Technology of slag fused casting train shaft

A technology for electroslag casting and train axles, which is applied to the production process of axles, can solve problems such as complex shapes, and achieve the effects of improving mechanical properties, metal densification, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

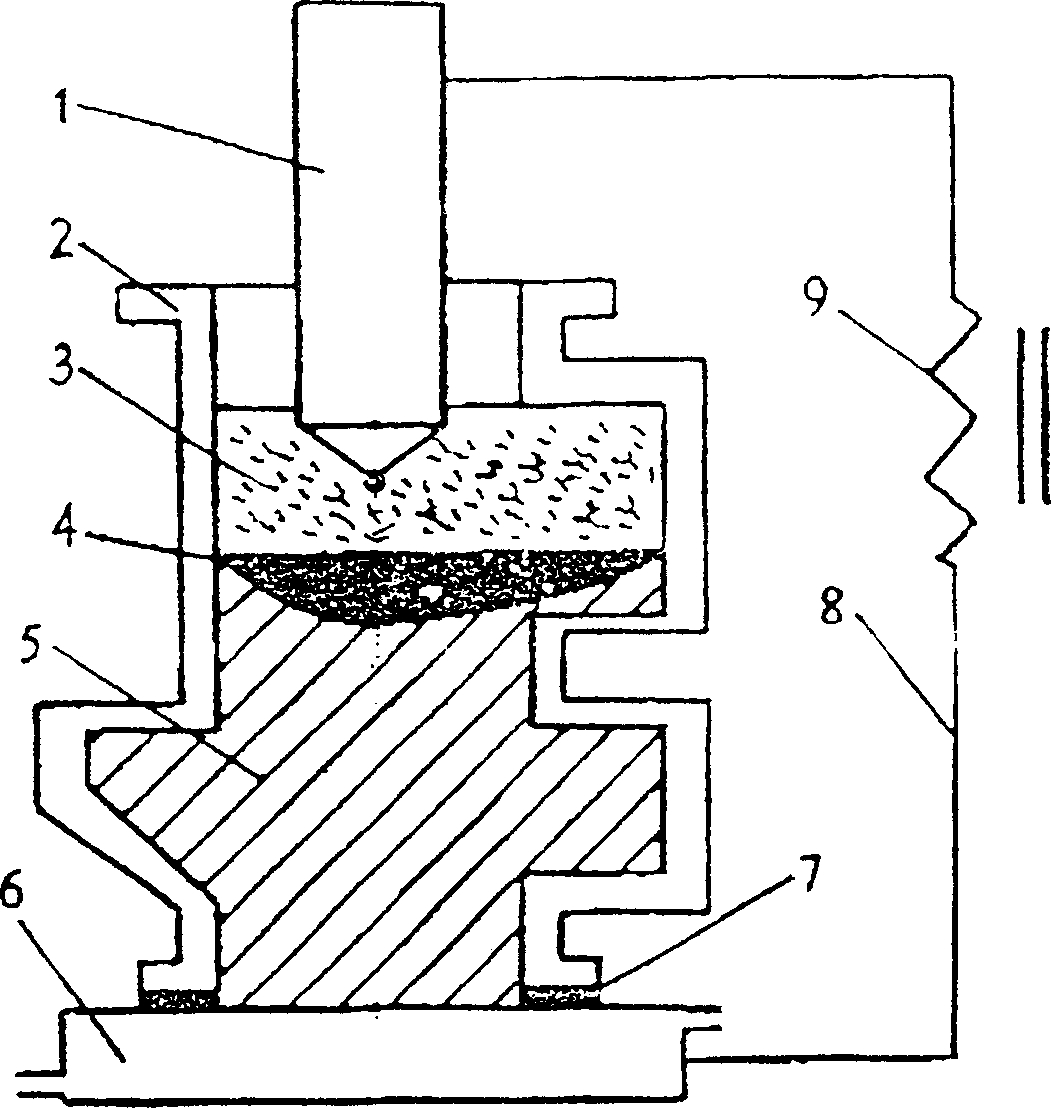

Method used

Image

Examples

Embodiment 1

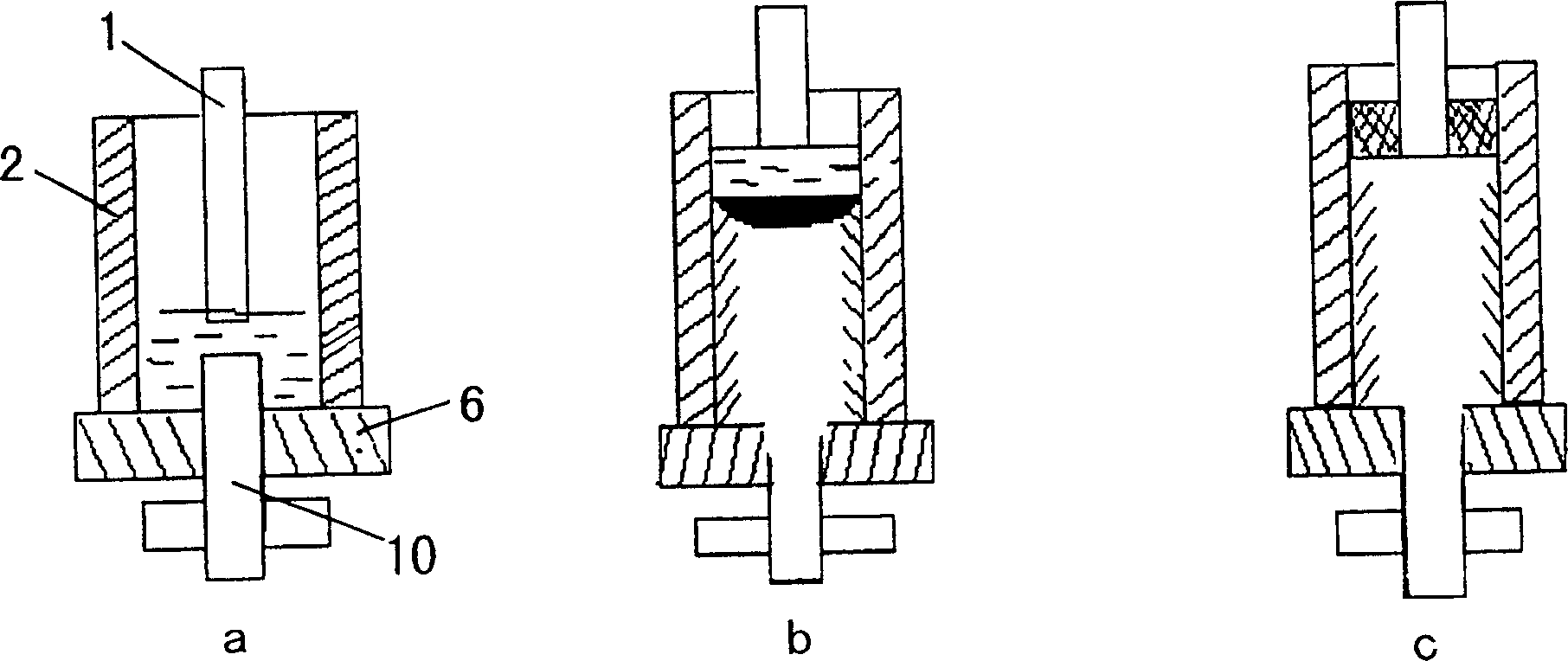

[0017] Embodiment one: attached figure 2 As shown, a, b, and c in the figure are the three processes of electroslag casting. First insert the formed journal into the center ingot head of the bottom water tray 6 as the dummy head 10, use the slag resistance heat in the melting and casting process to fuse the journal and the shaft body, continue to melt and cast until the shaft body is cast, and use it as a self-consumable electrode 1. The journal end of the remaining head is melted, and the journal is inserted into the molten pool when the power is off, and its operation is like electroslag contact welding. This method is very economical, not only the prefabricated journal can be used, but also the old journal can be used, and the hollow shaft can be melt-cast by fixing the metal water-cooled mandrel. This method is completely consistent with the chemical composition, structure and base metal of the overall casting, and has high and uniform mechanical properties.

[0018] In...

