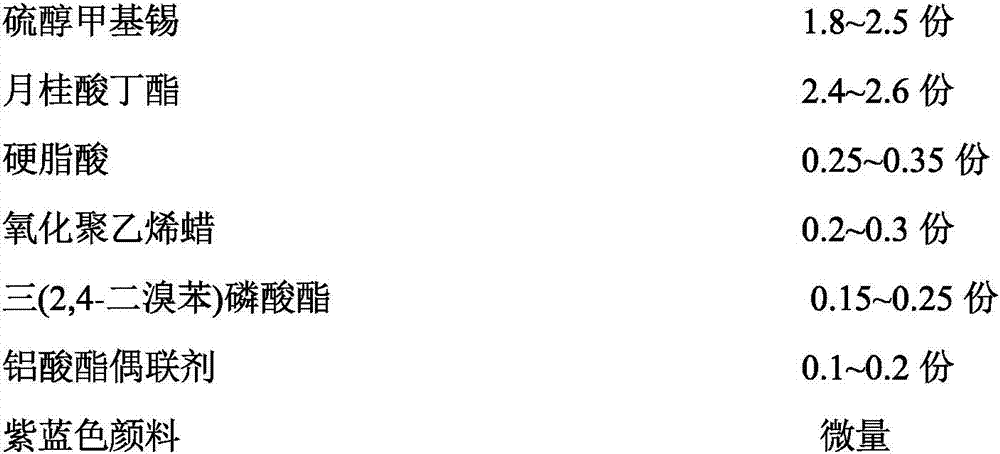

High-strength high-transparency thermal-resistant hard plastic alloy granular material

The invention relates to a high-strength high-transparency thermal-resistant hard plastic alloy granular material which comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin of which the polymerization degree is 700, 15-25 parts of a polyvinyl chloride resin of which the polymerization degree is 400, 7-9 parts of a methacrylate-butadiene-styrene copolymer, 10-15 parts of a maleic anhydride grafted ethylene-octylene copolymer elastomer, 1.5-2.0 parts of amino modified graphene oxide, 1.5-2.2 parts of a methacrylate processing additive, 1.8-2.5 parts of methyl tin mercaptide, 2.4-2.6 parts of butyl laurate, 0.25-0.35 part of stearic acid, 0.2-0.3 part of oxidized polyethlene wax, 0.15-0.2 part of tri(2,4-dibromo-benzene)phosphate, 0.1-0.2 part of an aluminic acid ester coupling agent and a trace amount of a purple blue pigment. The material is high in transparency, excellent in physical mechanical property and use processing property, and high in market application prospect.

Owner:WUXI JIAHONG PLASTICS TECH

Obtuse-angle-shaped glass curtain wall and construction method thereof

The invention discloses an obtuse-angle-shaped glass curtain wall and a construction method thereof, and belongs to the technical field of glass curtain walls. The obtuse-angle-shaped glass curtain wall installed by the construction method comprises two glass curtain wall panels and a keel, the keel is mounted on a building structure main body, the two glass curtain wall panels are fixed to the keel by a structural adhesive, and the two glass curtain wall panels are arranged to be of a structure with the center being an obtuse angle. An aluminum alloy glass sub-frame is fixedly connected to the obtuse angle positions of the two glass curtain wall panels through the structural adhesive, a bending aluminum plate and a stainless steel pressing block are separately and fixedly connected to theupper and lower parts of the aluminum alloy glass sub-frame, and the bending aluminum plate is connected with the stainless steel pressing block through screws in a penetrating mode. The two workpieces of the bending aluminum plate and the stainless steel pressing block are additionally arranged at the obtuse angle position of the obtuse-angle-shaped glass curtain wall, the structure is simple, the processing is convenient, the installation can be smoothly performed, and the installation is relatively firm and reliable, moreover, the moisturizing and waterproof effects at the obtuse angle position can be ensured, and the visual effect of the whole appearance is good.

