Recycling treatment method of dilute alkali wastewater

A technology for dilute alkali wastewater and treatment methods, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Simple, mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

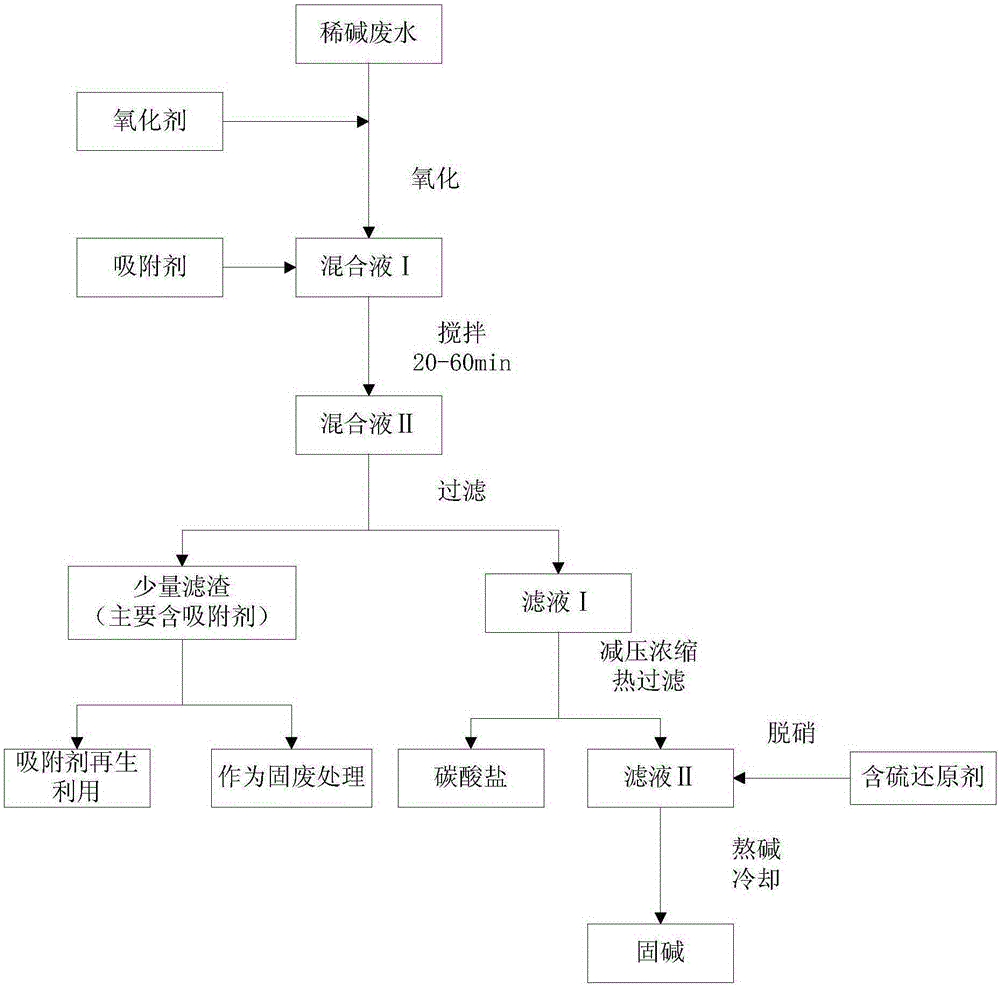

Method used

Image

Examples

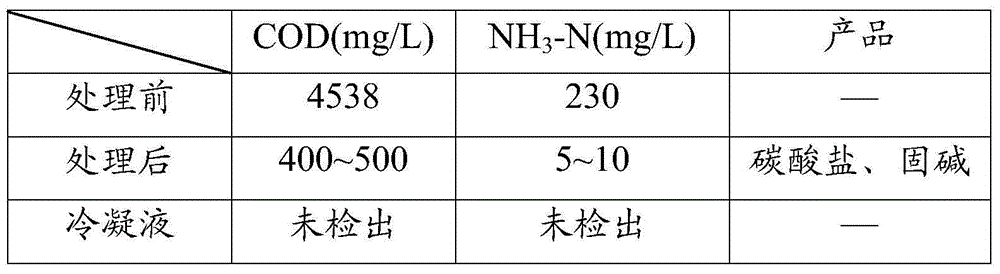

Embodiment 1

[0052] raw material:

[0053] The dilute alkali wastewater produced in the production process of certain indigo, wherein the mass fraction of NaOH and KOH is 14% in total, NaOH 2 CO 3 and K 2 CO 3 The total mass fraction of 1% also contains anilines, amides, cyanides, isatin, ammonia, etc.

