Light shield layer structure with infrared ray hole of flat plate display

A flat-panel display and infrared technology, which is applied to the structure of telephones, instruments, identification devices, etc., can solve problems such as differences in reflectivity, increased production costs, and imperishable colors, so as to maintain consistency, simplify processes, and reduce costs. The effect of good appearance and visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

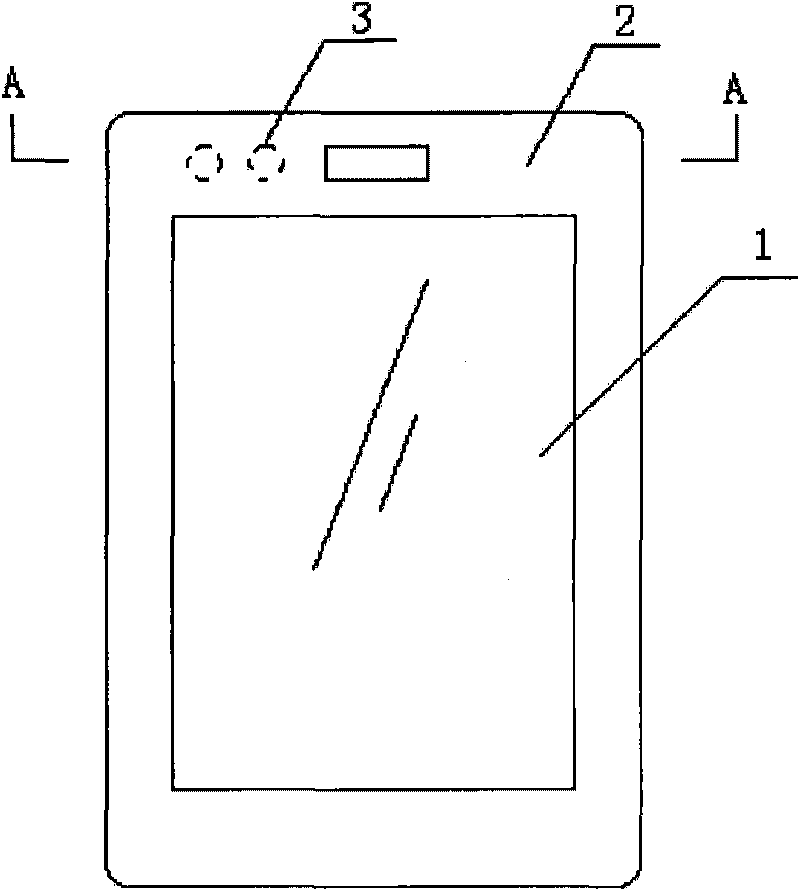

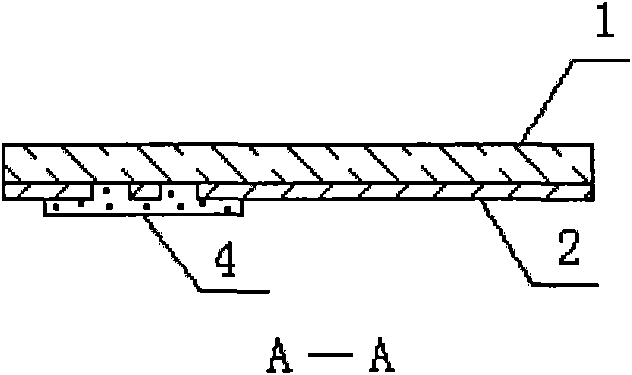

[0012] image 3 Shown is a light-shielding layer structure with an infrared hole for a flat-panel display of a mobile phone touch screen, including a light-transmitting substrate 1 and a light-shielding layer 2 with an infrared hole (IR hole) 3 on the substrate, on the light-transmitting substrate 1 and A layer of infrared light-transmitting material (IR material) 4 is arranged between the light-shielding layers 2 .

[0013] Manufacture process: on the part of the light-transmitting substrate 1 corresponding to the light-shielding layer 2, a layer of infrared light-transmitting material (IR material) 4 is first produced by deposition or coating method, and then the light-shielding material with infrared light-transmitting holes (IR hole) 3 is made Layer 2, so that the reflectivity of the entire light-shielding layer area (including the IR hole) can be consistent, and the IR hole area can realize the infrared transmission function.

[0014] The light-transmitting substrate inc...

Embodiment 2

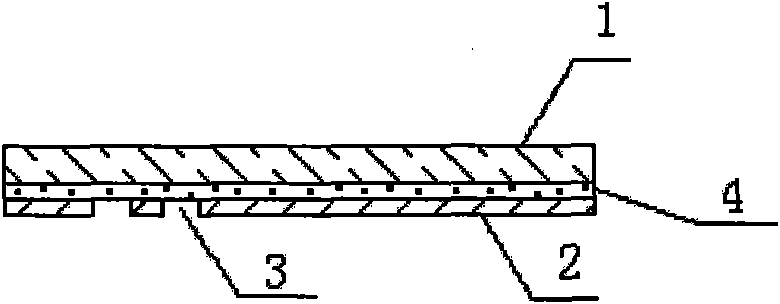

[0016] The present invention also provides another structural mode, that is, the infrared light-transmitting material (IR material) 4 can be made into multiple layers (see Figure 4 ), according to the different color requirements of the light-shielding layer of the flat panel display, the lens (Lens) with different color effects can be produced after superposition of multiple layers of IR materials, and the overall appearance of the mobile phone can be maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com