High-strength high-transparency thermal-resistant hard plastic alloy granular material

A hard plastic and high-strength technology, which is applied in the field of high-strength, high-transparency, heat-resistant hard plastic alloy pellets and plastic alloy pellets, can solve the problems of transparency, limiting the application range of PVC alloy injection molding products, zooming, etc., to achieve Excellent physical and mechanical properties, good market application prospects, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below through specific examples, but the claims of the present invention will not be limited in any way.

[0023] Unless otherwise specified, the raw materials involved in the following examples are commercially available general products, and the production equipment involved are conventional equipment in the art.

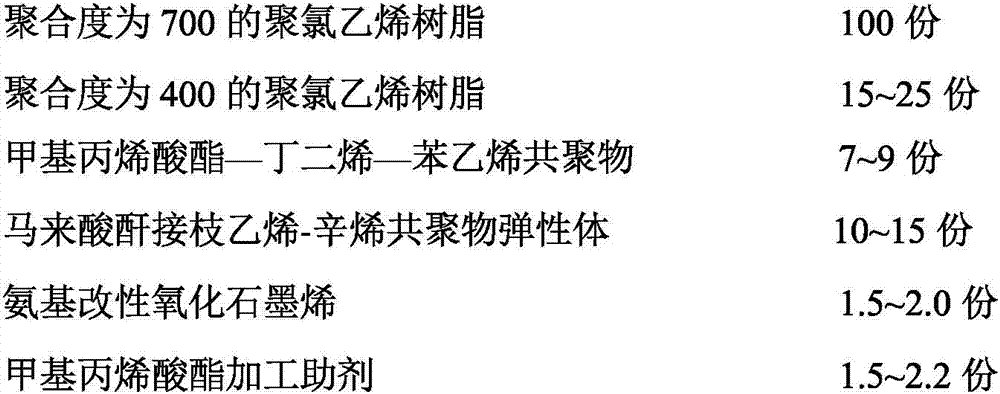

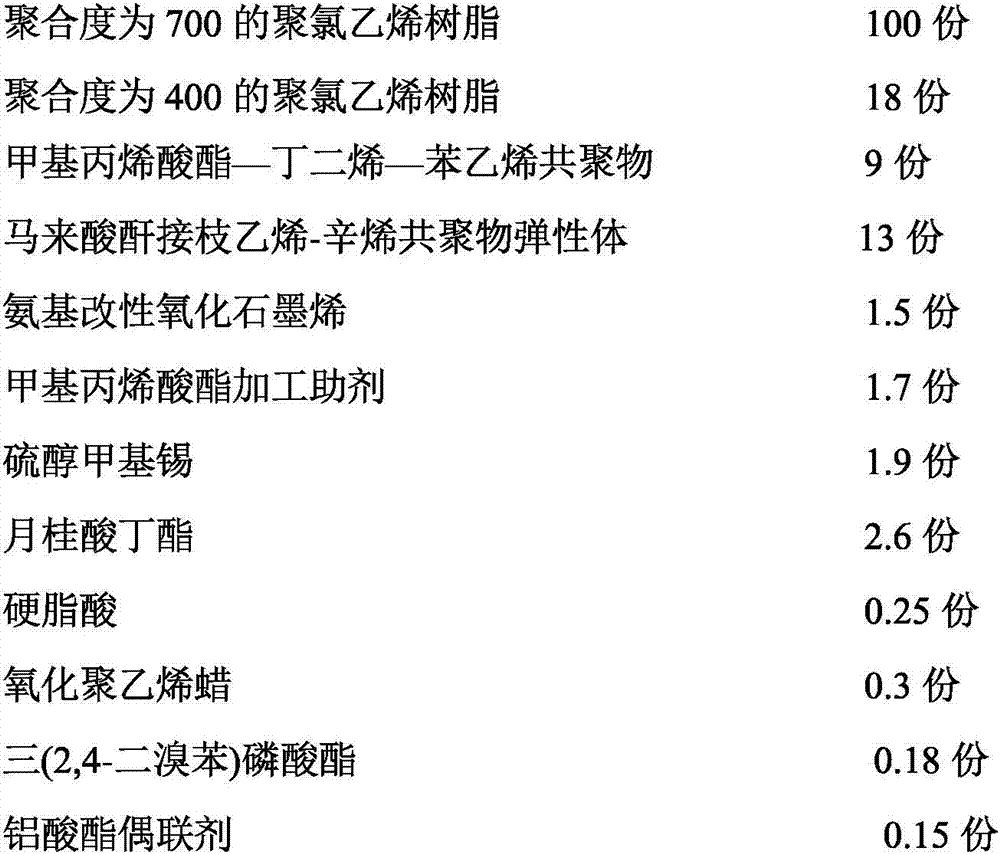

[0024] See Table 1 for the distribution ratio of each component of the plastic alloy pellets in Examples 1 to 4.

[0025] Table 1 Example 1~Example 4 The weight ratio of each component of the plastic alloy pellets (unit: kilogram)

[0026]

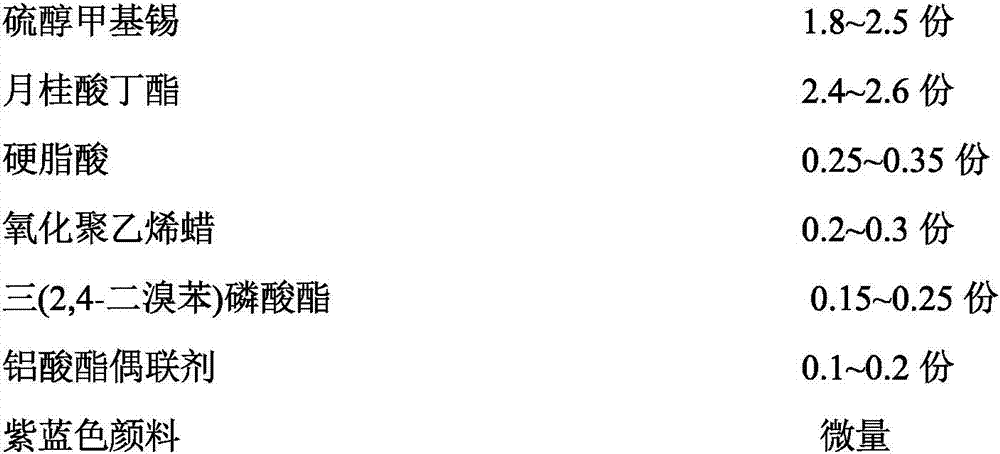

[0027] Examples 1 to 2 are VOC content (%) control groups, and the VOC content of each component is shown in Table 2; Examples 3 to 4 are control groups.

[0028] Table 2 Example 1~Example 2 VOC content (%) of each component of plastic alloy pellets

[0029]

[0030]

[0031] The concrete preparation method of embodiment 1~embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com