Energy-saving and environment-friendly furnace

An energy-saving and environmental protection furnace technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve pollution and other problems, and achieve the effect of low waste gas treatment cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

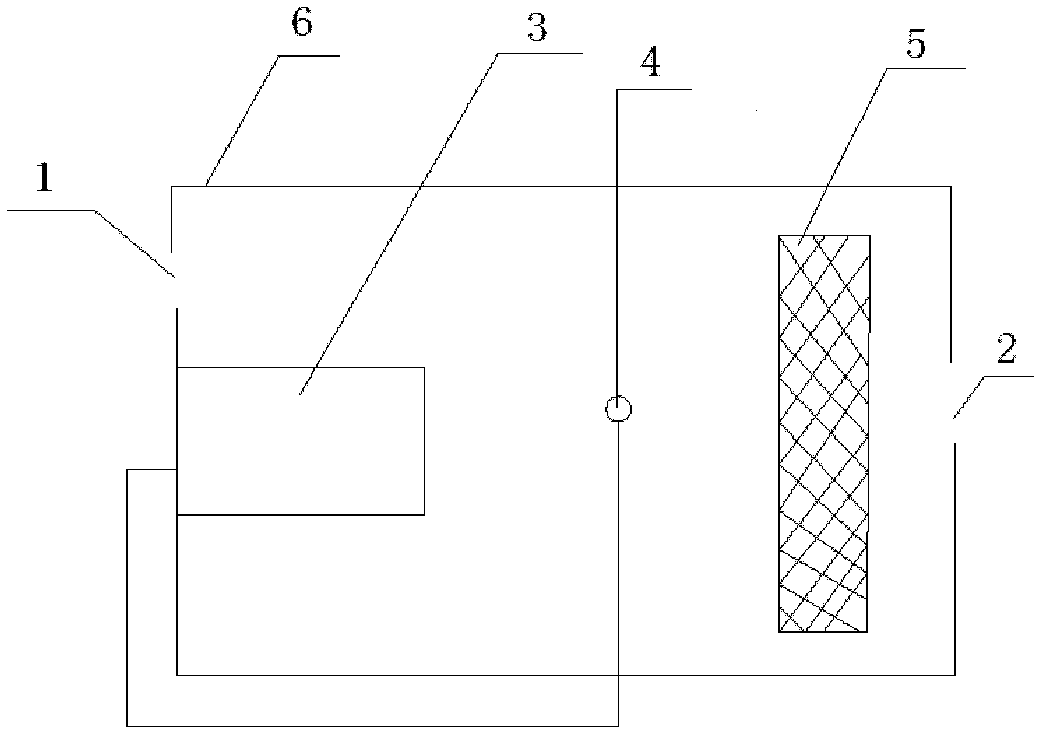

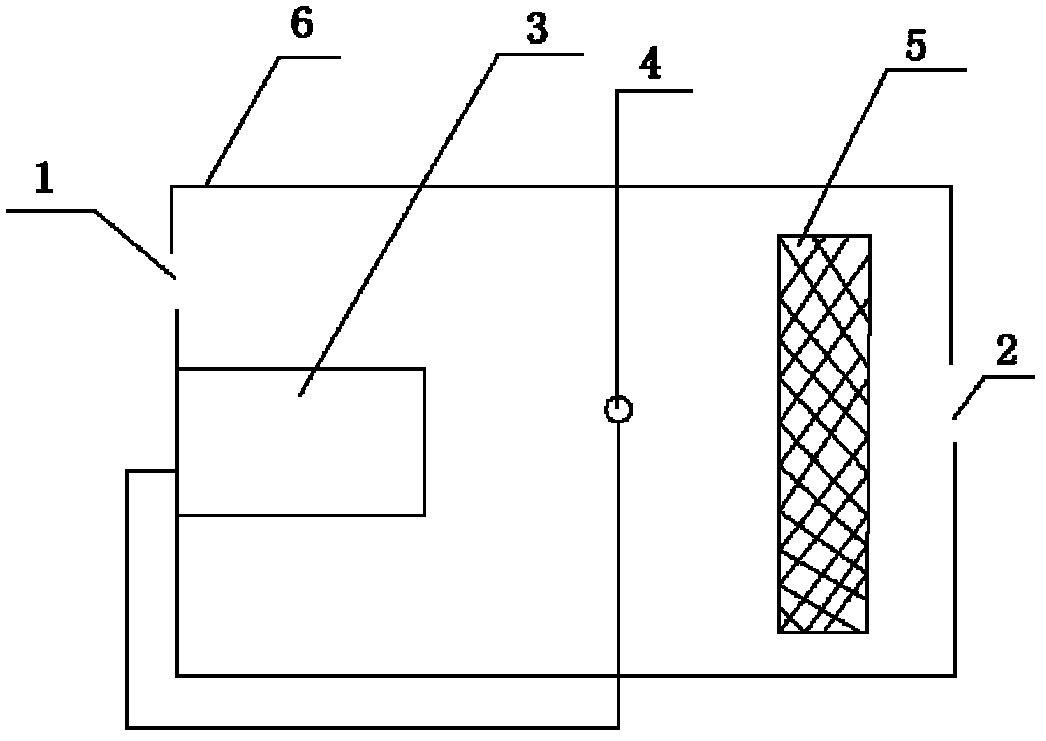

[0010] Such as figure 1 As shown, an energy-saving and environment-friendly furnace of the present invention comprises a furnace body 6, the furnace body 6 is provided with a gas inlet 1 and a gas outlet 2, the lower end of the gas inlet 1 is provided with a burner 3, and the furnace body 6 A thermocouple 4 connected to the burner 3 to control the burner 3 is provided inside, and a catalytic combustion device 5 is provided at the end of the furnace body 6 .

[0011] The working process of this example: when working, the organic solvent waste gas discharged from the drying link enters the furnace body 6 through the gas inlet 1 of the furnace body 6, and the burner 3 at the lower end of the gas inlet 1 of the furnace body 6 is used for the organic solvent waste gas. Combustion treatment, the thermocouple 4 in the furnace body 6 adjusts the combustion intensity of the burner 3 by detecting the burned gas. The exhaust gas passes through the catalytic combustion device 5 at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com