Patents

Literature

49 results about "Gas flare" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas flare, alternatively known as a flare stack, is a gas combustion device used in industrial plants such as petroleum refineries, chemical plants, natural gas processing plants as well as at oil or gas production sites having oil wells, gas wells, offshore oil and gas rigs and landfills.

Method and apparatus for disposal of well flare gas in oil and gas drilling and recovery operations

A wellhead gas recovery system and method for the generation of power from wellhead gas is provided. A gas conduit is used to direct wellhead gas from a wellhead casing or wellhead bore to a stirling engine where the wellhead gas is used as the fuel source for the stirling engine. The wellhead gas is ignited and the burning wellhead gas is used as the heat source for the stirling engine. The thermal energy from the burning wellhead gas is converted transferred into motion by the stirling engine and the output of the stirling engine can be used to drive devices at the wellsite, generate electricity or other use.

Owner:CUGNET MATT +1

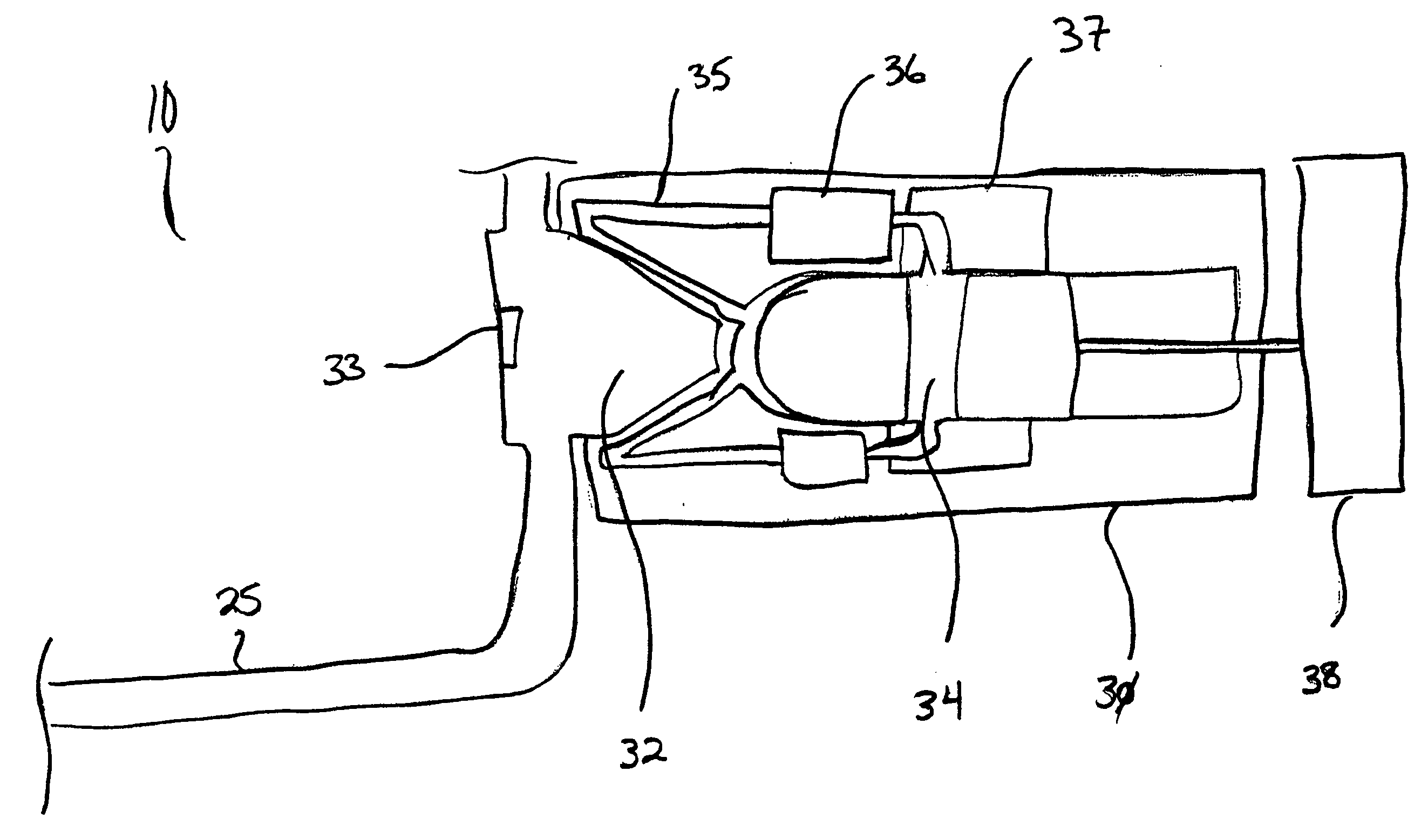

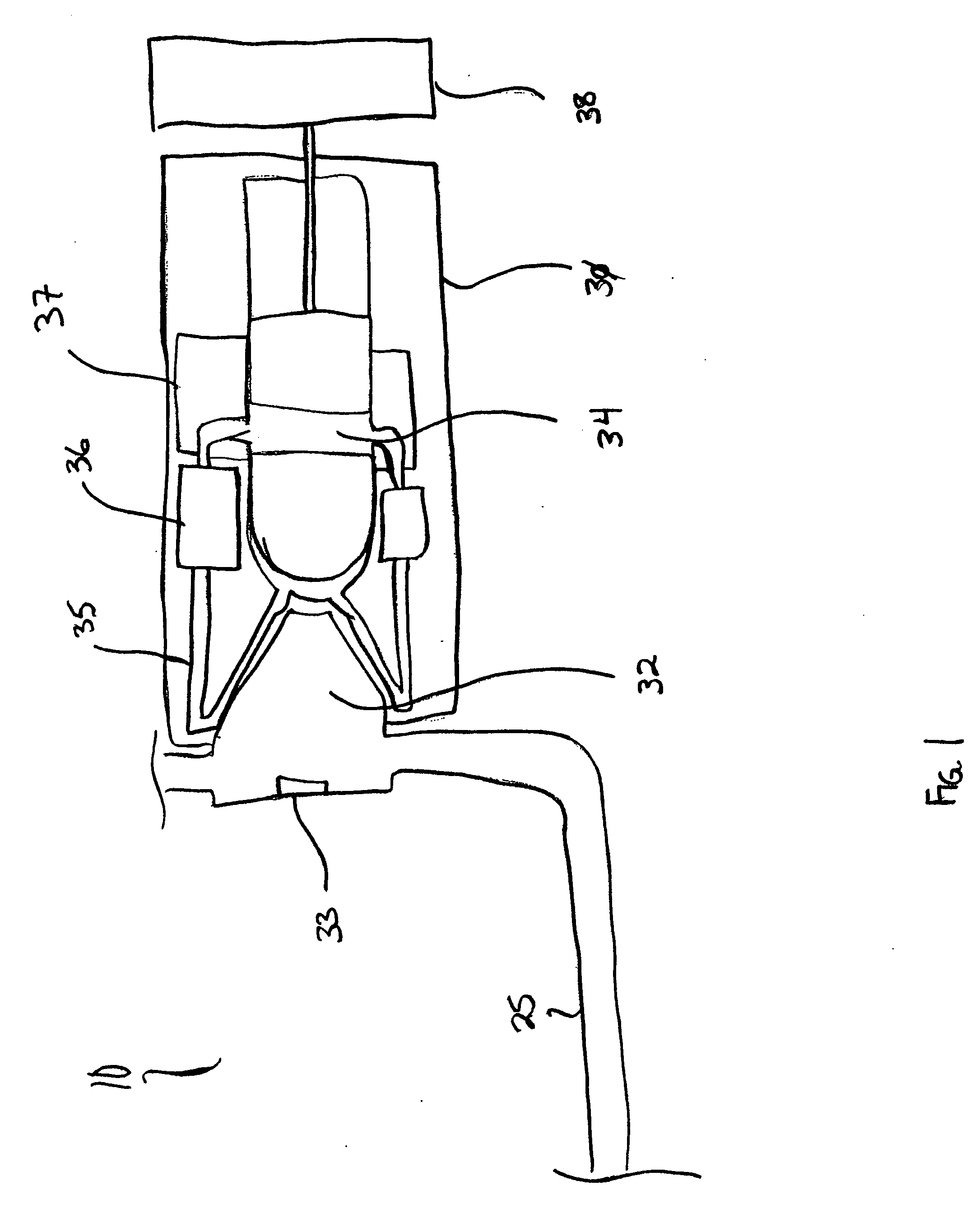

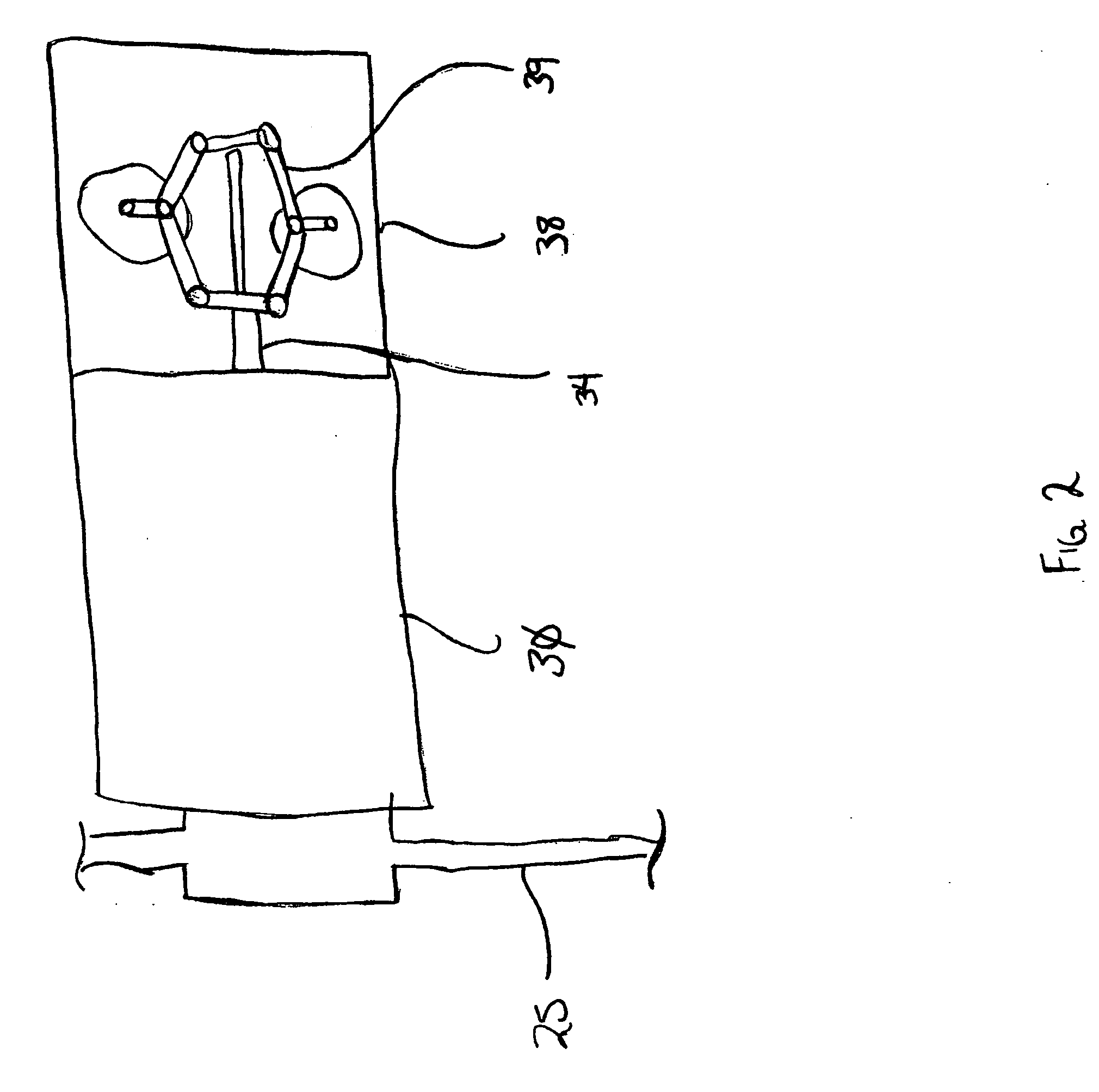

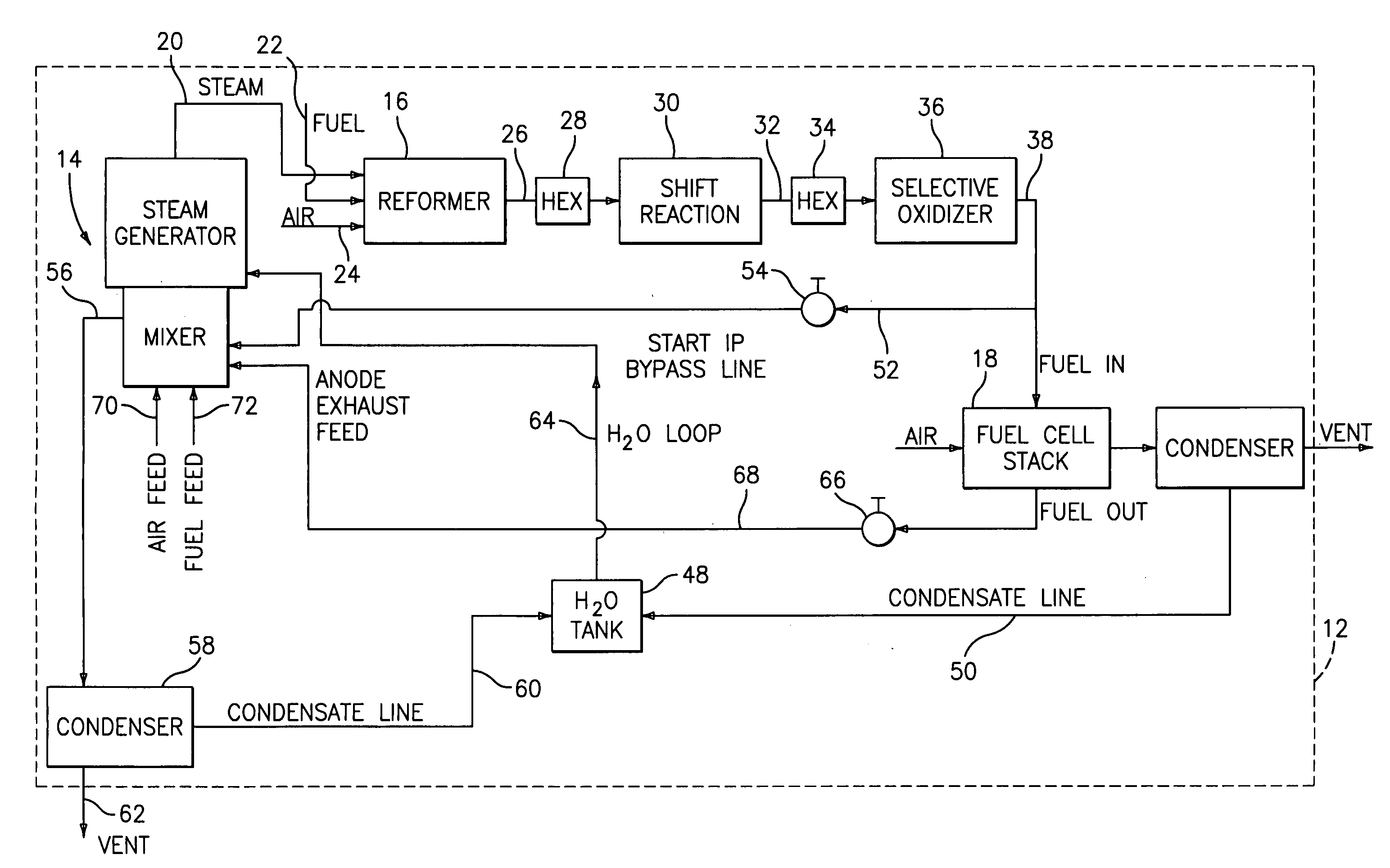

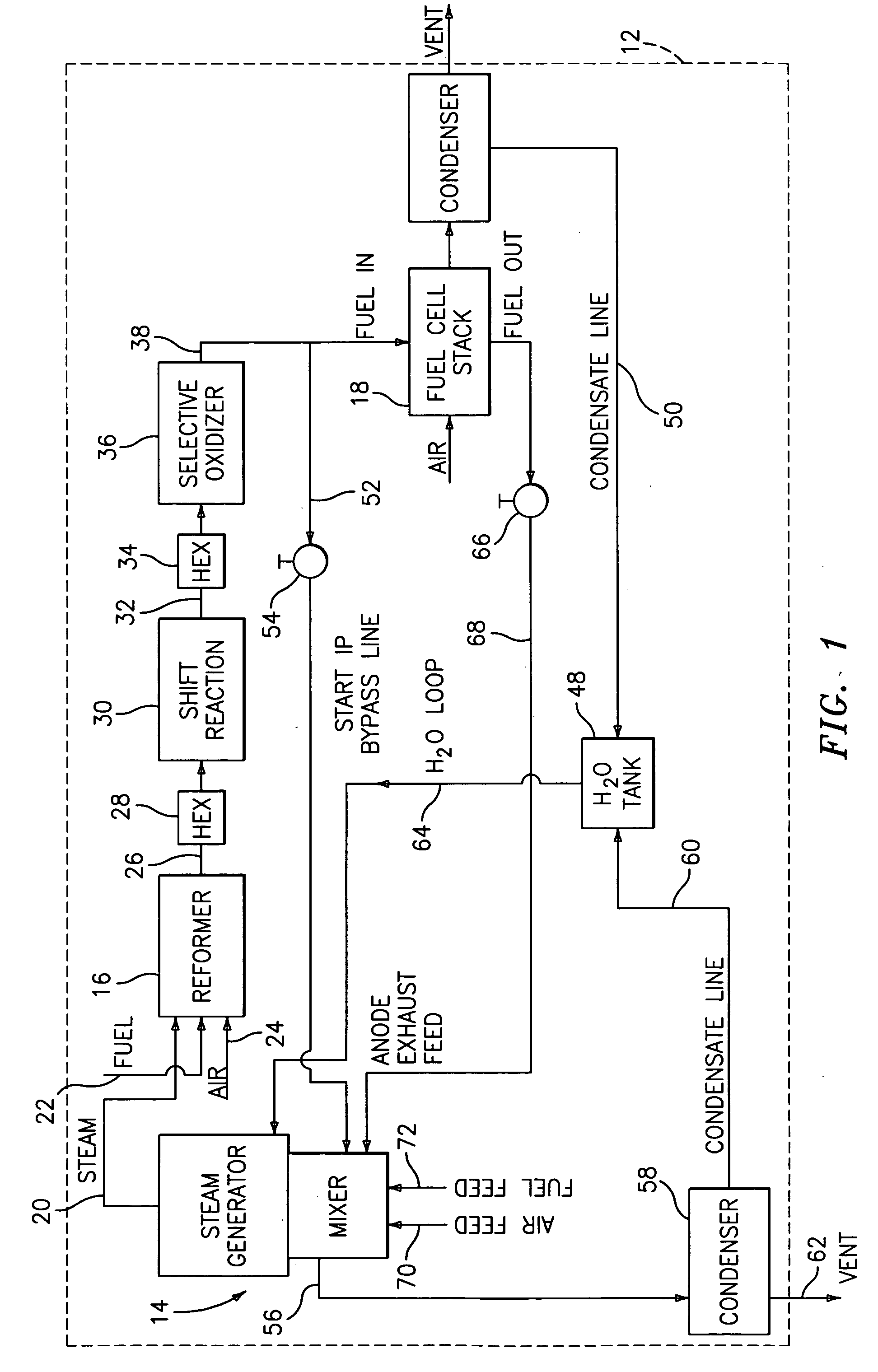

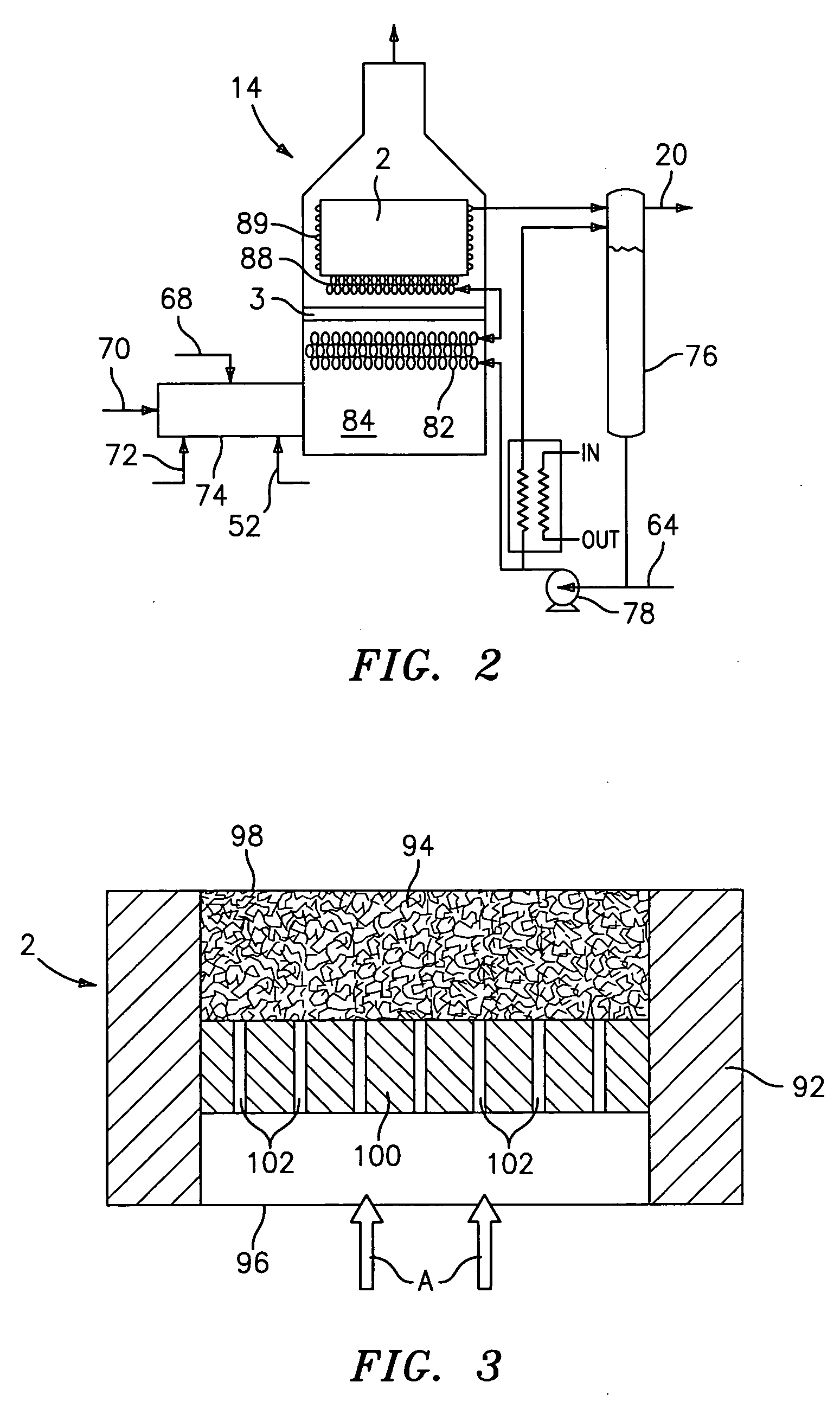

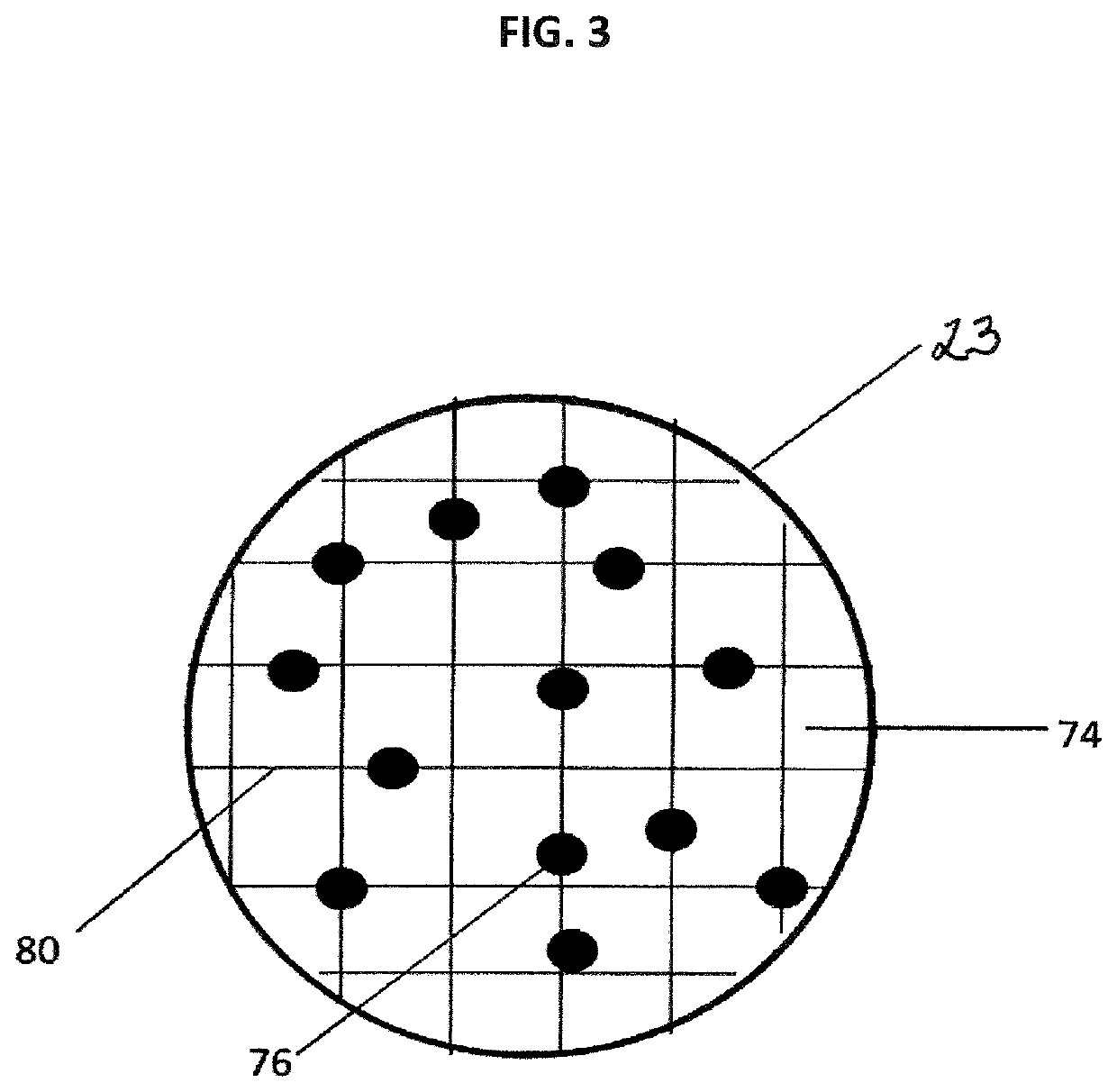

Burner for combusting the anode exhaust gas stream in a PEM fuel cell power plant

InactiveUS20050053816A1High open porosityIncreased catalytic surface areaBurnersFuel cells groupingAmbient pressureEngineering

A catalyzed burner is operative to combust an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, palladium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. The burner is able to combust hydrogen in the anode exhaust stream. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open pores, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet. The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (927° C.). The burner can combust anode exhaust during normal operation of the fuel cell assembly. The burner is not adversely affected by gasoline, gasoline combustion products, or anode bypass gas, the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line.

