Preparation method of composite material

A composite material and non-metallic material technology, applied in the field of composite material preparation, can solve the problems of poor appearance and visual effect, single product form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

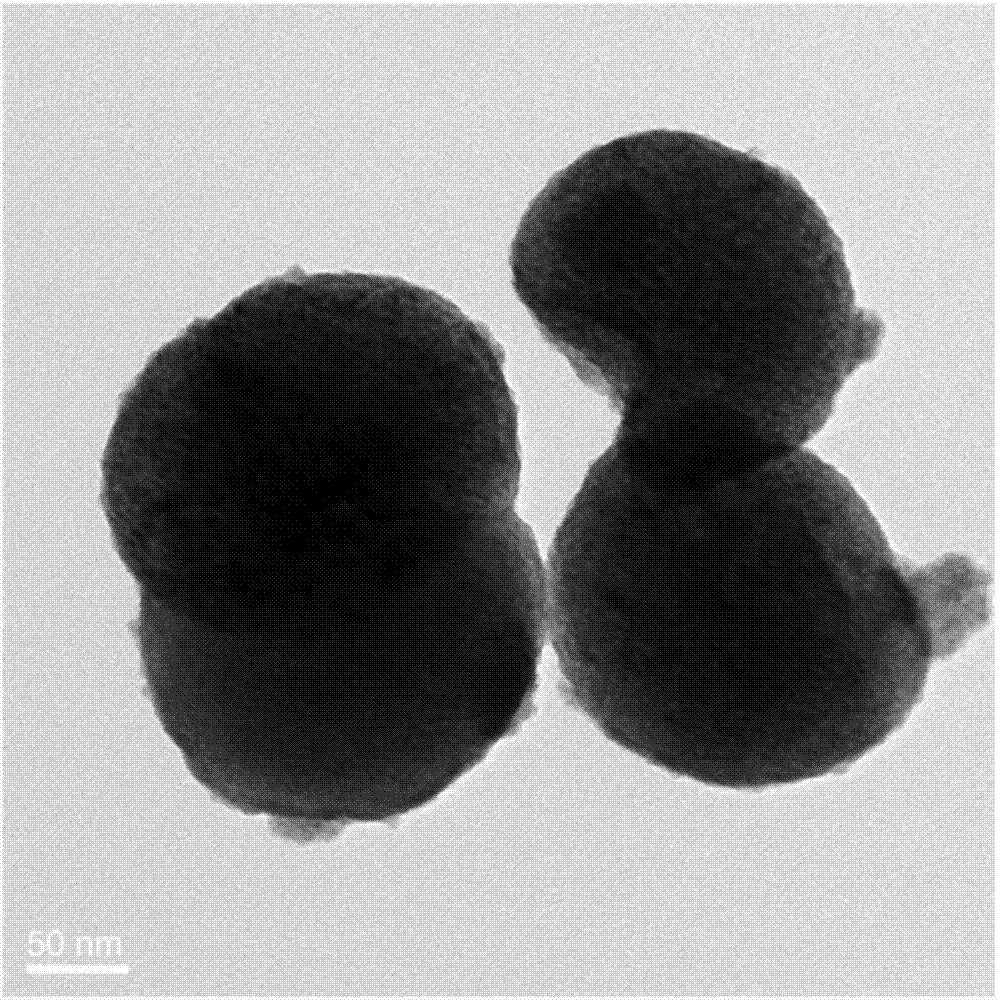

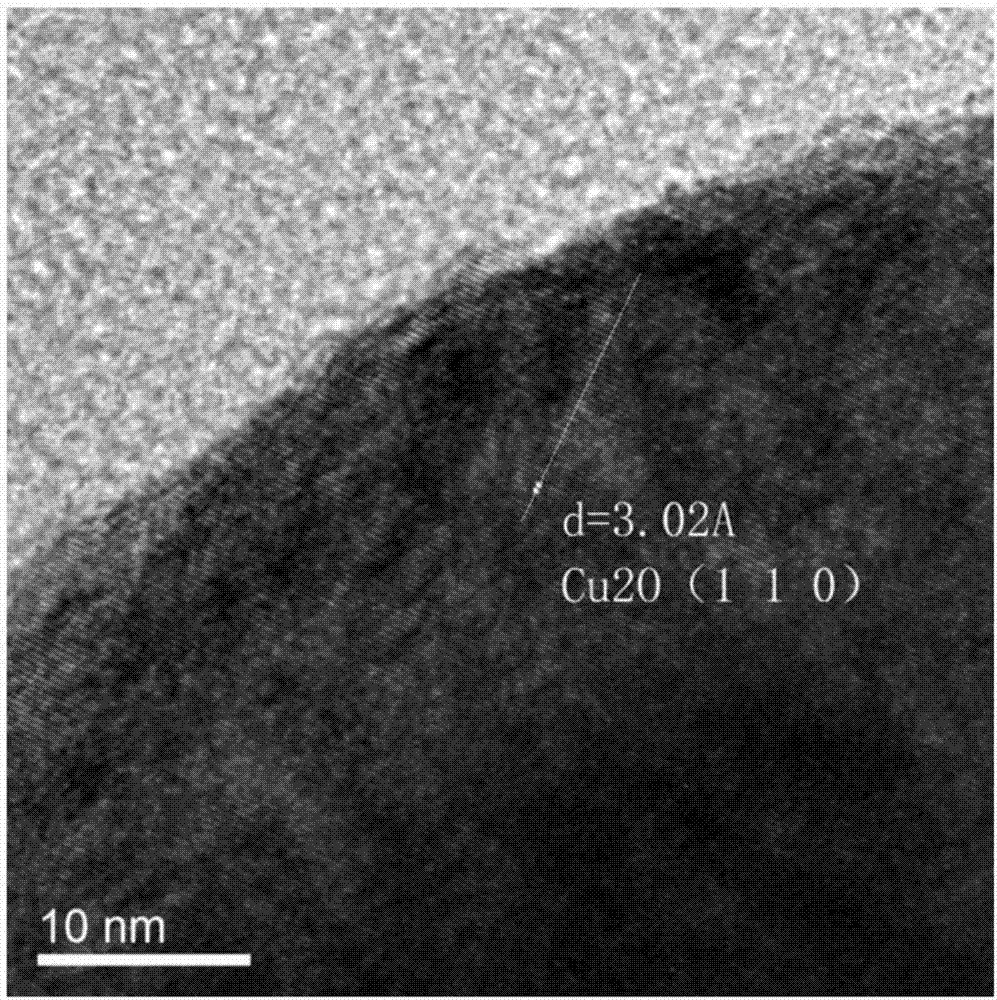

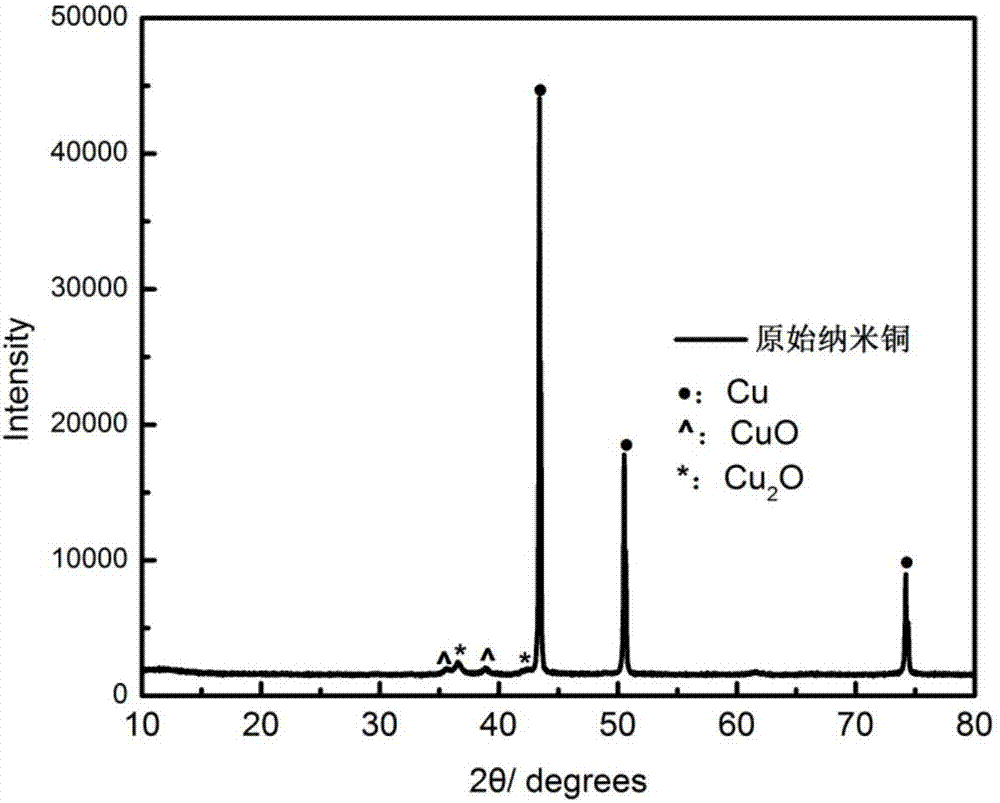

[0116] Weigh 5g of nano-copper powder (particle size about 50nm) and place it in a muffle furnace, raise the temperature to 300°C at a rate of 10°C / min in the air, keep it warm for 1h, and take it out after natural cooling to obtain oxidized nano-copper powder for later use .

[0117] Place 5g of absorbent cotton in an oven at 60°C, dry overnight, and set aside. 1.9513g of copper sulfate pentahydrate (mass ratio of copper ion to absorbent cotton is 1:10) was prepared into an aqueous solution, mixed evenly with absorbent cotton, and left overnight, so that the absorbent cotton and copper sulfate pentahydrate solution were fully mixed and evenly adsorbed.

