Movable efficient waste gas burner

A waste gas combustion and mobile technology, applied in the combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of changing the production process, insufficient combustion, prolonging the time interval, etc., and achieve the effect of increasing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

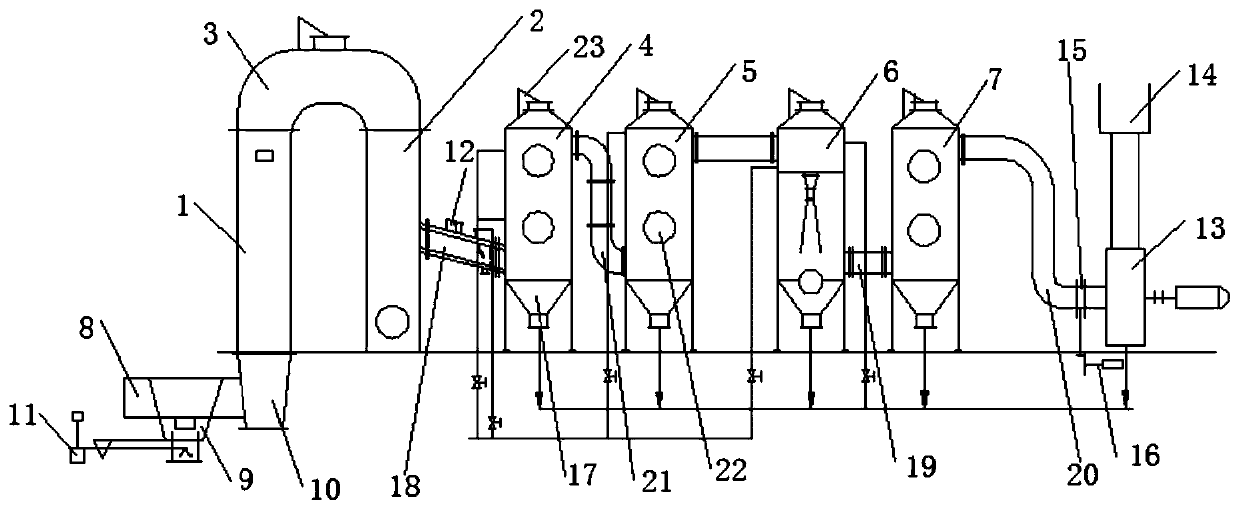

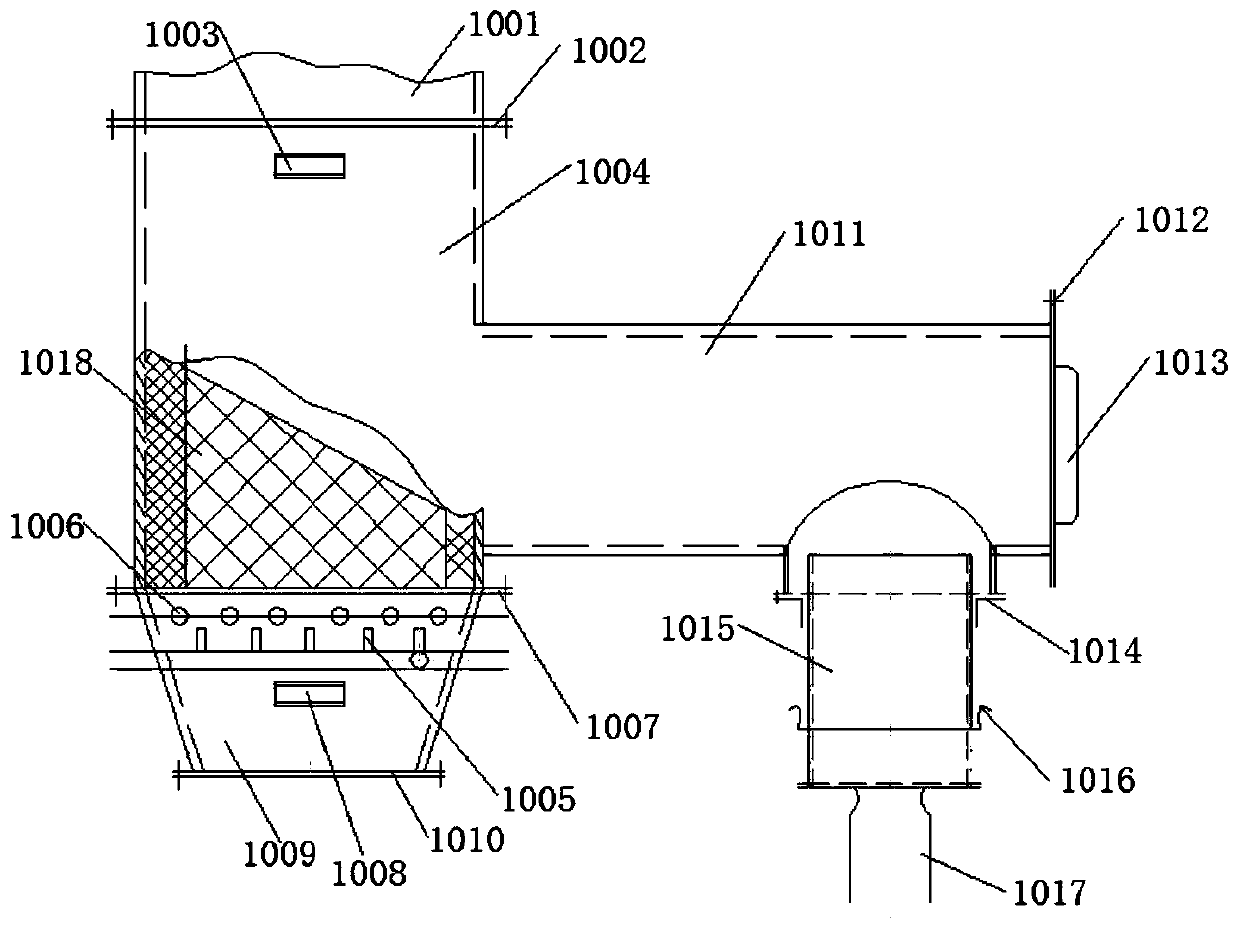

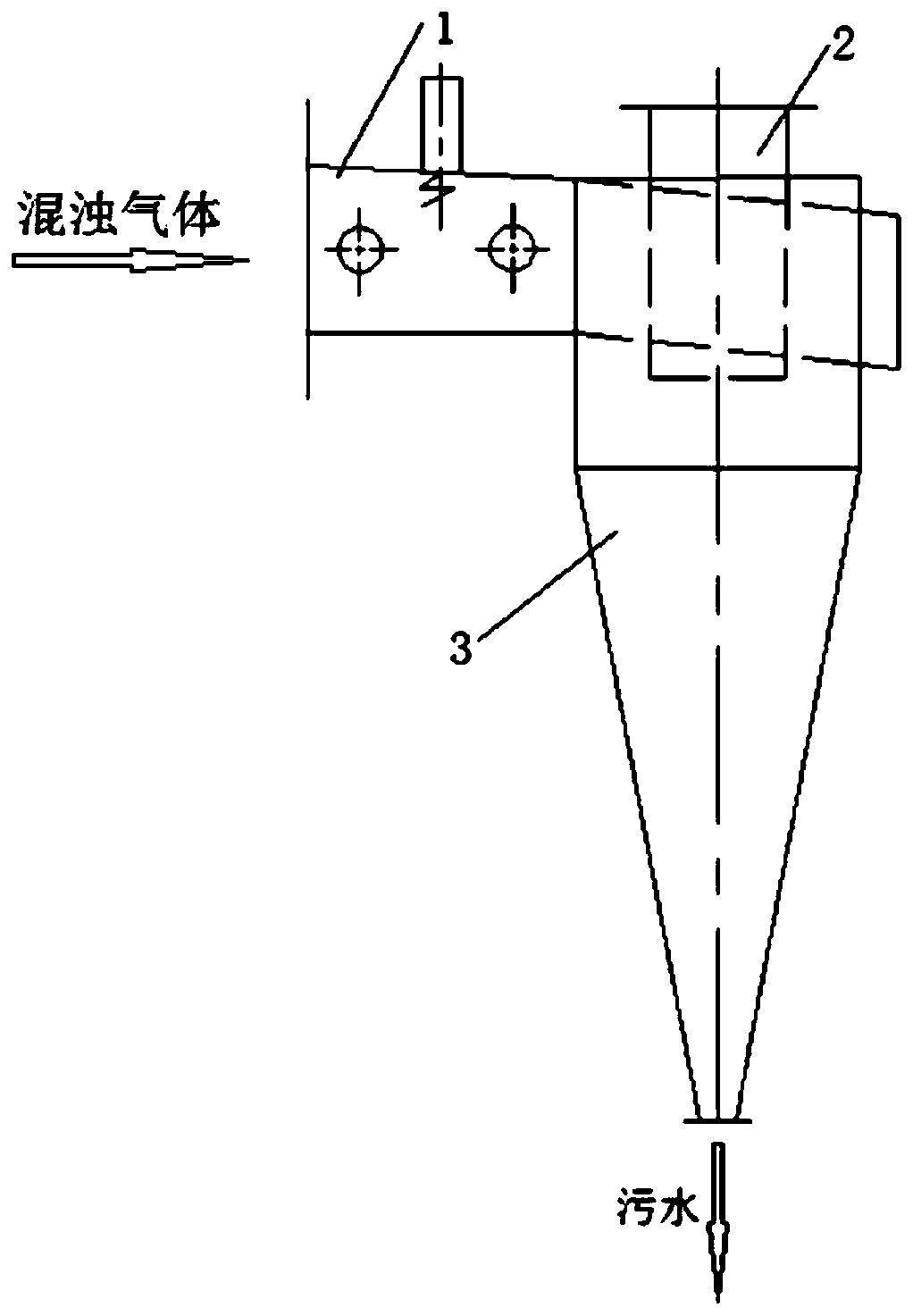

[0078] figure 1 A schematic diagram of smoke and dust removal according to an exemplary embodiment of the present invention is shown.

[0079] Such as figure 1 As shown, a mobile high-efficiency exhaust gas burner of the present invention includes: a first combustion chamber 1 connected in sequence, a combustion chamber filter section 3, a second combustion chamber 2, a dust collector, a water separator 7 and a fan 13, wherein ,

[0080] The combustion-supporting system 10 is arranged at the lower part of the first combustion chamber 1, and the first combustion chamber 1, the second combustion chamber 2 and the filter section 3 of the combustion chamber form an inverted "U" shape;

[0081] The combustion-supporting system 10 is connected with the combustion guide sleeve system 8;

[0082] The combustion guide sleeve system 8 cooperates with the guide system 9, and drives the guide system 9 to move up and down through the electric push rod 11;

[0083] The second combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com