Owner:INT FUEL CELLS

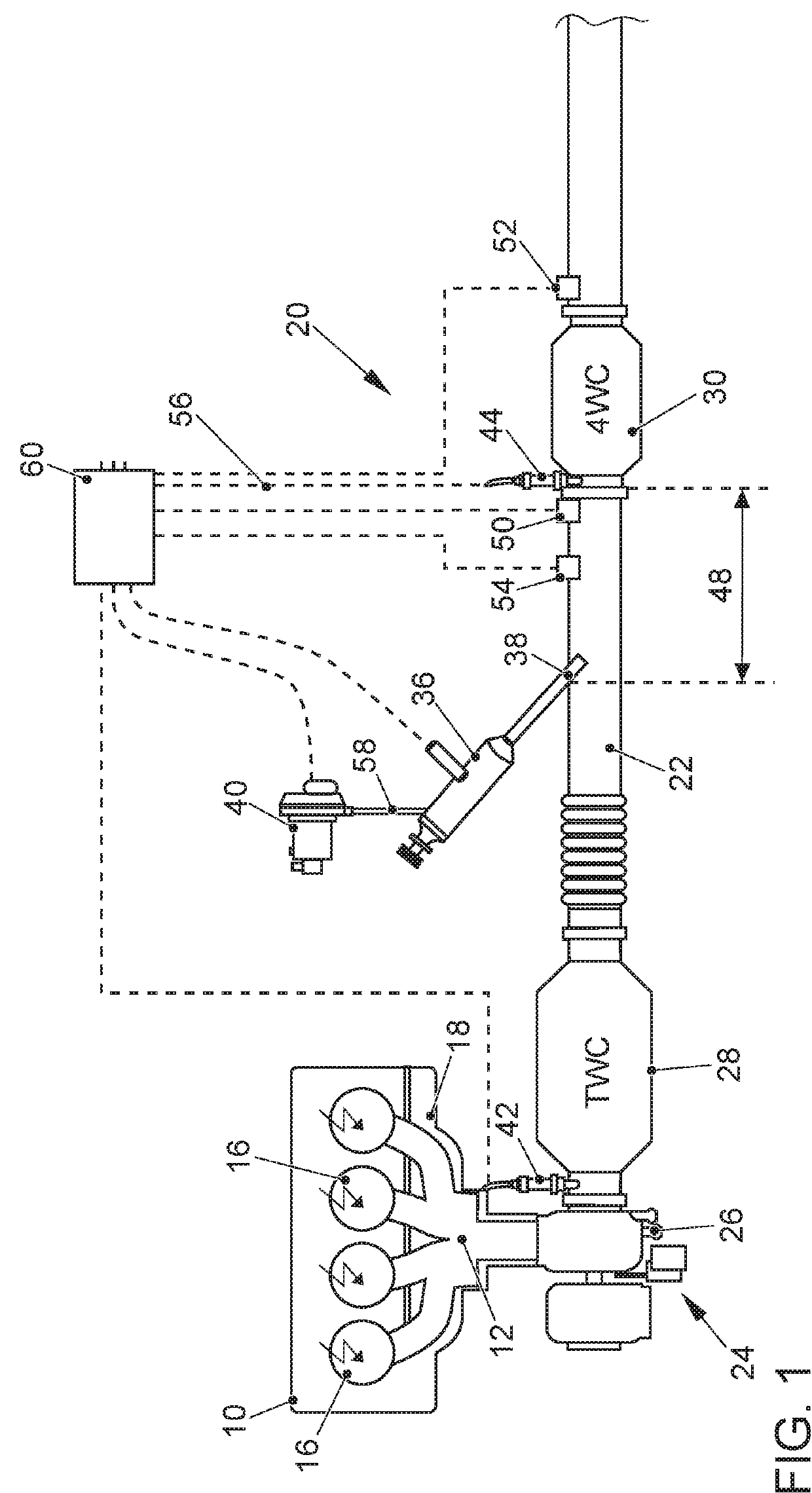

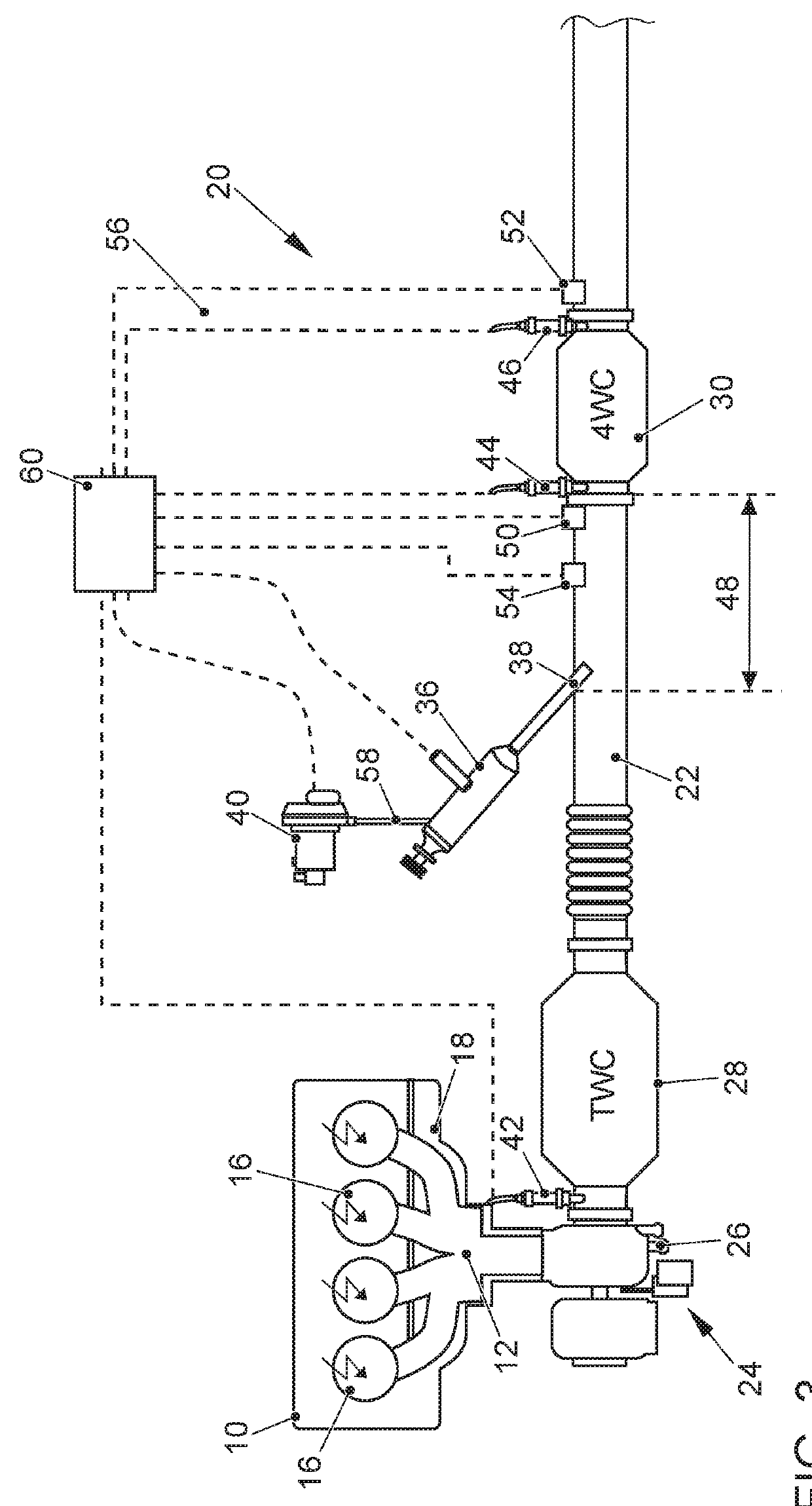

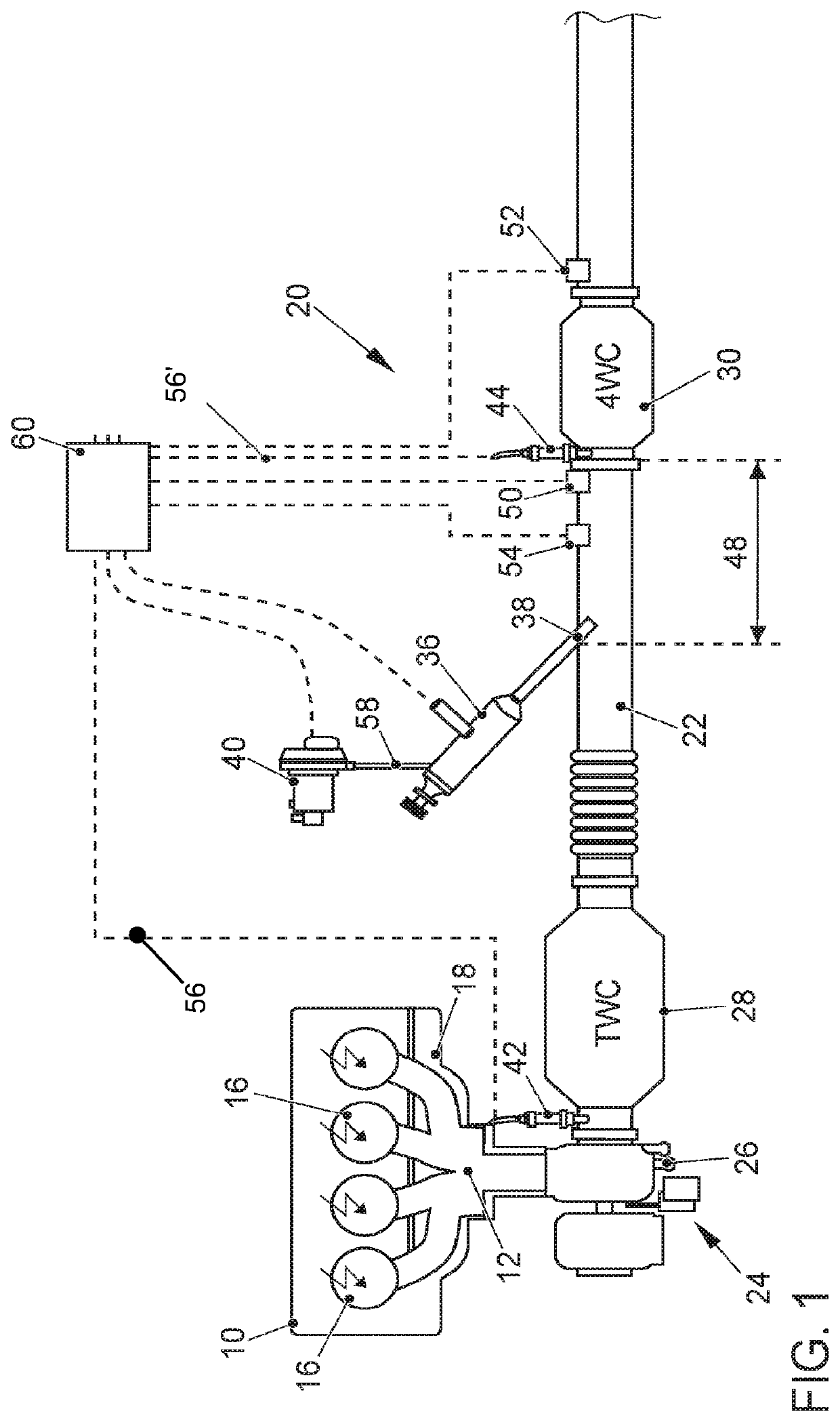

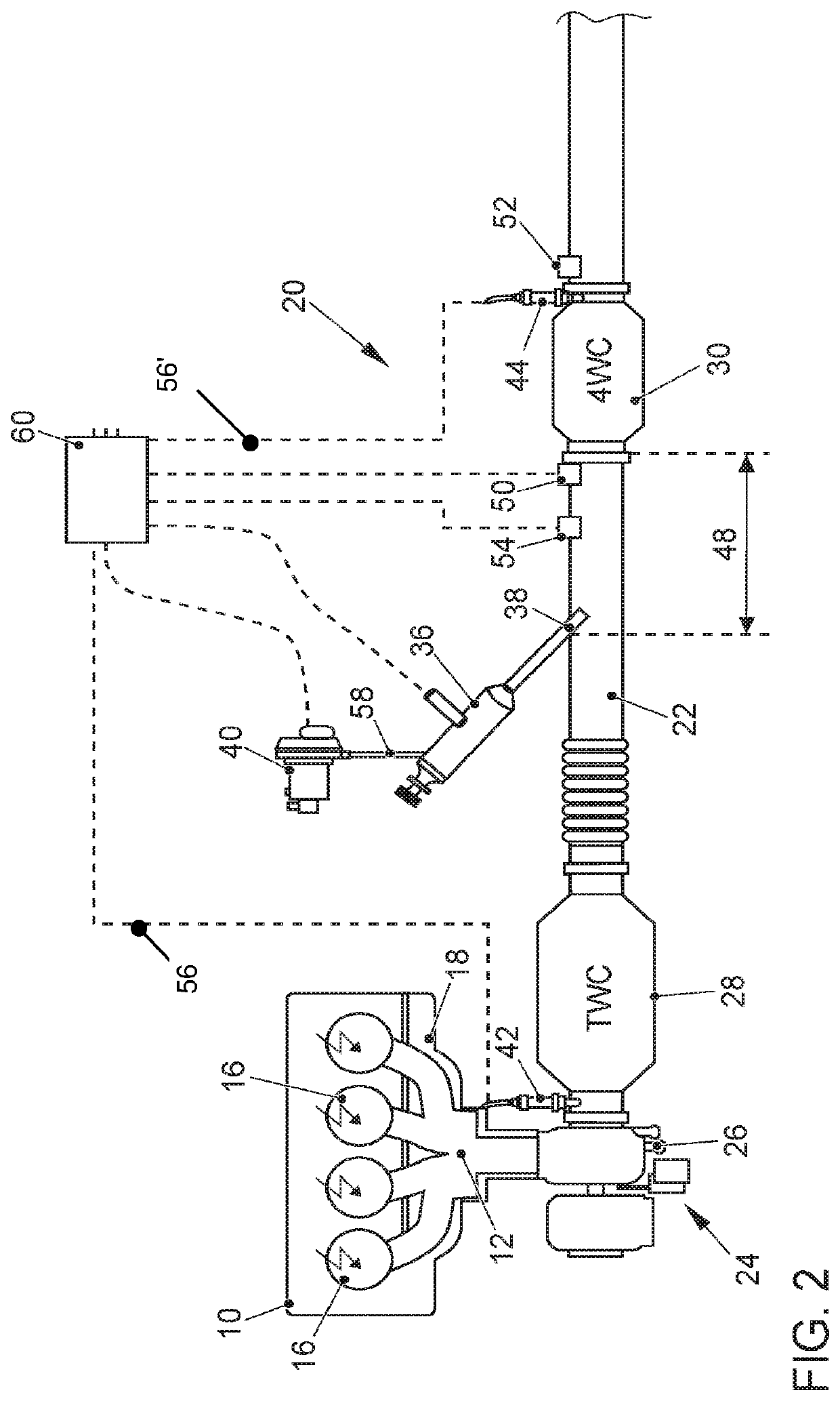

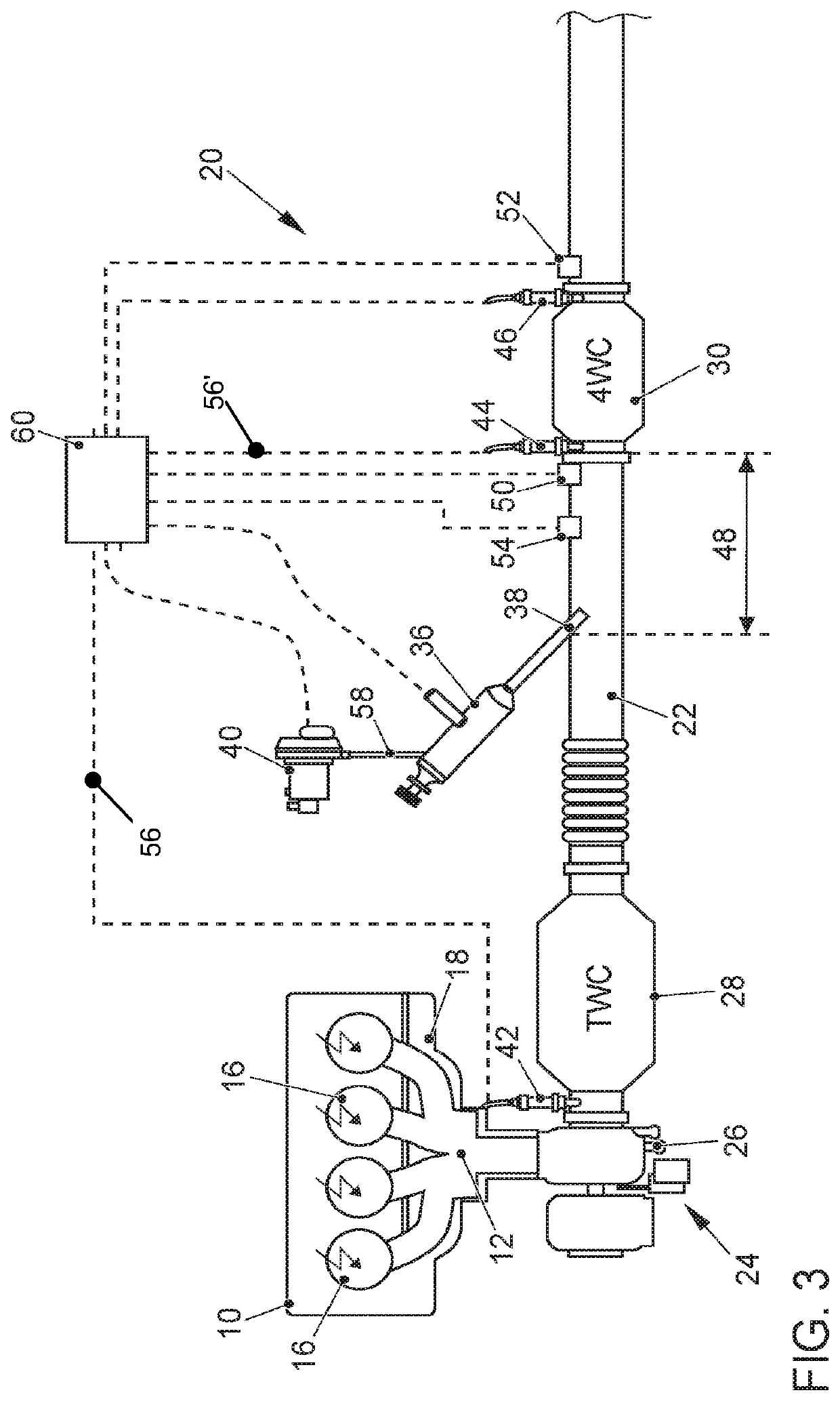

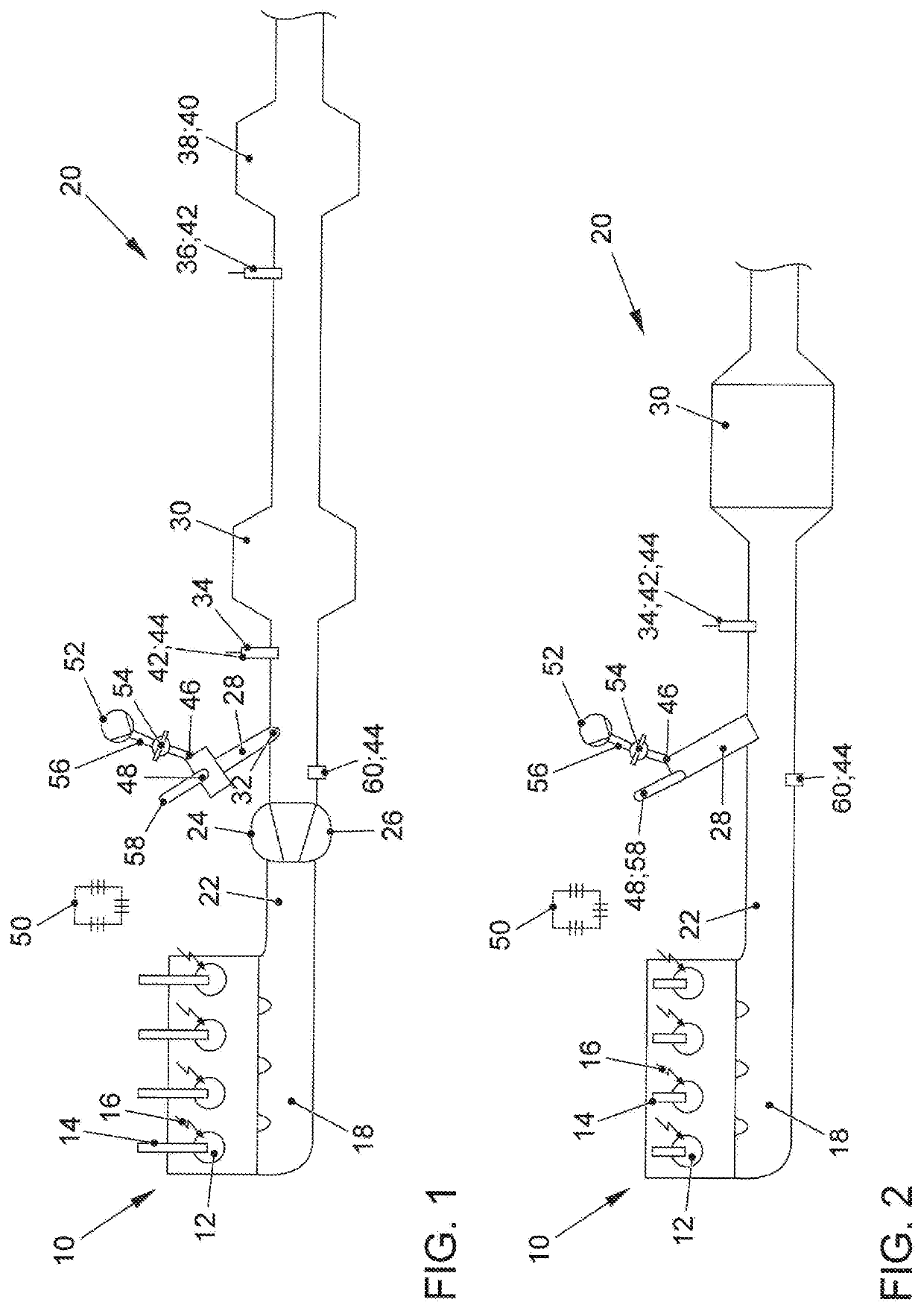

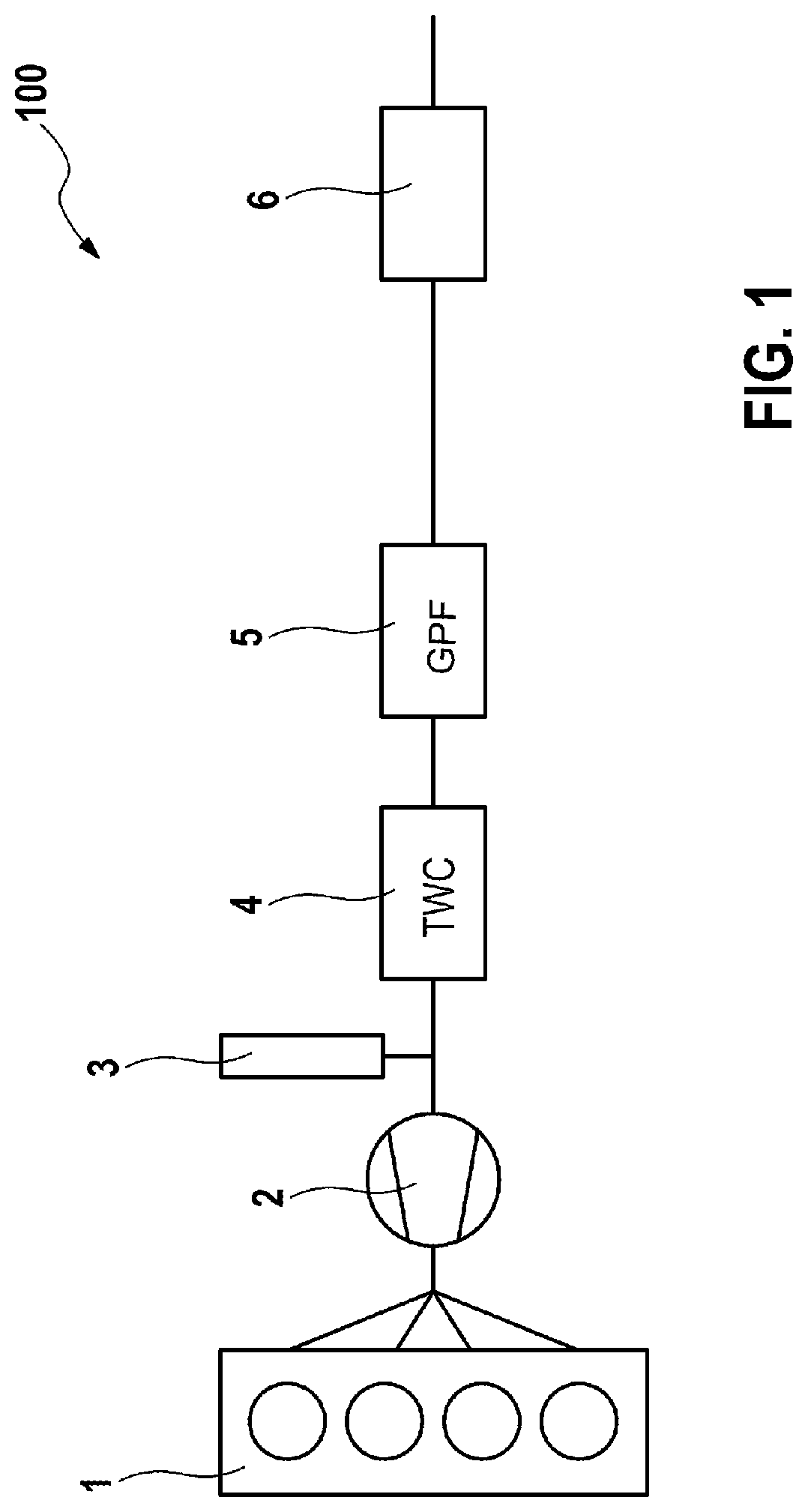

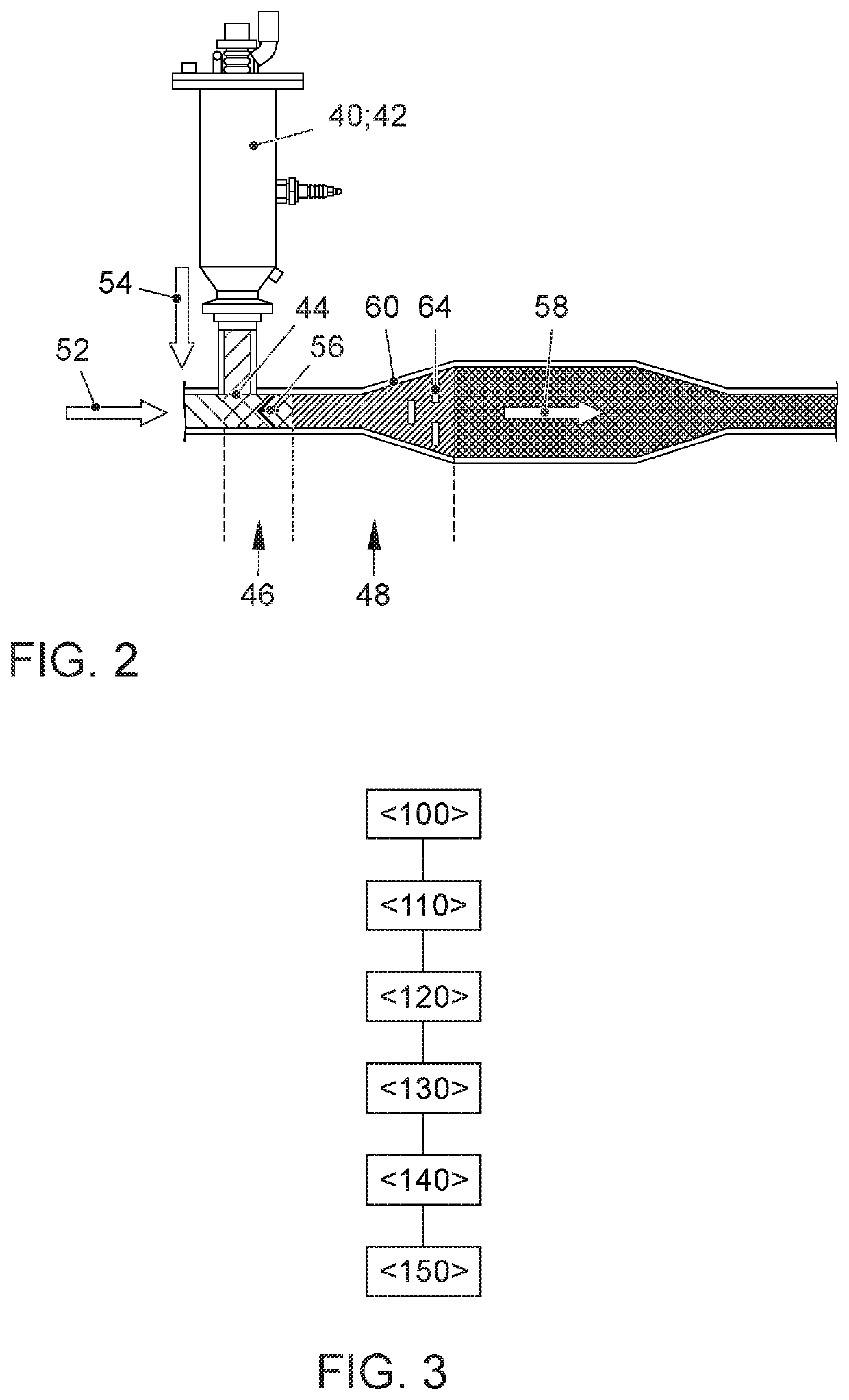

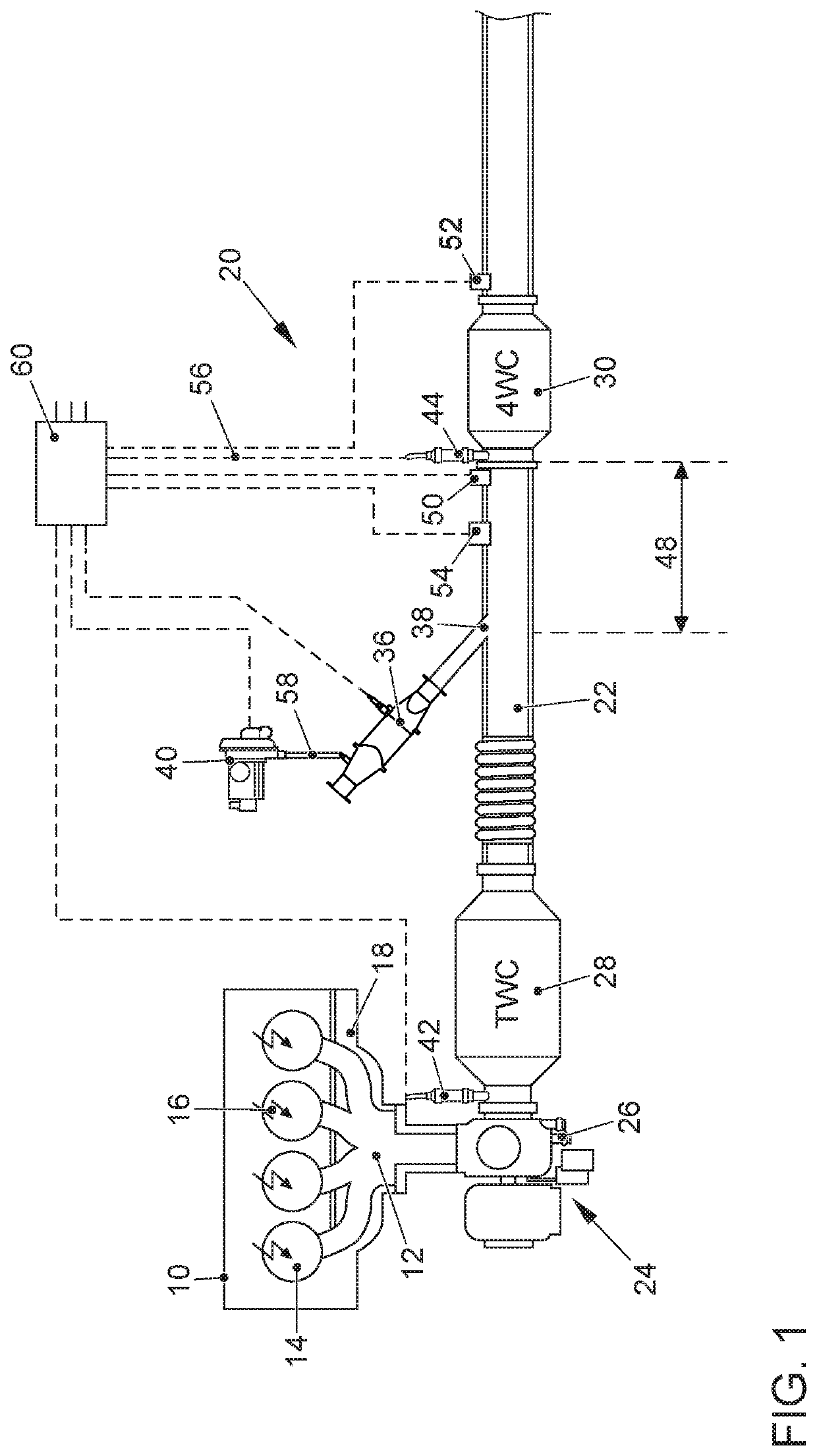

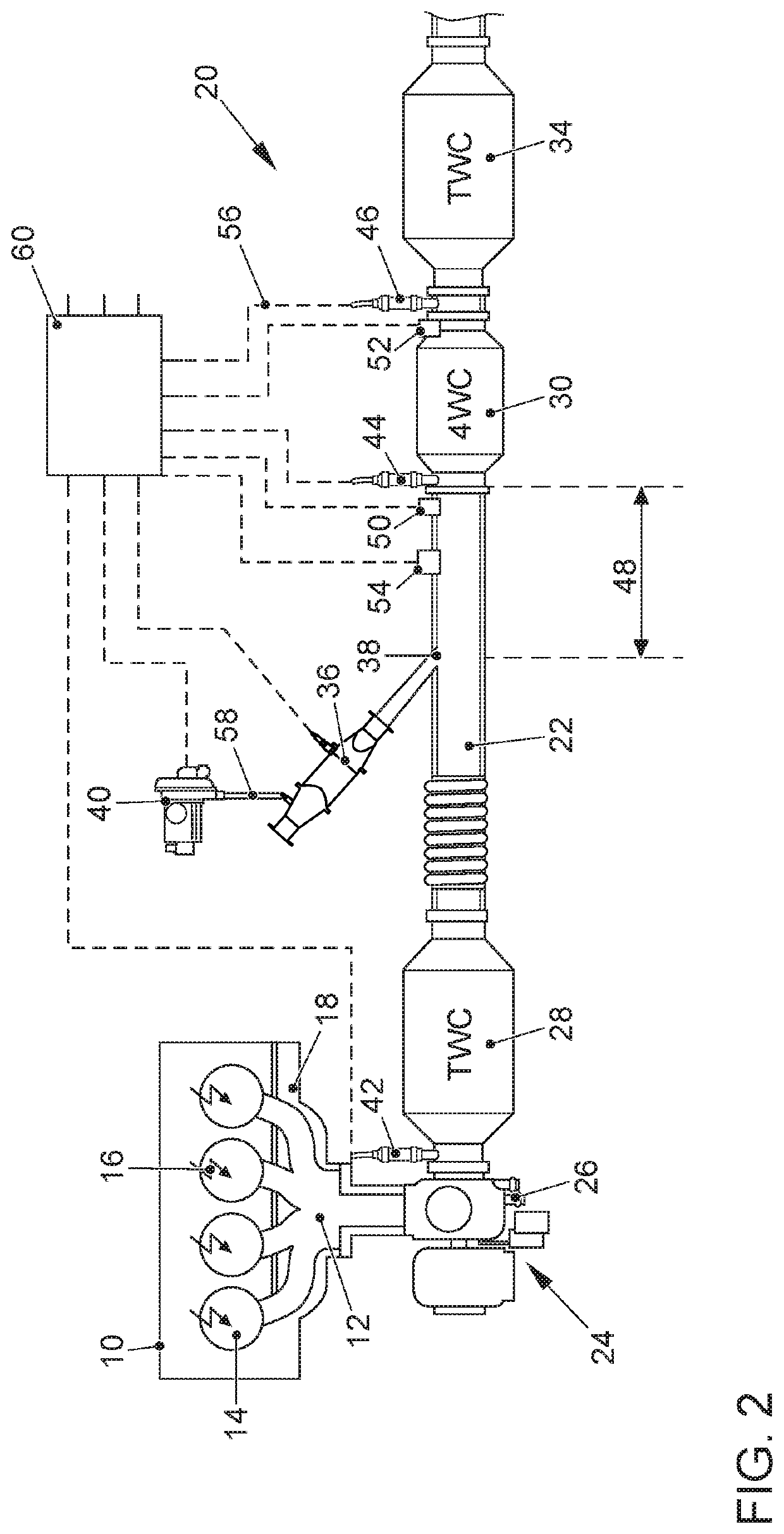

Exhaust gas aftertreatment system and method for exhaust aftertreatment of an internal combustion engine

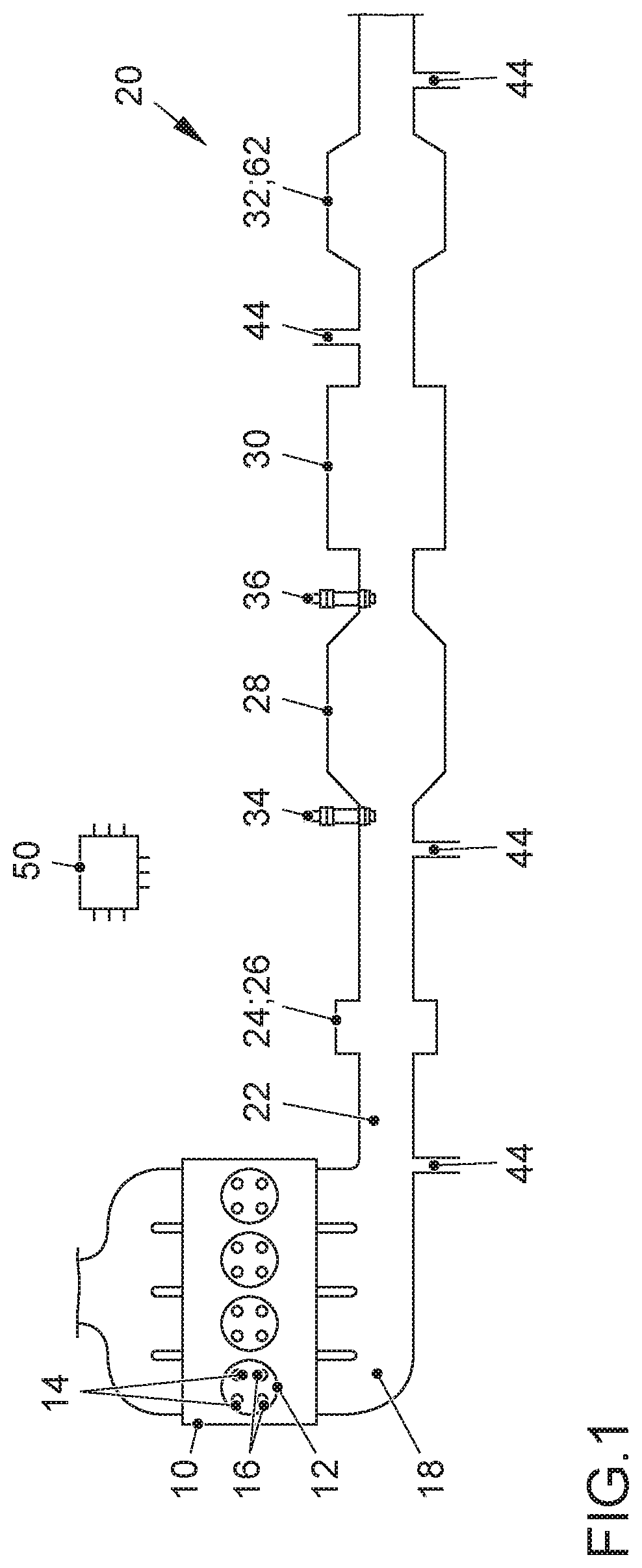

ActiveUS20190211725A1Increased tailpipe emissionReduce componentsInternal combustion piston enginesDispersed particle filtrationCombustorExternal combustion engine

The invention relates to an exhaust gas aftertreatment system for an internal combustion engine, in particular for a gasoline engine that is spark-ignited by means of spark plugs. A first three-way catalytic converter is situated in an exhaust gas system that is connected to an outlet of the internal combustion engine in a position close to the engine. Downstream from the first three-way catalytic converter, a four-way catalytic converter or a combination of a particle filter and a second three-way catalytic converter downstream from the particle filter is situated in the underbody position of the motor vehicle. An exhaust gas burner with which hot exhaust gas is introducible into the exhaust gas system downstream from the first three-way catalytic converter and upstream from the four-way catalytic converter or the particle filter is provided at an exhaust duct of the exhaust gas system. The exhaust gas burner is supplied with fresh air by a secondary air pump. The invention further relates to a method for exhaust aftertreatment of an internal combustion engine having such an exhaust gas aftertreatment system.

