Recovery method for waste gas of refinery plant sewage tank

A recycling method and sewage tank technology, which is applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of difficult airtight recycling of harmful gases, damage to tanks, and inability to eliminate environmental pollution, so as to reduce volatile organic compounds (VOC ) emissions, low operating costs, and the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

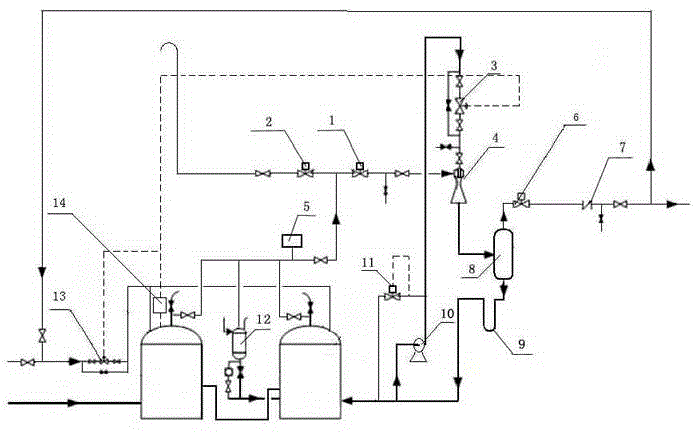

[0029] according to figure 1 As shown, there is a first sewage tank, the sewage tank sewage is used as a continuous power source, and there is a jet supercharger (4), the negative pressure end of the jet supercharger (4) is connected to the exhaust gas on the top of the tank, and the jet supercharger (4) There is an output pipe at the head to enter the gas-liquid separator (8), and the top pipe of the gas-liquid separator (8) is divided into two paths through the control gate valve (6) and then through the check valve (7), and one path enters the gas-liquid separator (8). In the refinery low-pressure gas flare system of the device, another pipeline enters the first sewage tank after passing through the gas regulating valve (13) for pressure regulation of the sewage tank. There is an output pipe at the lower end of the gas-liquid separator (8), and the output The condensate in the pipe is divided into two paths after passing through the U-shaped water-sealed pipe (9). (4) Inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com