Shock prevention and strengthening construction method for existing brickwork dwelling house fabricated structure

A masonry structure, prefabricated technology, applied in building construction, building maintenance, construction, etc., can solve problems such as damage to building exterior and interior components, poor living comfort, and high energy consumption, and achieve minimal disturbance to residents, Less wet work and less labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

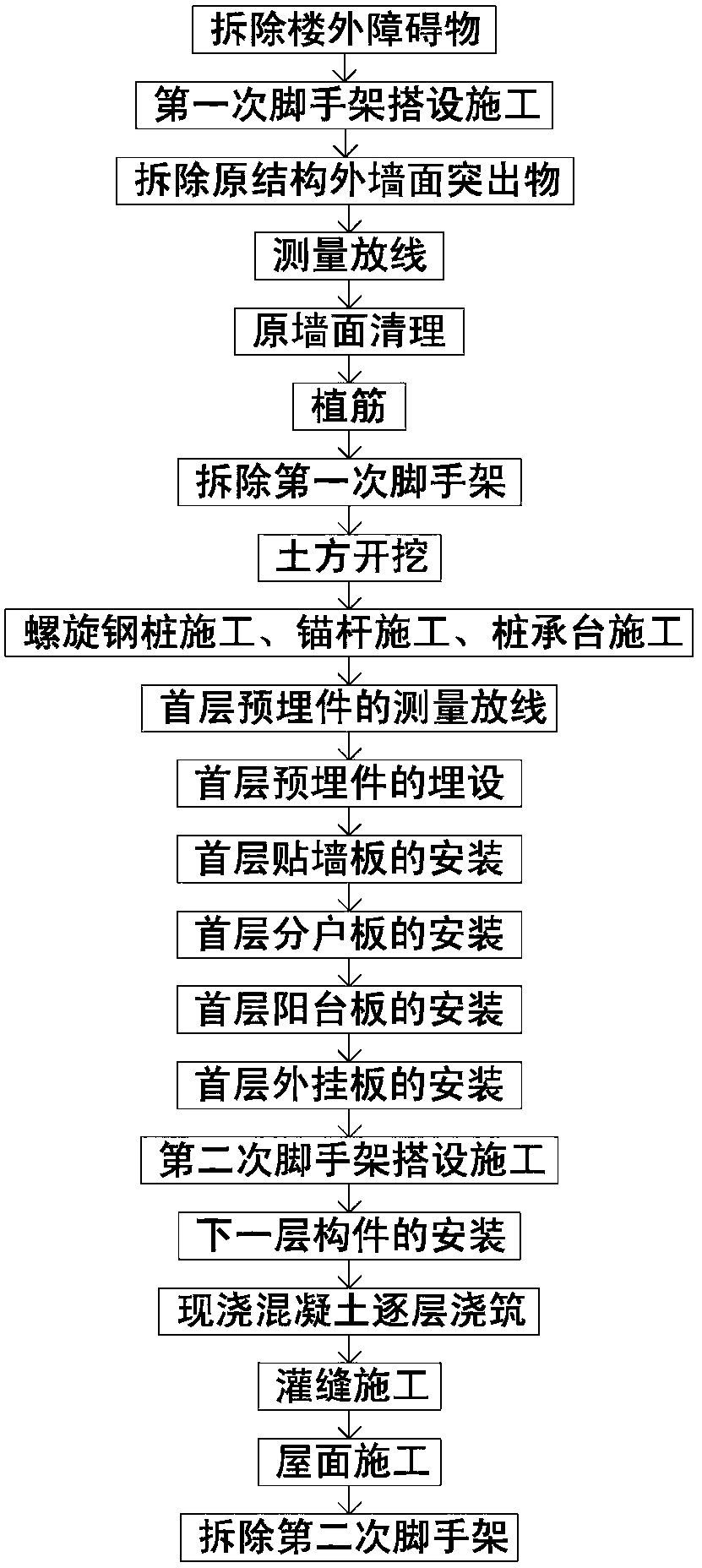

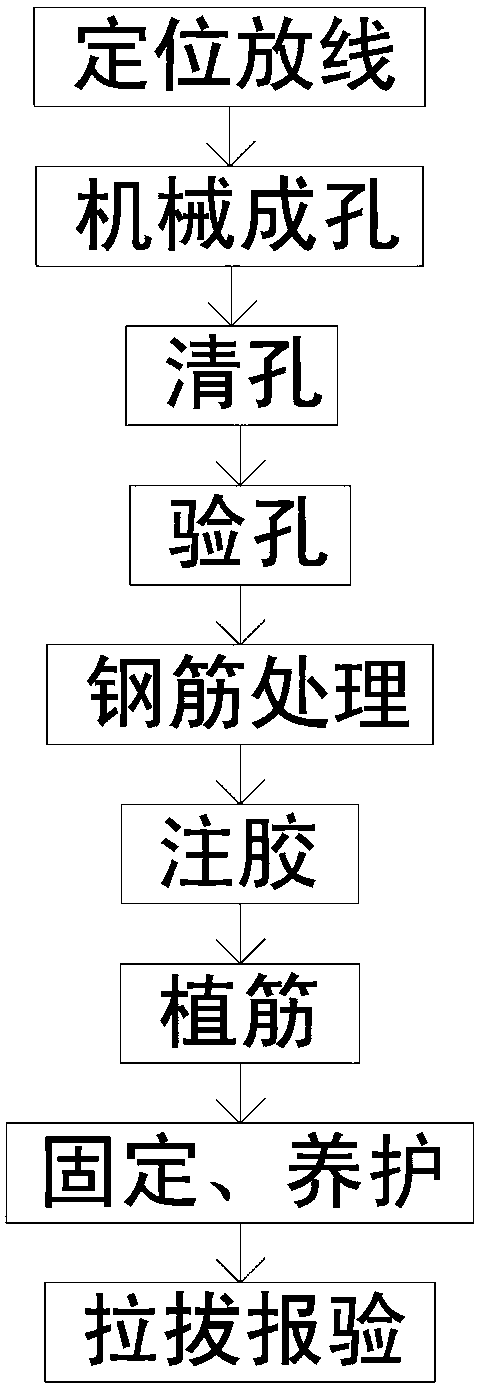

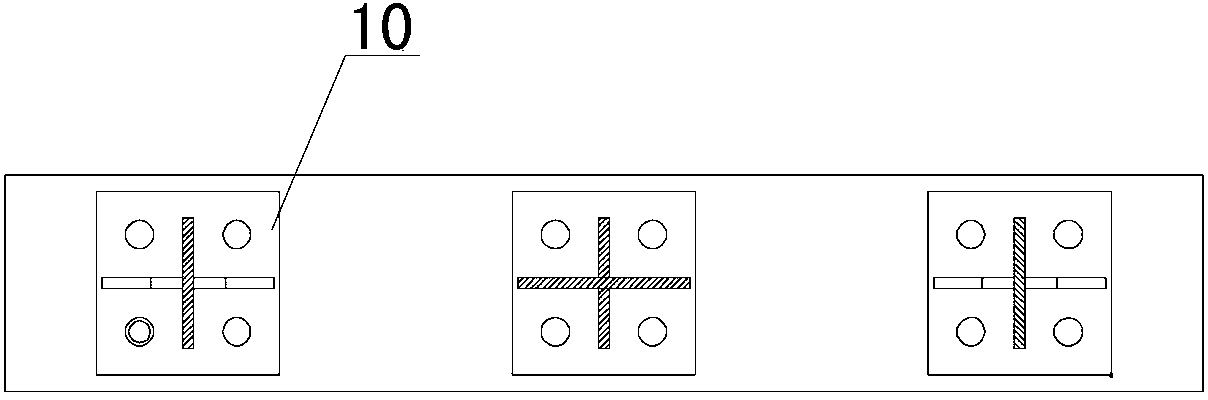

[0053] An assembled anti-seismic reinforcement structure of an existing masonry house, which is connected to the outside of the wall surface 1 of the original masonry structure, and includes wall panels 2, household panels 3, balcony panels 4 and external hanging panels corresponding to the original masonry structure. Plate 5, see for example figure 1As shown, the construction method for seismic reinforcement of prefabricated structures of existing masonry houses, the construction steps are as follows:

[0054] Step 1: Remove the external obstacles of the original masonry structure, carry out pre-renovation of the original underground pipelines that affect the new buildings before construction, and remove the illegal buildings (self-built small houses) of the residents.

[0055] Step 2, the first scaffold erection construction: connect the first scaffold with the original masonry structure, this scaffold is for the original balcony, air-conditioning board, overhanging eaves, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com