Owner:VOLKSWAGEN AG

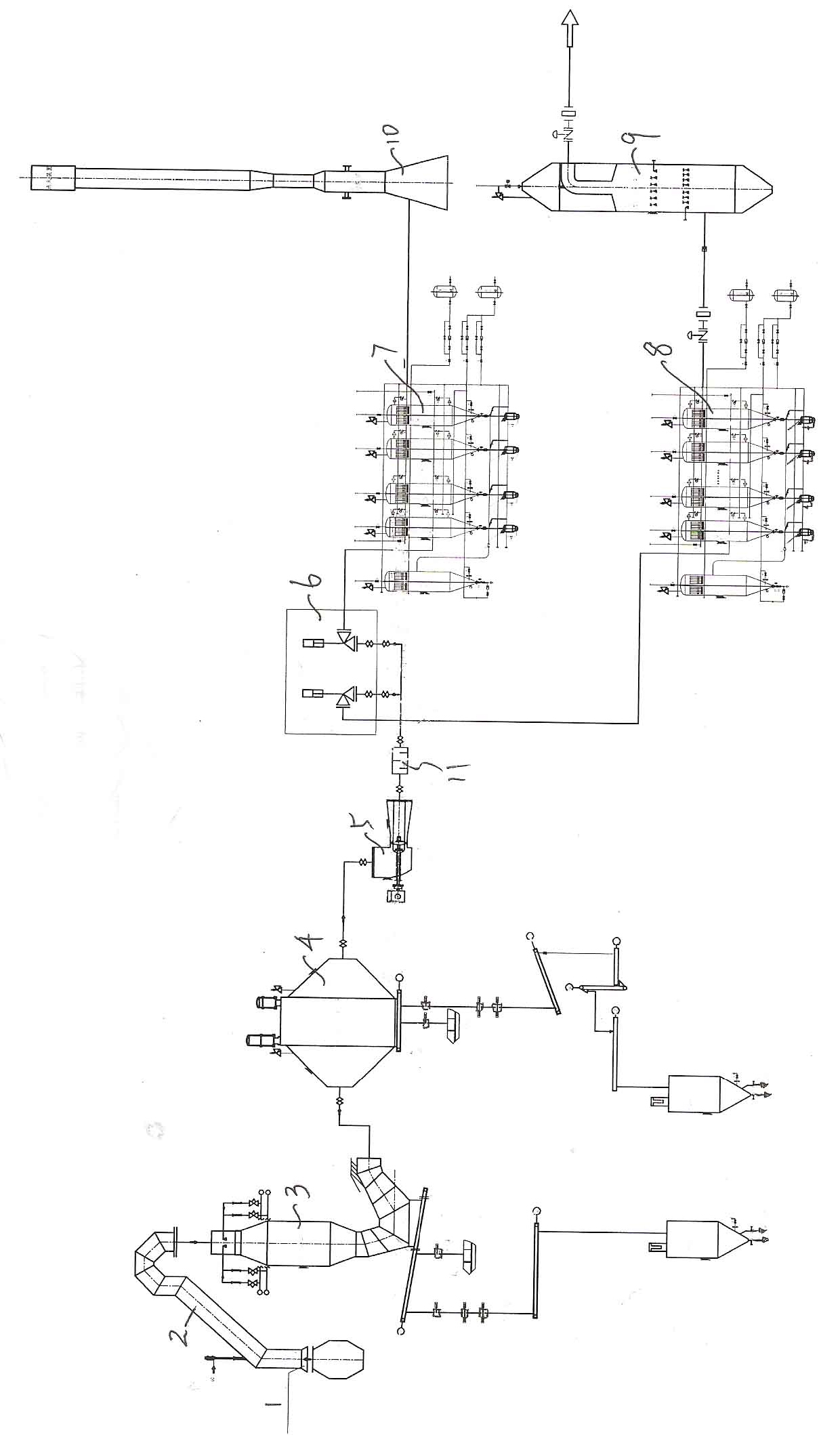

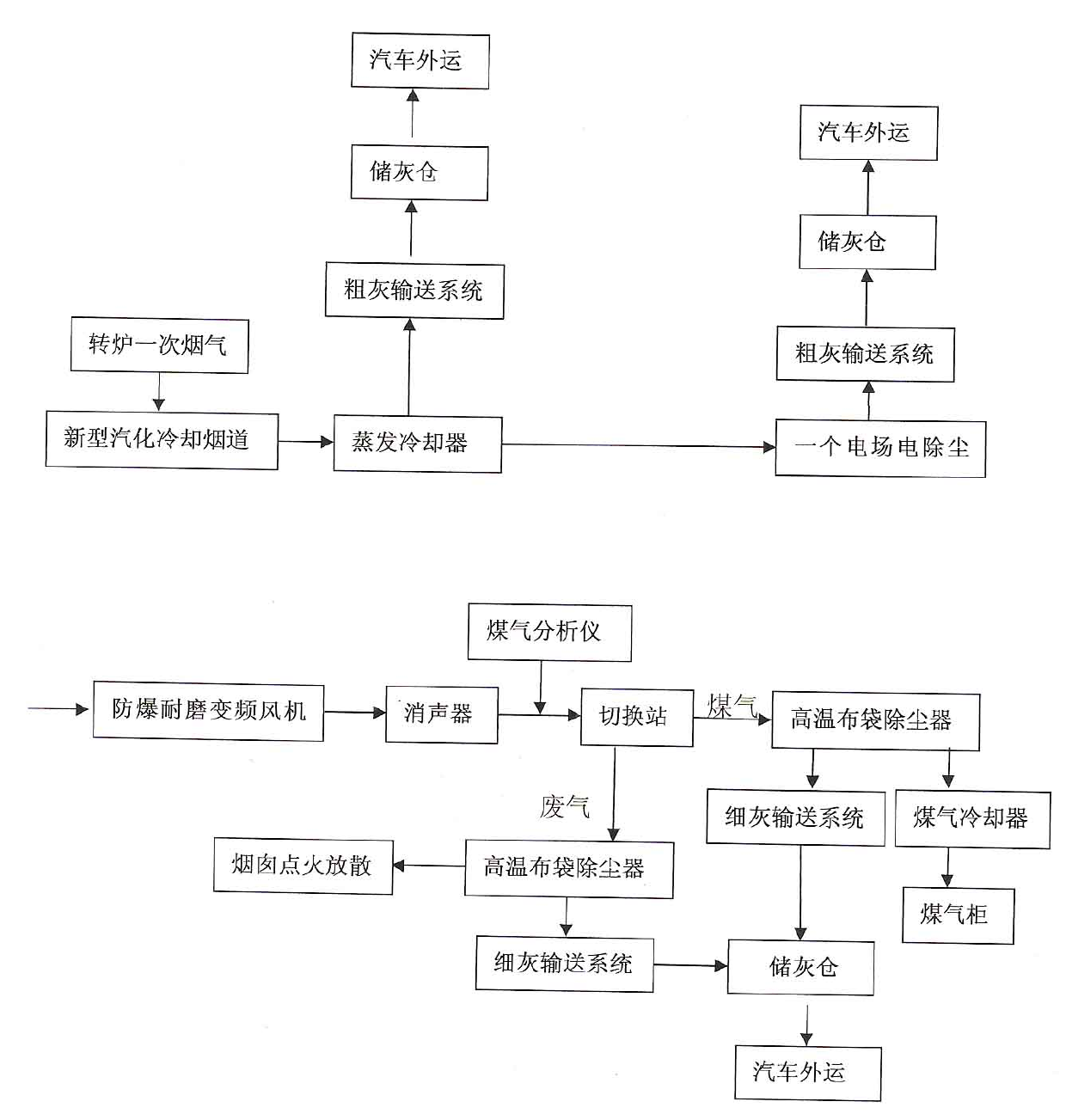

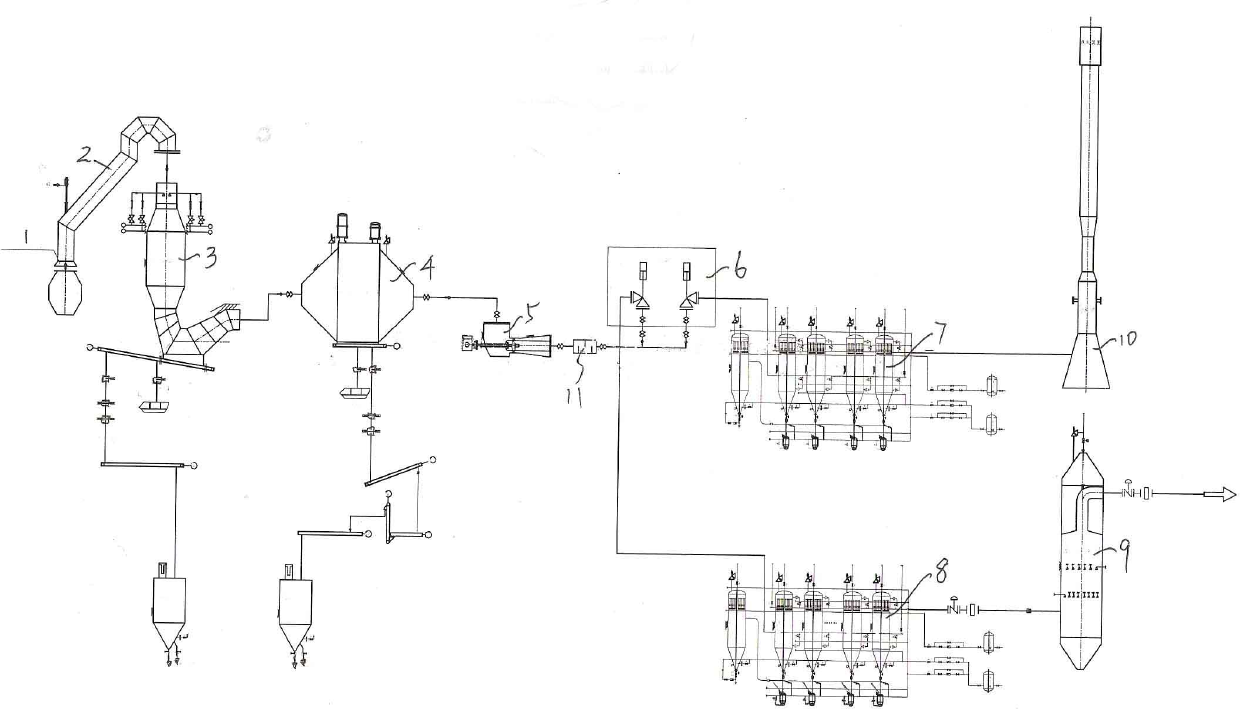

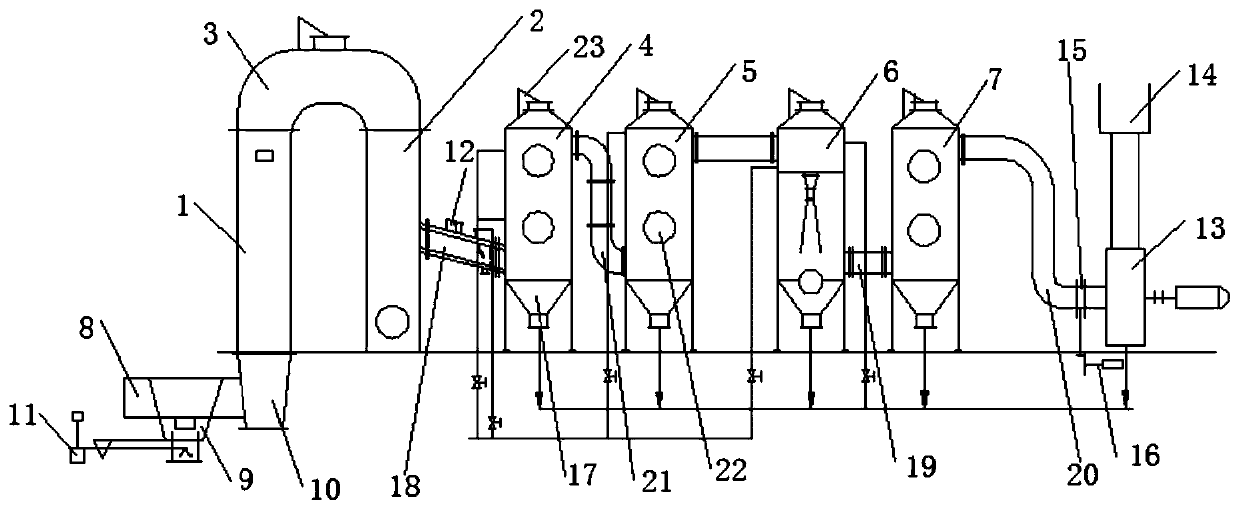

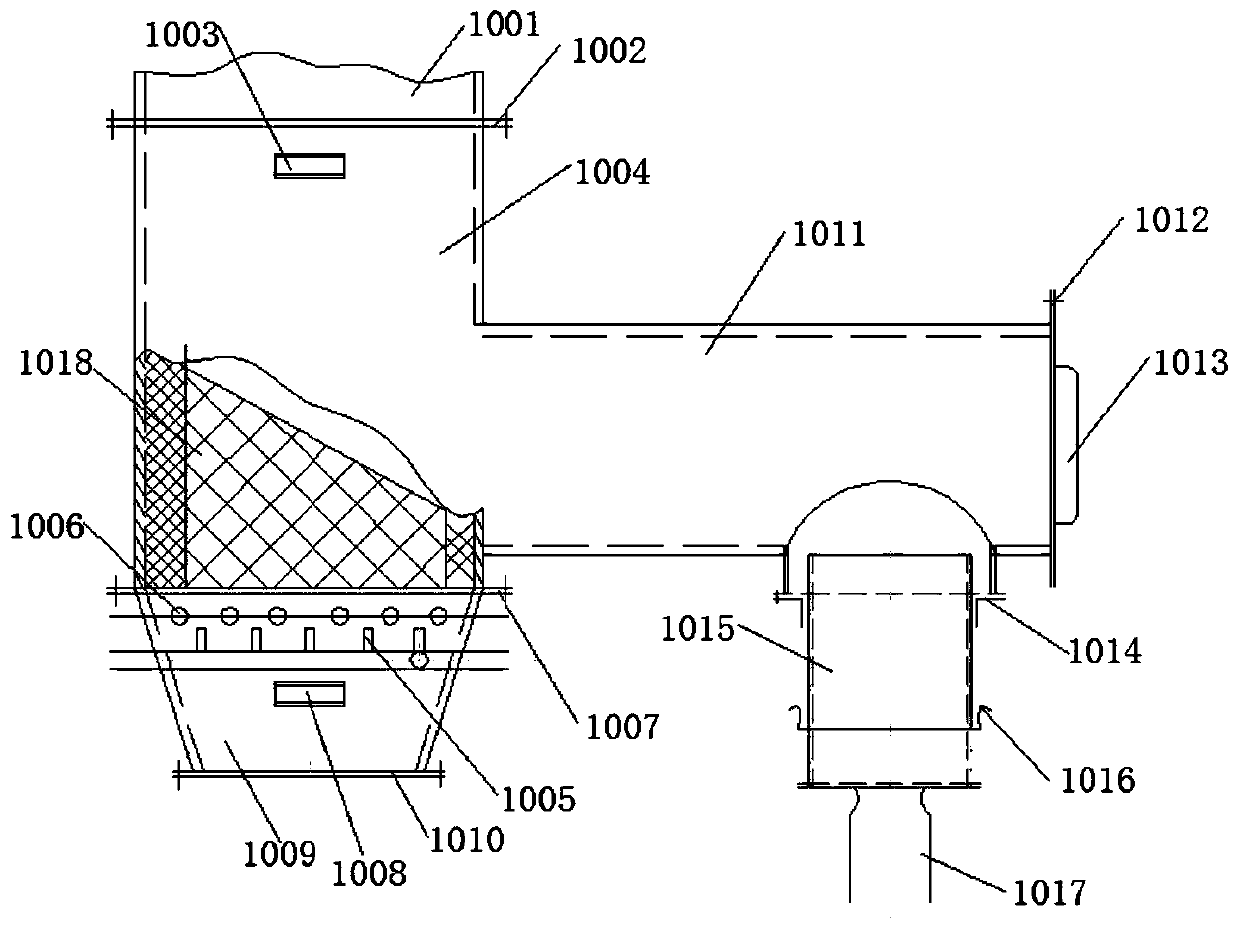

Electric-bag combined converter gas dry cleaning and recovering system

InactiveCN102653806AReduce cooling loadReduce the amount of cooling waterManufacturing convertersCooling towerCombustor

The invention discloses an electric-bag combined converter gas dry cleaning and recovering system. The system is characterized in that a gas hood is connected with an evaporation cooling stack; an evaporative cooling tower is arranged behind the evaporation cooling stack; a single-cell drum-type electrostatic dust collector is arranged behind the evaporative cooling tower; a fan is arranged behind the electrostatic dust collector; a switching station of a bag type waste gas dust collecting device and a bag type gas dust collecting device is arranged behind the fan; the bag type waste gas dust collecting device and the bag type gas dust collecting device are arranged behind the switching station; a gas cooler is arranged behind the bag type gas dust collecting device; and a waste gas burner is arranged behind the bag type waste gas dust collecting device. The system has reasonable structure and good working performances.

Owner:JIANGSU RUIFAN ENVIRONMENTAL PROTECTION EQUIPCO

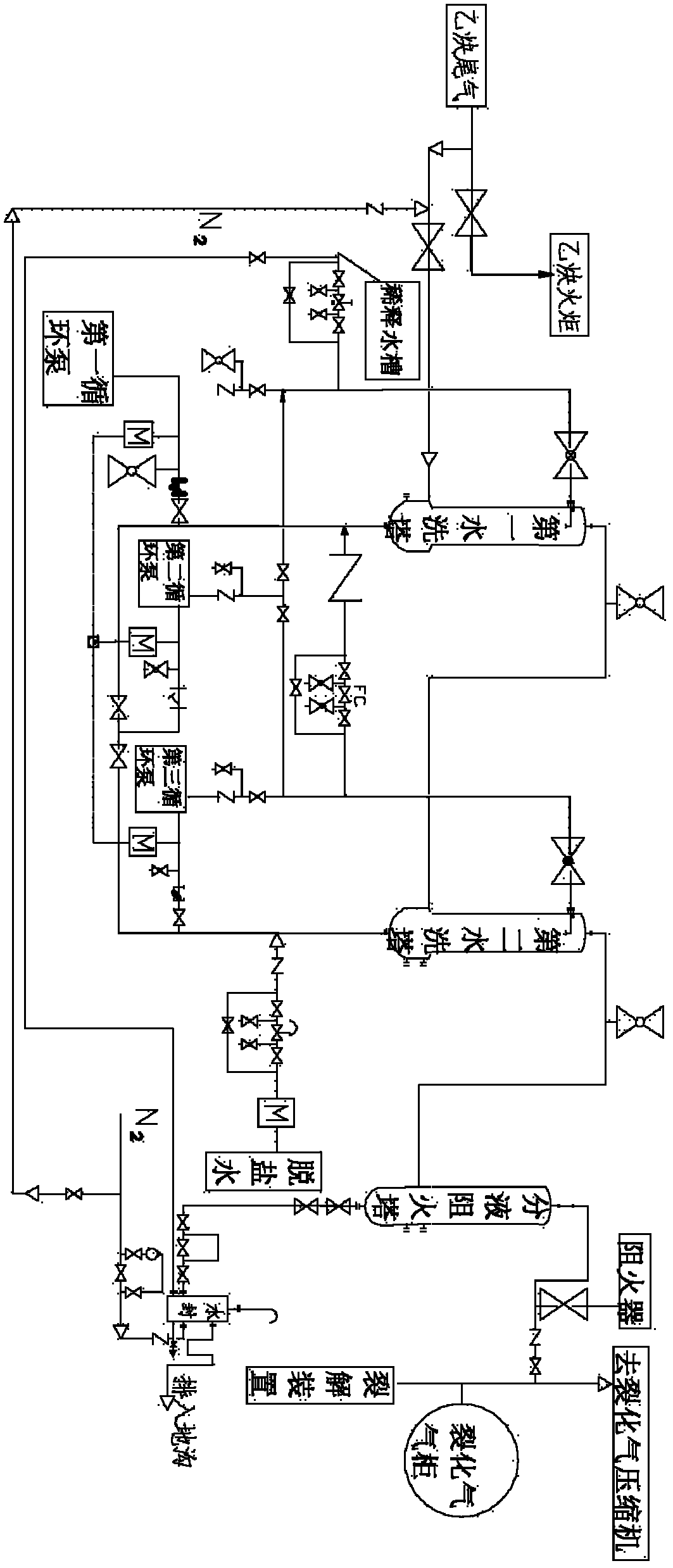

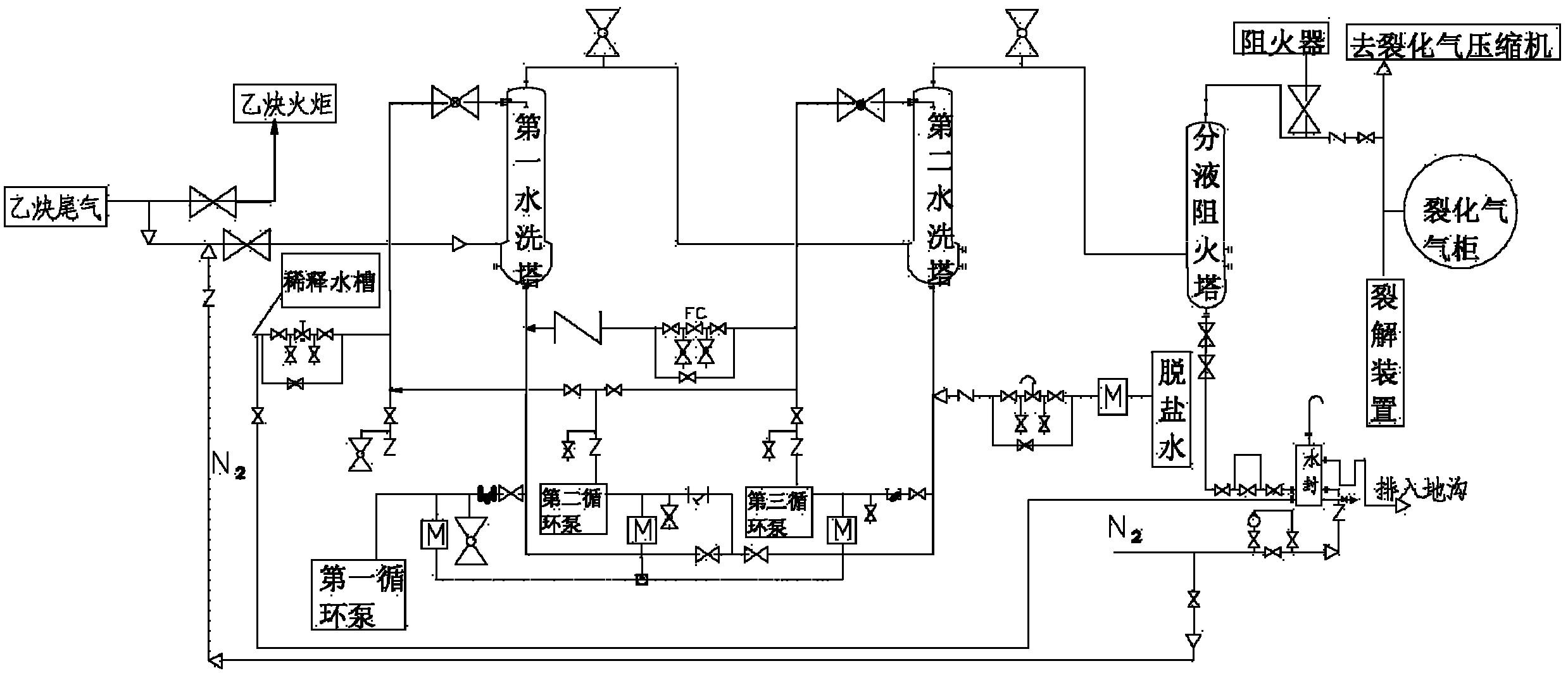

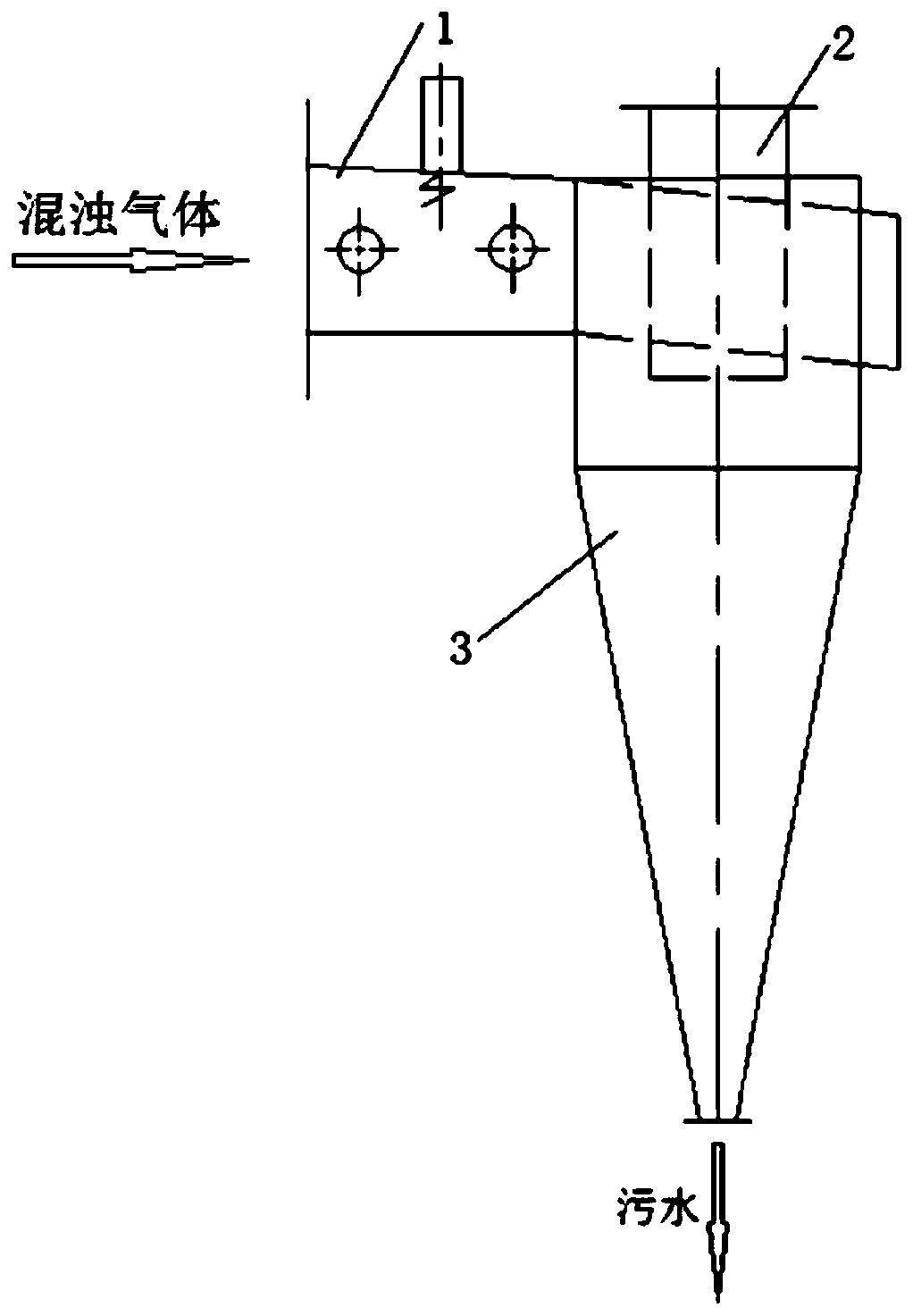

Acetylene tail gas recovery device

InactiveCN102357330AReach the purpose of recyclingDispersed particle separationAbsorption purification/separationProcess engineeringTower

The invention relates to an acetylene tail gas recovery device, which belongs to the field of energy conservation and pollution preservation and comprises a tee joint. Three ends of the tee joint are respectively connected with an acetylene tail gas discharge device, an acetylene torch and a first water washing tower. The first water washing tower is connected with a second water washing tower which is connected with a liquid separating fire retarding tower, the liquid separating fire retarding tower is connected with a cracked gas removal compressor inlet, and a cracked gas removal compressor outlet is connected with an extracting and concentrating device. Acetylene tail gas firstly enters the first water washing tower to be carried out preliminary washing, and then enters the second water washing tower to be carried out secondary washing. After two-stage washing of the tail gas, methanal in the tail gas is almost soluble in washing liquid completely, purified tail gas passes through the liquid separating fire retarding tower to be directly sent to an inlet of the cracked gas removal compressor inlet and mixed with pyrolysis gas, and then sent to the extracting and concentrating device after being pressurized by a cracked gas removal compressor, so that recovery and reusing purposes are achieved.