Owner:SHANGHAI BAOYE GRP CORP

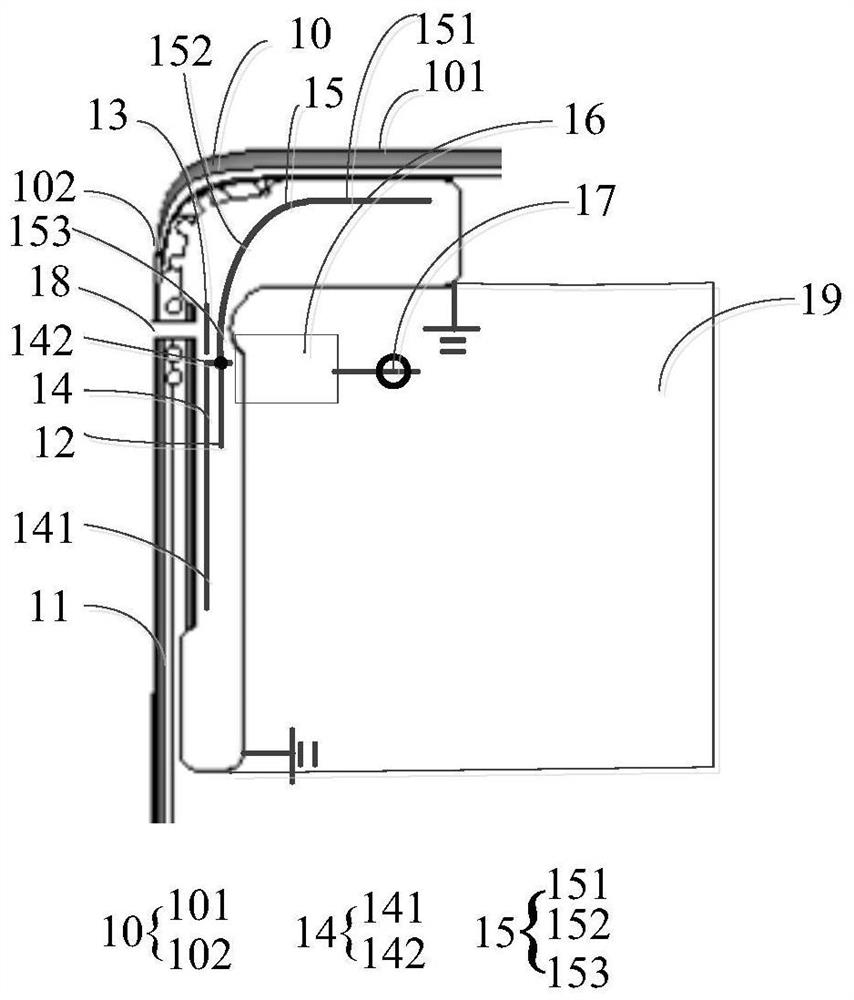

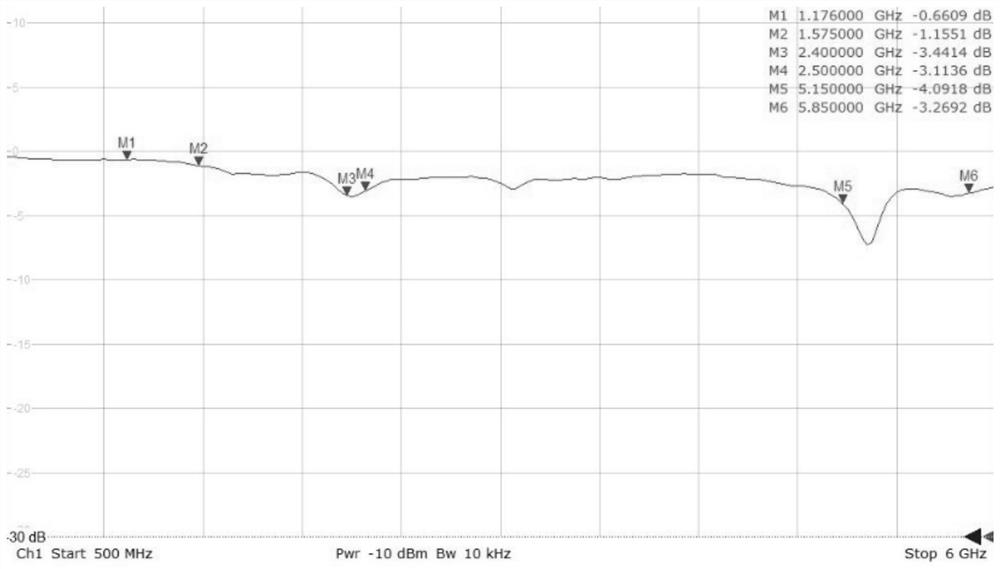

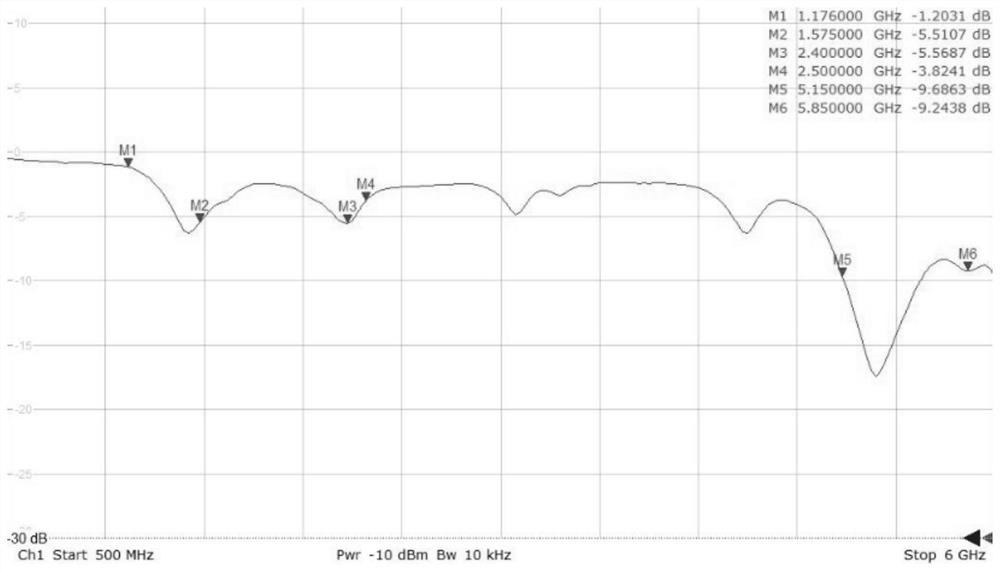

Mobile terminal antenna structure

ActiveCN112615139AReduce the number of slotsImprove structural strengthAntenna supports/mountingsAntennas earthing switches associationTelecommunicationsAntenna matching

The embodiment of the invention provides a mobile terminal antenna structure. The antenna structure comprises a first antenna, a second antenna, a third antenna, a fourth antenna, a fifth antenna, a sixth antenna, a matching circuit and a feed point, wherein a spacing area is arranged between one end of the first antenna and one end of the second antenna; a fourth antenna is arranged on one side of the spacing area, one end of a fifth antenna is opposite to one end of the fourth antenna, a third antenna is arranged on the side edge of the fifth antenna, and a feed point is arranged on the side edge of the third antenna; at least part of the third antenna is parallel to the fourth antenna and at least part of the third antenna is parallel to the first antenna; and the fifth antenna, the sixth antenna and the third antenna are electrically connected and intersect at one point, one end of the matching circuit is connected with the fifth antenna, the sixth antenna and the third antenna, and the other end of the matching circuit is connected with the feed point. According to the embodiment of the invention, the structural strength and the appearance visual effect of the mobile terminal can be improved, and the free space and the head-hand performance are better.

