NMP gas recovery system and technology thereof

A gas recovery and gas technology, applied in steam condensation, organic chemistry, dispersed particle separation, etc., can solve problems such as failure to meet environmental protection requirements, low recovery rate utilization, and increased operating costs, so as to avoid endangering the health of employees, Improve resource utilization and improve the effect of the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention and its beneficial effects will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

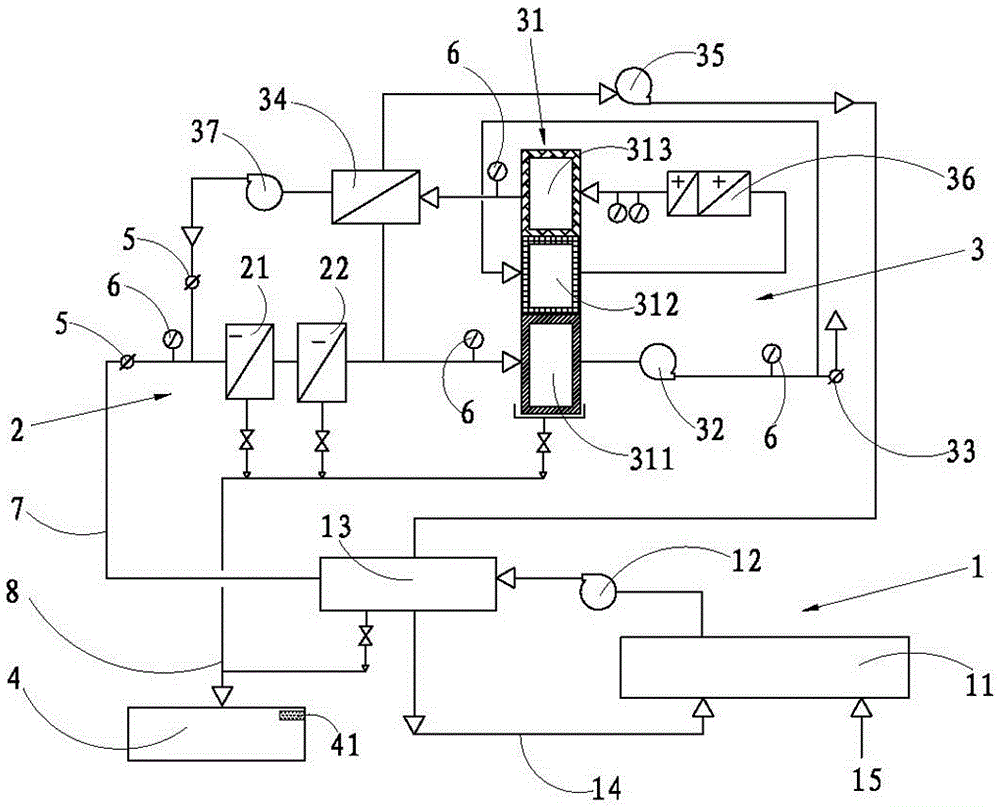

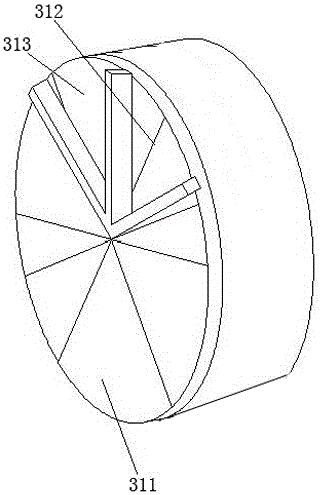

[0037] Such as Figure 1~2 As shown, an NMP gas recovery system includes a pre-cooling exchange unit 1, a condensation unit 2, an adsorption regeneration unit 3 and an NMP waste liquid recovery tank 4 connected in sequence, and also includes a control unit, a pre-cooling exchange unit 1, and a condensation unit 2 , the adsorption regeneration unit 3 and the NMP waste liquid recovery tank 4 are electrically connected to the control unit respectively; the pre-cooling exchange unit 1 includes a pole piece coating machine 11, a first blower fan 12 and a first air-to-air heat exchange unit connected in sequence by the air duct 7 13, the condensing unit 2 includes a primary water cooler 21 and a secondary water cooler 22 connected in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com