Owner:XINJIANG MARKORCHEM

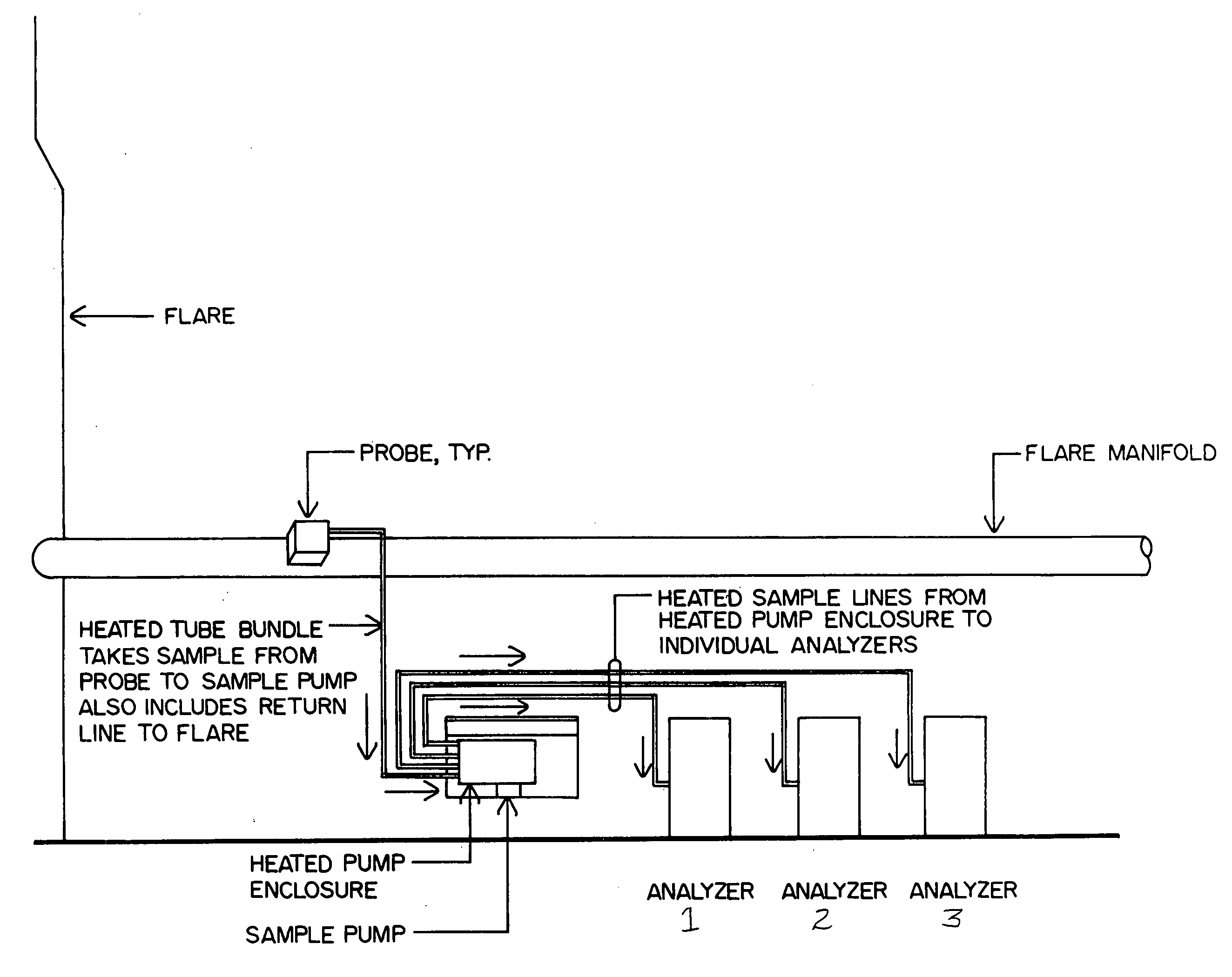

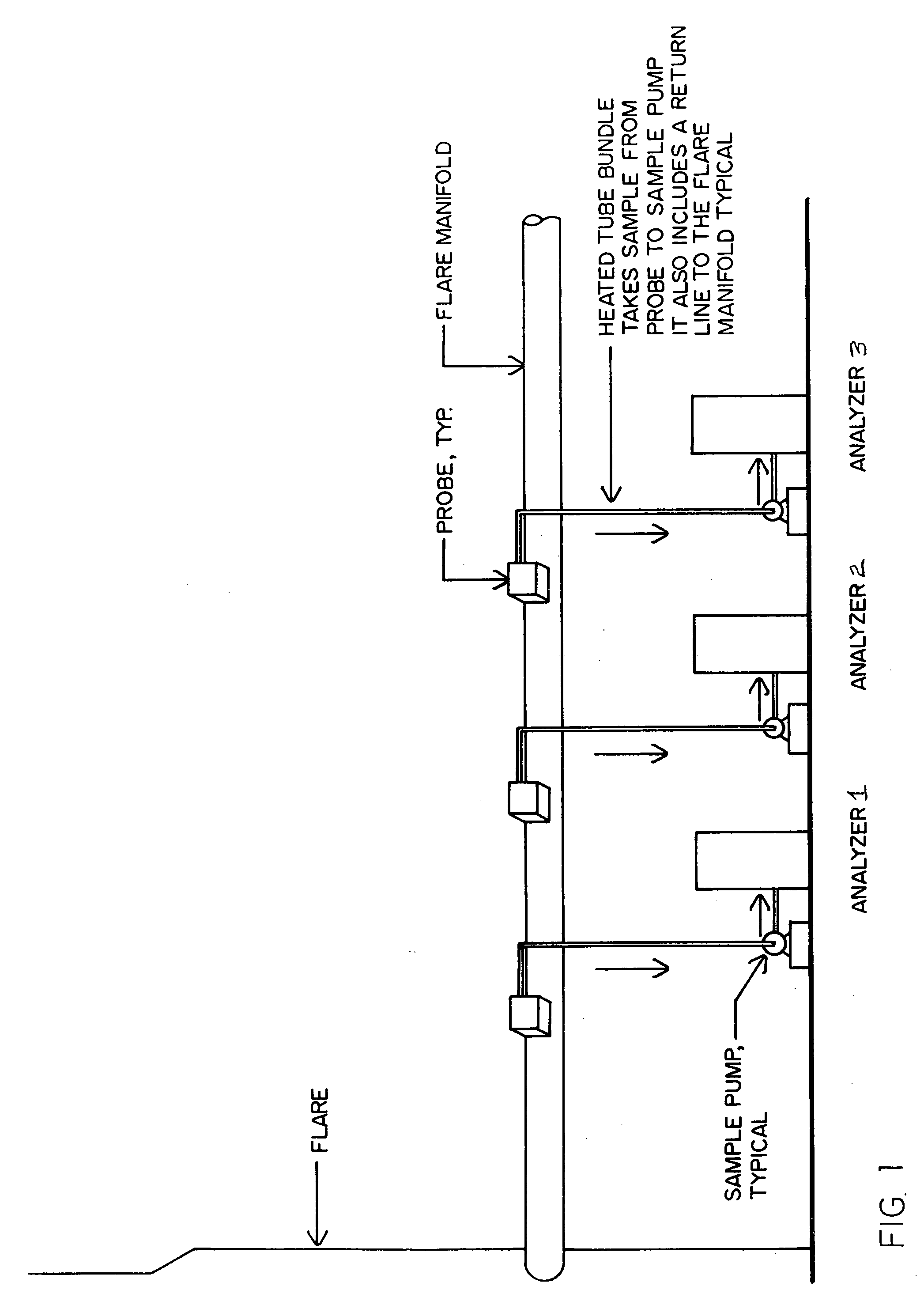

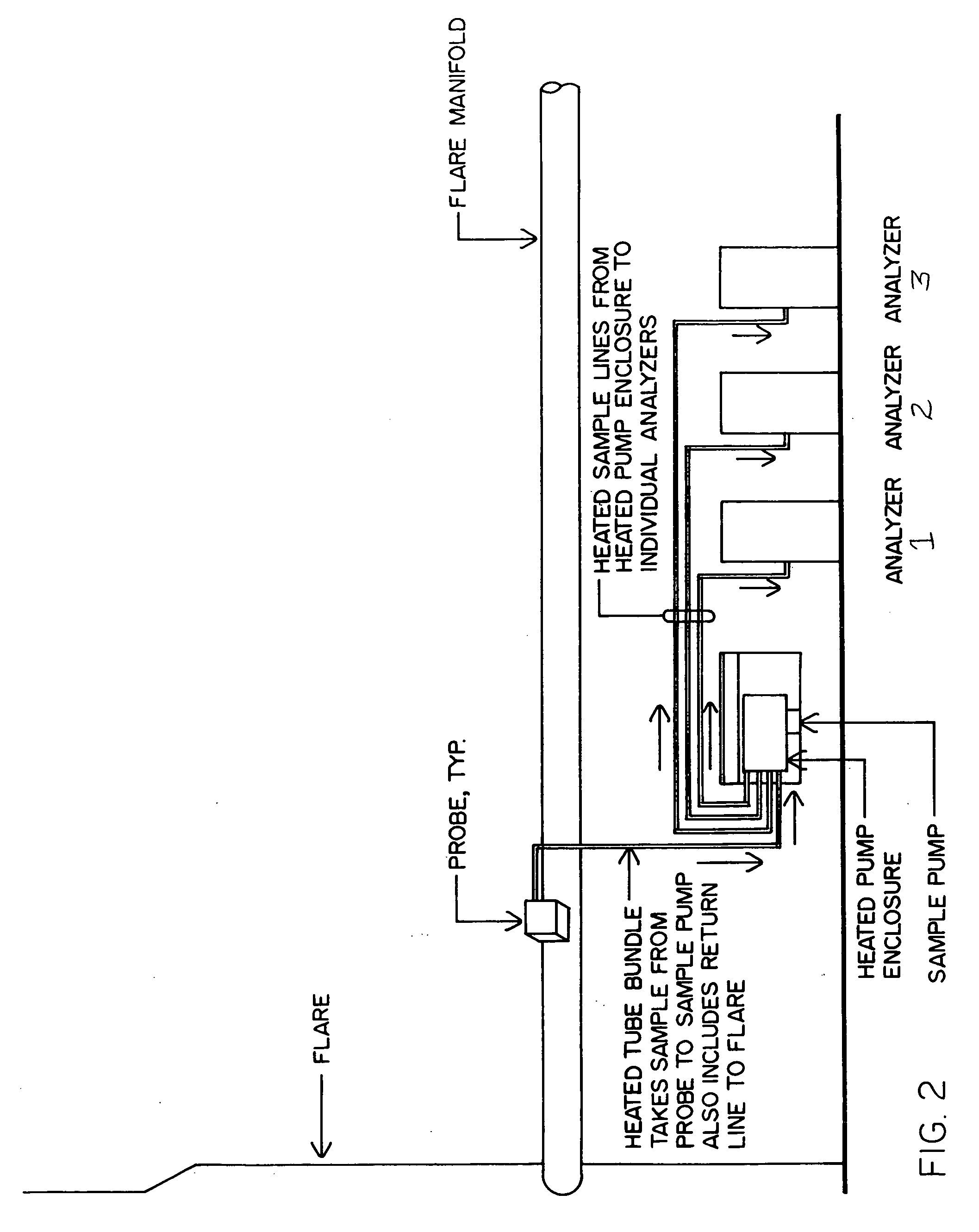

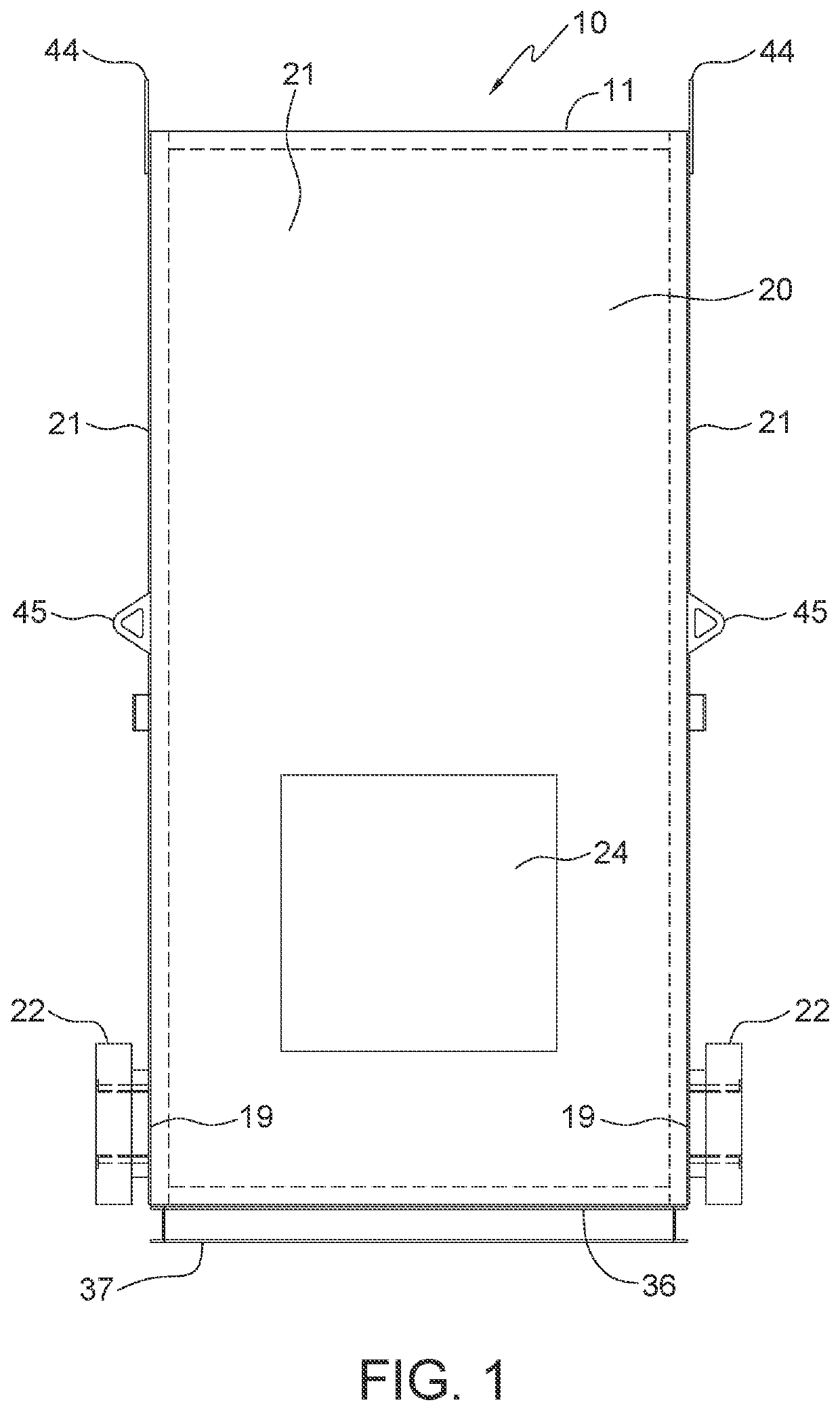

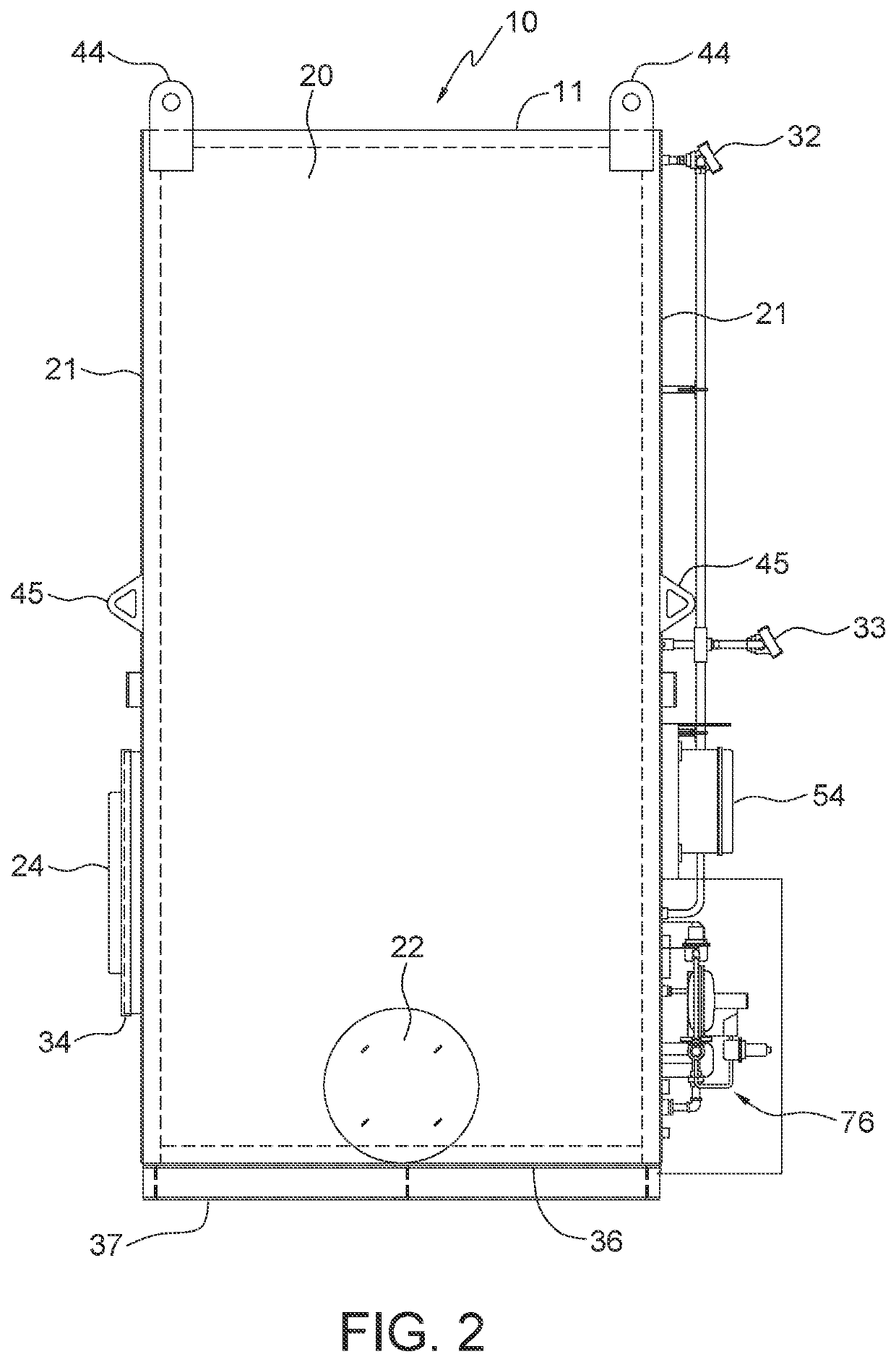

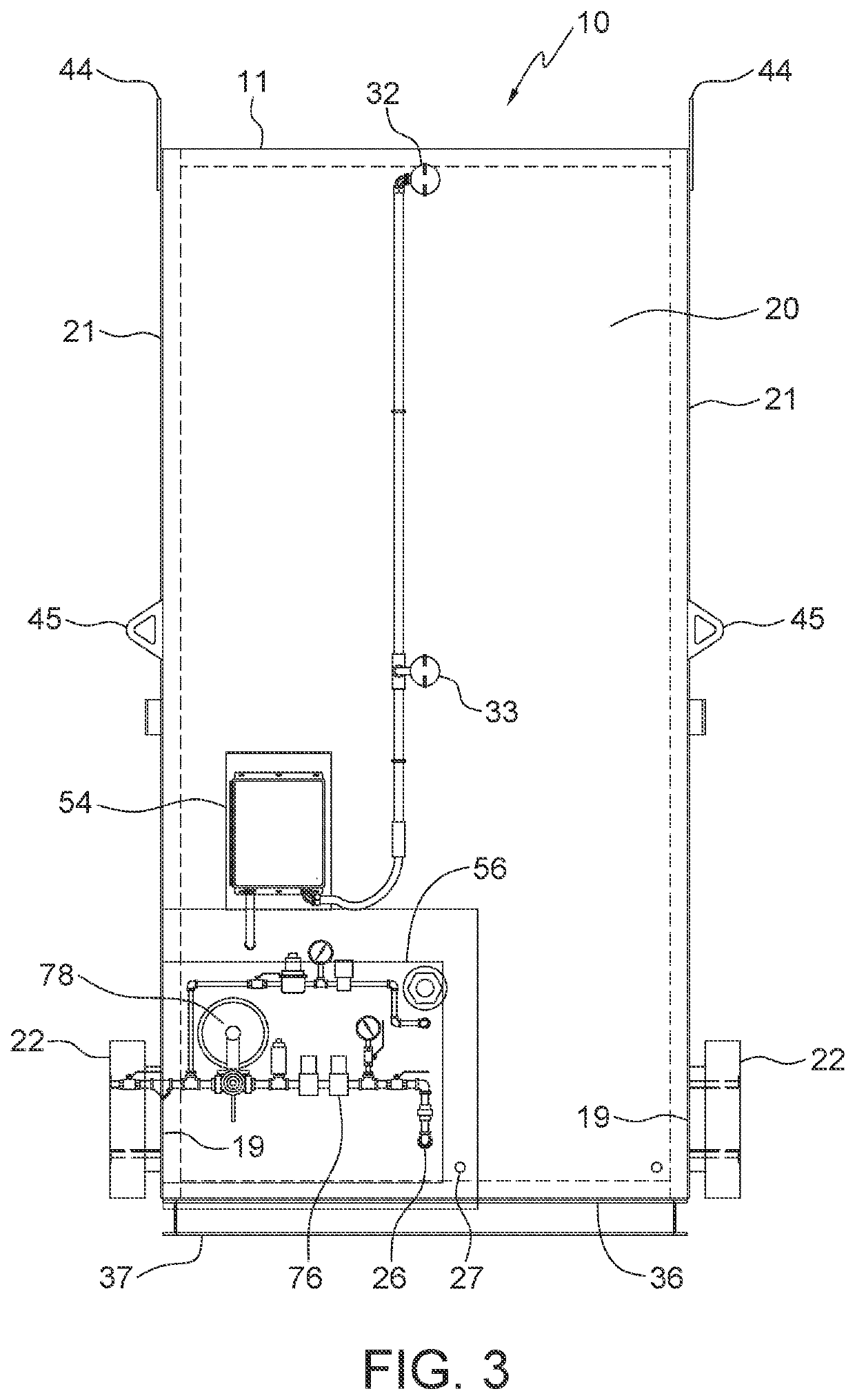

High temperature enclosure system for flare gas sampling

A heated sample pump enclosure maintains a regulated high temperature for the head of a pump as well as a plurality of sample lines that pass through it. The pump receives a flare sample from a process line and then discharges it to any number of external devices while maintaining a constant temperature, as it is being switched and routed within the heated enclosure. There are electrical, thermo and process safety shutdown systems that regulate and monitor the process within the enclosure by means of electrical instrumentation and temperature controls. The enclosure as well as the required equipment is preferably packaged as a unit.

Owner:MANGAN

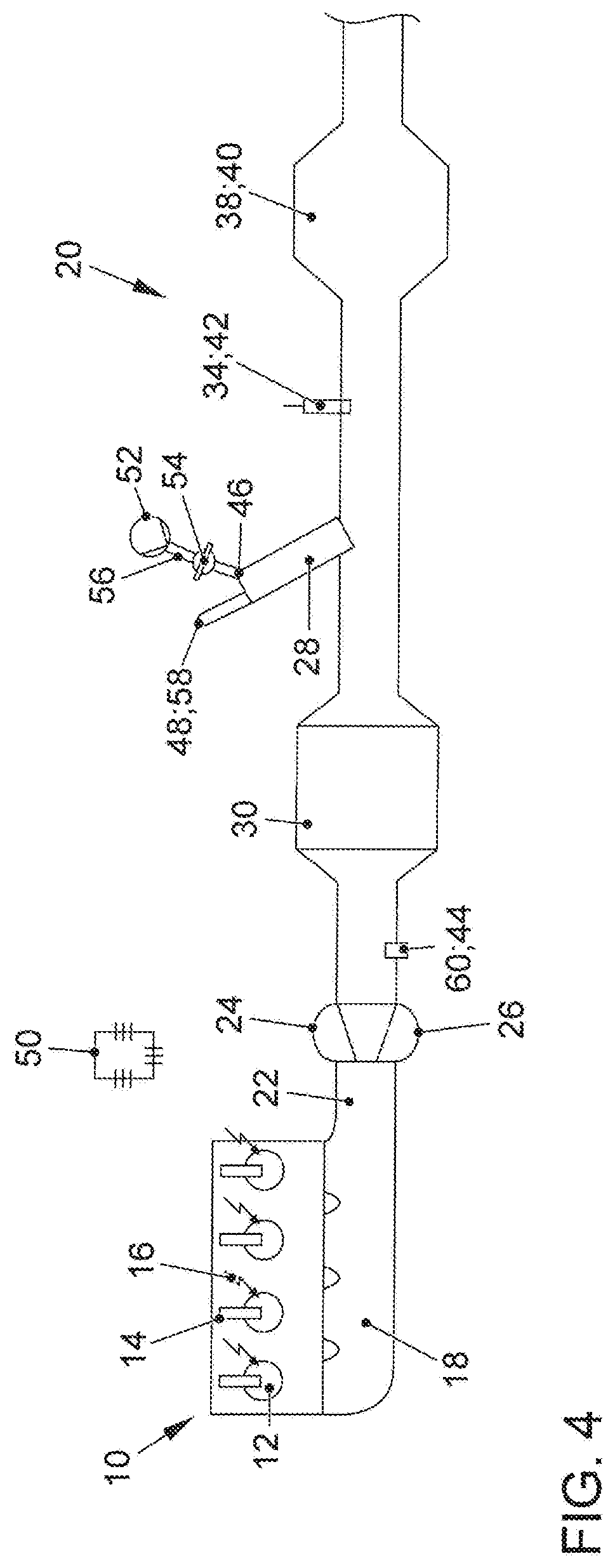

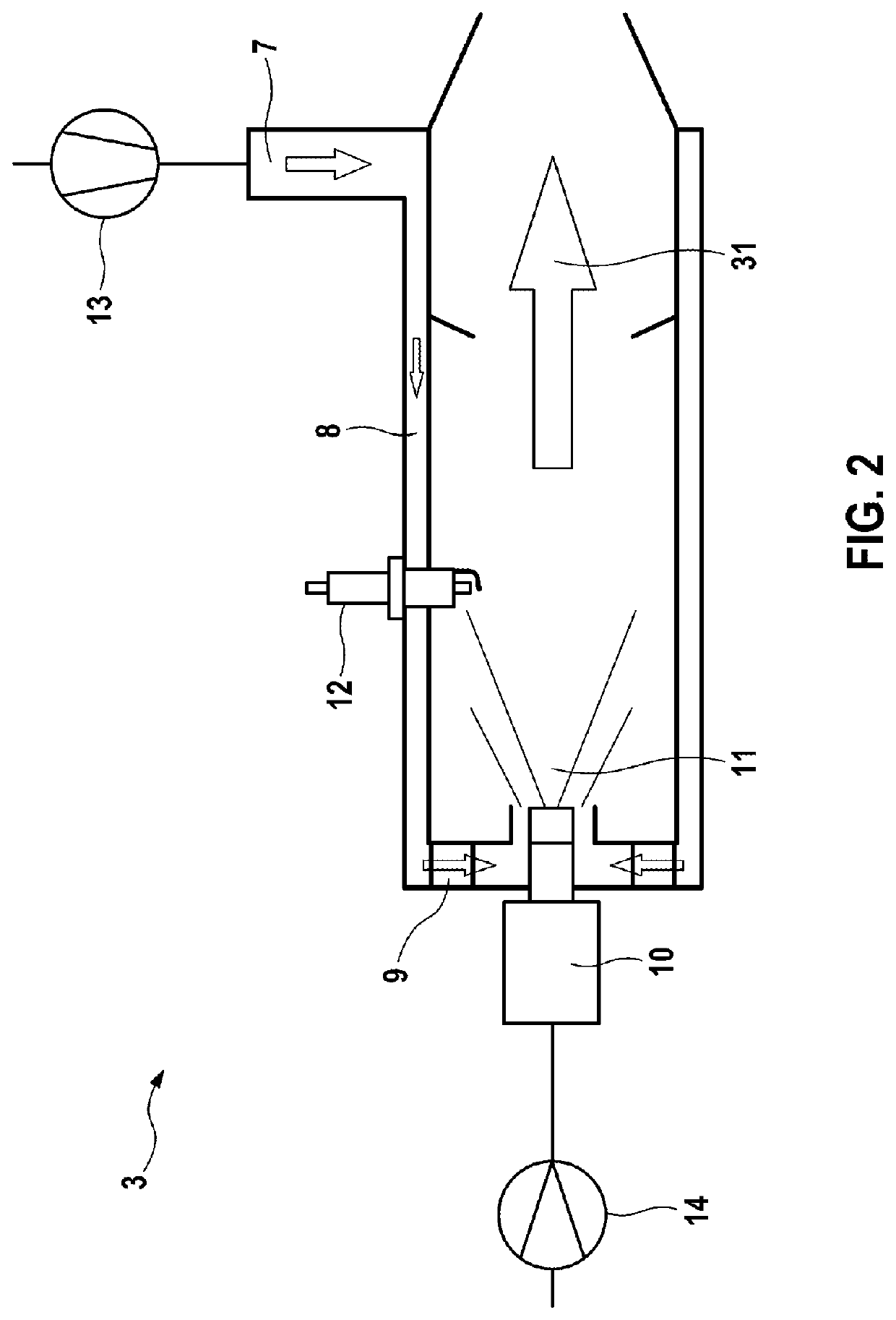

Method for the exhaust aftertreatment of an internal combustion engine and exhaust aftertreatment system

ActiveUS20200040784A1Emission reductionInternal combustion piston enginesExhaust apparatusCombustorExhaust fumes

The invention relates to a method for the exhaust aftertreatment of an internal combustion engine, which on the outlet side is connected to an exhaust gas system. Provided in the exhaust gas system is at least one exhaust aftertreatment component with which, upon reaching the light-off temperature of this exhaust aftertreatment component, the gaseous limited exhaust gas components may be converted into unlimited exhaust gas components. An introduction point is provided at an exhaust duct of the exhaust gas system, at which a hot gas, in particular an exhaust gas of an exhaust gas burner, is introduced into the exhaust duct. The hot gas mixes with the exhaust gas of the internal combustion engine in such a way that a hot mixed gas results in which the unburned exhaust gas components are oxidized to unlimited exhaust gas components, without a catalytically active surface. It is provided that the introduction of the hot gas is set as soon as the exhaust gas components of the exhaust aftertreatment system have reached their respective light-off temperature.

Owner:VOLKSWAGEN AG

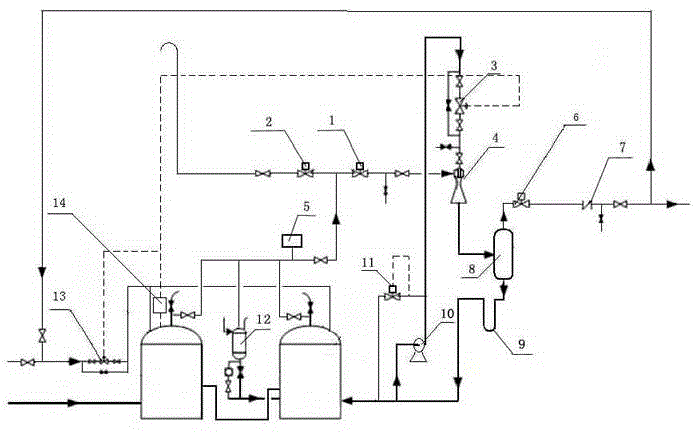

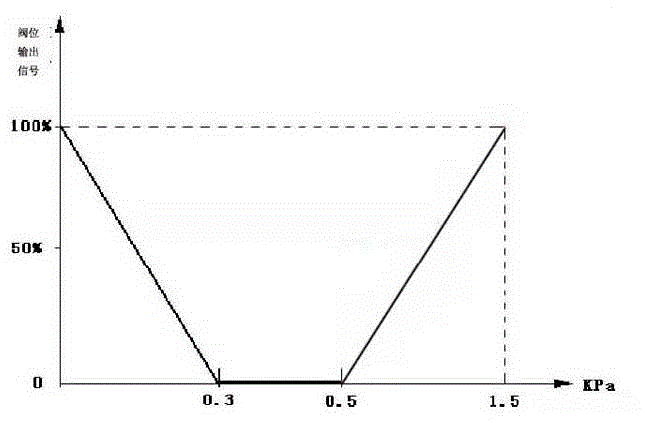

Recovery method for waste gas of refinery plant sewage tank

The invention relates to a recovery method for waste gas of a refinery plant sewage tank, which is used for sewage disposal of refiner plant sewage tanks. The invention discloses (1) a construction procedure of a recovery device for waste gas of a refinery plant sewage tank; and (2) normal operation (all indexes are set according to DCS); segmental automatic control on pressure at the top of the tank (all indexes are set according to DCS); and an instrument control scheme. According to the invention, after top and tail gas of an atmospheric storage tank are pressurized, the top and tail gas is introduced to a low pressure gas flare system of a refinery plant, enters a sewage tank due to self pressure to adjust pressure, and is pressurized together with a condensate separated from a gas-liquid separation tank in a pressurizing water pump, so as to be used as the power source of an injection pressurizer, thus replacing the functions of a steam power source, achieving the purpose of zero emission, solving the difficulties of the atmospheric storage tank that operation pressure is low and operation elasticity is small, and being safe and reliable in operation, less in one-time investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP

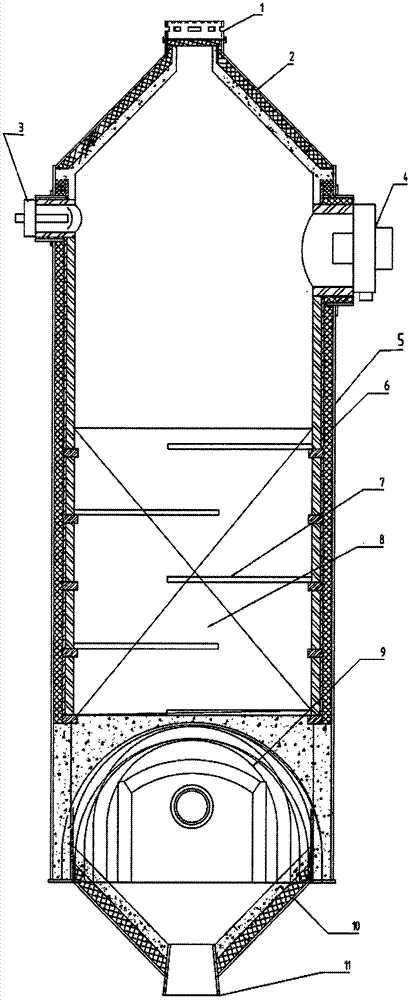

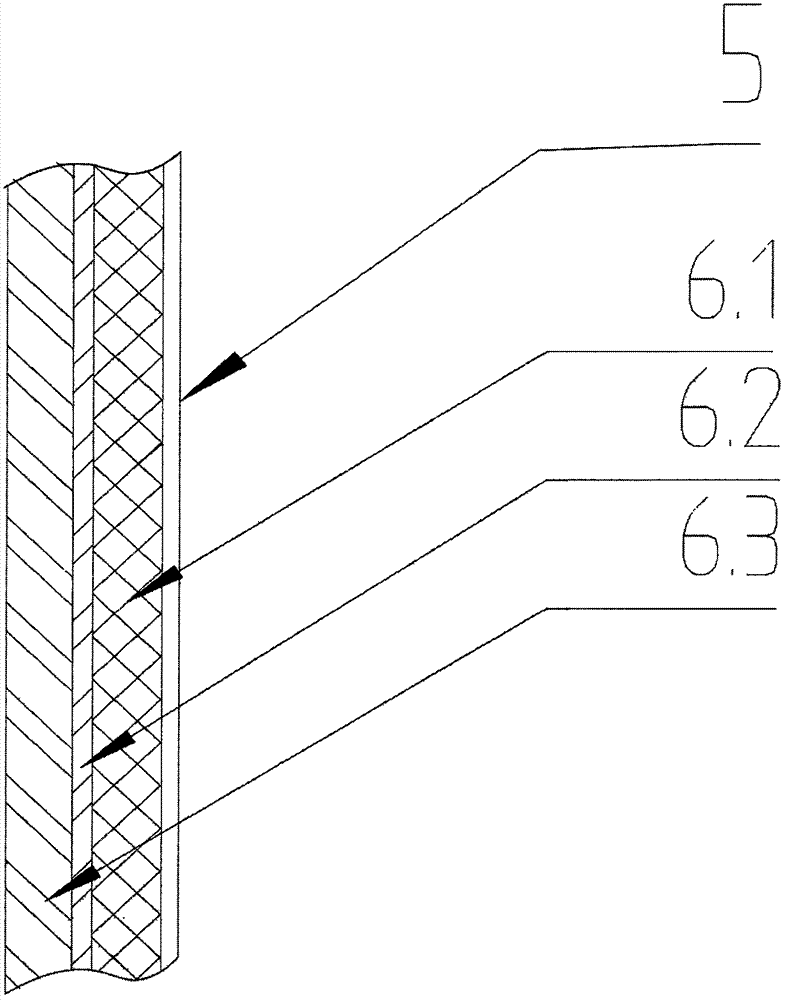

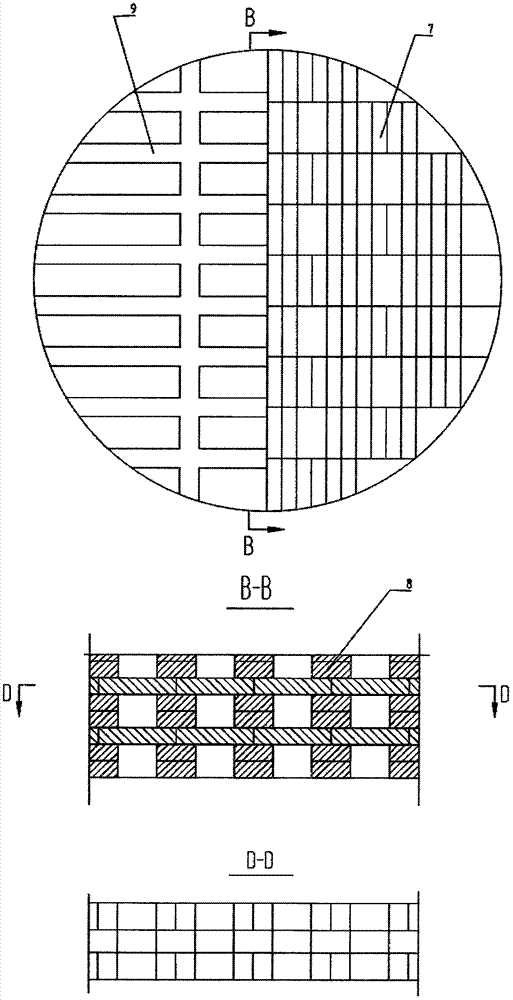

Efficient and safe low-calorific-value waste gas burner

PendingCN107543178AReduce lossesWell mixedCasings/liningsIncinerator apparatusCombustorBurn treatment

The invention discloses an efficient and safe low-calorific-value waste gas burner and belongs to the technical field of industrial low-calorific-value waste gas burning treatment waste gas burners. The efficient and safe low-calorific-value waste gas burner is mainly composed of an upper cone, a low-calorific-value burning device, a high-calorific-value burning device, a heat insulation layer, aheat storage layer and a lower cone. The efficient and safe low-calorific-value waste gas burner is characterized in that according to the burner, by arranging the heat insulation layer of a compositestructure and the multi-section turn-back-flow type heat storage layer, the upper cone, the lower cone, the low-calorific-value waste gas burning device and the high-calorific-value gas burning device are separately arranged, and it can be guaranteed that combustible waste gas and air are mixed and in contact with each other repeatedly and are ignited and burn out. The efficient and safe low-calorific-value waste gas burner has the beneficial effects that safe and efficient burning is achieved, and explosion caused by insufficient low-temperature (less than 650 DEG C) burning is avoided. Theefficient and safe low-calorific-value waste gas burner is stable in structure, easy and convenient to operate, efficient and safe.

Owner:阜阳市节能化工工程有限公司

Premixed duct burner

A fully premixed duct burner is provided that receives exhaust gas from a power generating device, such as a gas turbine or reciprocating engine. The burner may include a burner surface adapted to combust the mixture on or above the surface in blue-flame mode. Substantially all exhaust gas passes through the burner with the exception of some small fraction of exhaust gas that passes through cooling holes or slots. The burner assembly can also include an array of burner modules that receive substantially all of the exhaust gas and fully premixes the exhaust gas with burner fuel prior to combusting the mixture on or above an array of burner surfaces.