Owner:深圳市华熹投资有限公司

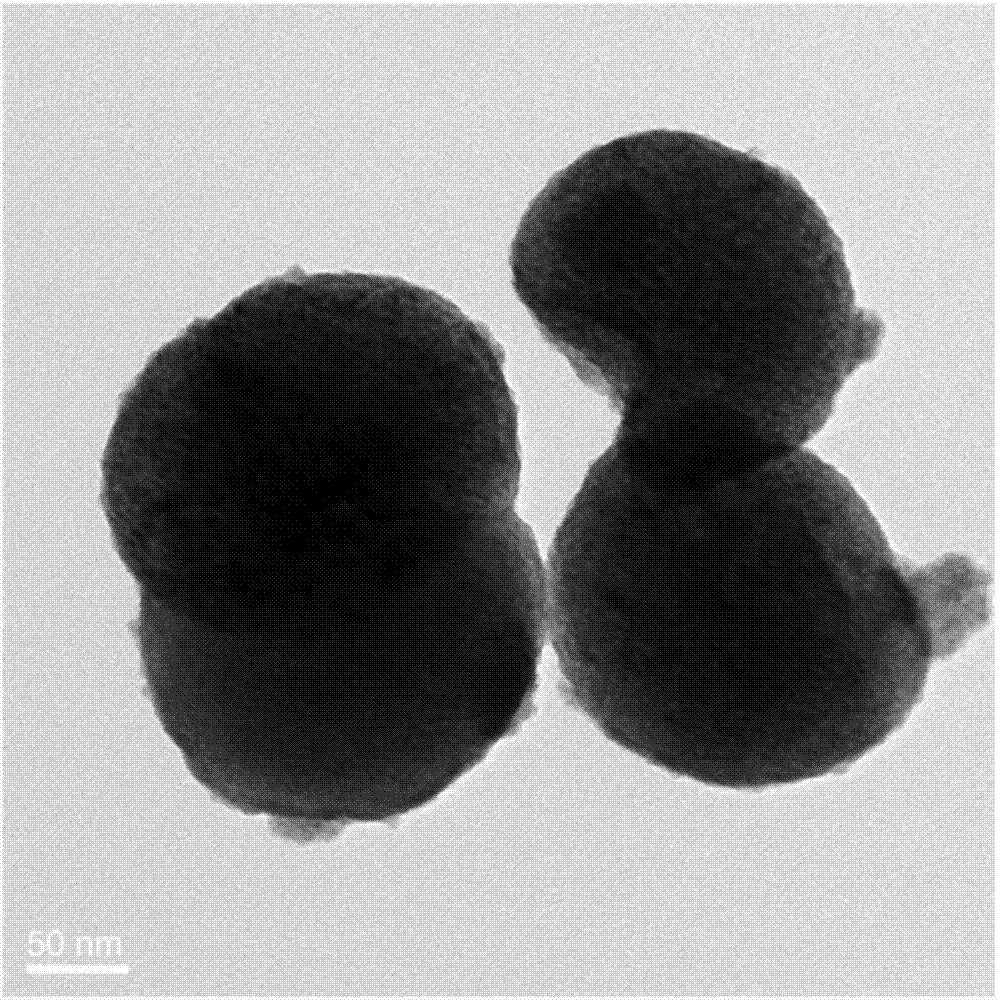

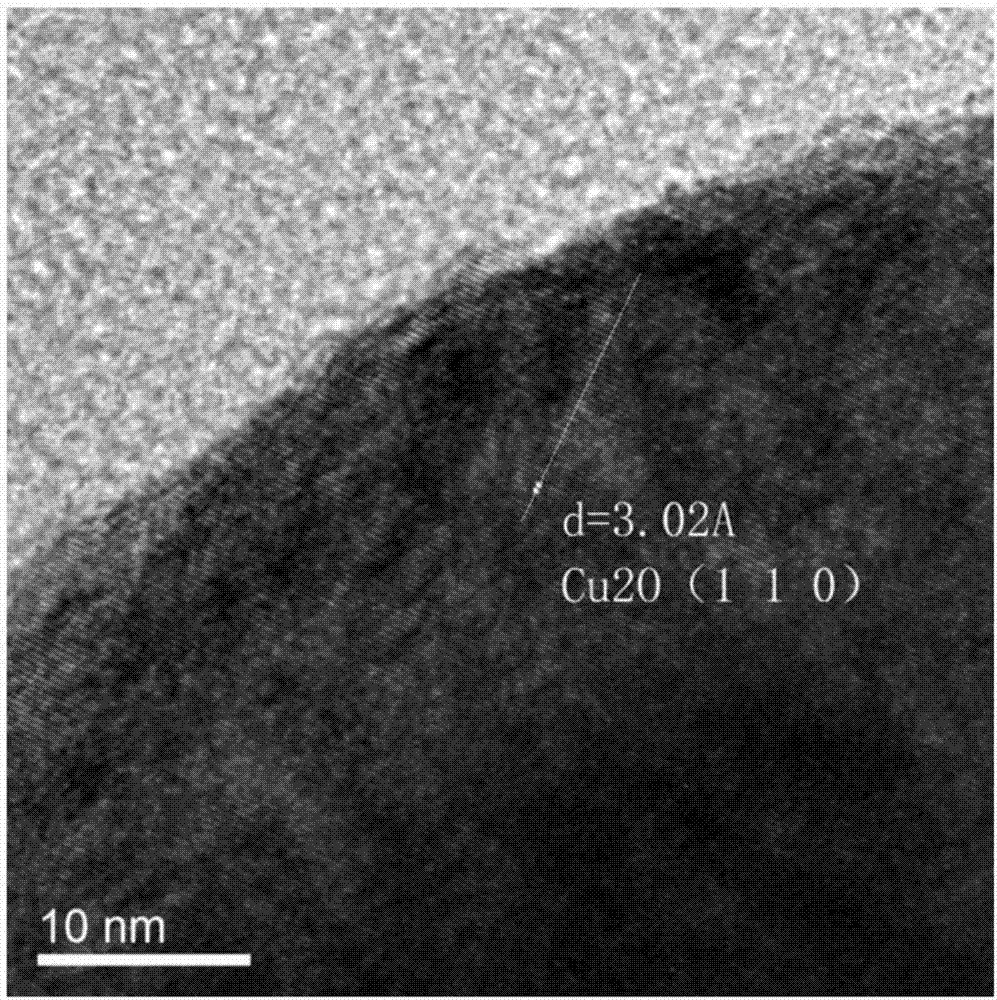

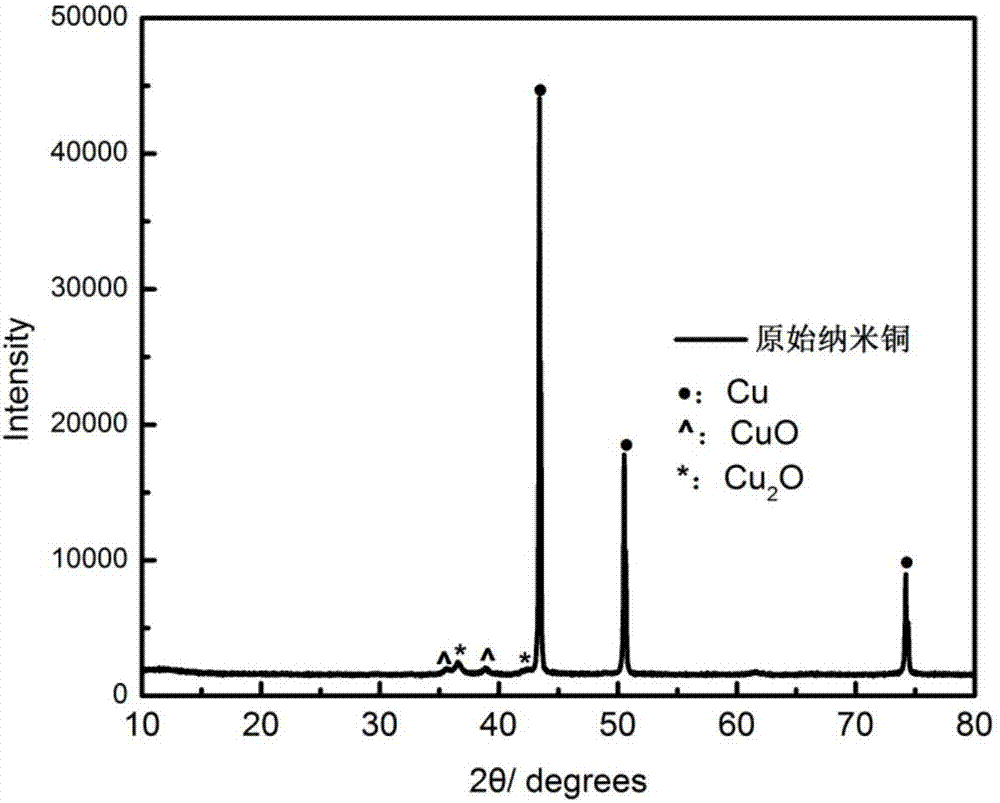

Preparation method of composite material

ActiveCN107331832AReach the purpose of recyclingEasy to prepareHybrid capacitor electrodesCell electrodesState of artFiber

The invention provides a preparation method of a composite material with characteristics of simple preparation method and high universality. The preparation method comprises: placing one or a plurality of materials selected from a metal oxide, an elementary metal, an alloy and a nonmetal material in mixed gas generated through pyrolysis of plant fibers, and placing at a temperature of 200-990 DEG C to make the surface of one or a plurality of the materials be coated with a carbon-based compound layer so as to obtain the composite material, wherein the plant fibers uniformly adsorb metal ions. According to the present invention, based on the technology in the prior art, the preparation method of the present invention has the following characteristics that the oxide of the metal is reduced by the reducing atmosphere generated through the pyrolysis of the plant fibers, and the carbon-based compound layer is deposited on the surface so as to produce the carbon-based compound coated metal structure, or the reducing atmosphere generated through the pyrolysis of the plant fibers and the elementary metal, the alloy or the nonmetal material directly form the carbon-based compound coated composite material.