[0118] Put the oxidized nano-copper powder and the absorbent cotton with copper sulfate pentahydrate adsorbed into the alumina crucible, put them into the tube furnace in turn, pass nitrogen, the gas flow is 100cc / min, and the temperature is raised to 390 at a rate of 10℃ / min. ℃, keep warm for 1h, take out the crucible after t...

Embodiment 2

[0121] Put 10g of absorbent cotton in an oven at 60°C, dry overnight, and set aside. 1.9513g of copper sulfate pentahydrate (mass ratio of copper ions to absorbent cotton is 1:20) is configured into an aqueous solution, mixed with absorbent cotton evenly, and left overnight, so that the absorbent cotton and copper sulfate pentahydrate solution are fully mixed and evenly adsorbed.

[0122] Put 5g of micron copper powder and absorbent cotton adsorbed with copper sulfate pentahydrate into an alumina crucible, put them into a tube furnace one by one, pass nitrogen gas at a flow rate of 100cc / min, and raise the temperature to 390 at a rate of 10°C / min. ℃, keep warm for 1h, take out the crucible after the furnace cools down, and obtain the composite material of carbon-based compound-coated copper.

[0123] Figure 7 It is the TEM picture of the original micron copper powder. It can be seen from the figure that the micron copper powder is in the shape of an irregular strip, with a w...

Embodiment 3

[0125] Put 10g of absorbent cotton in an oven at 60°C, dry overnight, and set aside. 1.9513g of copper sulfate pentahydrate (mass ratio of copper ions to absorbent cotton is 1:20) is configured into an aqueous solution, mixed with absorbent cotton evenly, and left overnight, so that the absorbent cotton and copper sulfate pentahydrate solution are fully mixed and evenly adsorbed.

[0126] Place a stainless steel sheet about the size of a coin in an acetone solution for ultrasonication to remove impurities on its surface, rinse it with absolute ethanol and dry it for later use.

[0127] Place the stainless steel sheet and the absorbent cotton adsorbed with the copper sulfate pentahydrate aqueous solution together in an alumina crucible, place the crucible in a tube furnace, let the air flow pass through the absorbent cotton and the stainless steel sheet in turn, and pass nitrogen at a flow rate of 100cc / min. Raise the temperature to 390°C at a rate of 10°C / min, keep it warm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com