Manufacturing method of product with gradient shading

A gradient color and shading technology, which is applied in the process field of gradient color shading products, can solve the problems that the injection molding process does not carry out the shading printing process, and the visual effect of the appearance cannot be achieved, and achieve the effect of enhancing the visual effect of the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

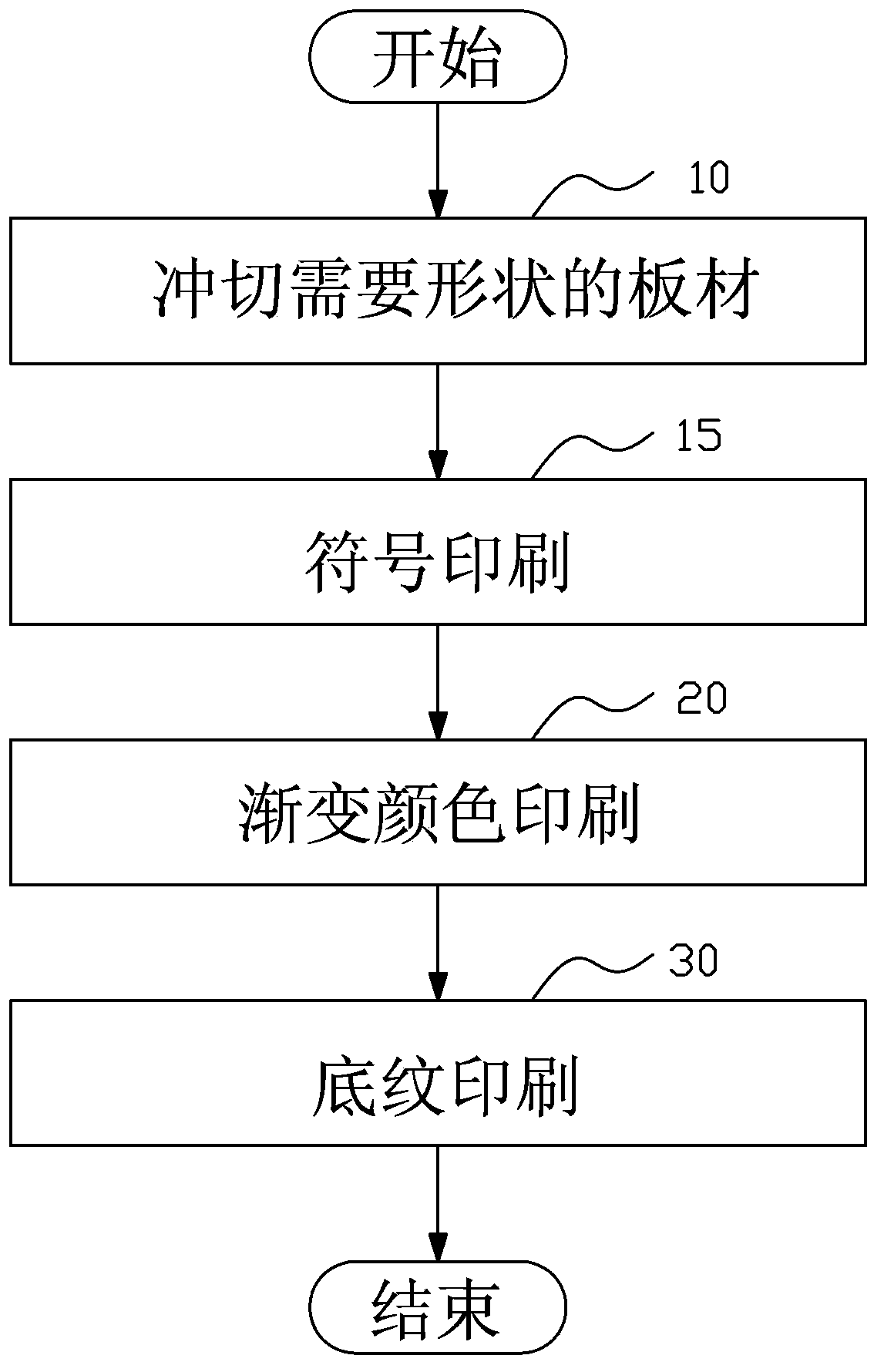

[0018] see figure 1 As shown, the present invention provides a kind of manufacturing method of gradient shading product comprising the following steps:

[0019] Step 10: Die-cut the board with the required shape; in this embodiment, the board in step 10 is a transparent board; the transparent board can realize the visual effect of light transmission;

[0020] Step 15: Symbol printing; required symbols can be printed as required;

[0021] Step 20: Gradient color printing; two or more primers can be printed as required to produce a gradient effect in the appearance of the product, and also produce different appearance color effects at different angles.

[0022] Step 30: shading printing, you can choose one color shading printing (single-color shading printing) or more than one color shading printing (multi-color shading printing) as required. In this embodiment, the shading Printing includes silver hot stamping shading printing and black shading printing, silver gilding shadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com