Owner:ALZETA

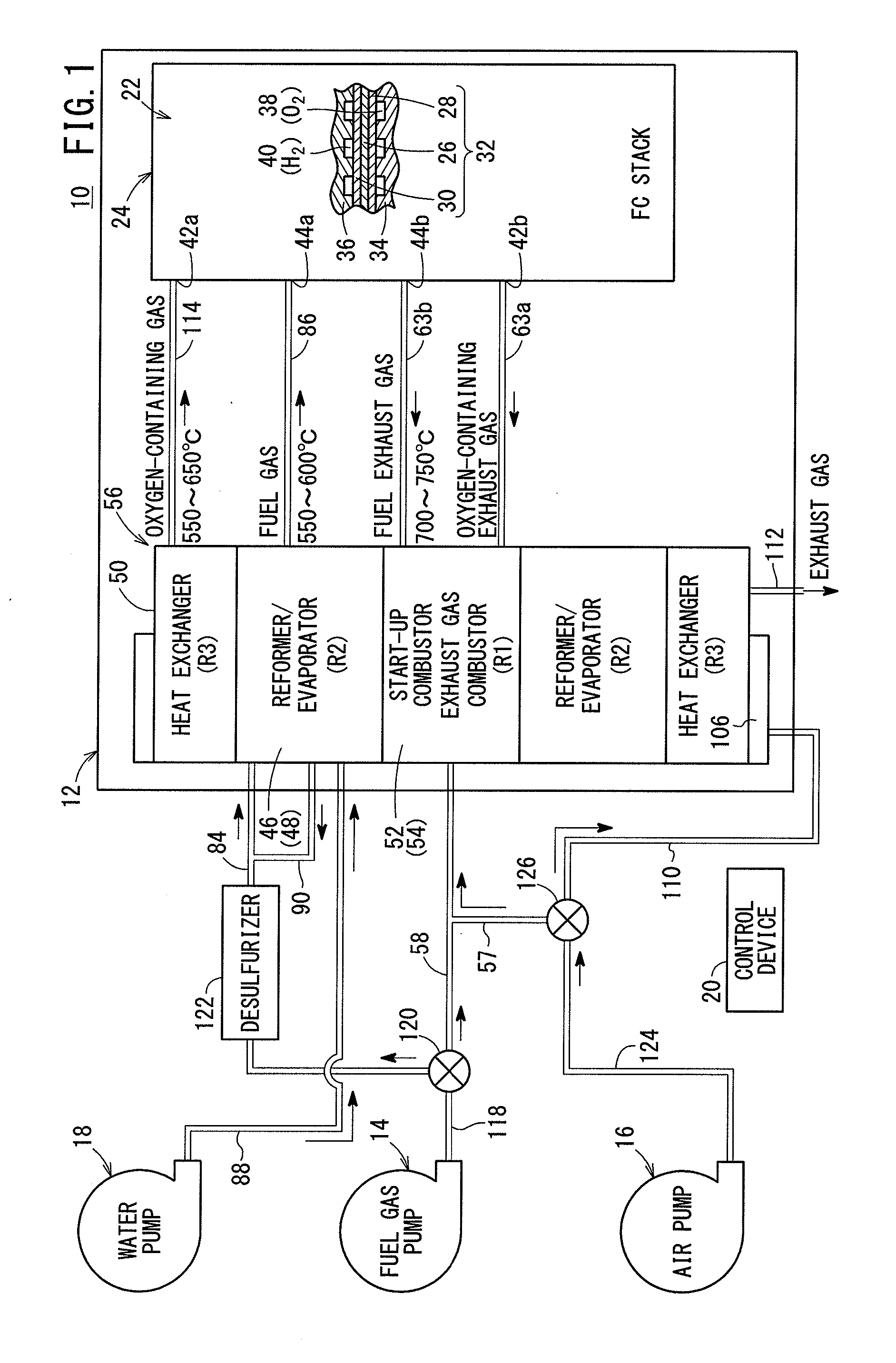

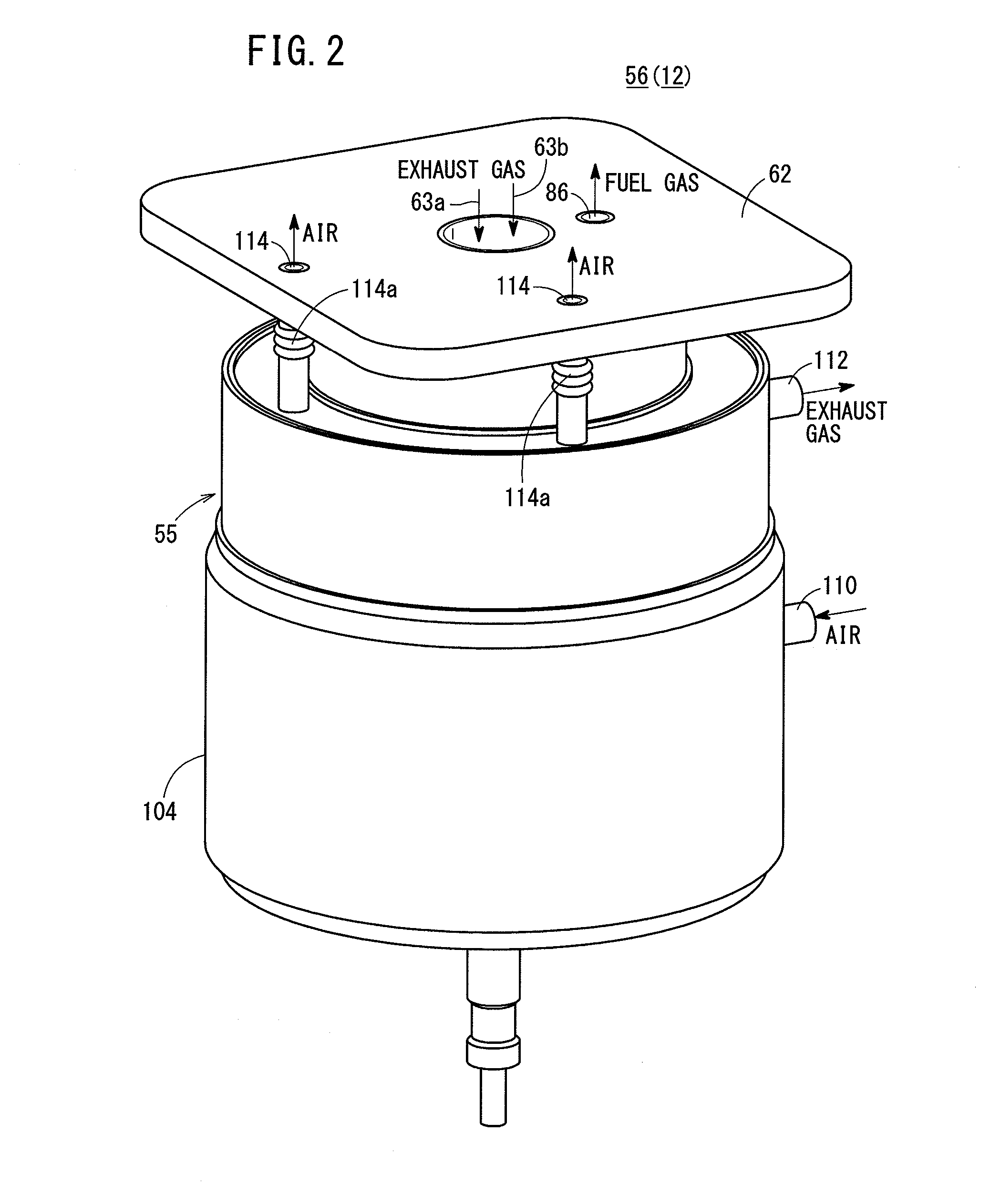

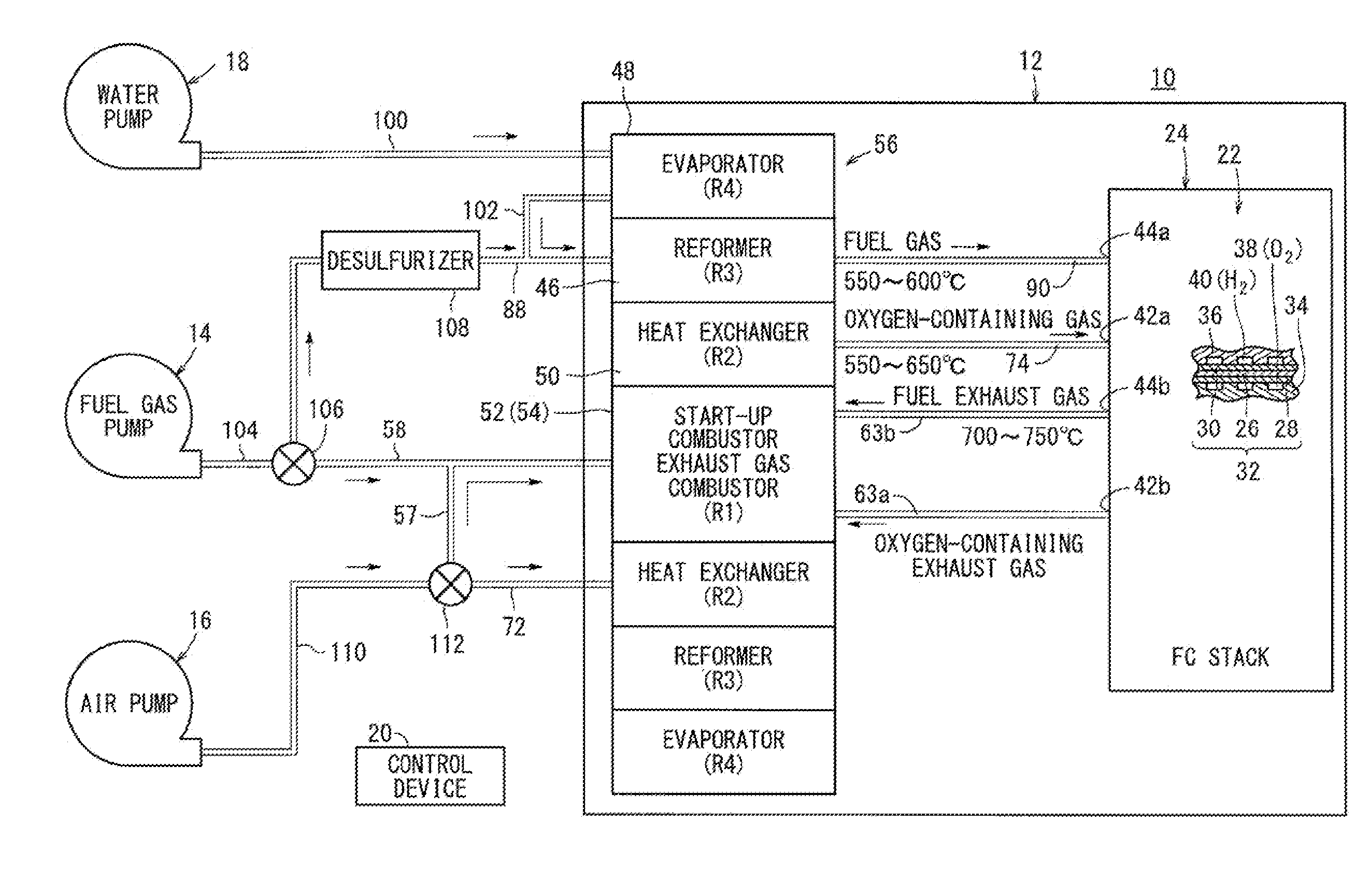

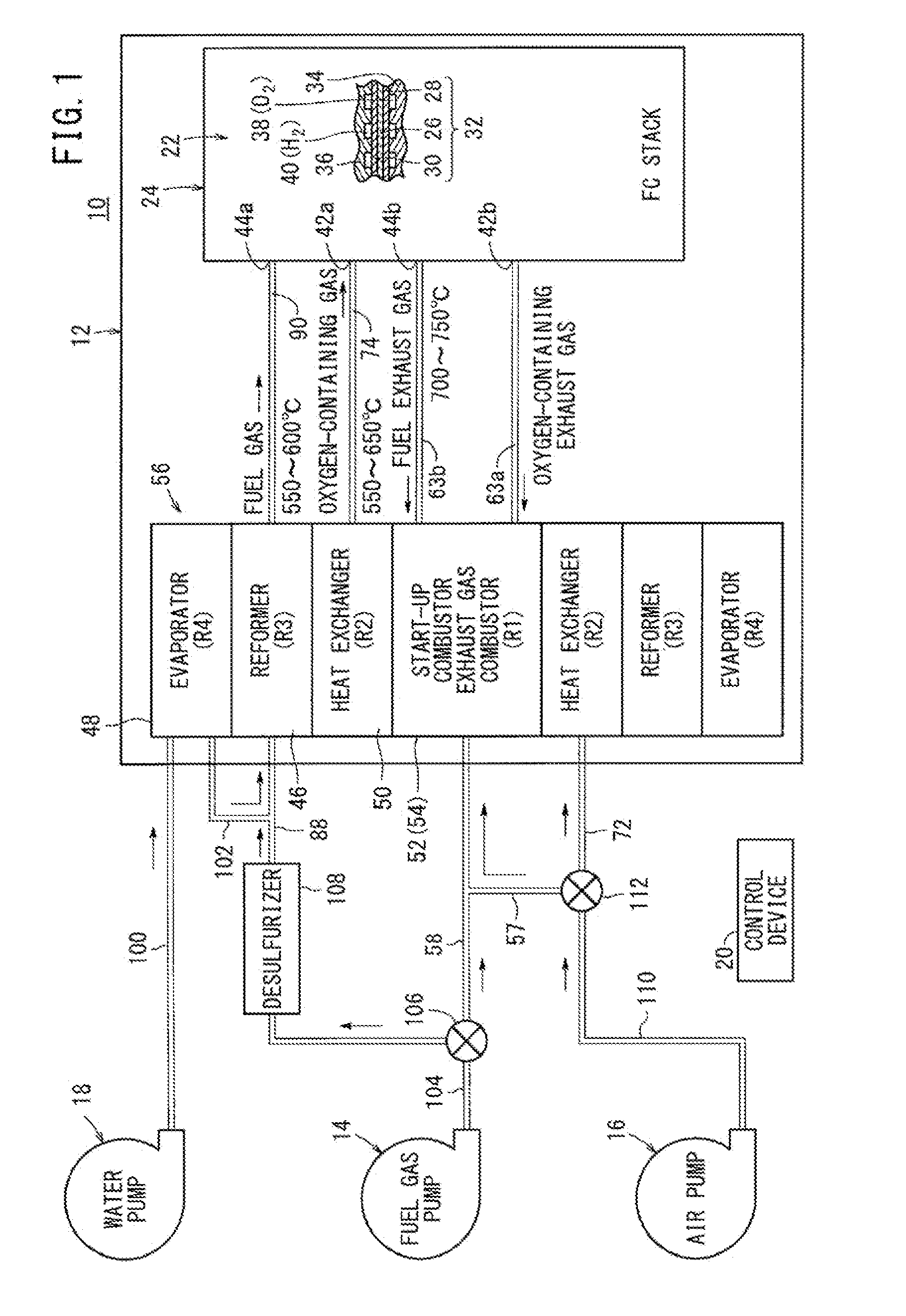

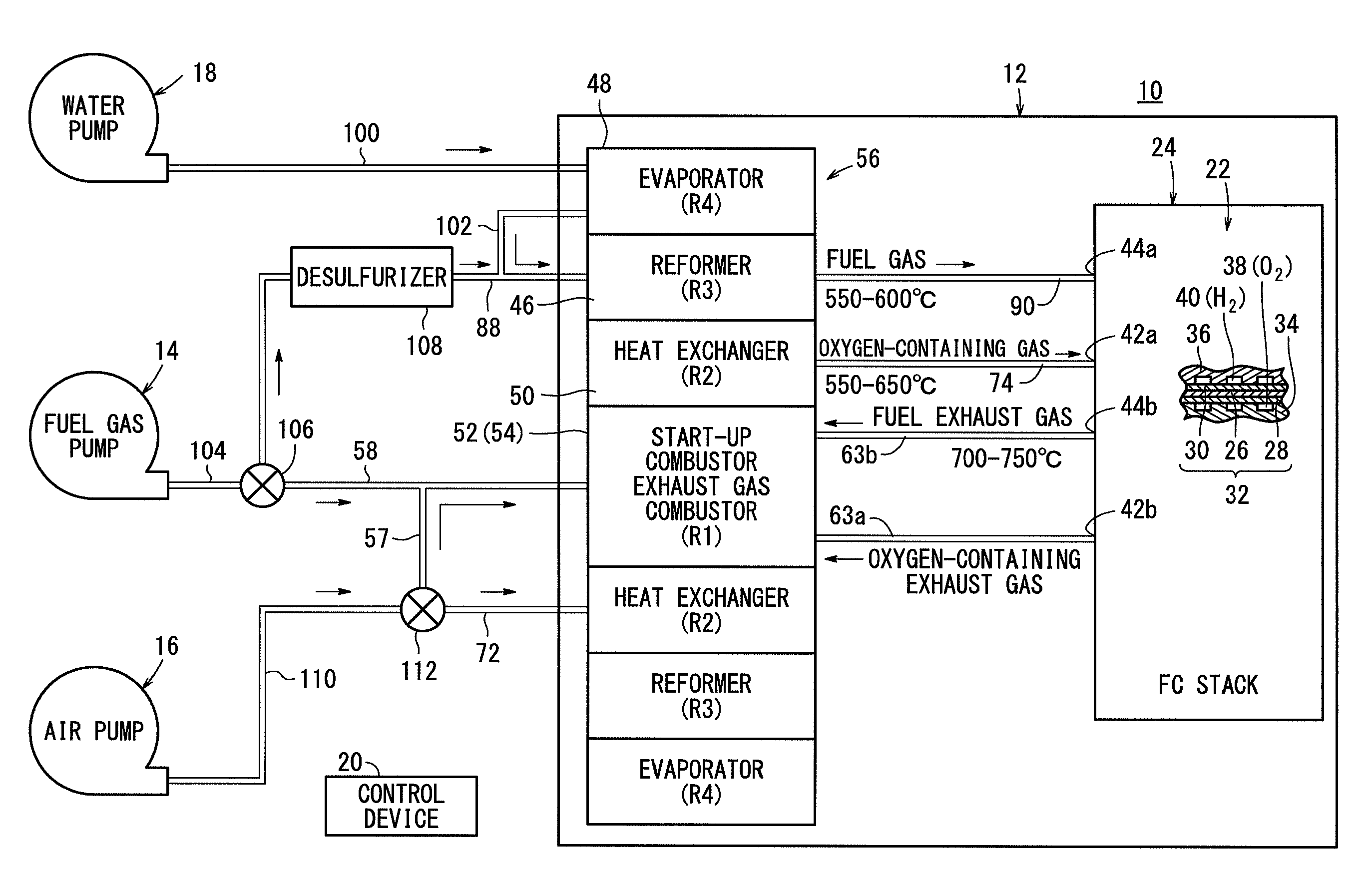

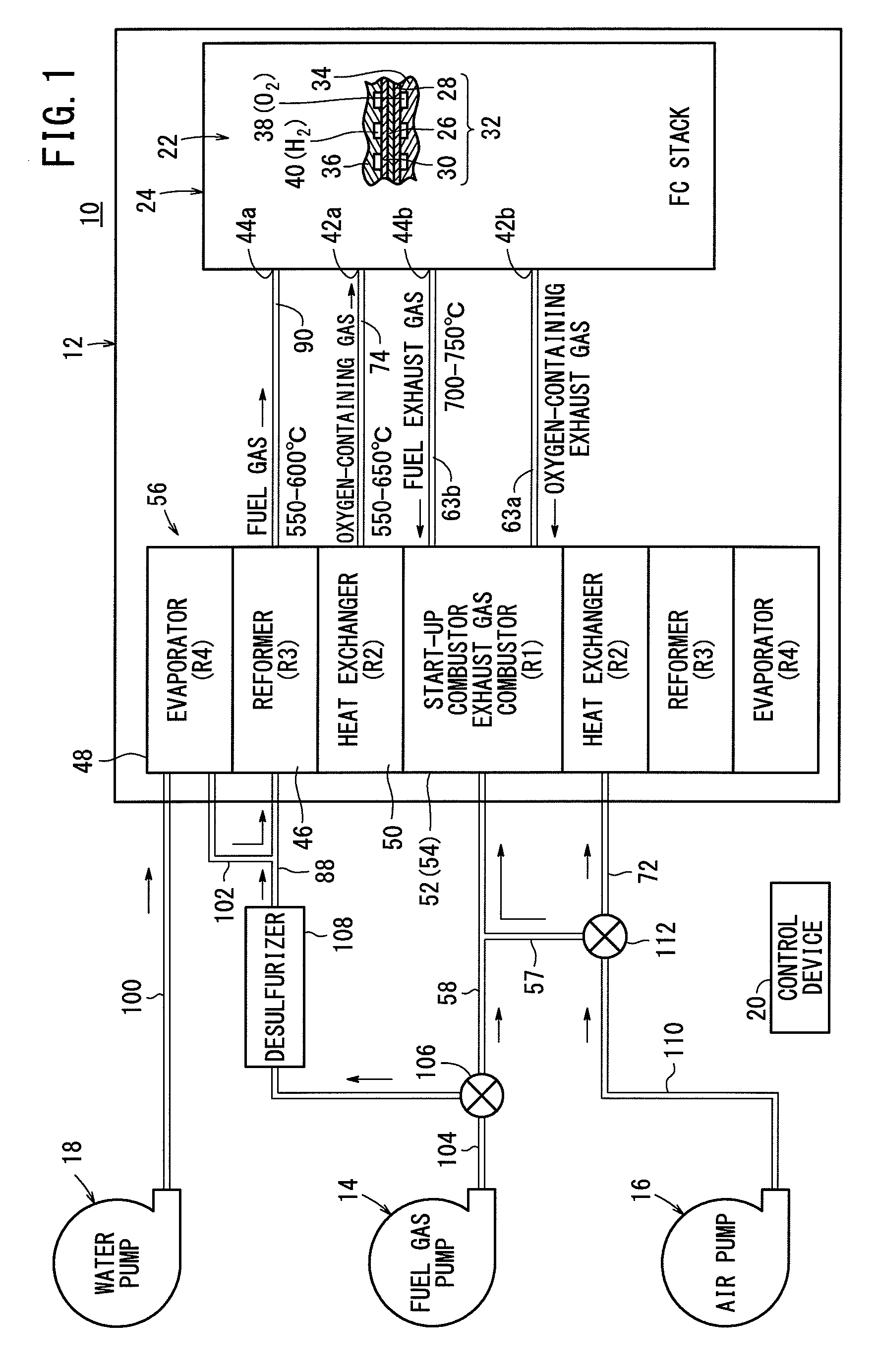

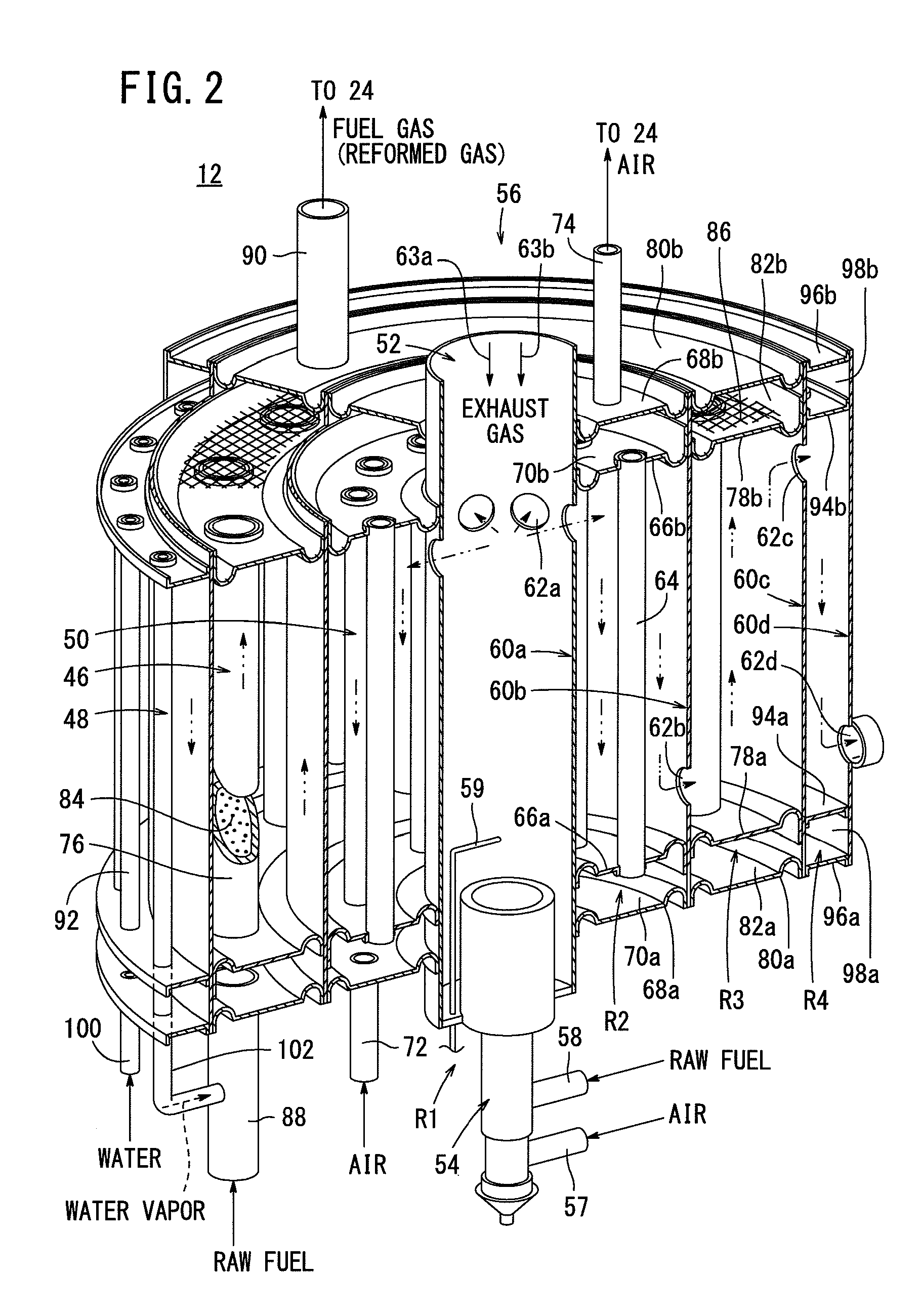

Fuel cell module

ActiveUS20150255811A1Improve heating efficiencySimple and compact structureHydrogenFuel cells groupingFuel cellsCombustor

A fuel cell module includes a first area where an exhaust gas combustor and a start-up combustor are provided, an annular second area around the first area and where a reformer and an evaporator are provided, an annular third area around the second area and where a heat exchanger is provided, and an annular heat recovery area around the third area as a passage of oxygen-containing gas for recovery of heat radiated from the third area toward the outer circumference.

Owner:HONDA MOTOR CO LTD

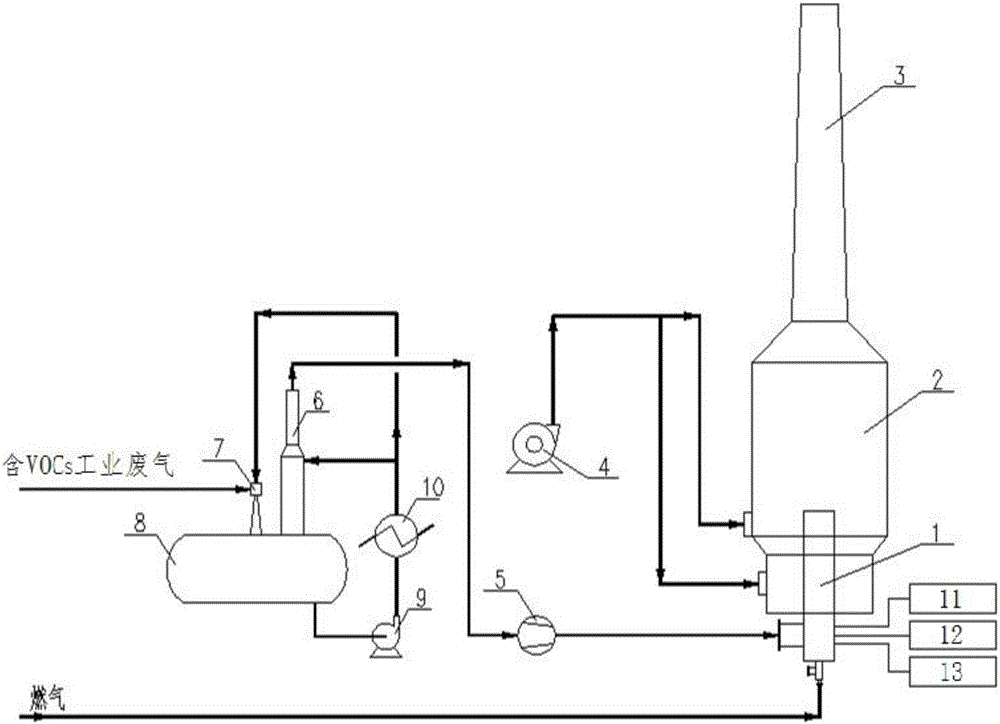

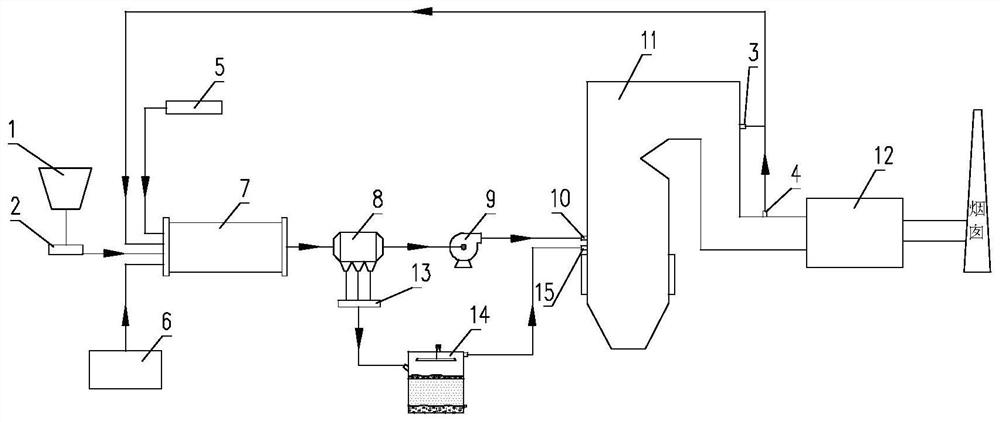

VOCs containing industrial waste gas treatment process and system

InactiveCN106237820AImprove purification efficiencyReduce loadDispersed particle separationIncinerator apparatusCombustorAtmospheric air

The invention relates to VOCs containing industrial waste gas treatment process and system. An absorbent outlet is formed at the bottom of an absorbent circulating tank, a mixture inlet and an exhaust cleaning tower are arranged at the top of the absorbent circulating tank, the absorbent outlet is connected with a nozzle on the exhaust cleaning device by an absorbent delivery pipeline, and an absorbent circulating pump and an absorbent cooler are sequentially arranged on the absorbent delivery pipeline; the absorbent delivery behind the absorbent cooler is additionally connected with an absorbent inlet at the upper part of the exhaust cleaning tower; a waste gas inlet of the exhaust cleaning tower is connected with an industrial waste gas pipeline, and a mixture outlet of the exhaust cleaning tower is connected with the mixture inlet of the absorbent circulating tank; a waste gas outlet at the top of the exhaust cleaning tower is connected to a waste gas combustor at the bottom of a waste gas incinerator by a waste gas draught fan; and a chimney is arranged at the top of the waste gas incinerator. According to the invention, a method of combining absorption and incineration is adopted to effectively remove VOCs in industrial waste gas, the process is simple and the investment is low.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

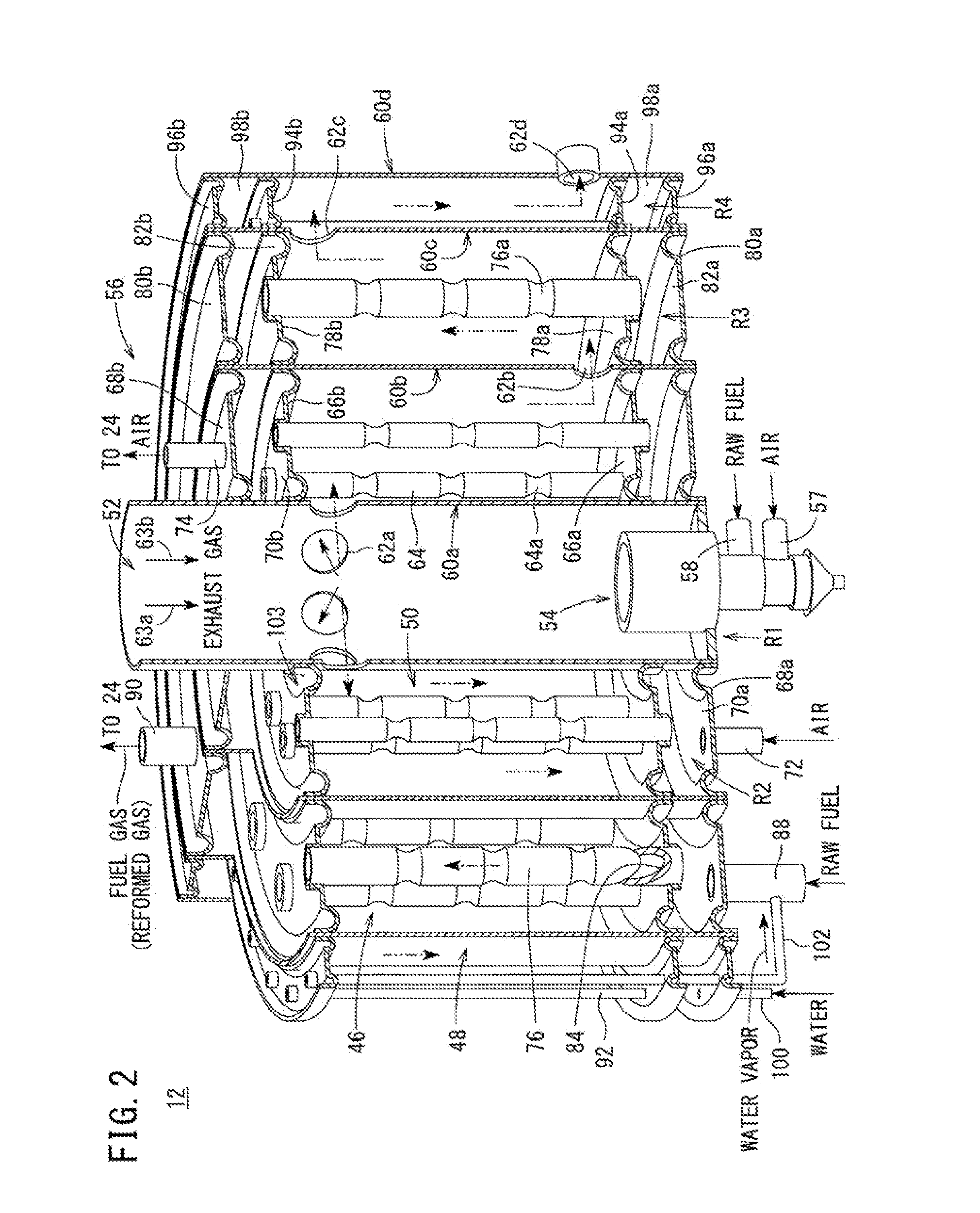

Fuel cell module

ActiveUS20150147669A1Improve heating efficiencySimple and compact structureHydrogenFuel cells groupingCombustorFuel cells

A fuel cell module includes a first area where an exhaust gas combustor and a start-up combustor are provided, an annular second area around the first area where a heat exchanger is provided, an annular third area around the second area where a reformer is provided, an annular fourth area around the third area where an evaporator is provided. A plurality of heat exchange pipes are provided in the heat exchanger around a first partition plate. At least one of the heat exchange pipes has at least one constricted portion.

