Method for spraying double-color hubs

A technology of two-color wheels and hubs, which is applied to coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as low efficiency, achieve high production efficiency, good appearance and visual effects, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

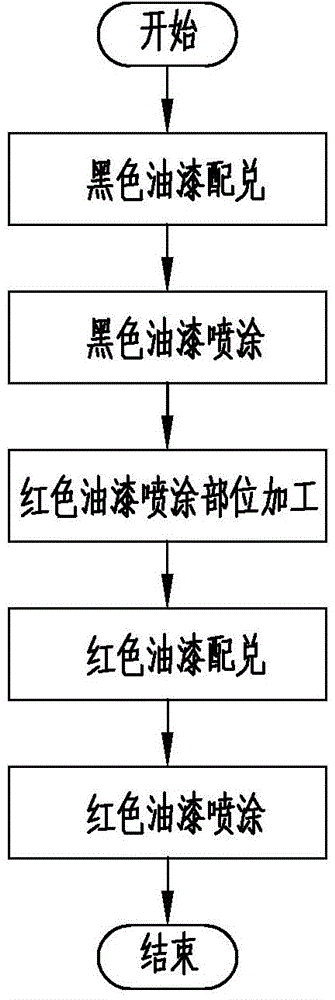

[0019] see figure 1 , a two-color wheel hub spraying method, comprising the following steps:

[0020] The first step, black paint blending: use banana water as a diluent to blend acrylic matte black paint, and use a flow cup to check the viscosity of acrylic matte black for 10-12 seconds;

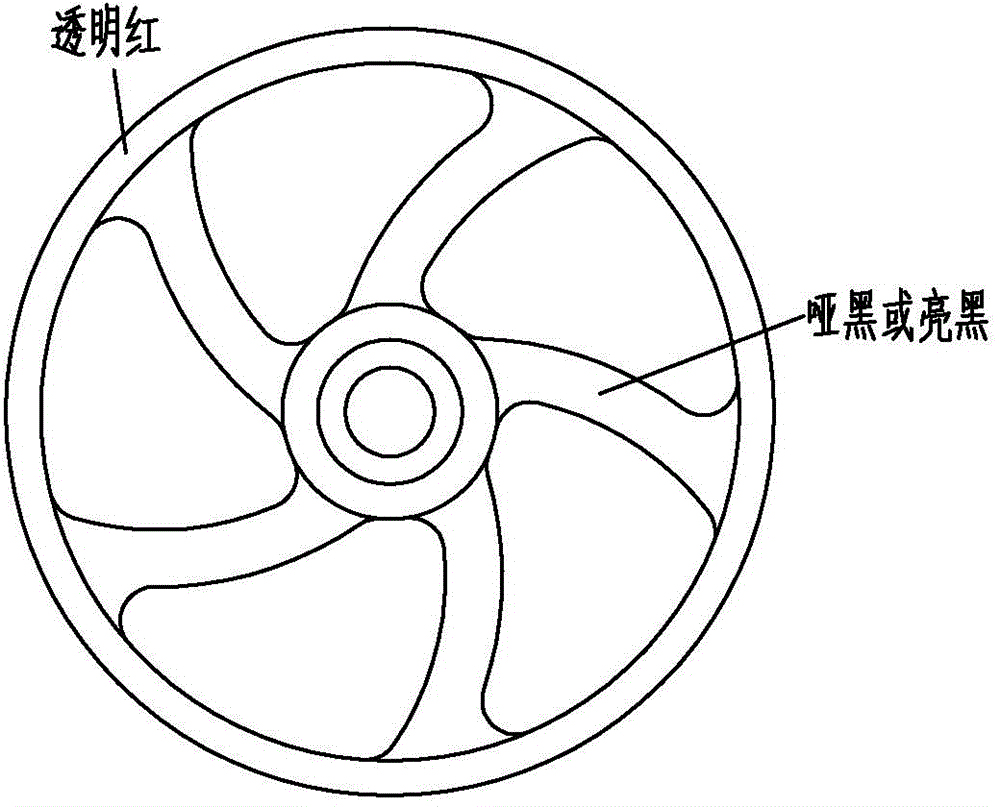

[0021] The second step, black paint spraying: use a spray gun to use compressed air to spray the blended acrylic matte black paint to the set thickness to the part where the black paint is to be sprayed on the wheel hub, that is, the spoke part of the motorcycle wheel hub;

[0022] The third step, paint drying: heat and dry the hub until the black paint film is completely dry;

[0023] The fourth step is the processing of the red paint spraying part: the part of the wheel hub that is to be sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com