Owner:SUZHOU GUANJIE NANO ANTI BACTERIAL COATING TECH CO LTD

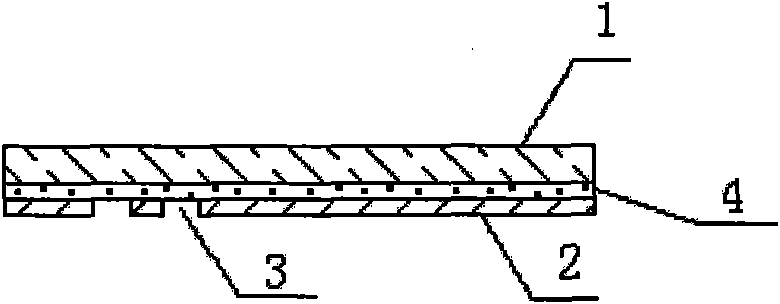

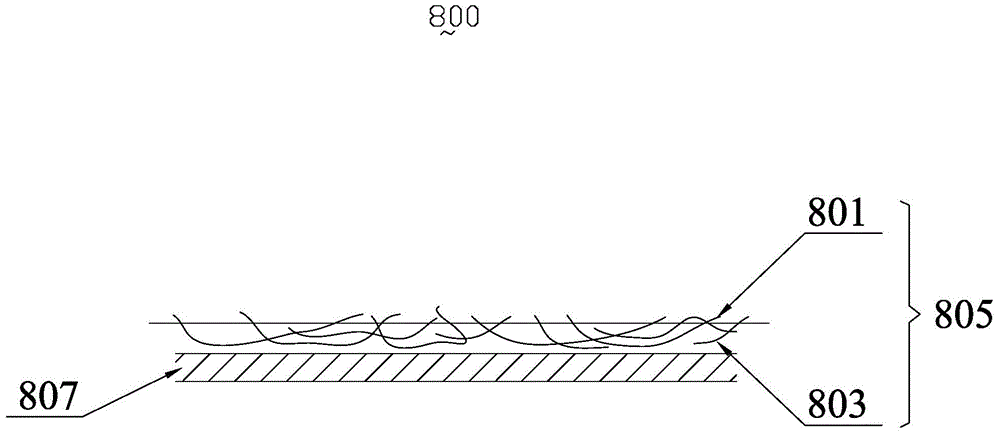

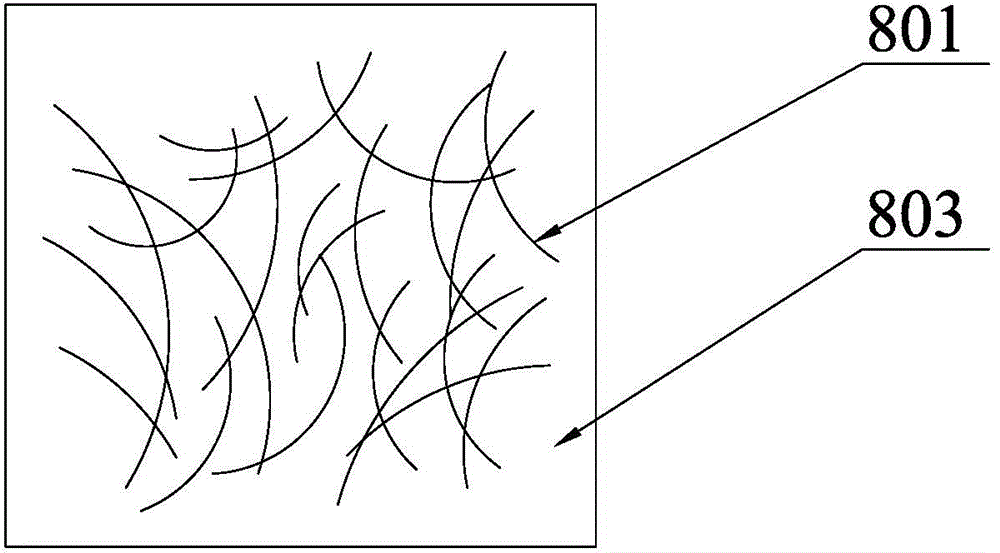

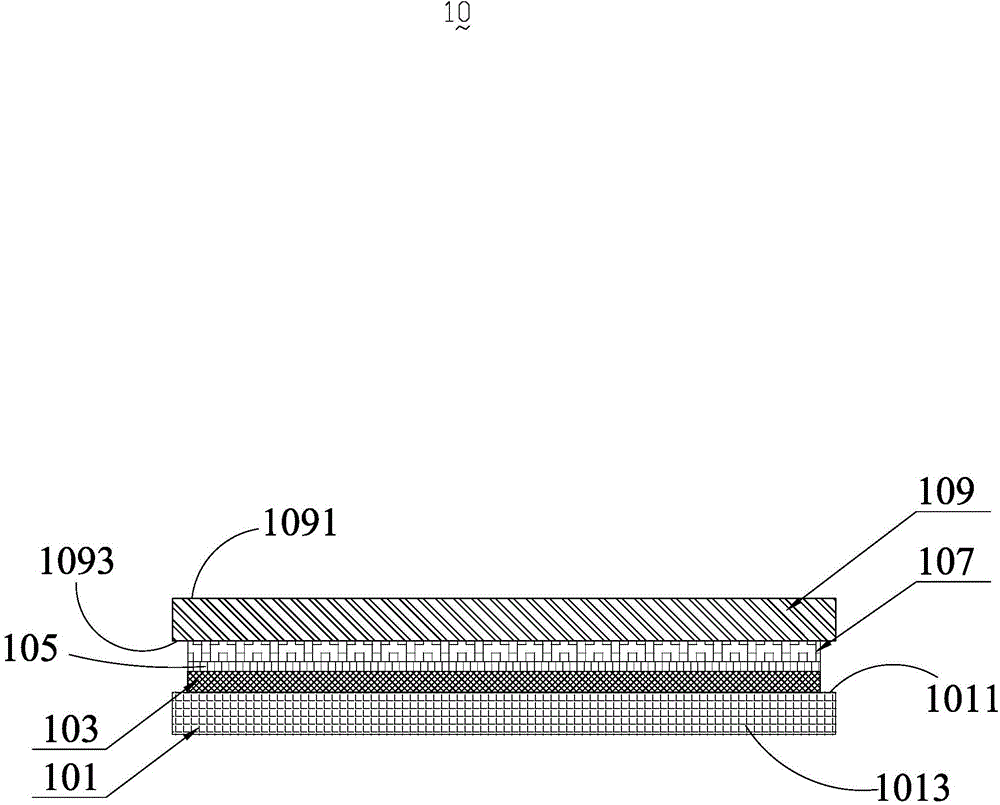

Touch panel

ActiveCN105204673AImprove appearance visual effectImprove conductivityInput/output processes for data processingTouch panelPhysics

The invention relates to the technical field of touch, in particular to a touch panel. The touch panel comprises a cover plate, a first electrode layer and a second electrode layer; the cover plate comprises a first surface and a second surface, wherein the first surface serves as the touch surface; the first electrode layer is located between the second surface and the second electrode layer, the first electrode layer and the second electrode layer are used for detecting multi-point touch, and a nano-silver wire electrode layer is adopted as the second electrode layer.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

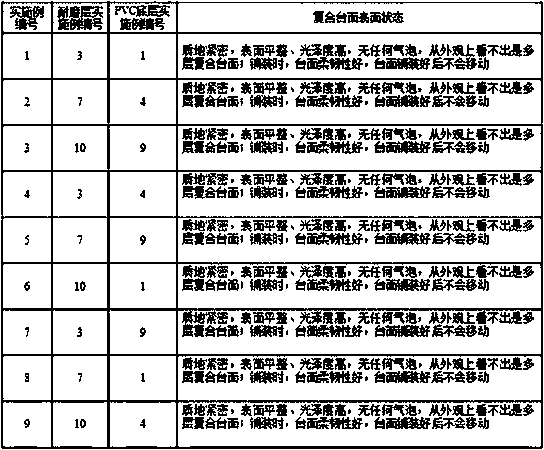

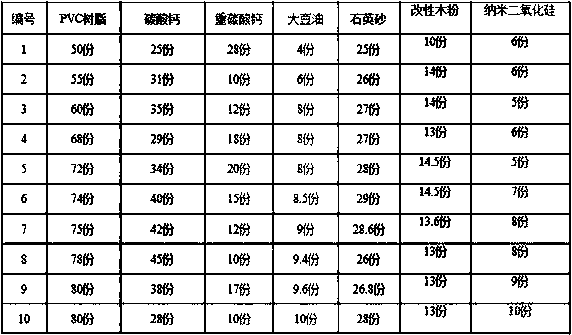

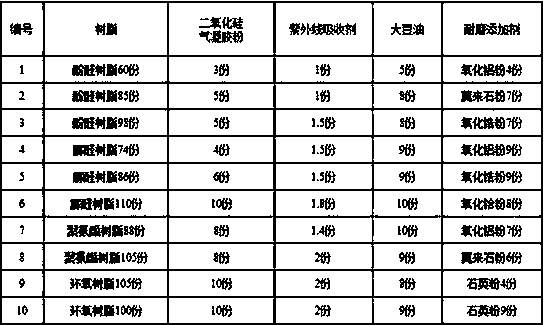

Composite PVC (polyvinyl chloride) table face and preparation method thereof

InactiveCN108327371ABeautiful method of preparationThe preparation method is simple and reliableDomestic upholsterySynthetic resin layered productsCalcium bicarbonateUltraviolet lights

The invention discloses a composite PVC table face. The composite PVC table face sequentially comprises an anti-wear layer, a printing layer and a PVC bottom layer; the anti-wear layer is prepared from, in parts by weight, 60-110 parts of resin raw materials, 3-10 parts of silicon dioxide aerogel powder, 1-2 parts of ultraviolet light absorber, 5-10 parts of soybean oil and 4-10 parts of anti-wearadditive; the PVC bottom layer is prepared from 50-80 parts of PVC resin, 25-45 parts of calcium carbonate, 10-20 parts of calcium bicarbonate, 4-8 parts of soybean oil, 25-40 parts of quartz sand, 10-15 parts of modified wood powder and 5-10 parts of nano silicon dioxide. The table face in the invention does not only solve the problems that a homoplasmon PVC table face cannot roll and is hard topave, the appearance of the table face is improved through design of the printing layer, and the appearance visual effect of the table face is greatly changed. Furthermore, the composite table face is thickened, the additionally arranged anti-wear layer prolongs the service life of the composite table face, and thus the beautiful appearance can be maintained durably. The preparation method of thePVC composite table face is simple and reliable, and high in practicality, and is suitable for industrial scale application and popularization.

