A sintering process for magnet production

A magnet and process technology, applied in the field of sintering process for magnet production, can solve the problems affecting the production efficiency of magnet sintering, uneven distribution of magnet intergranular phases, slow magnet heating speed, etc., to reduce slow heat dissipation process, reduce heat preservation time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

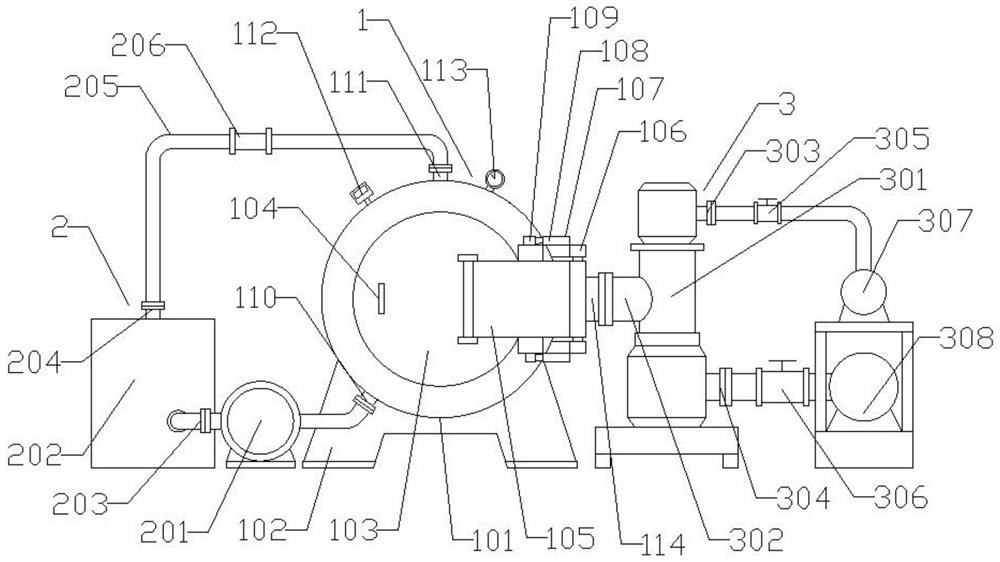

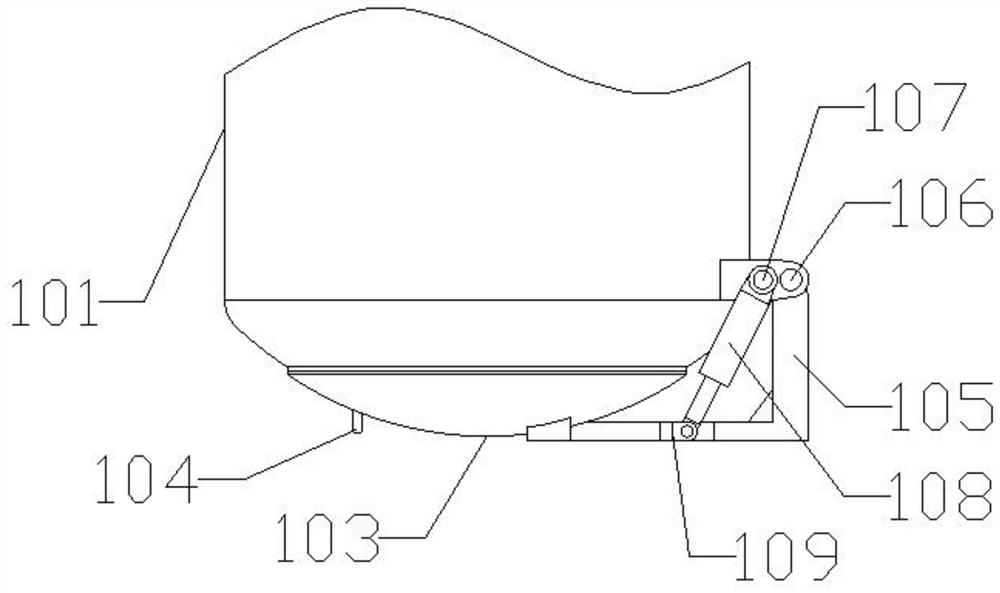

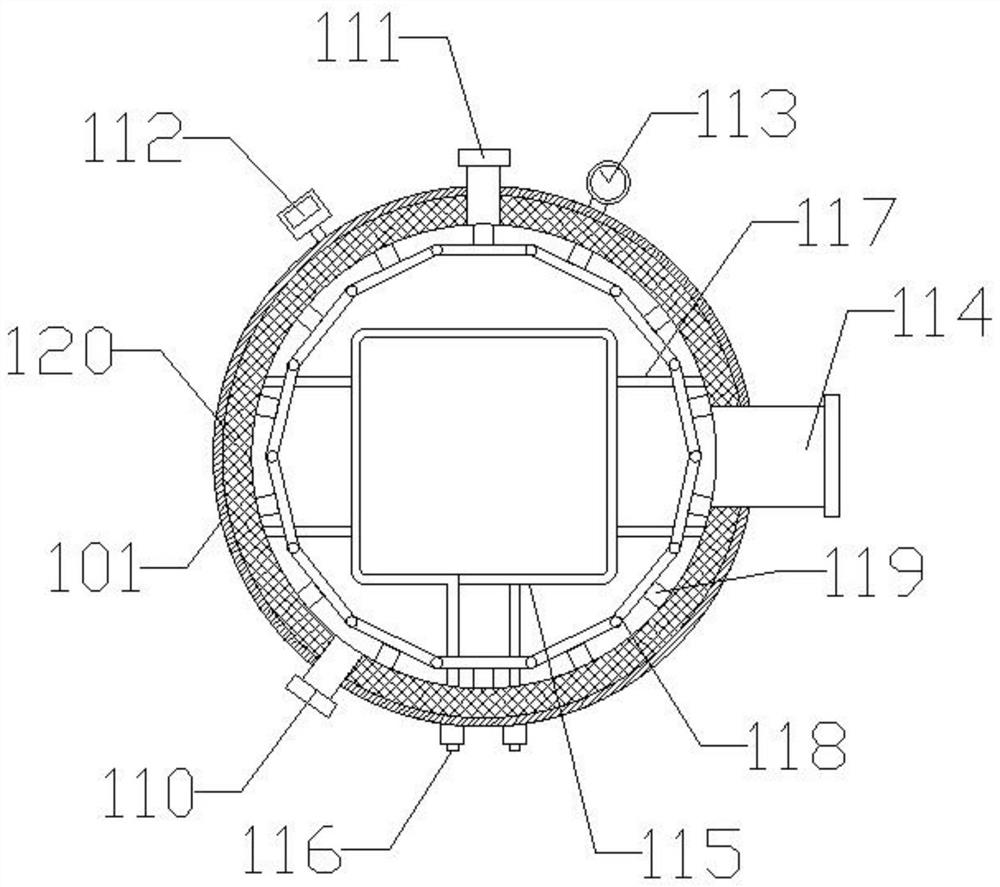

[0034] A sintering process for magnet production, specifically comprising the following steps:

[0035] Step S1: Place the formed magnet compacts neatly in the induction coil 115 of the vacuum induction sintering furnace equipment according to a uniform gap, control the telescopic cylinder 108 to shrink, so that the furnace door 103 is closed and sealed, and at the same time start the first vacuum pump 308 and The second vacuum pump 307 pumps the vacuum inside the furnace body 101 to 2Pa, then closes the first valve 306 and the second valve 305, energizes the induction coil 115, and raises the temperature of the magnet compact from room temperature at a heating rate of 100°C / s To the first temperature of 300°C, keep warm for 8 minutes, open the first valve 306 during the heat preservation process, and evacuate the inside of the furnace body 101 to stabilize the vacuum degree at 50Pa;

[0036] Step S2: Heat the magnet treated in step S1 with the induction coil 115, and raise th...

Embodiment 2

[0040] A sintering process for magnet production, specifically comprising the following steps:

[0041] Step S1: Place the formed magnet compacts neatly in the induction coil 115 of the vacuum induction sintering furnace equipment according to a uniform gap, control the telescopic cylinder 108 to shrink, so that the furnace door 103 is closed and sealed, and at the same time start the first vacuum pump 308 and The second vacuum pump 307 pumps the vacuum inside the furnace body 101 to 4Pa, then closes the first valve 306 and the second valve 305, energizes the induction coil 115, and raises the temperature of the magnet compact from room temperature at a heating rate of 100°C / s To the first temperature of 350°C, keep warm for 9 minutes, open the first valve 306 during the heat preservation process, and evacuate the inside of the furnace body 101 to stabilize the vacuum degree at 50Pa;

[0042] Step S2: Heat the magnet treated in step S1 with the induction coil 115, and raise th...

Embodiment 3

[0046] A sintering process for magnet production, specifically comprising the following steps:

[0047] Step S1: Place the formed magnet compacts neatly in the induction coil 115 of the vacuum induction sintering furnace equipment according to a uniform gap, control the telescopic cylinder 108 to shrink, so that the furnace door 103 is closed and sealed, and at the same time start the first vacuum pump 308 and The second vacuum pump 307 pumps the vacuum inside the furnace body 101 to 5Pa, then closes the first valve 306 and the second valve 305, energizes the induction coil 115, and raises the temperature of the magnet compact from room temperature at a heating rate of 100°C / s To the first temperature of 400°C, keep warm for 10 minutes, open the first valve 306 during the heat preservation process, and vacuum the inside of the furnace body 101 to stabilize the vacuum degree at 50Pa;

[0048] Step S2: Heat the magnet treated in step S1 with the induction coil 115, raise the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com