Glass cover plate surface color gradient printing process

A color gradient and glass cover technology, applied in printing, printing devices, etc., can solve problems such as unnatural transition, difficulty in controlling the gradient interface, oil accumulation, etc., achieve uniform and natural gradient colors, good visual effects, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Making a glass cover plate with red and black gradient effect

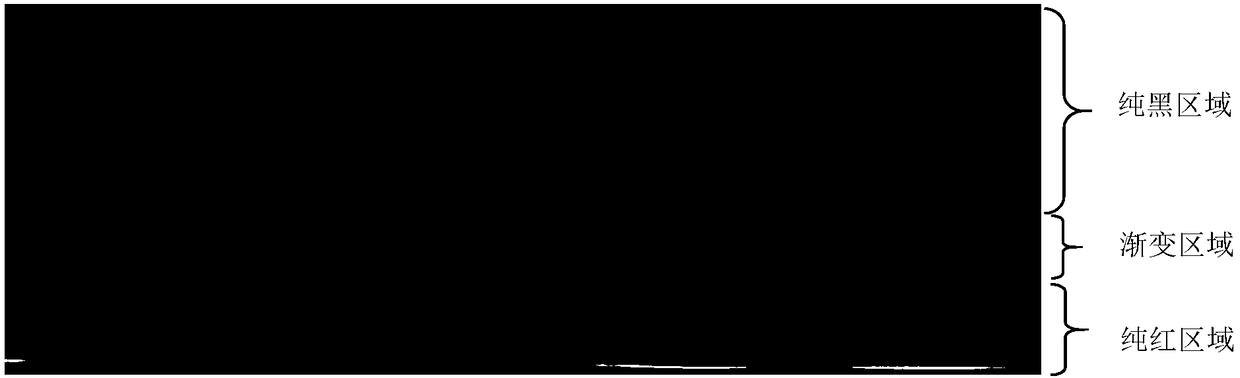

[0025] (1) Design and manufacture the film, and make a five-layer screen that is suitable for the size of the area to be processed on the surface of the cover plate. Plan a pure black area, a gradient area, and a pure red area in the area to be processed on the surface of the cover plate; place the cover plate on the Enter the screen printing machine to start screen printing;

[0026] (2) Silk screen black ink: use the first layer of screen to print black ink on the pure black area and gradient area on the surface of the cover plate, and gradually reduce the size of the screen dots from 0.24mm to 0.08mm, so that the next step can be printed on the dots Screen-print red ink in the gaps; the mesh number of the screen is 420 mesh; after the screen printing, the cover plate is dried at a temperature of 120° C., and the drying time is 5 minutes. The thickness of the obtained single-layer ink is 3 μm...

Embodiment 2

[0032] Embodiment 2 Making a glass cover plate with red and blue gradient effects

[0033] (1) Design and manufacture the film, and make a five-layer screen that is suitable for the size of the area to be processed on the surface of the cover, and plan a pure black area, a gradient area, and a pure blue area in the area to be processed on the surface of the cover; place the cover Enter the screen printing machine to start screen printing;

[0034] (2) Screen printing blue ink: use the first layer of screen to print blue ink on the pure blue area and gradient area on the surface of the cover plate, and gradually reduce the size of the screen dots from 0.24mm to 0.08mm, so that the next step can Screen-print red ink in the gaps of the dots; the screen mesh is 420 mesh; after the screen printing, the cover plate is dried at a temperature of 120° C. and a drying time of 5 minutes, and the thickness of the obtained ink is 3 μm.

[0035] (3) Silk screen red ink: use the second laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com