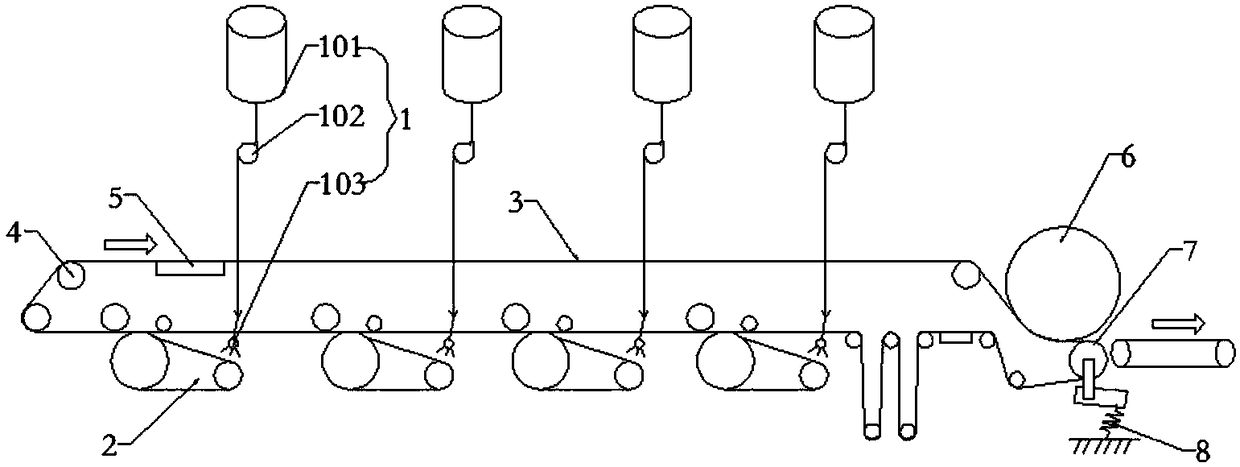

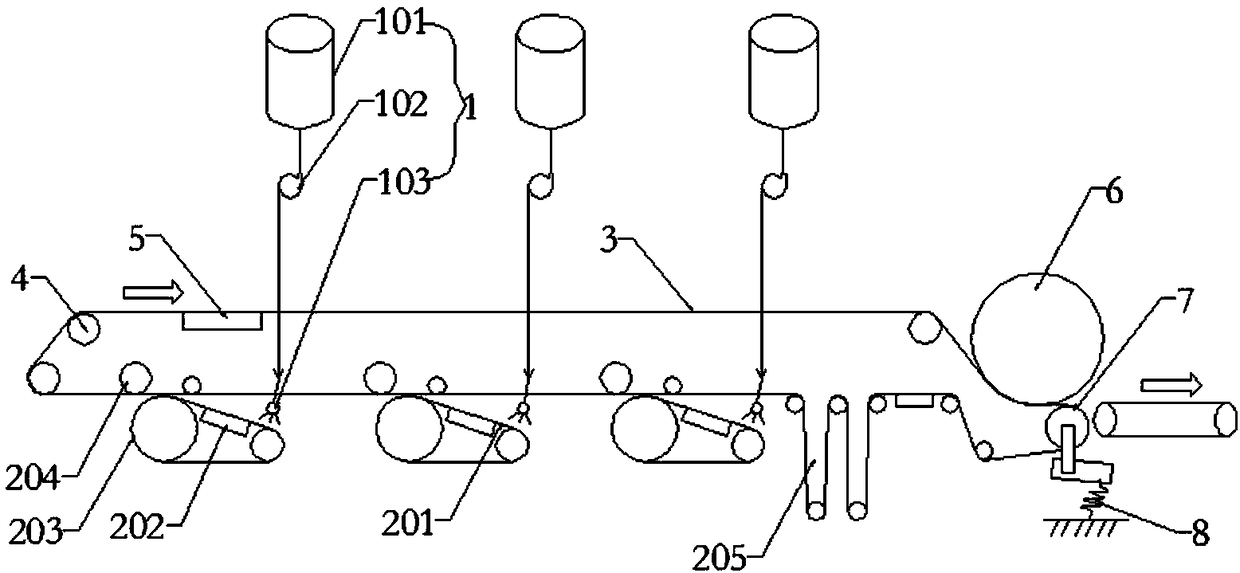

Production technology and production device of calcium silicate board blank, calcium silicate board and production technology thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] A production process of calcium silicon board, comprising the following steps:

[0117] Mix 35 parts by weight of diatomite, 35 parts by weight of lime, 25 parts by weight of quartz powder, and 5 parts by weight of wood fiber, add 110 parts by weight of water to stir and mix thoroughly, pump the mixed materials into five material barrels, and Add red, orange, yellow, green and purple pigments into the five material barrels respectively, and feed them into the distributing pipes through the feeding pumps respectively, leading to five different preforming cylinders, and open the appropriate distributing pipes to make the preformed Appropriate thickness of the preformed plate is formed on the forming cylinder, and finally the preformed plate of five colors formed on the five preforming cylinders is rolled and rolled by the forming cylinder, and the pigments penetrate and fuse with each other, and after dehydration, a gorgeous autumn color silicon is formed. Calcium slab; ...

Embodiment 2

[0121] A production process of calcium silicon board, comprising the following steps:

[0122] Mix 35 parts by weight of diatomite, 35 parts by weight of lime, 25 parts by weight of quartz powder, and 5 parts by weight of wood fiber, add 110 parts by weight of water to stir and mix thoroughly, pump the mixed materials into three material barrels, and Add red, yellow and orange pigments into the three material barrels respectively, and feed them into the distributing pipes through the feeding pumps respectively, leading to three different preforming cylinders, and open the appropriate distributing pipes to make the preforming cylinders form Appropriate thickness of the pre-formed board, finally the pre-formed boards of three colors formed on the three pre-formed cylinders are rolled and rolled by the forming cylinders, and the pigments are infiltrated and fused with each other, and after dehydration, a sunset-colored calcium-silicon board slab is formed ;

[0123] All the othe...

Embodiment 3

[0126] A production process of calcium silicon board, comprising the following steps:

[0127] Mix 35 parts by weight of diatomite, 35 parts by weight of lime, 25 parts by weight of quartz powder, and 5 parts by weight of wood fiber, add 110 parts by weight of water to stir and mix thoroughly, pump the mixed materials into two material barrels, and Add two kinds of blue and purple pigments into the two material barrels respectively, and feed them into the distribution pipes through the feed pumps respectively, leading to two different preforming cylinders, and open the appropriate distributing pipes to form a suitable color on the preforming cylinders. The thickness of the pre-formed board, and finally the two-color pre-formed board formed on the two pre-formed cylinders is rolled and rolled by the forming cylinder, and the pigments penetrate and fuse with each other, and after dehydration, a blue calcium-silicon board slab is formed;

[0128] All the other are the same as in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com