[0054] The measured COD of waste water=4538mg / L, NH 3 -N=230mg / L, c(OH - )=3.32mol / L, c(CO 3 2- )=0.23mol / L.

[0055] Processing steps:

[0056] (1) Removal of organic matter: take 300g of dilute alkali wastewater, after filtering, continue to pass ozone reaction for 4h, and the ozone flow rate is 50L / h. Add 0.3 g of activated carbon to the oxidized dilute alkaline wastewater, stir for 30 minutes, filter and separate, and collect the filtrate Ⅰ.

[0057] (2) Carbonate recovery: After the filtrate I was concentrated 4 times under reduced pressure, the temperature was lowered to 40°C and filtered to separate the carbonate and filtrate II.

[0058] (3) Denitrification: add sodium s...

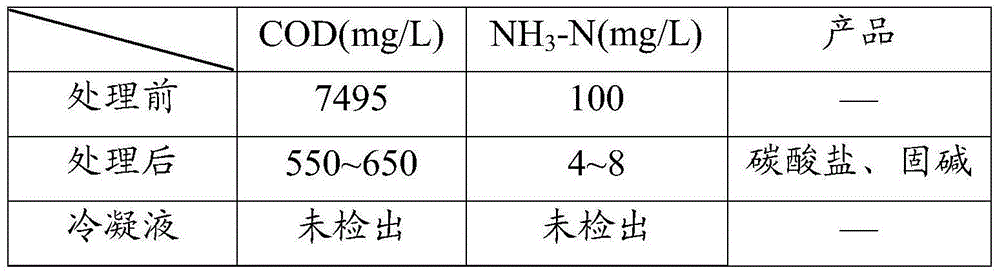

Embodiment 2

[0074] raw material:

[0075] A certain indigo dilute alkali wastewater mainly contains sodium salt and amine organic matter. It is determined that the wastewater w(NaOH)=14.64%~15.09%, COD=7495mg / L, NH 3 - N = 100 mg / L.

[0076] Processing steps:

[0077] (1) Removal of organic matter: take 300g of waste water, after filtration, continue to pass ozone reaction for 6h, and the flow rate of ozone is 40L / h. Add 0.15 g of activated carbon to the oxidized dilute alkaline wastewater, stir for 30 minutes, filter and separate, and collect the filtrate Ⅰ.

[0078] (2) Carbonate recovery: the filtrate I was concentrated under reduced pressure, cooled to 30° C., filtered and separated to obtain carbonate and filtrate II.

[0079] (3) Denitrification: Add sodium sulfite with a theoretical dosage of 75% to the filtrate II, stir and react for 1 hour to obtain reaction solution III. The nitrate removal rate measured by sampling was 90%.

[0080] (4) Soda boiling: put the reaction solut...

Embodiment 3

[0085] raw material:

[0086] A certain printing and dyeing wastewater contains NaOH, a small amount of carbonate and other organic matter. The measured COD of waste water=5236mg / L, NH 3 -N=227mg / L, phenolphthalein alkalinity is 18%.

[0087] Processing steps:

[0088] (1) Removal of organic matter: take 400g of dilute alkaline wastewater, after filtration, continue to pass ozone for 5h until the wastewater is completely oxidized. Then add 0.4g of activated carbon to the dilute alkali wastewater, stir for 40 minutes, then filter and separate, and collect the filtrate Ⅰ.

[0089] (2) Carbonate recovery: After the filtrate I was concentrated under reduced pressure, the carbonate and filtrate II were separated by hot filtration at 40°C.

[0090] (3) Denitrification: Add sodium sulfide with a theoretical dosage of 80% to the filtrate II to remove nitrate in the waste water, and stir for 1 hour to obtain the reaction solution III. The nitrate removal rate measured by sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com