Owner:HONDA MOTOR CO LTD

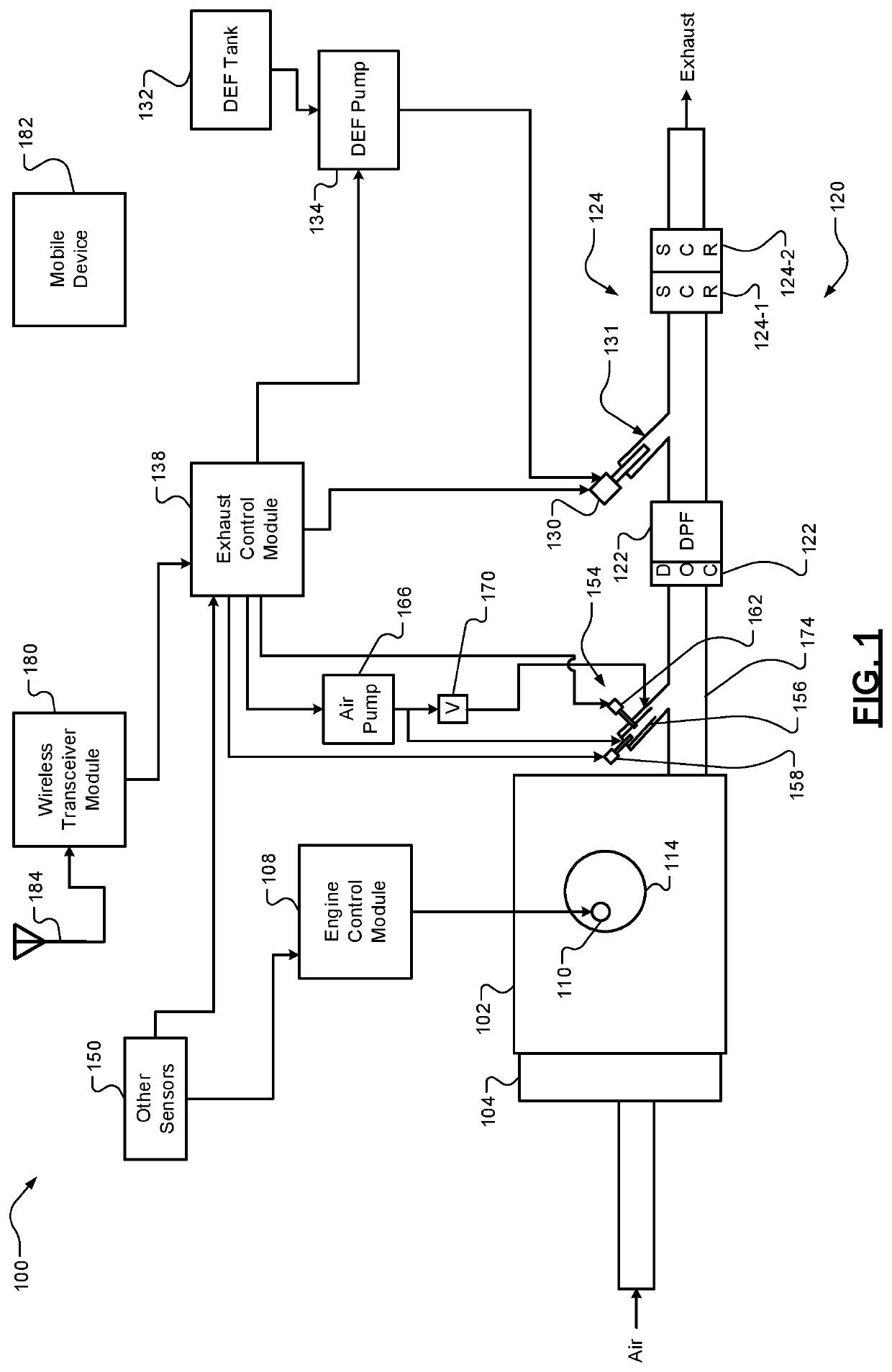

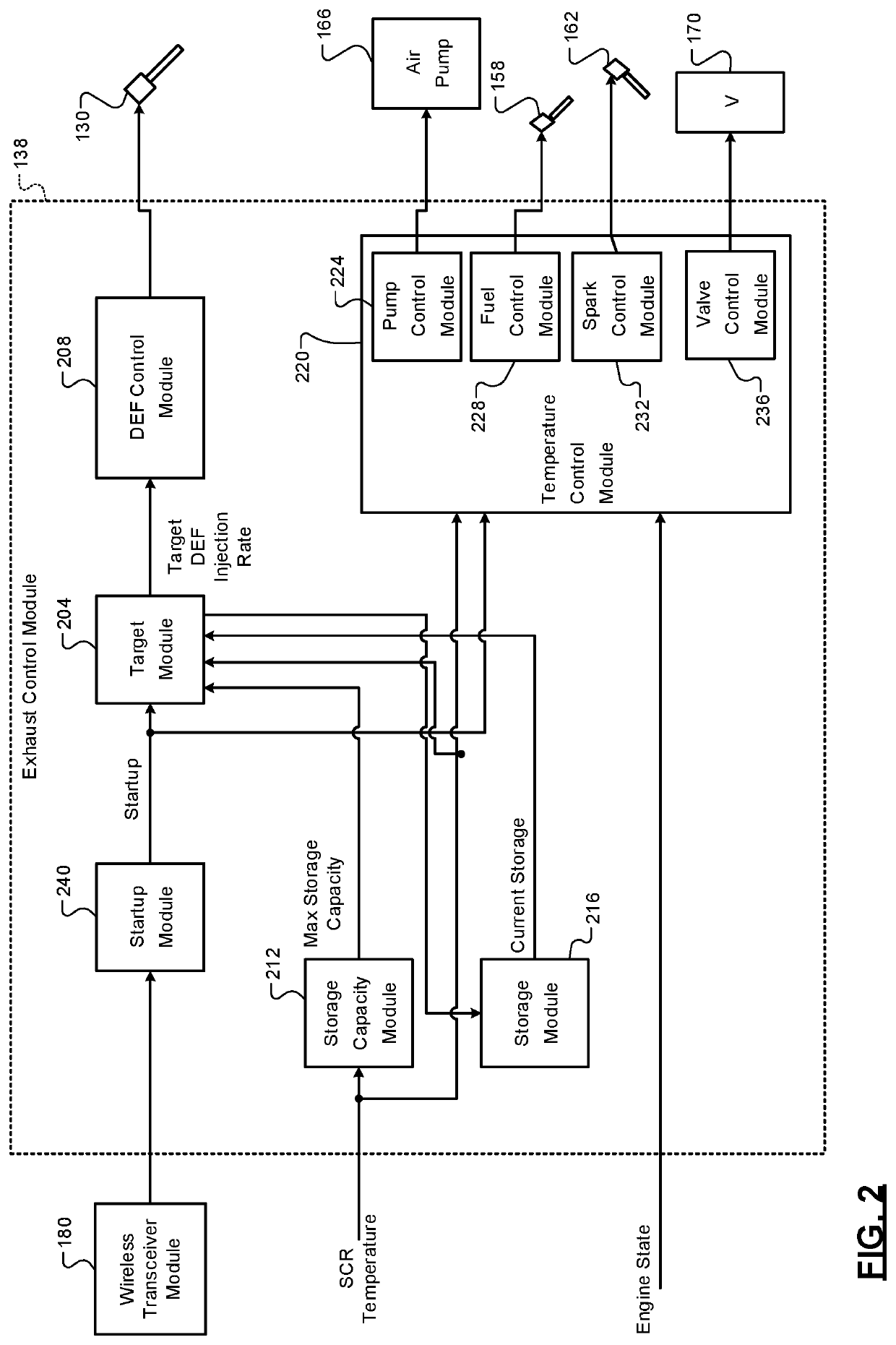

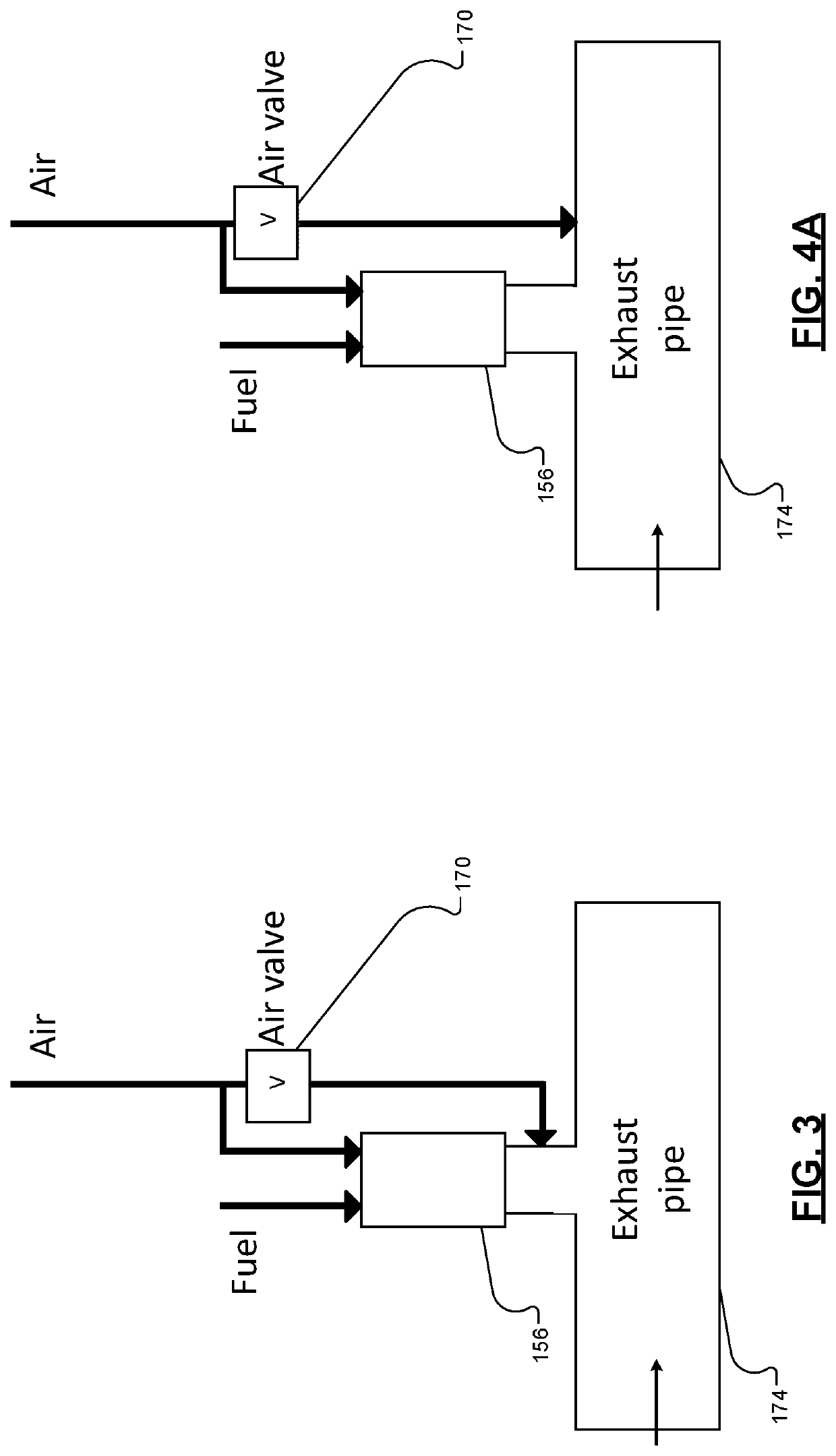

Selective catalytic reduction catalyst pre-heating and exhaust burner air control

ActiveUS11506136B1Electrical controlInternal combustion piston enginesCombustion chamberPtru catalyst

An exhaust control system of a vehicle includes a fuel injector configured to inject fuel into a combustion chamber of a burner of an exhaust system upstream of a selective catalytic reduction (SCR) catalyst; an air pump configured to pump air into the combustion chamber of the burner; a spark plug configured to ignite an air / fuel mixture within the combustion chamber of the burner; a fuel control module configured to, while an engine is off before an engine startup, selectively actuate the fuel injector and begin fuel injection; a pump control module configured to, while the engine is off before the engine startup, selectively turn on the air pump; and a spark control module configured to, while the engine is off and before the engine startup, selectively apply power to the spark plug and begin providing spark.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

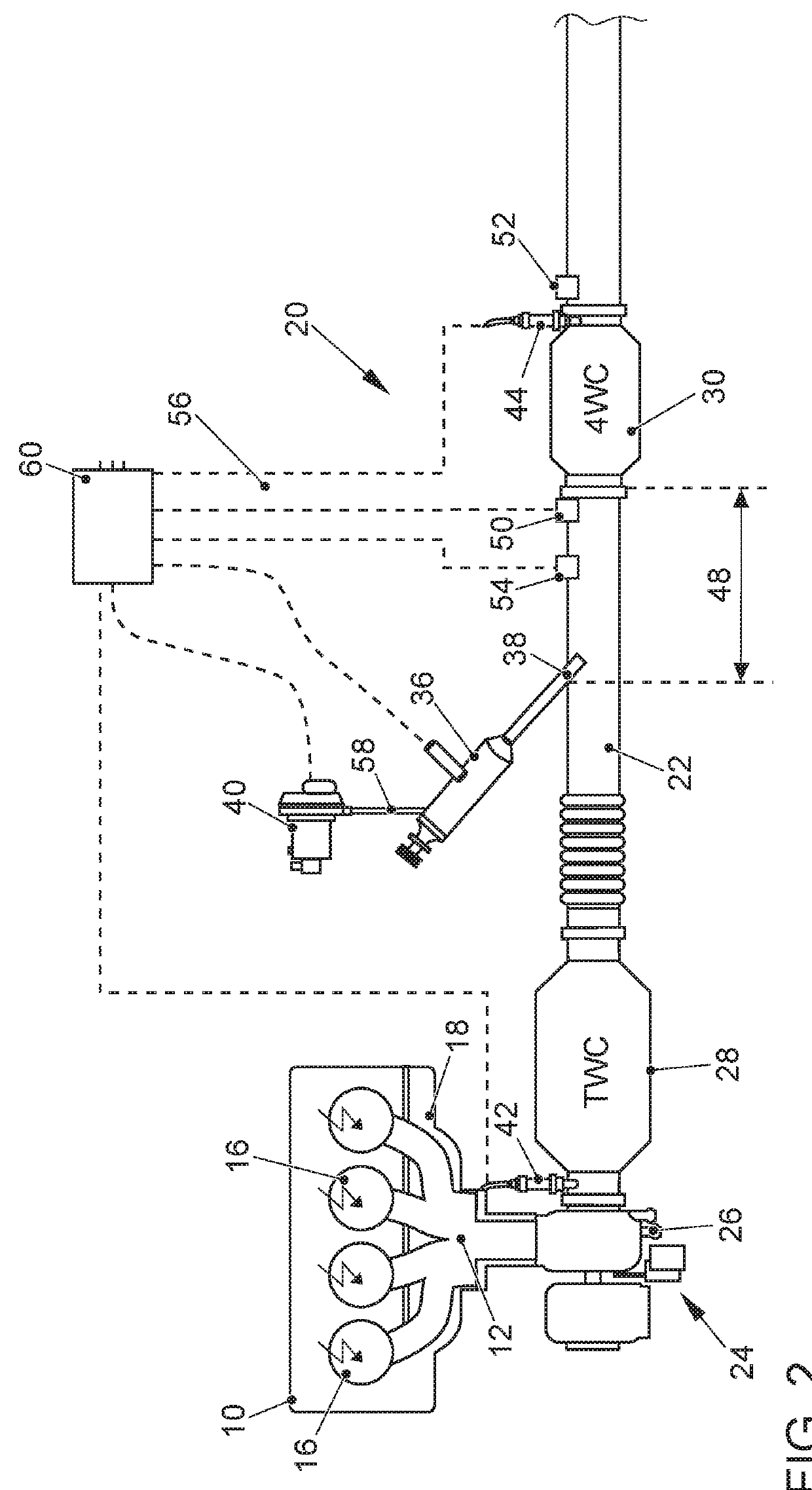

Exhaust gas aftertreatment system and method for exhaust aftertreatment of an internal combustion engine

ActiveUS10907519B2Improve aging behaviorEfficient conversionInternal combustion piston enginesDispersed particle filtrationCatalytic transformationCombustor

The invention relates to an exhaust gas aftertreatment system for an internal combustion engine, in particular for a gasoline engine that is spark-ignited by means of spark plugs. A first three-way catalytic converter is situated in an exhaust gas system that is connected to an outlet of the internal combustion engine in a position close to the engine. Downstream from the first three-way catalytic converter, a four-way catalytic converter or a combination of a particle filter and a second three-way catalytic converter downstream from the particle filter is situated in the underbody position of the motor vehicle. An exhaust gas burner with which hot exhaust gas is introducible into the exhaust gas system downstream from the first three-way catalytic converter and upstream from the four-way catalytic converter or the particle filter is provided at an exhaust duct of the exhaust gas system. The exhaust gas burner is supplied with fresh air by a secondary air pump. The invention further relates to a method for exhaust aftertreatment of an internal combustion engine having such an exhaust gas aftertreatment system.

Owner:VOLKSWAGEN AG

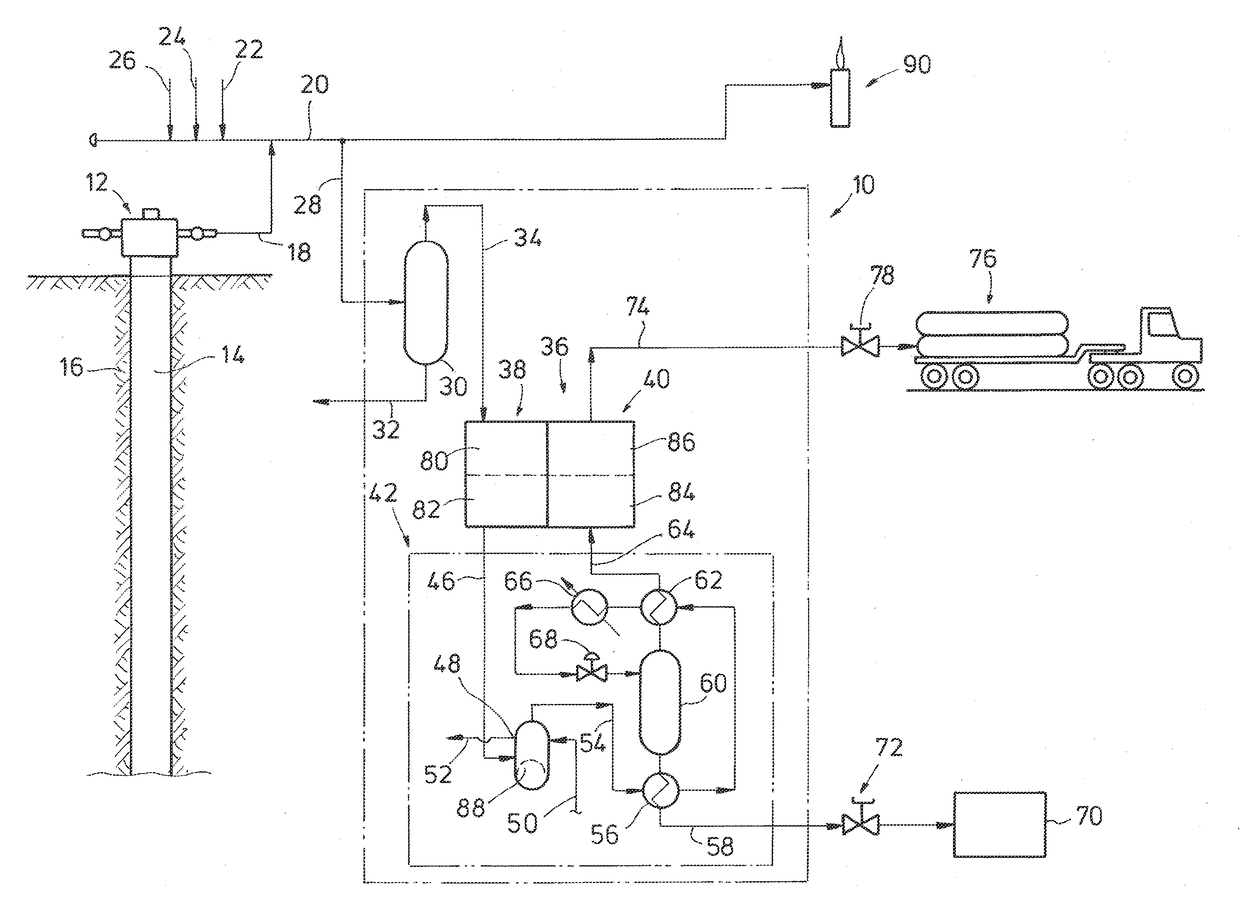

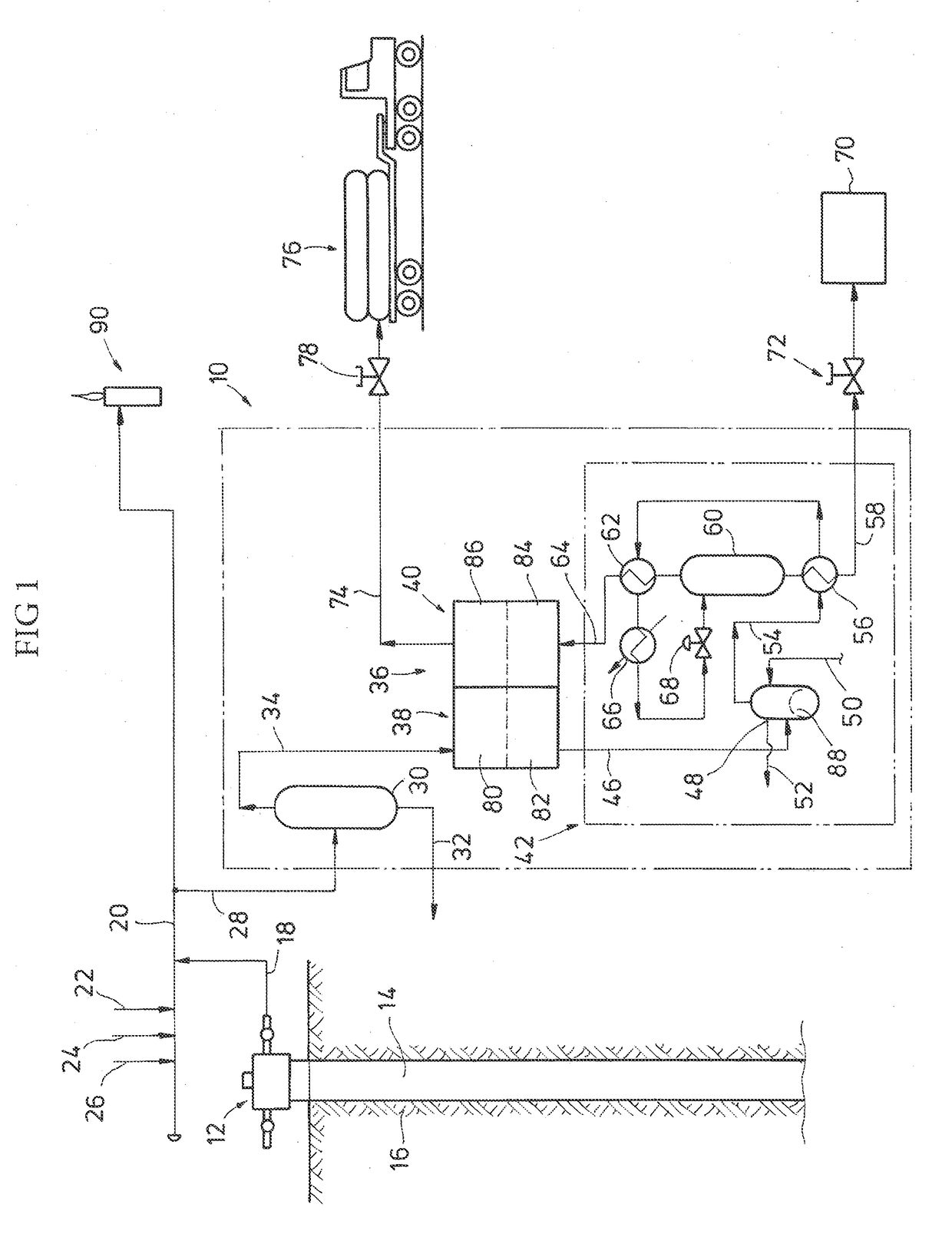

System and method for compressing and conditioning hydrocarbon gas

ActiveUS20170254187A1Gas treatmentDispersed particle separationCompressed natural gasProcess engineering

A system and method captures and processes flare gas so that the gas is usable as compressed natural gas (“CNG”). The flare gas is pressurized by a combination of a booster compressor and a CNG compressor. While interstage and between the booster compressor and the CNG compressor, the gas is treated to remove moisture and to separate out higher molecular weight hydrocarbons. The moisture is removed by contacting the interstage gas with a hygroscopic agent within a dehydration unit. The moisture free hydrocarbon fluid is expanded, and / or externally cooled and directed to a knock out drum. Higher molecular weight hydrocarbons are separated from the fluid in the knock out drum. Gas from the knock out drum is compressed in the CNG compressor.

Owner:GE OIL & GAS INC

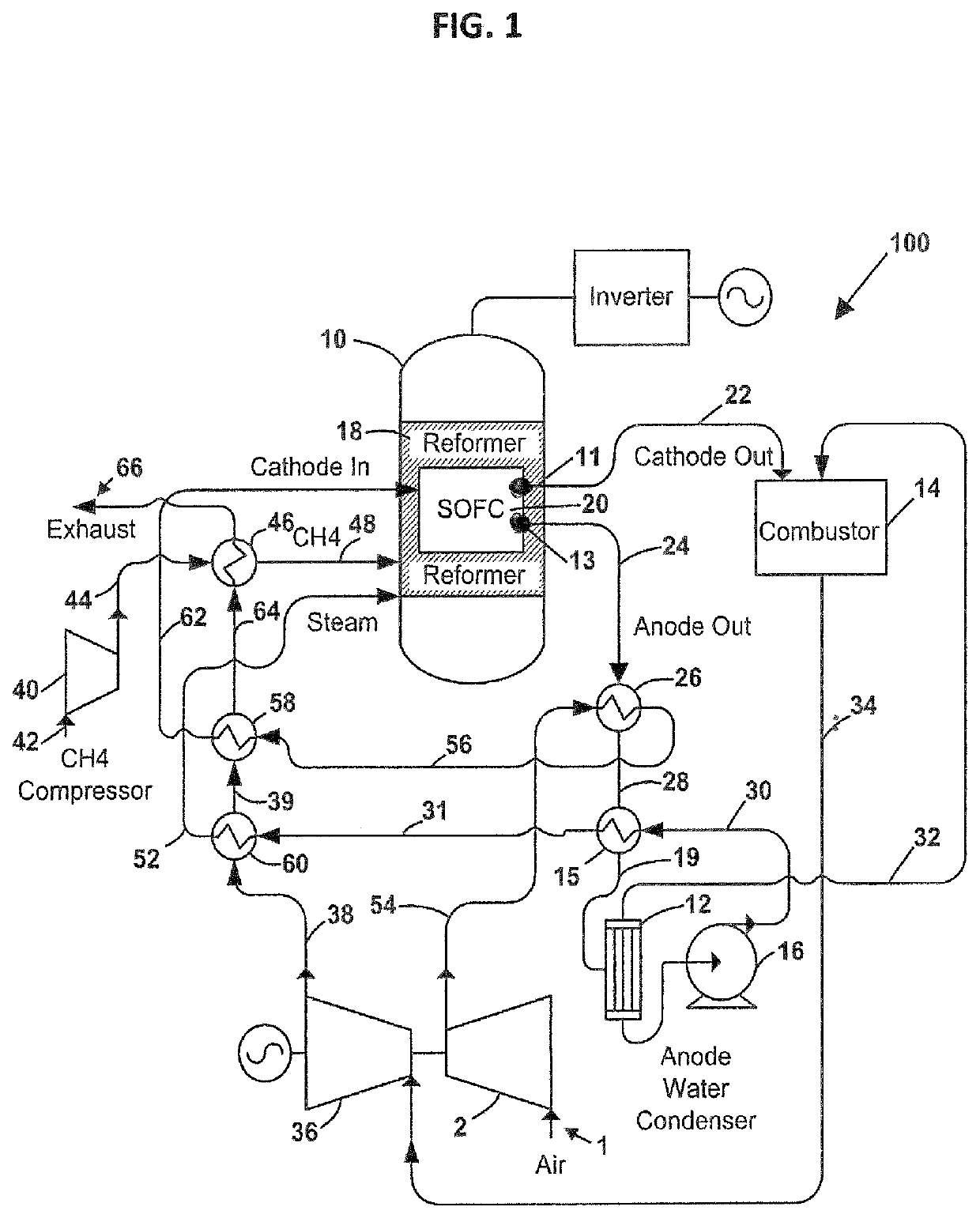

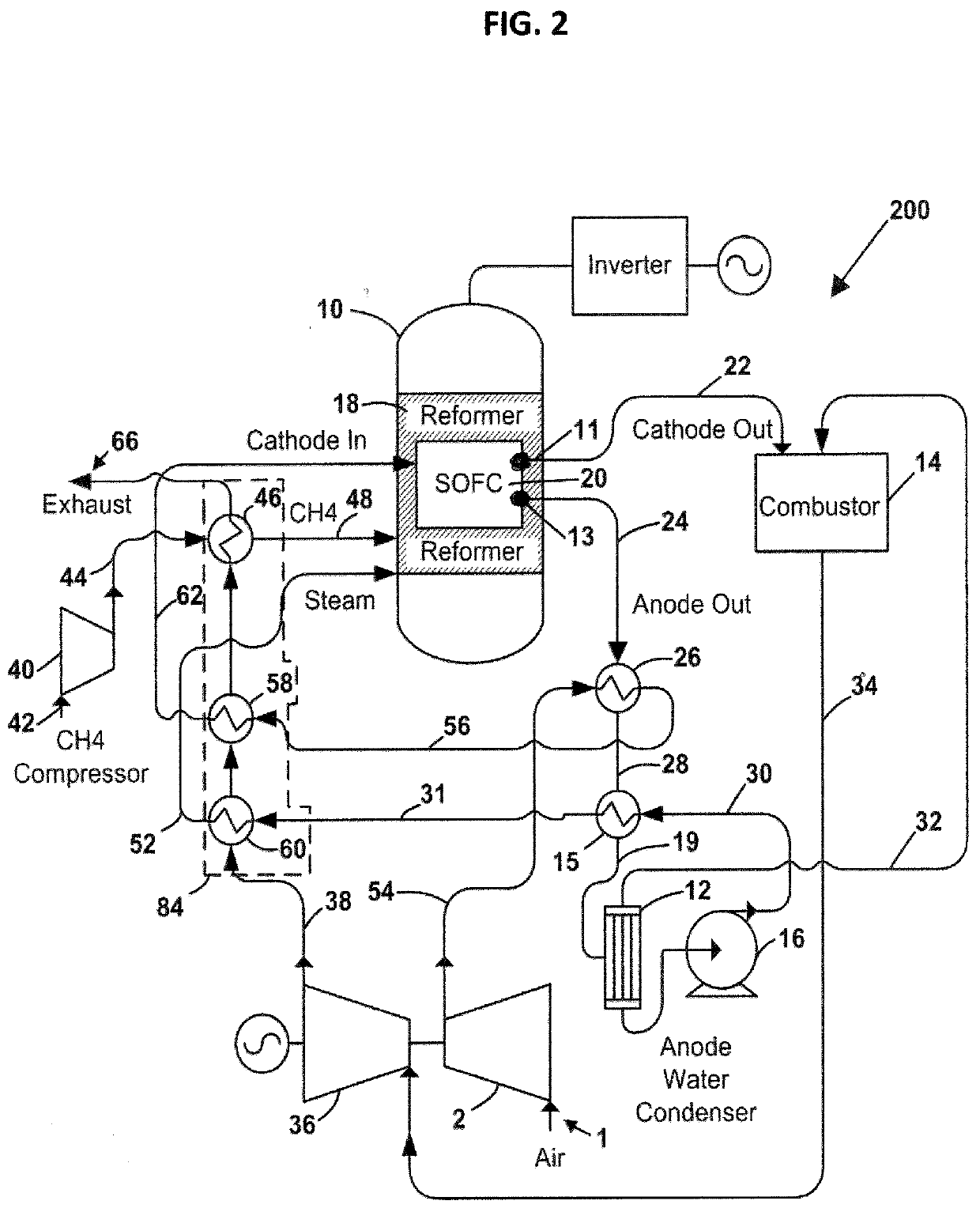

Integrated power generation system

PendingUS20210384537A1Improve electricity efficiencyReduce lossesFuel cell heat exchangeSteam reformingPhysics

An integrated power generation system including: a hotbox containing a steam reformer and at least one solid oxide fuel cell (SOFC) stack; a condenser, a combustor, a heater, and a turbomachine comprising a compressor and an expander. The steam reformer is configured to convert a hydrocarbon fuel and steam into a stack fuel. The SOFC stack is configured to convert the stack fuel into a first anode waste gas. The condenser functions to remove water from the first anode waste gas, thereby producing a second anode waste gas of higher fuel energy density. The combustor bums the second anode waste gas with release of exothermic heat. The heater thermally transmits heat from an expanded combustion product to water collected in the condenser, so as to generate steam. A steam line fluidly connects the heater to the steam reformer.

