Glass printing technology with gradually-changing effect

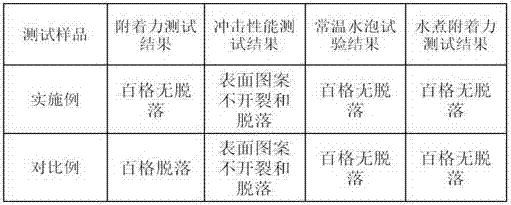

A gradient effect, glass technology, applied in printing, post-processing of printing, printing devices, etc., can solve the problems of poor adhesion between transfer patterns and glass materials, time-consuming, labor-intensive, and large-scale costs, and achieve good appearance and visual effects. The preparation process is simple and the three-dimensional effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The formula and composition of the UV coating used in the present embodiment are:

[0033]

[0034] The raw materials used in the preparation of UV coatings are all commercially available raw materials, and the average particle size of iron powder is 3 μm. If you need to obtain a pattern with a very strong three-dimensional effect, you can choose iron powder with a relatively larger average particle size. In the process, the coating thickness of the thermosetting metal ink is correspondingly increased to completely cover the UV coating layer. The light curing agent used in the UV coating is a combined curing agent composed of TPO, ITS and 184 with a mass ratio of 1:1:3. The weight-average relative molecular weight of the selected polyurethane acrylate resin is 2300. The selected auxiliary agent is a mixing auxiliary agent composed of adhesion promoter and leveling agent with a mass ratio of 1:1.

[0035] The preparation method of UV coating is: mix pure acrylic pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com