Owner:FOSHAN RICH FIELD COMMODITIES CO LTD

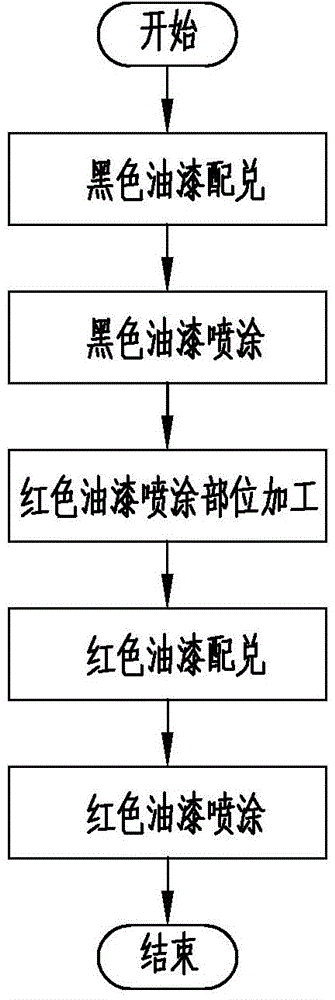

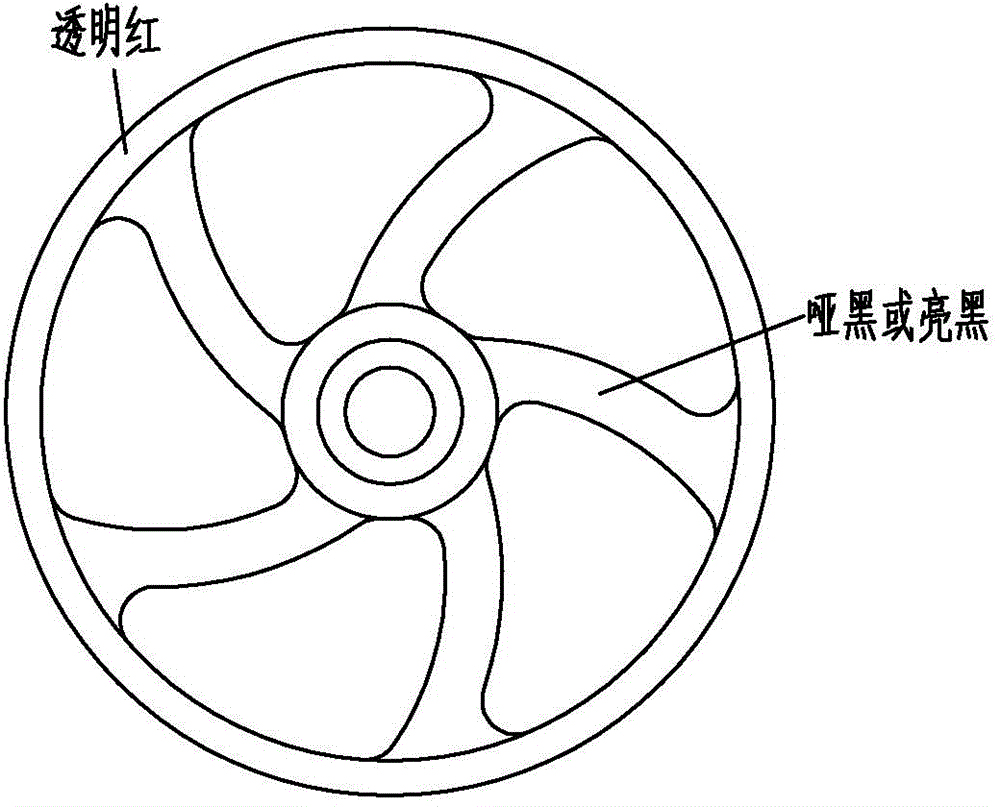

Method for spraying double-color hubs

InactiveCN103599880AFully reflect the two-color effectGood appearance and visual effectSpecial surfacesCoatingsBlack paintDiluent

The invention discloses a method for spraying double-color hubs. The method includes black paint blending: blending acrylic acid matted black or bright black paint with diluents until a viscosity value of a flow cup ranges from 10 seconds to 20 seconds; black paint spraying: spraying the blended acrylic acid matted black or bright black paint to portions, where the black paint needs to be sprayed, of a hub until a set thickness requirement is met; paint drying: heating and drying the hub until black paint films are thoroughly dried; red paint sprayed portion machining: cutting and machining portions, where red paint needs to be sprayed, of the hub until a natural color of a base of the hub is completely exposed; red paint blending: blending acrylic acid transparent red paint by diluents until a viscosity value of a flow cup is 15 seconds; red paint spraying: directly spraying the blended acrylic acid transparent red paint to the portions, where the red paint needs to be sprayed, of the hub until a set thickness requirement is met; drying: heating and drying the hub until red paint films are thoroughly dried. The method has the advantages that shielding measures are omitted when the second colored paint is sprayed to the hub, accordingly, the double-color hub spraying production efficiency is high, and the production cost is low.

Owner:CHONGQING FUJI MACHINE MFG

Environment-friendly water-proof packaging bag and manufacturing method thereof

ActiveCN101934880BStrong three-dimensional senseRich color changeSynthetic resin layered productsBagsWater basedCompound a

The invention discloses an environment-friendly water-proof packaging bag and a manufacturing method thereof, belonging to the technical field of packing materials. The packaging bag is manufactured by taking a chrome paper or a card paper as the base material, compounding a thin film with an environment-friendly water-based adhesive and combining a Glitter powder layer on the outer surface of the compounded thin film; drying and die-cutting the product; and making through a bag making machinery. The invention has the advantages of excellent effect for preventing water or vapour from being transmitted, environment protection and no harm to the human body and improved tensile intensity because of the combination of the base material, the thin film and the Glitter powder. The Glitter powderlayer has strong three-dimensional effect, rich colour change and twinkling effect so that the visual impact of the packaging bag is improved.