Owner:PRECISION COMBUSTION

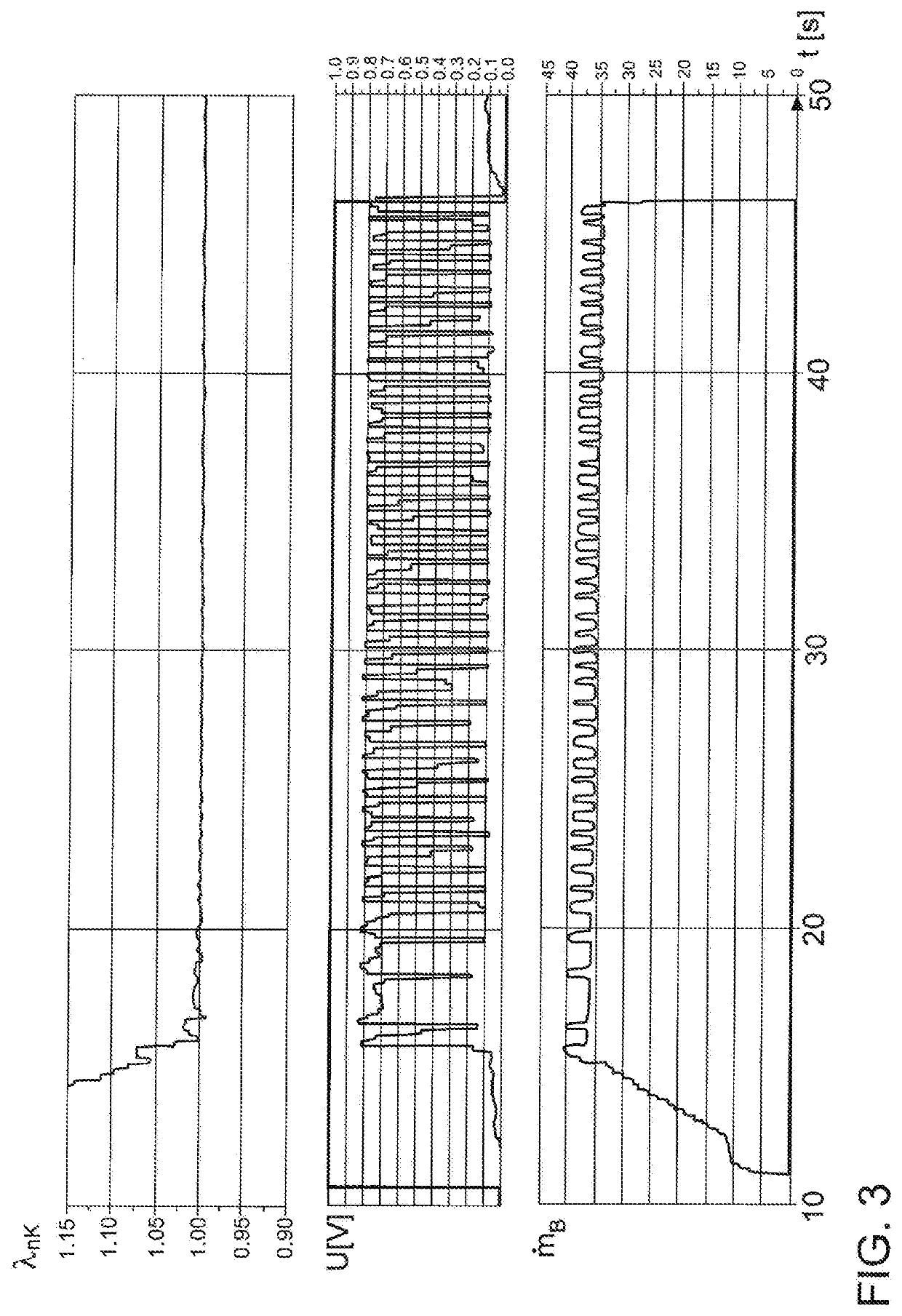

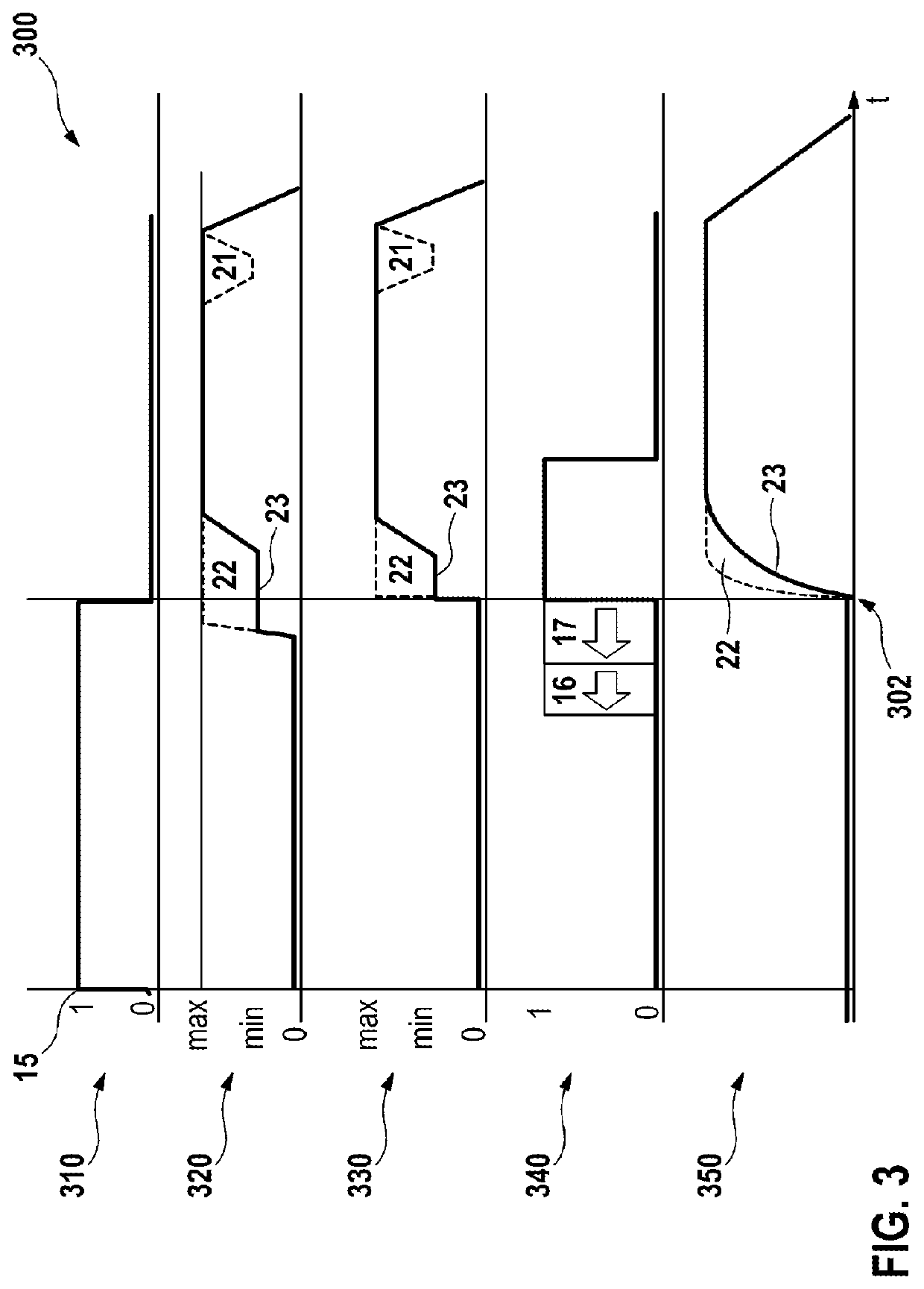

Method for heating a catalytic converter and exhaust gas aftertreatment system

ActiveUS20210040873A1Reduce heat lossReduce stepsElectrical controlInternal combustion piston enginesCatalytic transformationCombustor

A method for heating a catalytic converter in an exhaust system of an internal combustion engine, in which an exhaust gas burner for heating the catalytic converter is arranged, upstream of the catalytic converter. A lambda probe for controlling the combustion air ratio of the exhaust gas burner is arranged immediately downstream of the exhaust gas burner and upstream of the catalytic converter. The method includes operating the internal combustion engine with a stoichiometric combustion air ratio (λE=1), activating the exhaust gas burner, which is operated alternately with a substoichiometric combustion air ratio (λB<1) and a superstoichiometric combustion air ratio (λB>1), wherein from the substoichiometric combustion air ratio (λB<1) to the superstoichiometric combustion air ratio (λB>1) as soon as a rich breakthrough is detected by the second lambda probe (34), and wherein a switchover from the superstoichiometric combustion air ratio (λB>1) to the substoichiometric combustion air ratio (λB<1) takes place as soon as a lean breakthrough is detected by the second lambda probe.

Owner:VOLKSWAGEN AG

Heavy metal-containing multi-source waste disposal system and method based on pulverized coal boiler

ActiveCN113883524AAchieve recyclingAchieve removalCrucible furnacesIncinerator apparatusEconomizerWaste disposal

The invention discloses a heavy metal-containing multi-source waste disposal system and method based on a pulverized coal boiler. The system involves a material storage system, a hot air system, an alkaline removal agent system, an integrated disposal system, a gas-solid separation system, a burner, the pulverized coal boiler, a melting system and a waste gas burner; an outlet of the material storage system is connected with a material inlet of the integrated disposal system, a high-temperature flue gas connector is arranged at the position, between a hearth outlet of the pulverized coal boiler and a coal economizer, of a flue, a medium-temperature flue gas connector is arranged at the position, at an outlet of the coal economizer of the pulverized coal boiler, of the flue, and the high-temperature flue gas connector and the medium-temperature flue gas connector are connected with a flue gas inlet of the integrated disposal system; and an outlet of the hot air system is connected with an air inlet of the integrated disposal system, and an outlet of the alkaline removal agent system is connected with a solution inlet of the integrated disposal system. The system and method can achieve treatment of multi-source waste and have the characteristics of being low in cost and high in utilization rate.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

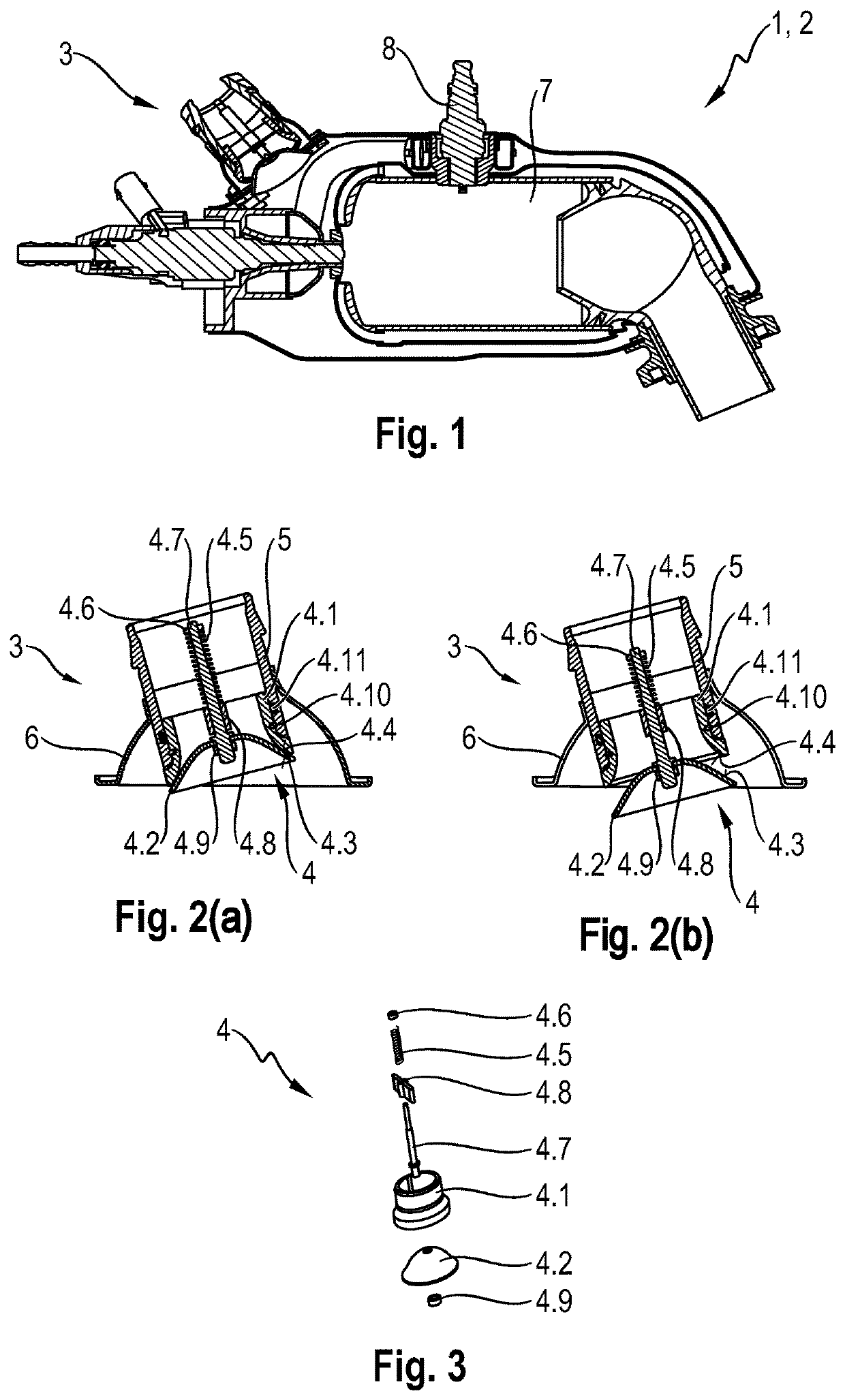

Method for operating an exhaust gas burner

ActiveUS20220307401A1Faster burner startFast evaporationInternal combustion piston enginesExhaust apparatusCombustorExhaust fumes

A method for operating an exhaust gas burner (3) downstream of an internal combustion engine (1) and upstream of an exhaust gas catalytic converter (4), comprising controlling an ignition device (12) of the exhaust gas burner (3) during a predeterminable preheating phase without supplying fuel (11) to the exhaust gas burner (3) during the preheating phase and, after completion of the preheating phase, supplying fuel (11) to the exhaust gas burner (3) and burning the supplied fuel (11) in the exhaust gas burner (3). A processor unit and a computer program product for carrying out such a method are furthermore proposed.

Owner:ROBERT BOSCH GMBH

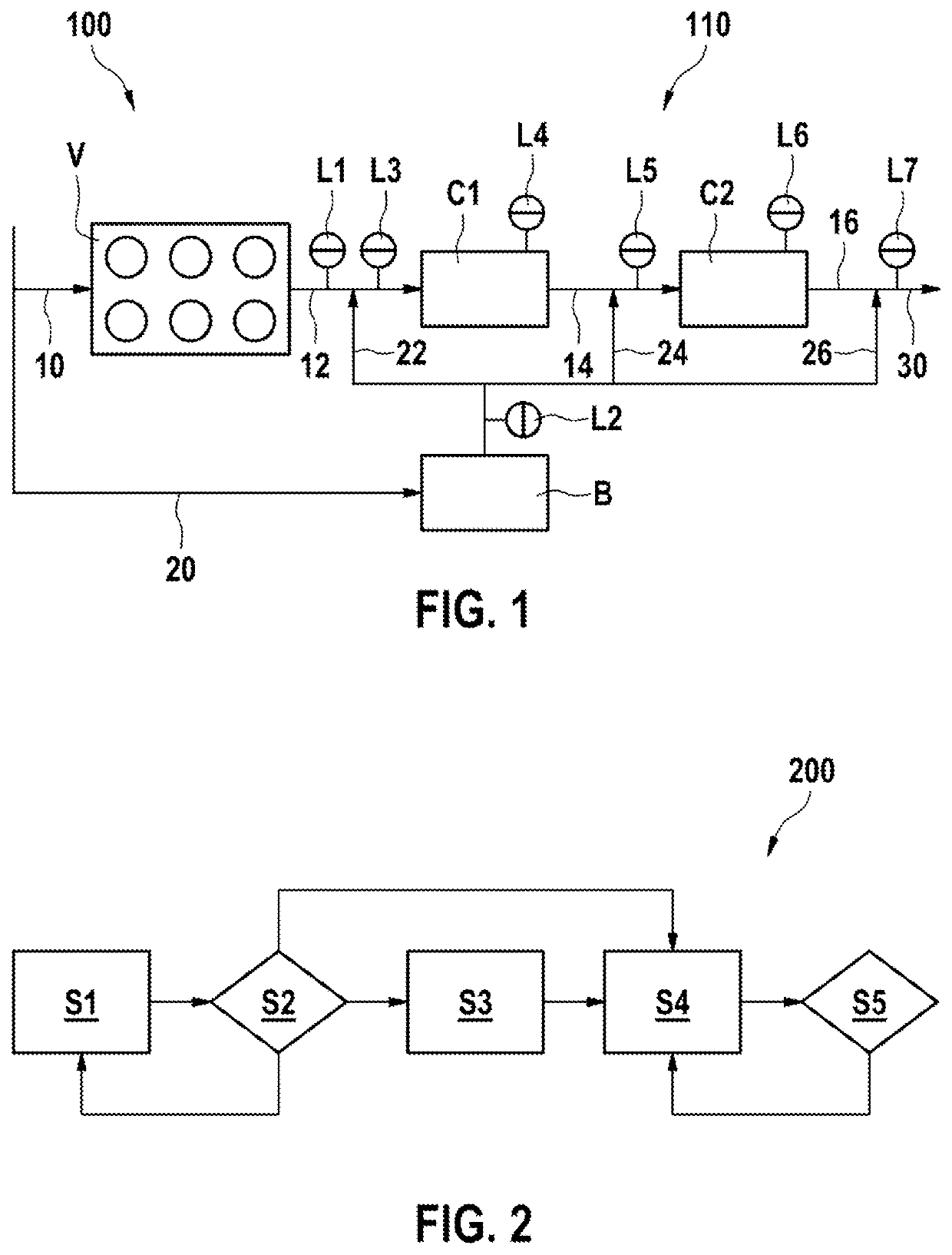

Lambda compensation with exhaust-gas burner

ActiveUS20210254525A1Reduce storage capacityEasy to implementInternal combustion piston enginesExhaust apparatusCatalytic transformationExhaust fumes

A method for operating an exhaust-gas burner (B) of a vehicle (100) which has at least an internal combustion engine (V) and a catalytic converter (C1, C2), wherein exhaust gases (22, 24) of the exhaust-gas burner (B) are merged, upstream of the catalytic converter (C1, C2), with exhaust gases (12) of the internal combustion engine (V), forming an exhaust-gas mixture, wherein a lambda value of the exhaust gases (22, 24) of the exhaust-gas burner (B) is set in a manner dependent on a lambda value of the exhaust gases (12) of the internal combustion engine (V).