Embodiment 2

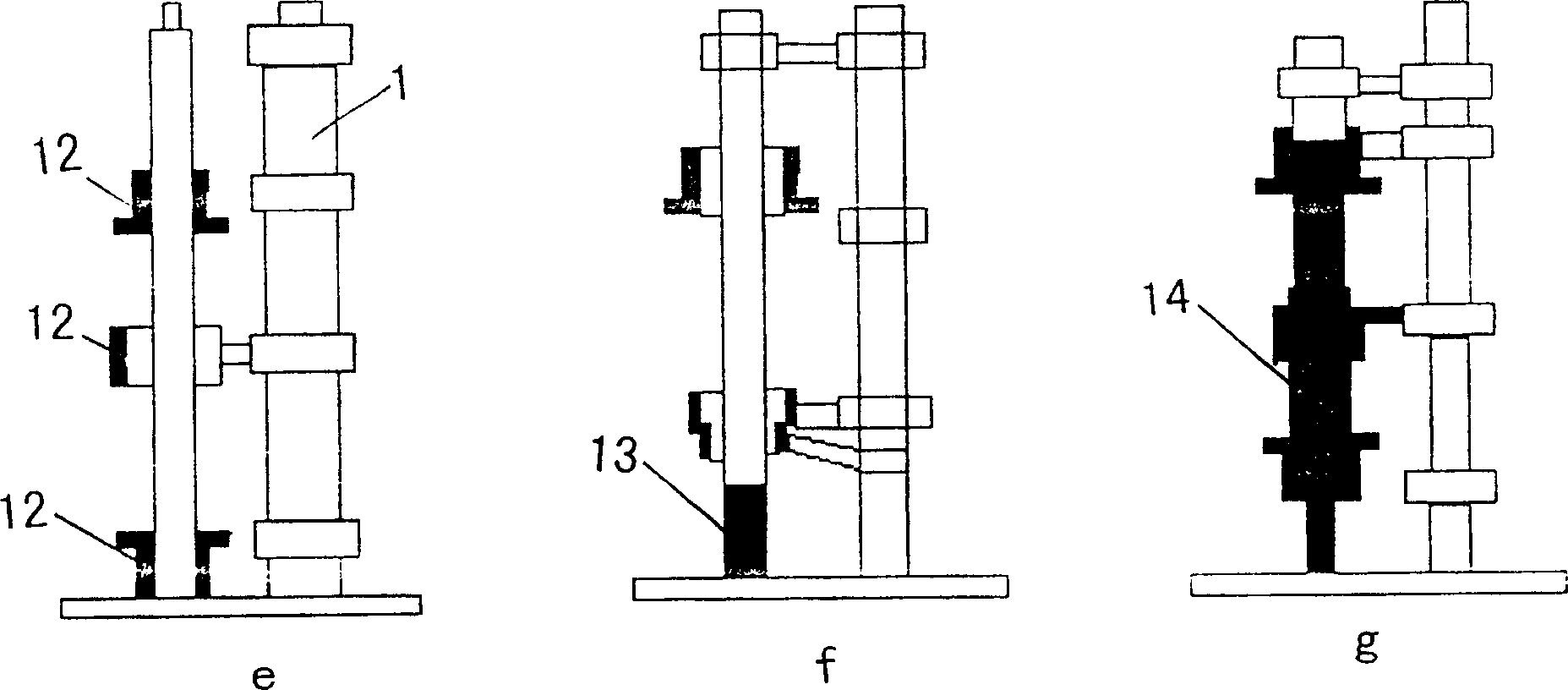

[0020] Embodiment 2: In order to obtain the integral casting train axle, adopt the crystallizer lifting method to melt and cast the integral axle, as attached image 3 The processes of e, f, and g shown. This special equipment also has three short crystallizers 12 and each subsidiary bottom water tray 6, three dollies carrying crystallizers except sending electrode dolly, and each dolly is used to move corresponding short crystallizer 12. The inner cavity of each short crystallizer is designed as the corresponding part of the axle shaft, and the shape and size are the same as the axle shaft. The first short crystallizer 12 in the lower part is ignited to start melting and casting. The crystallizer is lifted during the melting and casting process to form the axle journal 13 and then replaced The second short crystallizer 12 in the middle melts and casts the shaft body 14, adds dried solid slag, and after the shaft body 14 is melted and casts, replaces the upper third short mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com