Owner:常熟市双乐彩印包装有限公司

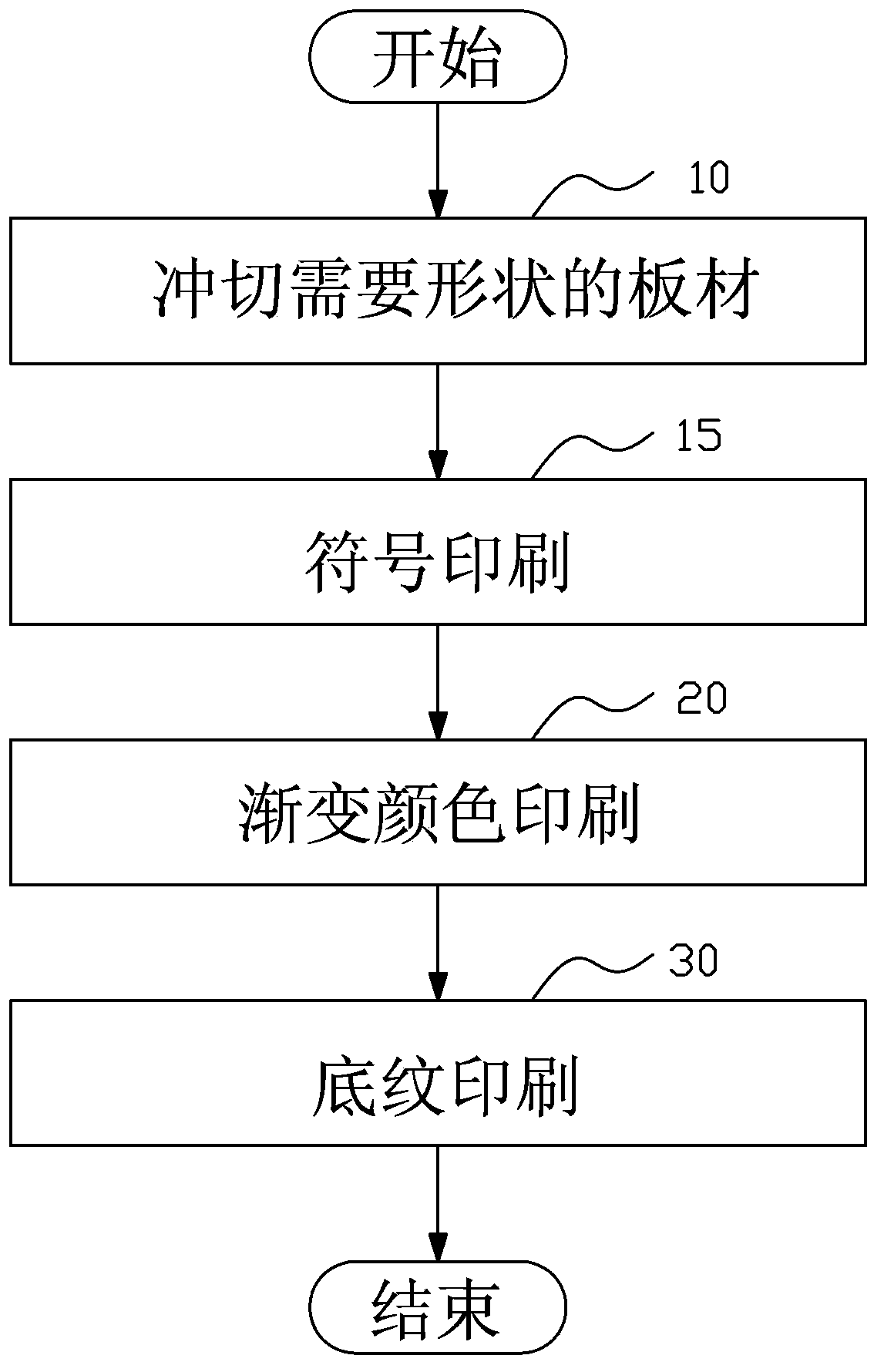

Manufacturing method of product with gradient shading

InactiveCN103862899AImprove appearance visual effectPattern printingOther printing apparatusManufacturing engineering

The invention provides a manufacturing method of a product with gradient shading. The manufacturing method of the product with gradient shading comprises the following steps of: punching a plate into a required shape, printing gradient color and printing shading. According to the manufacturing method of the product with gradient shading, printing of the shading can be performed on basis of printing of the gradient color, and thus the appearance visual effect is enhanced.

Owner:KUNSHAN YANDA COMP TECH

touch panel

ActiveCN105204673BImprove appearance visual effectImprove conductivityInput/output processes for data processingIndium tin oxideTouch panel

The invention relates to the technical field of touch, in particular to a touch panel. The touch panel comprises a cover plate, a first electrode layer and a second electrode layer; the cover plate comprises a first surface and a second surface, wherein the first surface serves as the touch surface; the first electrode layer is located between the second surface and the second electrode layer, the first electrode layer and the second electrode layer are used for detecting multi-point touch, and a nano-silver wire electrode layer is adopted as the second electrode layer.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