Owner:ROBERT BOSCH GMBH

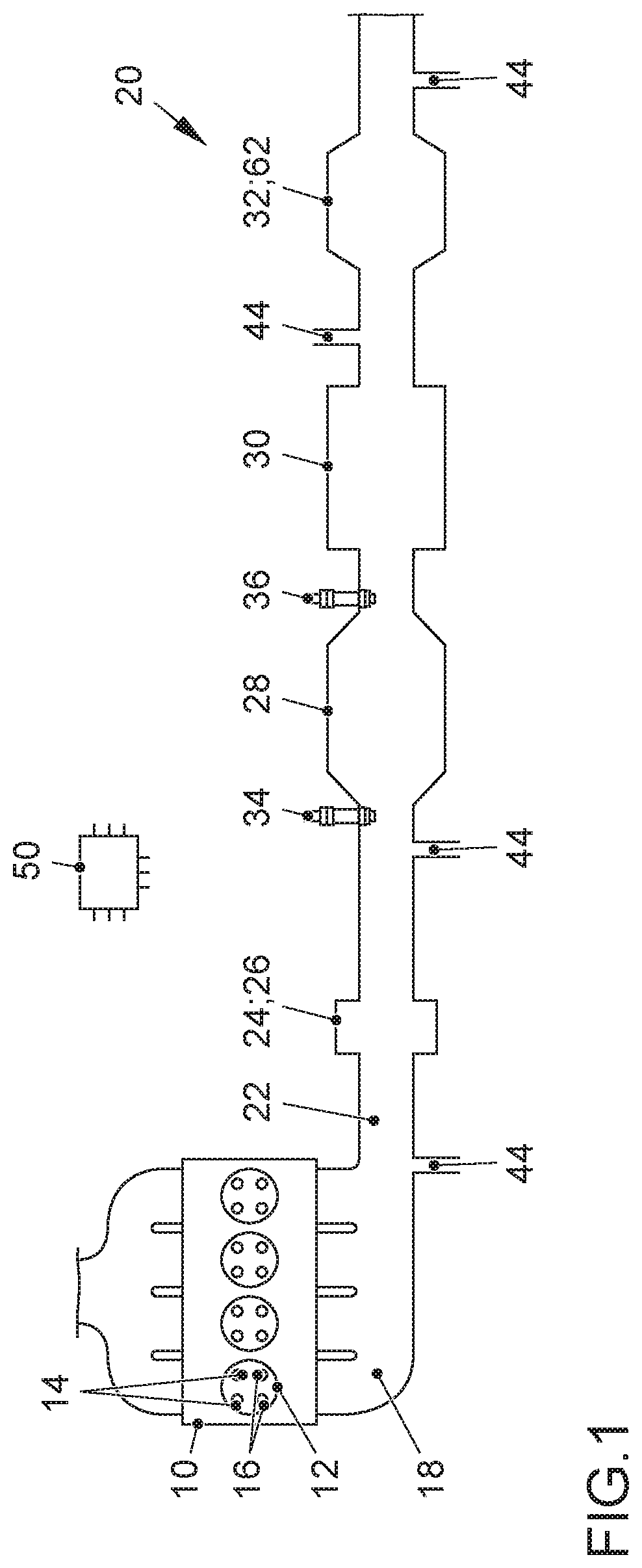

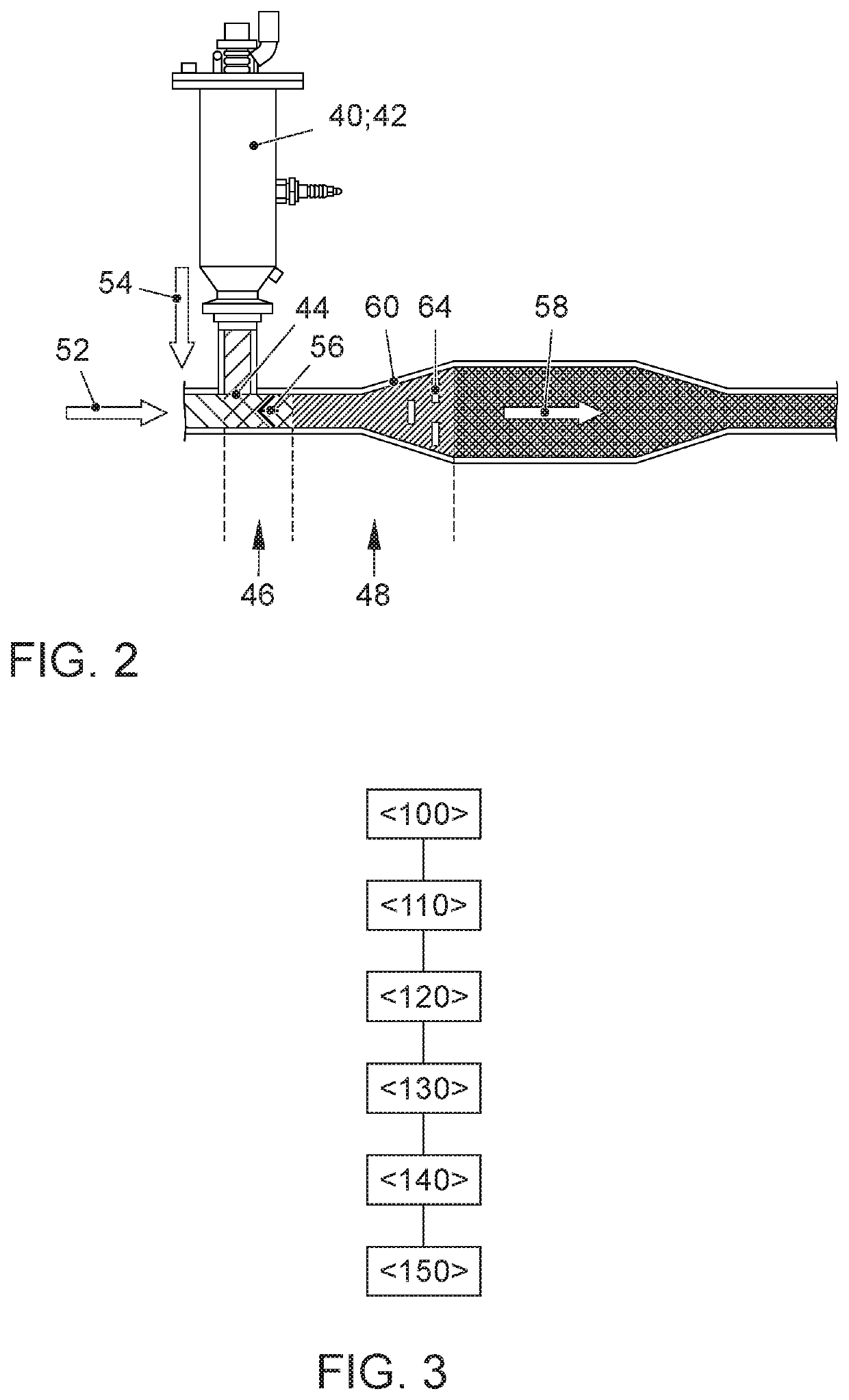

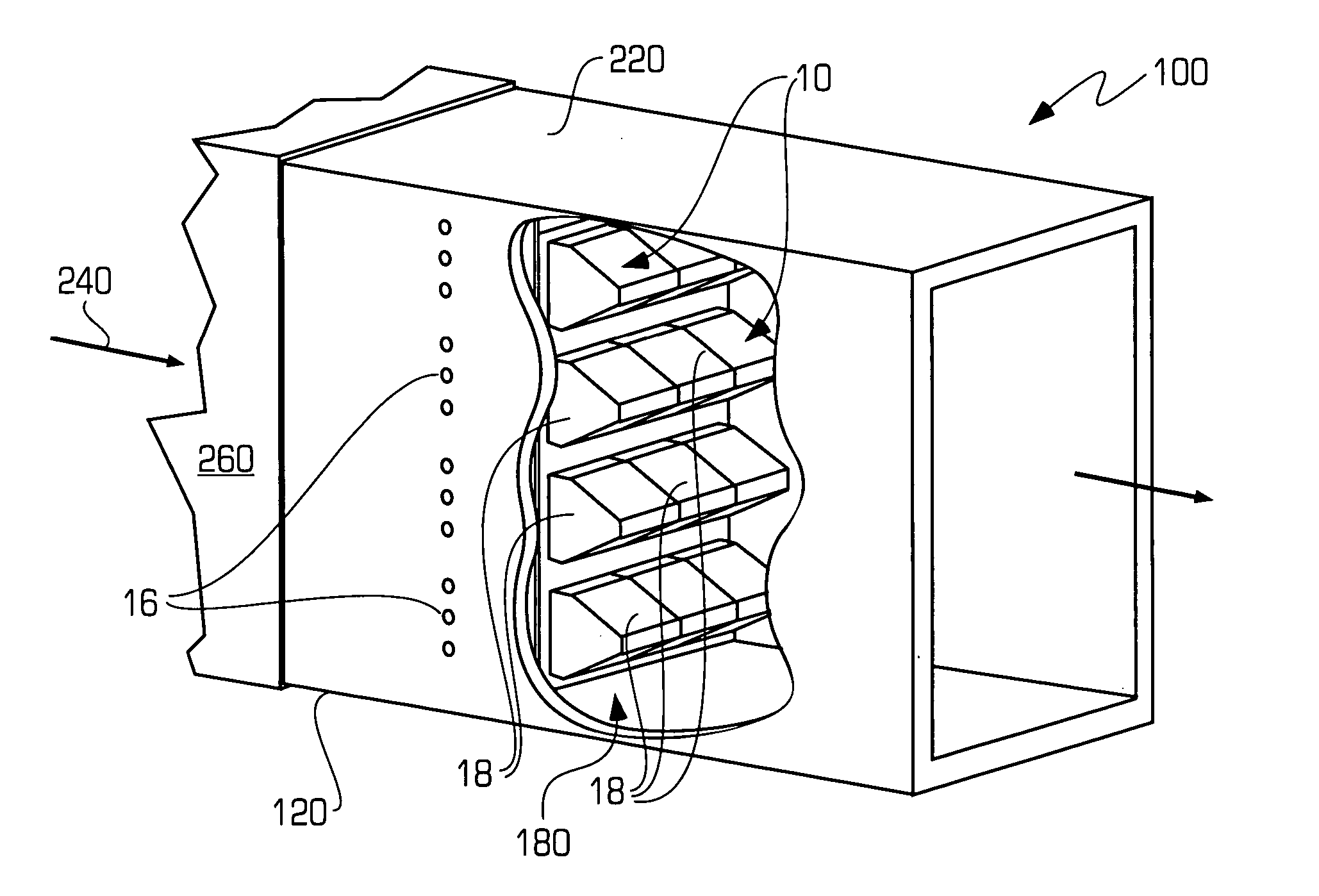

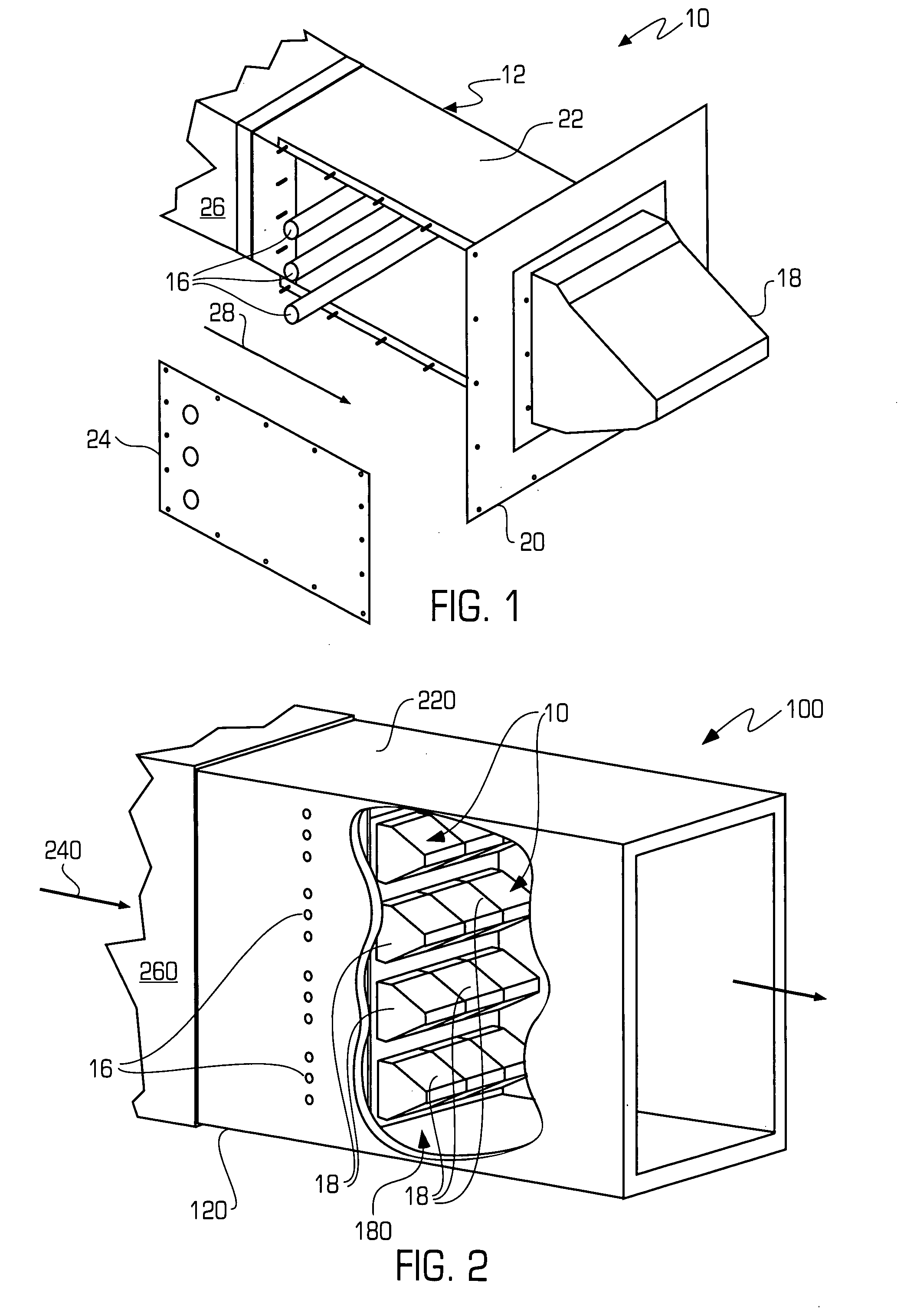

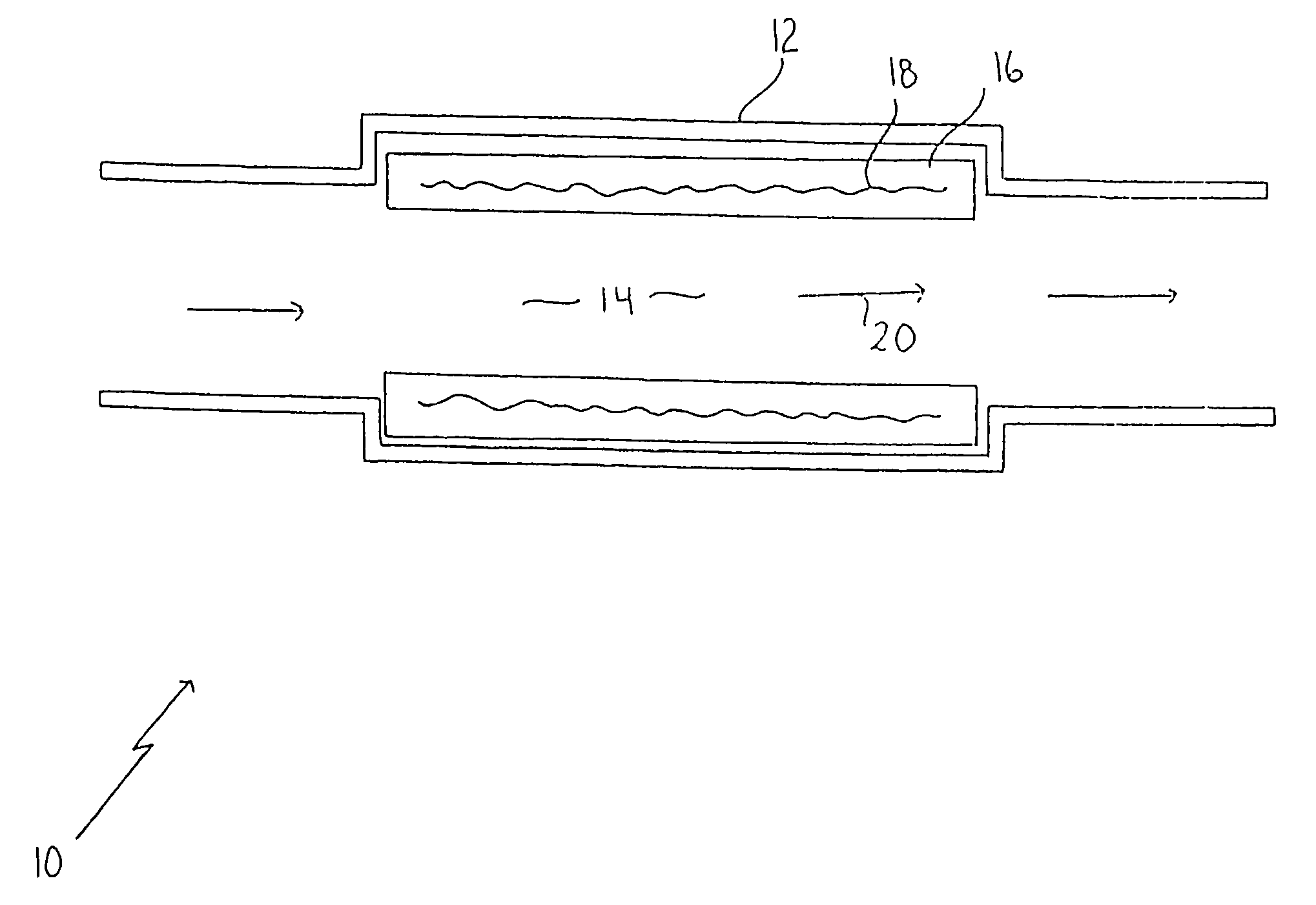

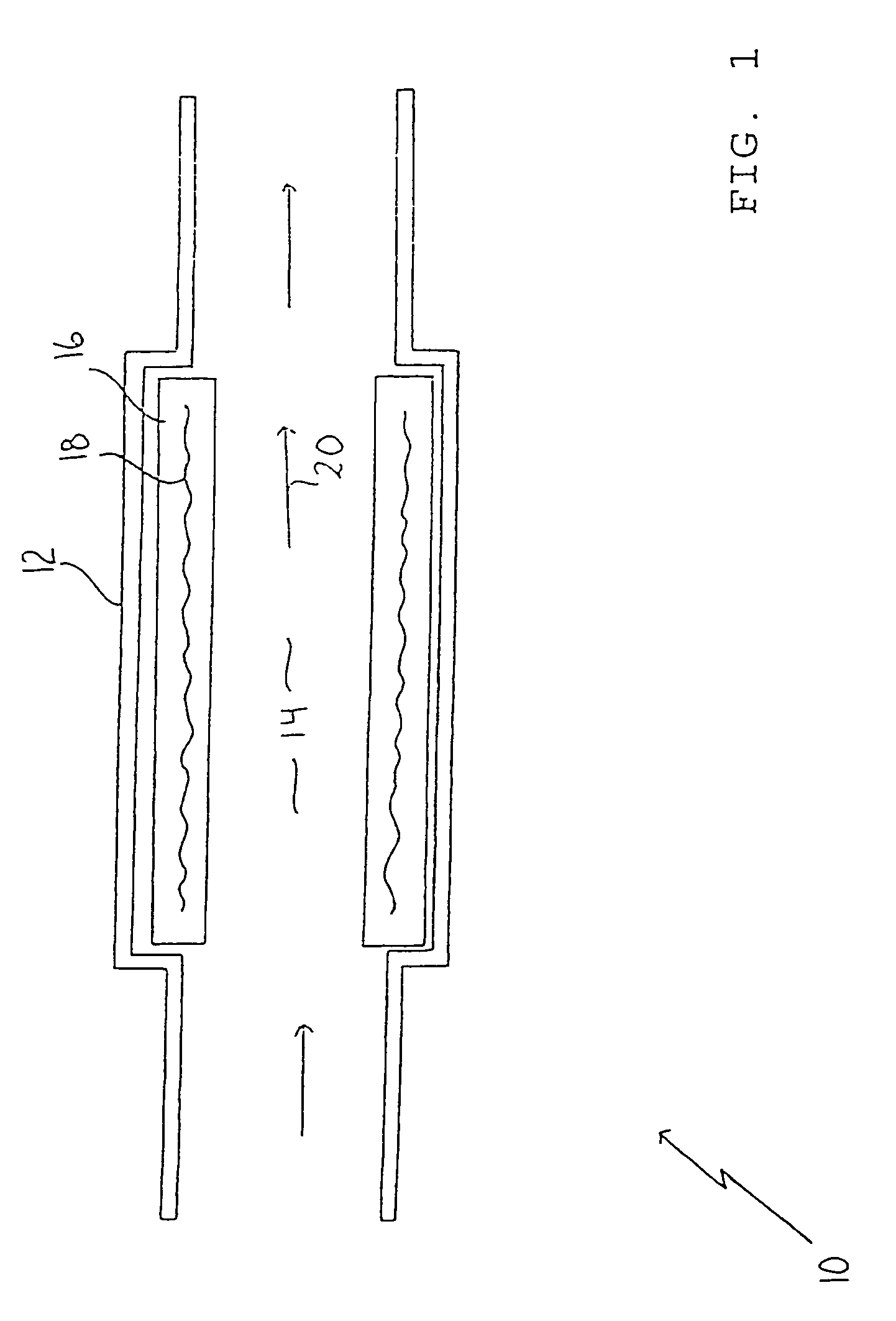

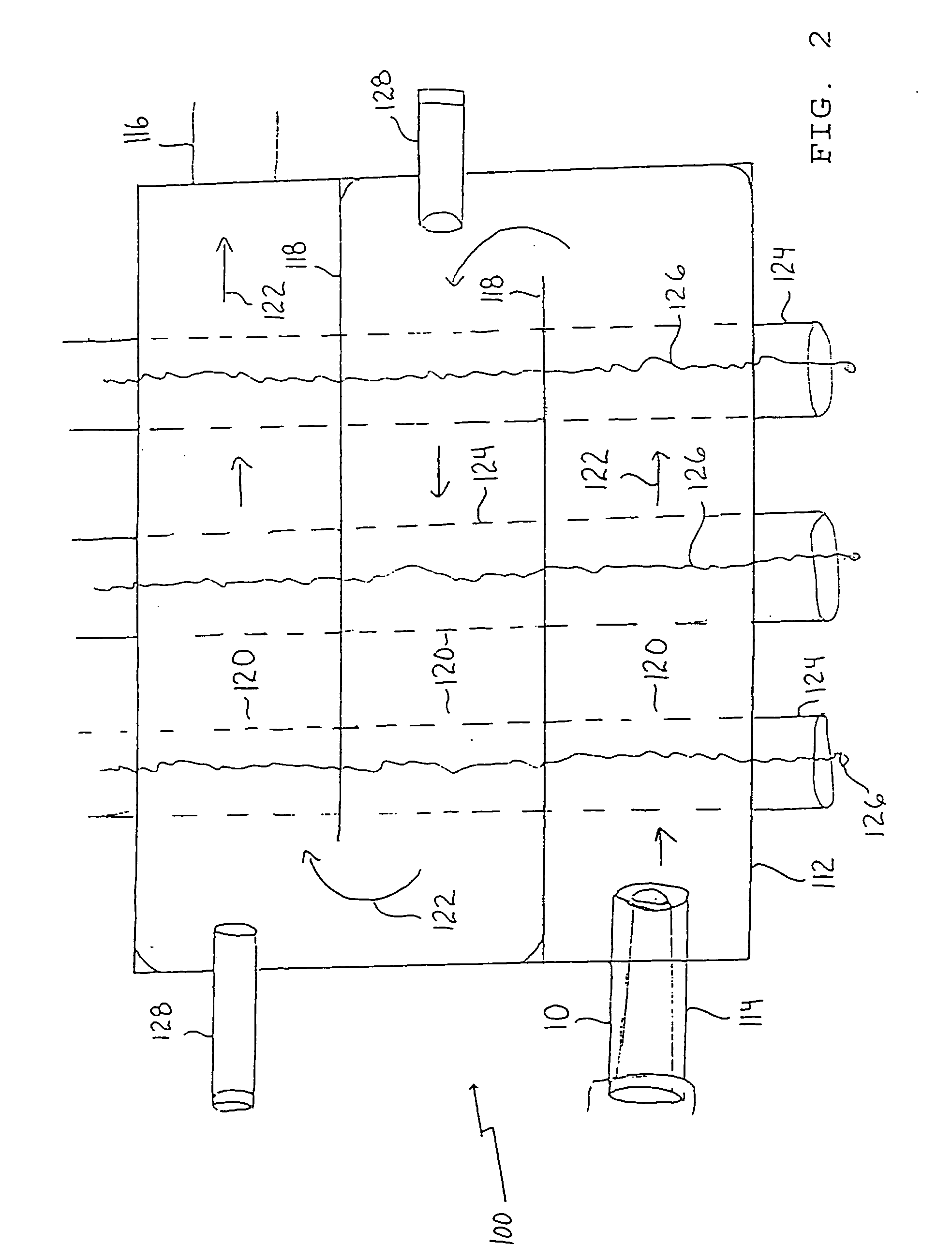

Method and apparatus for igniting a gas flare and a gas flare

A method and apparatus for igniting a gas flare includes a housing (12, 112) and at least one flow passage (14, 120) extending through the housing (12, 112). A body (16, 124) made from a heat conducting material in communication with the at least one flow passage (14, 120). A heating element (18, 126) embedded in the body (16, 124) maintains the body (16, 124) at a temperature above an ignition temperature of a combustible mixture of combustion air and combustible gases. The combustible mixture passing along the at least one flow passage (14, 120) is ignited immediately upon coming in contact with the body (16, 124). The apparatus can be a separate from the gas flare or can be incorporated into the construction of the gas flare.

Owner:RASMUSSEN ADAIR

Method for the exhaust aftertreatment of an internal combustion engine and exhaust aftertreatment system

ActiveUS10934912B2Emission reductionInternal combustion piston enginesExhaust apparatusCombustorExhaust fumes

The invention relates to a method for the exhaust aftertreatment of an internal combustion engine, which on the outlet side is connected to an exhaust gas system. Provided in the exhaust gas system is at least one exhaust aftertreatment component with which, upon reaching the light-off temperature of this exhaust aftertreatment component, the gaseous limited exhaust gas components may be converted into unlimited exhaust gas components. An introduction point is provided at an exhaust duct of the exhaust gas system, at which a hot gas, in particular an exhaust gas of an exhaust gas burner, is introduced into the exhaust duct. The hot gas mixes with the exhaust gas of the internal combustion engine in such a way that a hot mixed gas results in which the unburned exhaust gas components are oxidized to unlimited exhaust gas components, without a catalytically active surface. It is provided that the introduction of the hot gas is set as soon as the exhaust gas components of the exhaust aftertreatment system have reached their respective light-off temperature.

Owner:VOLKSWAGEN AG

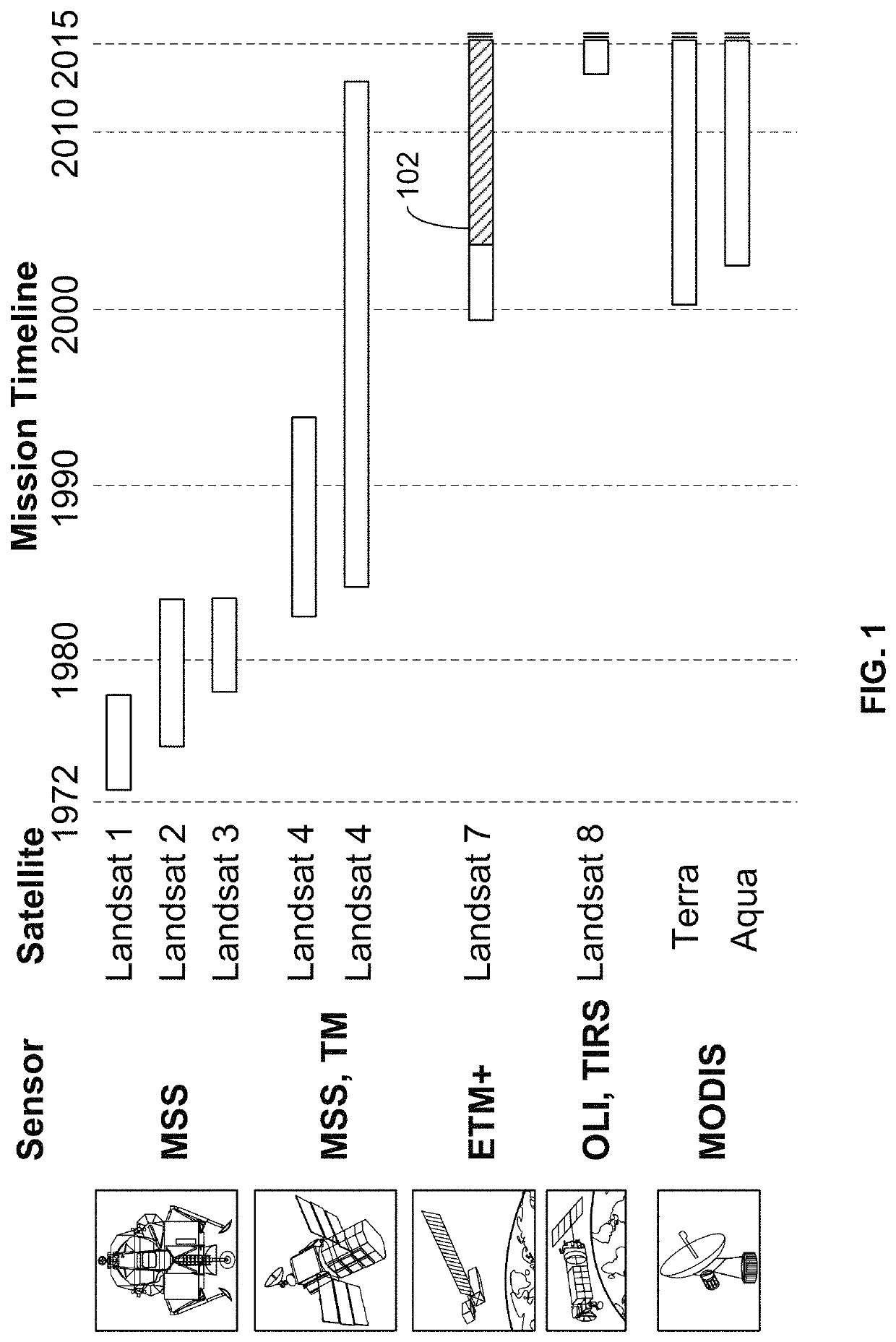

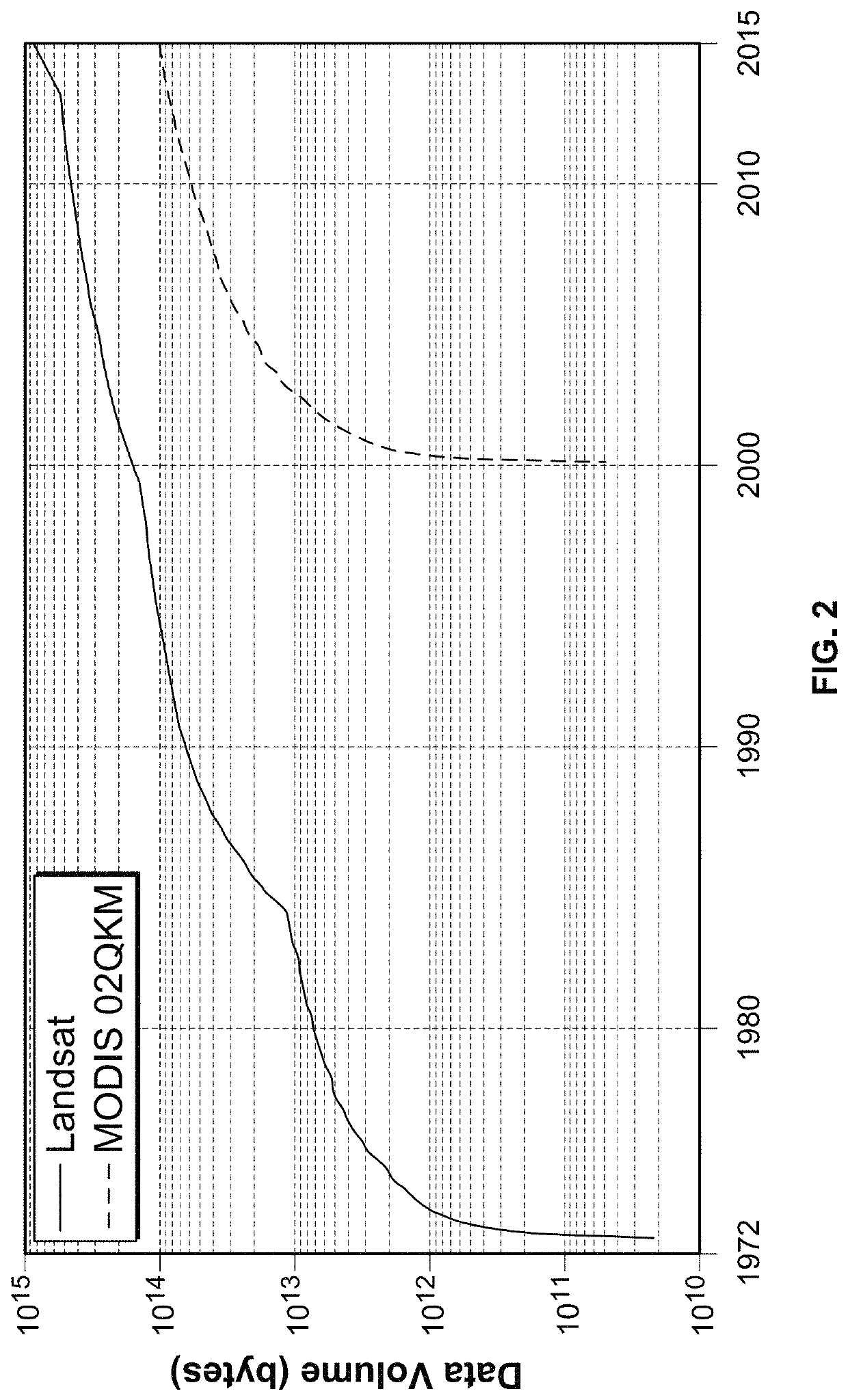

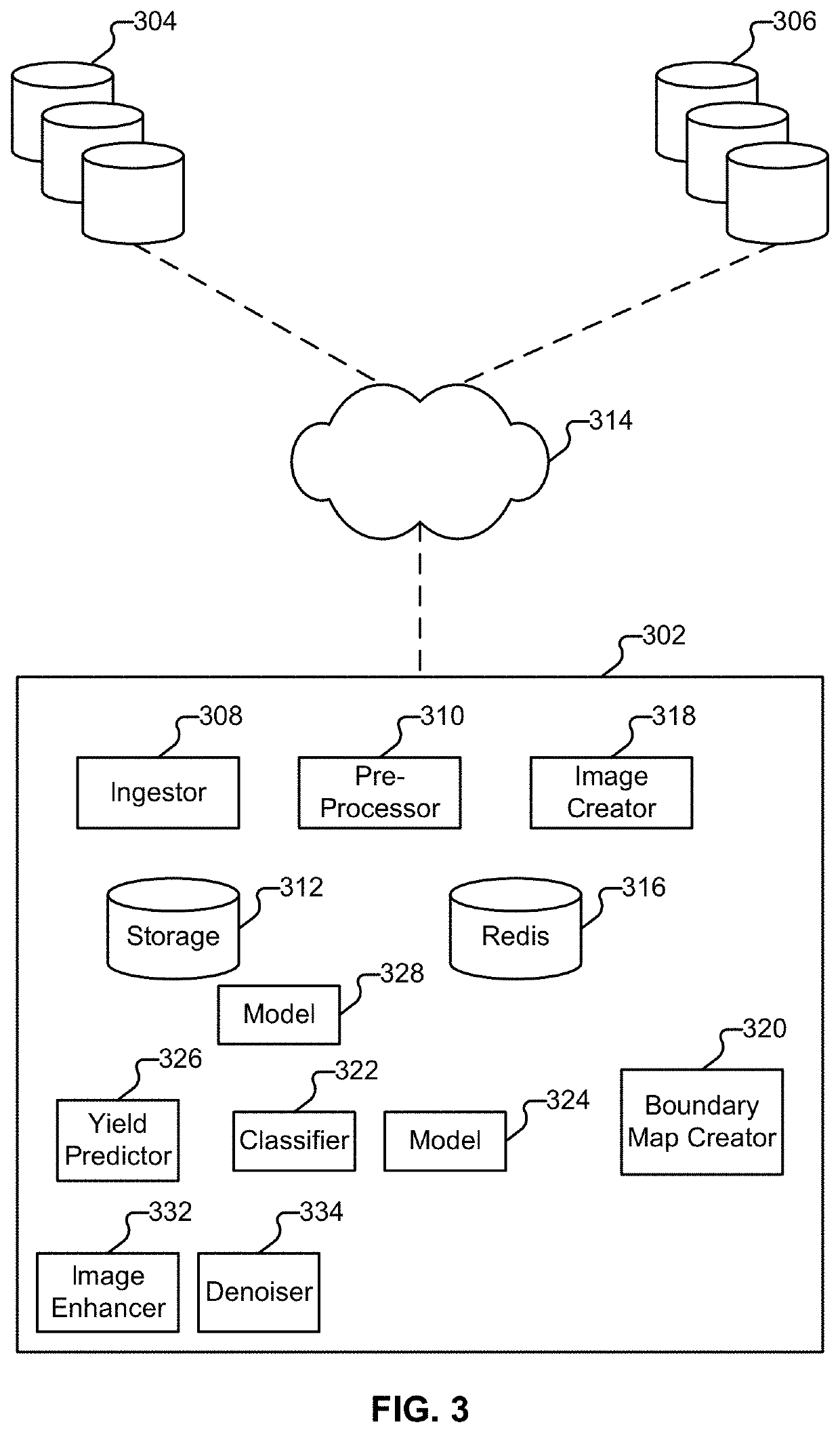

Thermal anomaly detection and classification

Owner:DESCARTES LABS INC

Waste Gas Combustor

PendingUS20220099293A1Reduces length and diameter and costEasy to placeAir/fuel supply for combustionIncinerator apparatusCombustorAtmospheric air

A combustor having a rectangular prism structure with a burner assembly mounted inside for burning waste hydrocarbon gases with combustion air provided through flame arrestors from outside atmospheric air, the combusted hydrocarbon gas exiting through an opening on top of the structure. The combustor includes a controller for operating an igniter on the burner assembly and thermocouples for measuring the temperature of exhaust gas exiting the combustor and for measuring the skin temperature of the structure. The controller can relay the operational data and the location of the combustor to a central control center through a SCADA unit connected to a telecommunications network. The controller can also relay the volume of waste gas burned to the central control center to determine the carbon credits earned by preventing the waste gas being vented to the atmosphere.

Owner:CLEAR RUSH CORP

Movable efficient waste gas burner

InactiveCN111006227AIncrease working temperatureGuaranteed temperatureIncinerator apparatusCombustion chamberCombustor

The invention discloses a movable efficient waste gas burner. The burner comprises a combustion-supporting system arranged at a lower part of a first combustion chamber, wherein the first combustion chamber, a second combustion chamber and a combustion chamber filtering section form an inverted U shape, the combustion-supporting system is connected with a combustion guide sleeve system, the combustion guide sleeve system is matched with a guide system and drives the guide system to move up and down through an electric push rod, the second combustion chamber is connected with a dust remover through a first connecting pipe, a cooler is arranged on the first connecting pipe, the dust remover is connected with a water separator through a second connecting pipe, the water separator is connectedto a draught fan through a third connecting pipe, an air inlet system is arranged on the third connecting pipe, and an adjusting door is arranged below the air inlet system. A drainage system is arranged below the dust remover, an explosion-proof device is arranged above the dust remover and the water separator, and an emptying pipe is connected above the fan. The burner is advantaged in that theconstant temperature of the combustion chamber is kept, and the coal gas in various states can be fully combusted.

Owner:马鞍山领瞻机械科技有限公司

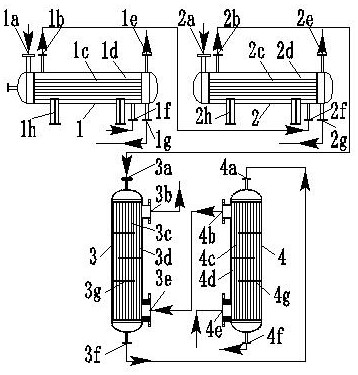

Waste heat recycling system of complete set of waste oil treatment equipment

PendingCN113566617AReduce the temperatureFavorable post-process treatmentRecuperative heat exchangersCombustion technology mitigationCombustorFlue gas

The invention discloses a waste heat recycling system of a complete set of waste oil treatment equipment, and relates to a heating device for waste oil regeneration. The system is characterized in that a bottom line oil heat exchanger, a side line oil heat exchanger, a flue gas rear-section heat exchanger and a flue gas front-section heat exchanger form four-stage heating of waste oil; a heating medium of the bottom line oil heat exchanger is bottom line oil of a fractionating tower, a heating medium of the side line oil heat exchanger is side line oil of the fractionating tower, a heating medium of the flue gas rear-section heat exchanger is flue gas of the rear section of a waste gas burner, and a heating medium of the flue gas front-section heat exchanger is flue gas of the front section of the waste gas burner; the bottom line oil heat exchanger and the side line oil heat exchanger are horizontal cylindrical tank bodies with the same structure, and the flue gas rear-section heat exchanger and the flue gas front-section heat exchanger are vertical hanging type tank bodies with the same structure; and four stages of waste oil heaters are connected in series through pipelines and pipe fittings. The system is scientific and reasonable in structure, safe and reliable, saves energy, reduces the cost of waste oil regeneration, greatly improves high-temperature emission of flue gas, facilitates emission and has popularization value.

Owner:CHONGQING FANGSHENG CLEANING EQUIP CO LTD

Exhaust-gas tract for a motor vehicle

ActiveUS20220112826A1Reduce manufacturing costBurnersInternal combustion piston enginesCombustion chamberExhaust fumes

An exhaust-gas tract for a motor vehicle has an exhaust-gas burner that includes an air inlet connection for the introduction of air into the exhaust-gas burner. The air inlet connection has a connection piece in which a check valve for the closure of the connection piece is arranged. The air inlet connection has an air inlet flange which connects the connection piece to a combustion chamber of the exhaust-gas burner and which seals off the combustion chamber. A motor vehicle incorporates the exhaust-gas tract.

Owner:DR ING H C F PORSCHE AG

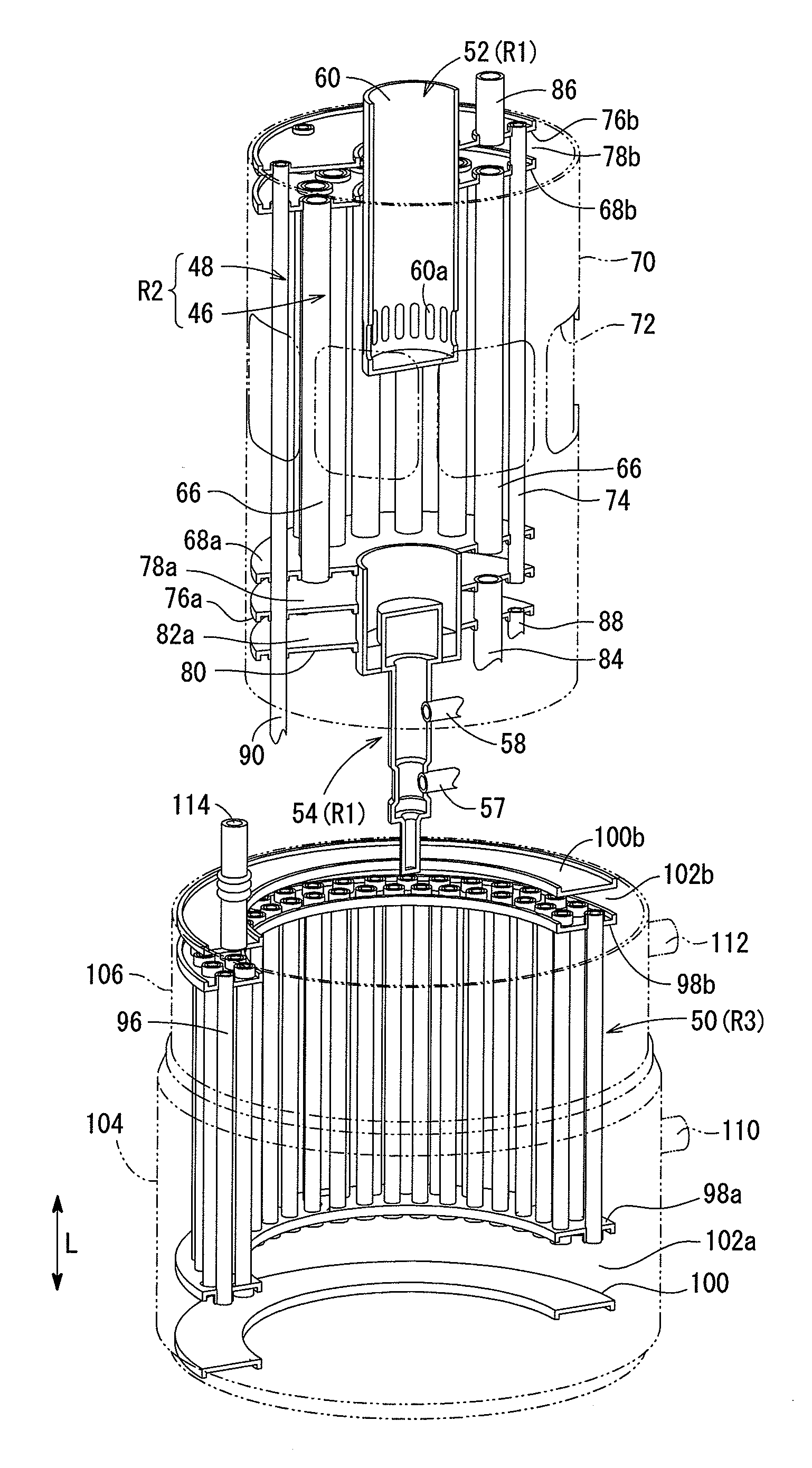

Fuel cell module

ActiveUS9343765B2Simple and compact structureImprove heating efficiencyFuel cells groupingFuel cell auxillariesCombustorFuel cells

A fuel cell module includes a first area where an exhaust gas combustor and a start-up combustor are provided, an annular second area disposed around the first area where a heat exchanger is provided, an annular third area disposed around the second area where a reformer is provided, and an annular fourth area disposed around the third area where an evaporator is provided. In the first area, the exhaust gas combustor and the start-up combustor are provided coaxially in the same space.

Owner:HONDA MOTOR CO LTD

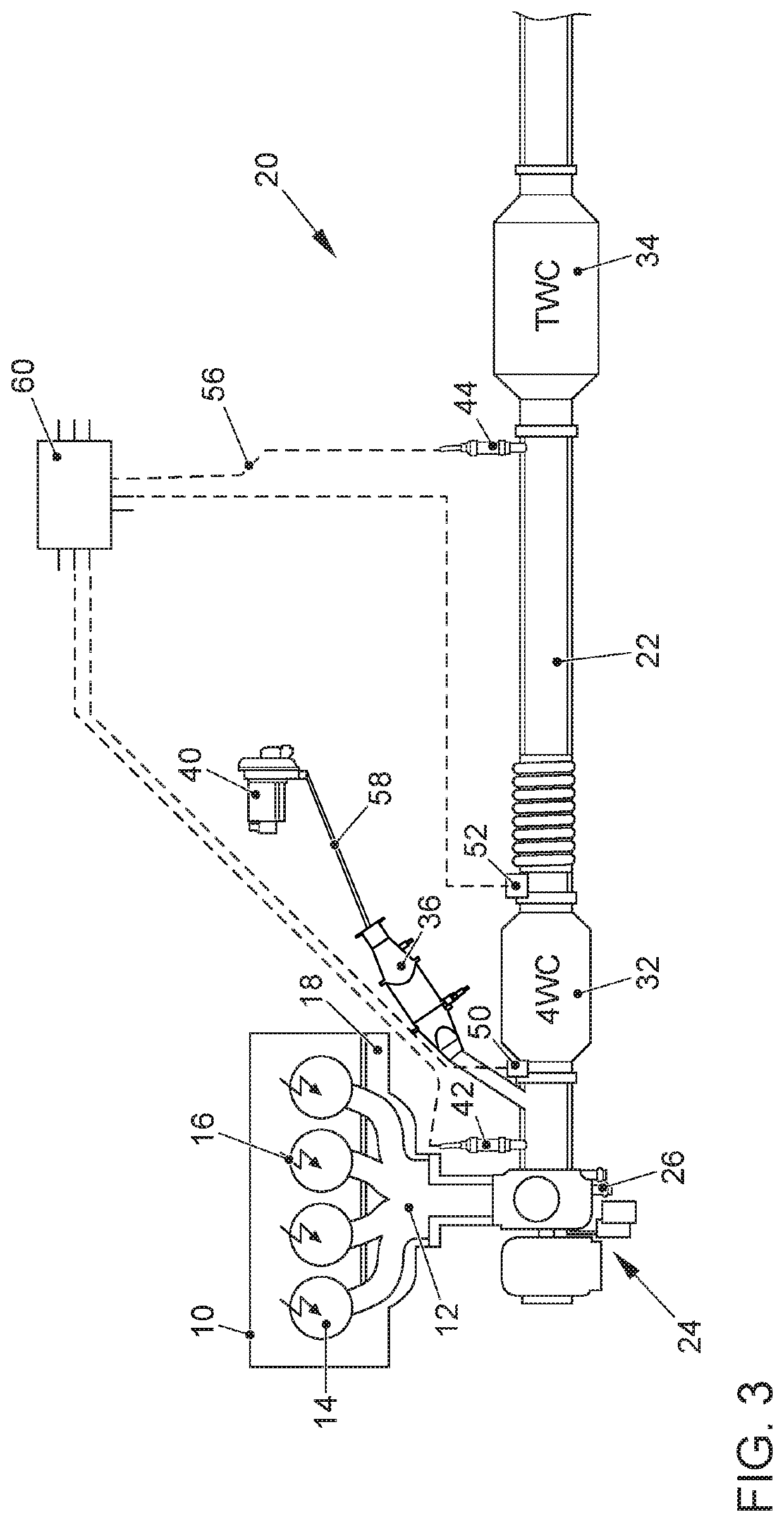

Exhaust gas aftertreatment system and method for exhaust aftertreatment of an internal combustion engine

ActiveUS10815861B2Avoid secondary emissionsAvoid heat damageElectrical controlInternal combustion piston enginesCombustorFresh air

The invention relates to an exhaust gas aftertreatment system for an internal combustion engine, in particular for a gasoline engine that is spark-ignited by means of spark plugs. A four-way catalytic converter and at least one three-way catalytic converter are situated in an exhaust gas system that is connected to an outlet of the internal combustion engine. An exhaust gas burner with which hot exhaust gas is introducible into the exhaust gas system directly downstream from the four-way catalytic converter is provided at an exhaust duct of the exhaust gas system. The exhaust gas burner is supplied with fresh air by a secondary air pump. The invention further relates to a method for exhaust aftertreatment of an internal combustion engine having such an exhaust gas aftertreatment system.

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com