Acetylene tail gas recovery device

A technology of acetylene tail gas and recovery device, which is applied in the direction of absorption purification/separation, separation method, organic chemistry, etc., and can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

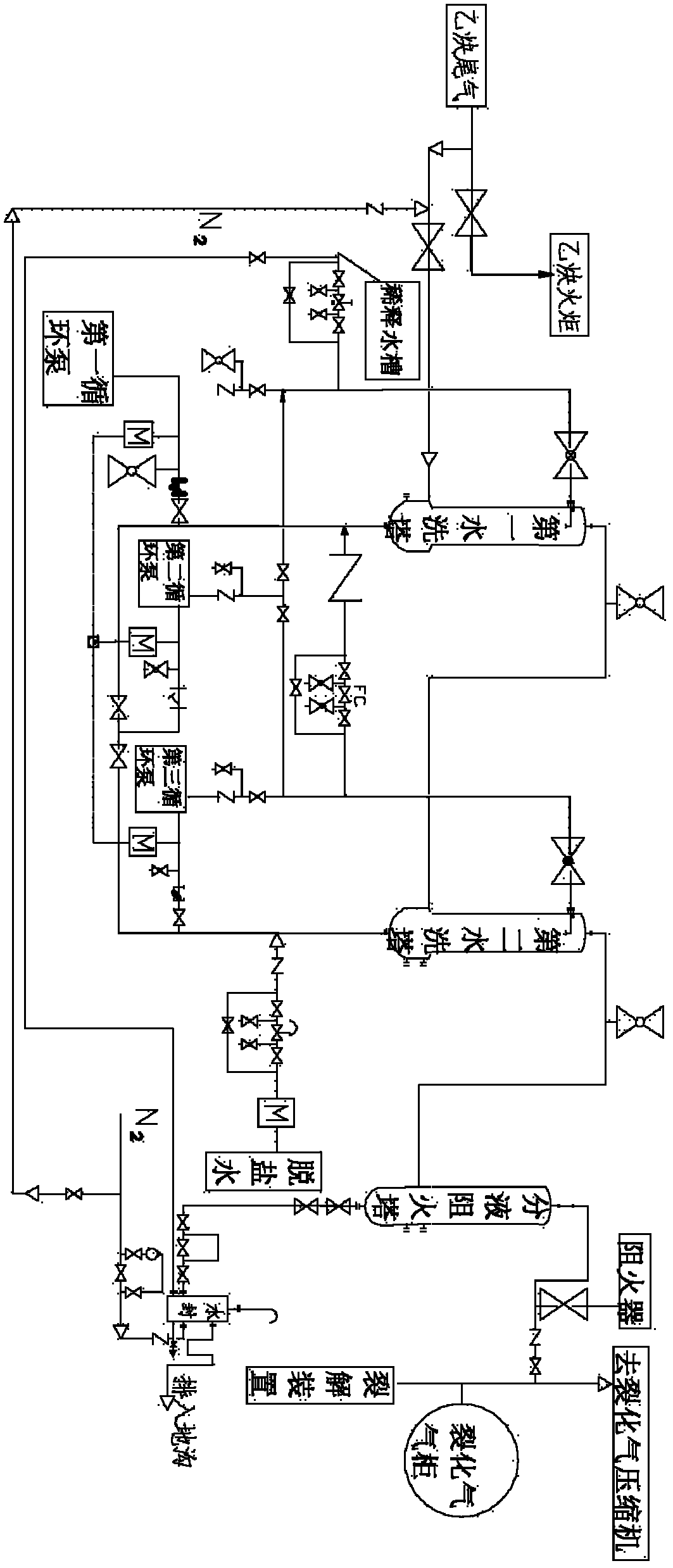

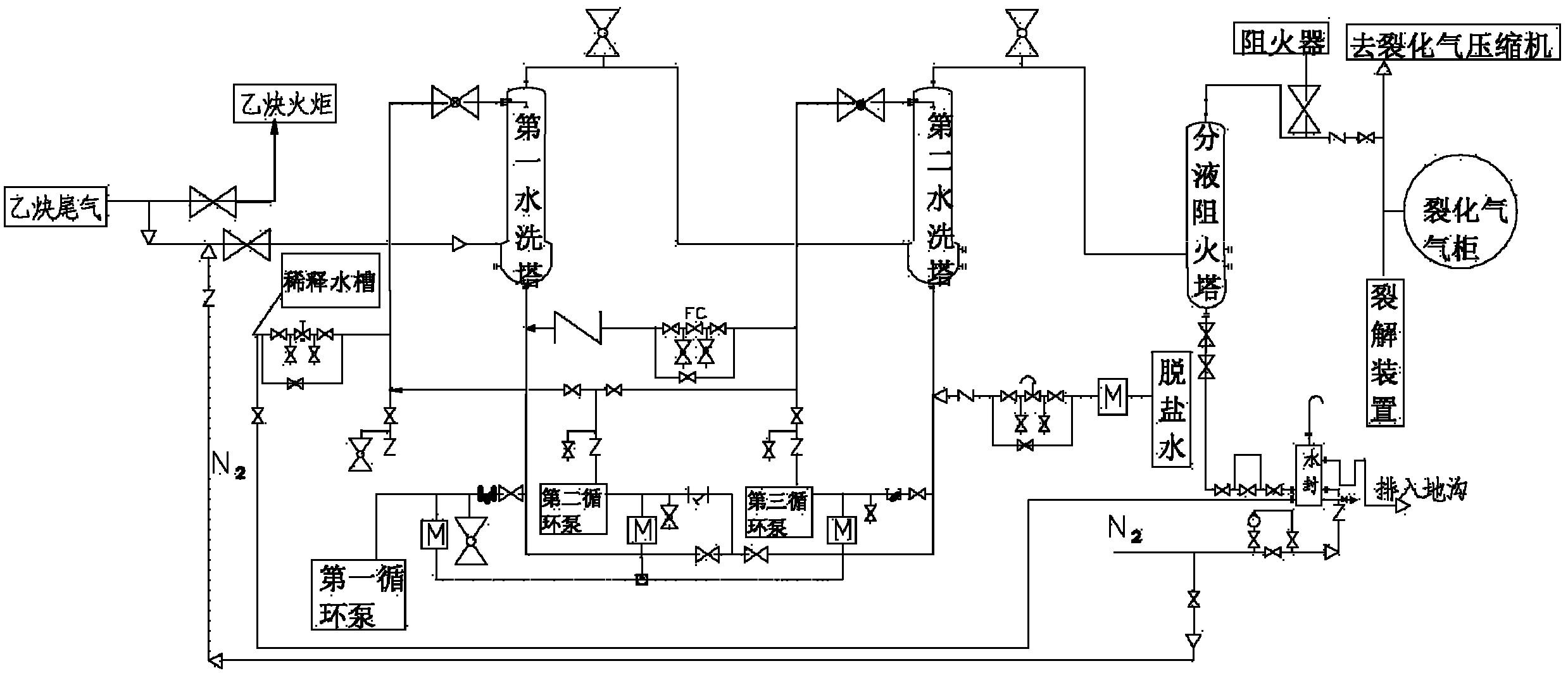

[0011] Such as figure 1 Shown:

[0012] The acetylene tail gas first enters the first water washing tower for preliminary washing, and then enters the second water washing tower for secondary washing. After the tail gas is washed in two stages, formaldehyde is the main formaldehyde, and almost all impurities including methanol and propargyl alcohol are included. Dissolved in the washing liquid, the purified tail gas is sent directly to the inlet of the decracking gas compressor after passing through the liquid separation and fire arresting tower, and after being mixed with the cracking gas, it is pressurized by the decracking gas compressor and then sent to the enri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com