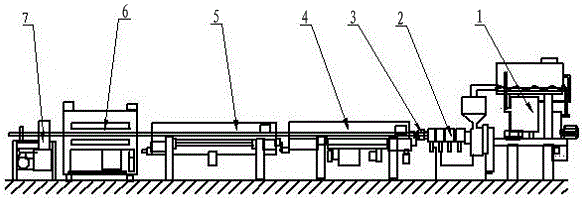

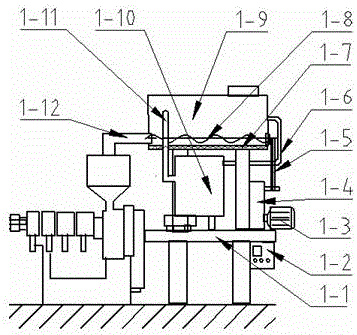

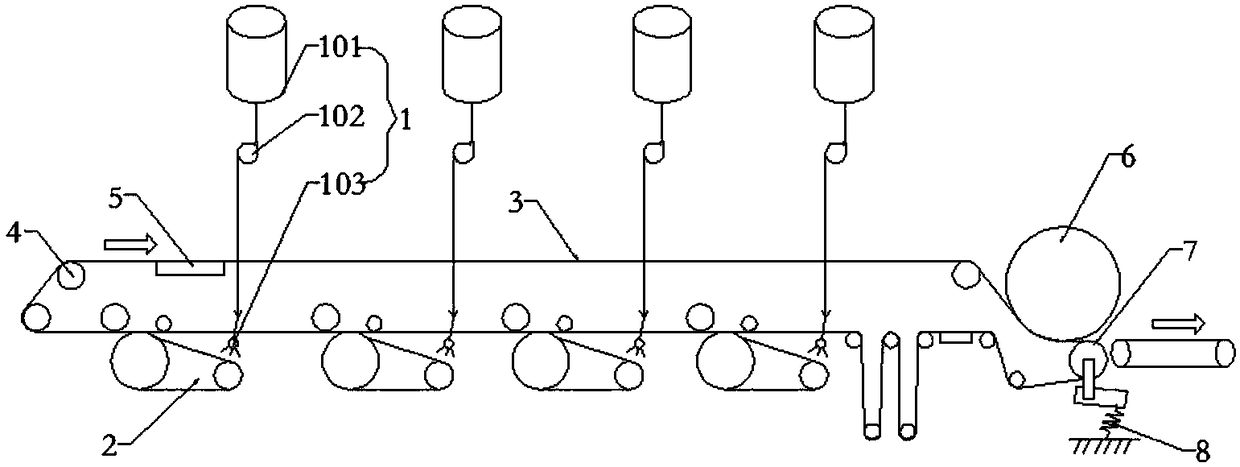

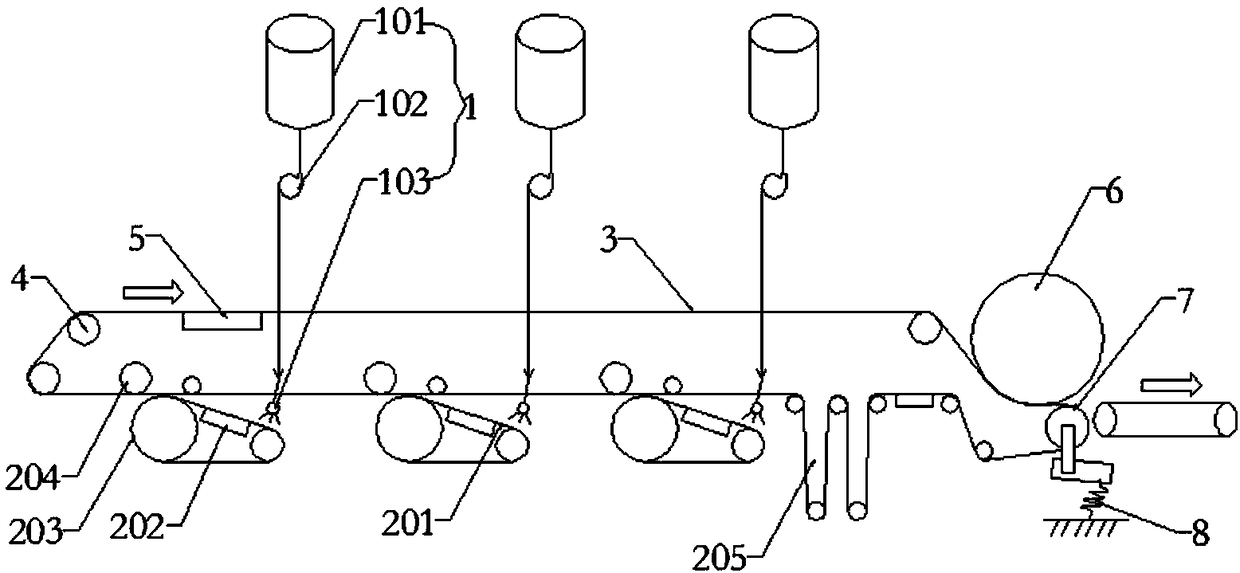

Production technology and production device of calcium silicate board blank, calcium silicate board and production technology thereof

InactiveCN108424103AGood product quality and stabilityImprove performanceCeramic shaping plantsFeeding arrangmentsCalcium silicateSlurry

The invention belongs to the technical field of production of calcium silicate board, and relates to a production technology and a production device of a calcium silicate board blank, a calcium silicate board and a production technology thereof. The production technology of the calcium silicate board blank comprises the following steps: arranging multiple sets of separately arranged feeding devices above preforming devices, wherein the multiple sets of feeding devices are filled with pigment slurries containing at least two colors; conveying the prepared slurries to the preforming devices through the feeding devices; conveying material layers treated by the preforming devices to a material conveying blanket, enabling the material layers on the material conveying blanket to move towards a forming cylinder under the driving of a transmission mechanism, superimposing and laminating the material layers conveyed by the multiple sets of feeding devices in the moving process, then winding andperforming press forming through the forming cylinder, and dewatering to form the calcium silicate board blank. The technical problem that in the conventional production technology, a colorful calcium silicate board cannot be produced can be alleviated.

Owner:江苏古德乐环保科技有限公司 +1

Vehicle lamp optical unit, vehicle lamp module and vehicle

PendingCN113883469AImprove appearance visual effectAvoid it happening againVehicle headlampsLighting and heating apparatusFirst lightEngineering

The invention relates to a vehicle lighting device, and discloses a vehicle lamp optical unit, a vehicle lamp module and a vehicle. The automobile lamp optical unit comprises a first optical element, the rear end face and the front end face of the first optical element in the light emitting direction are a light-in structure datum plane and a first light outlet surface respectively, and a light-in part is formed at the rear end of the first optical element and comprises at least one first light-in structure arranged in the left-right direction of the light-in structure datum plane. A first light channel is formed between the light-in part and the first light outlet surface; wherein the first light-in structure are arranged to extend from the upper side or the lower side of the reference surface of the light-in structure to the first light channel, and each first light-in structure can guide light received by the light-in structure to be emitted towards the first light channel and transmitted to the first light outlet surface along the first light channel. According to the automobile lamp optical unit, the visual effect during automobile lamp illumination can be improved, and the requirements of multiple illumination modes and lightening modes are met.

Owner:HASCO VISION TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com