VOCs containing industrial waste gas treatment process and system

A technology of industrial waste gas and treatment system, which is applied in the direction of air quality improvement, combustion method, lighting and heating equipment, etc. It can solve the problem of high energy consumption, achieve high purification efficiency, simple and compact structure, and avoid harmful gas escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

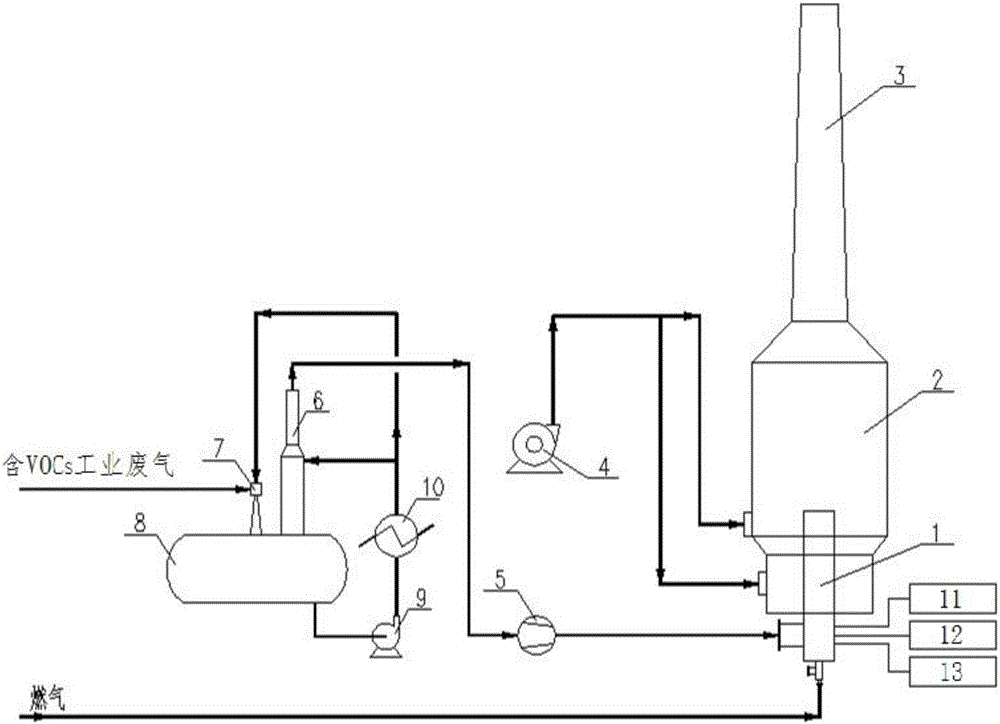

[0040] Such as figure 1 Shown, a kind of treatment process containing VOCs industrial waste gas of the present invention, comprises the steps:

[0041] 1) The absorbent in the absorbent circulation tank 8 is pumped out by the absorbent circulation pump 9, and after being cooled to 30-80°C by the absorbent cooler 10, it is sent to the nozzle of the exhaust gas cleaner 7, and enters the exhaust gas scrubber. The absorbent pressure of the cleaner 7 is 0.4~1.0Mpa; the pressure of the waste gas inlet in the exhaust cleaner 7 is -1~-5kPa, and the industrial waste gas containing VOCs is sucked into the exhaust cleaner 7 by using this negative pressure, so that the exhaust cleaner 7 contains The VOCs industrial waste gas is fully mixed with the absorbent, and a physical and chemical reaction occurs;

[0042] 2) The mixture of industrial waste gas and ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com