Composite PVC (polyvinyl chloride) table face and preparation method thereof

A countertop and wear-resistant layer technology, which is applied in the field of composite countertops, can solve problems such as unrollable and difficult to pave, and achieve the effects of energy saving, strong practicability, and simple and reliable preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

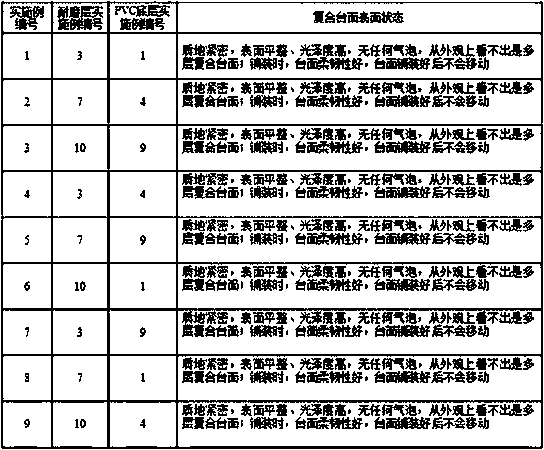

[0029] The solutions provided in the present invention are further described by way of examples below.

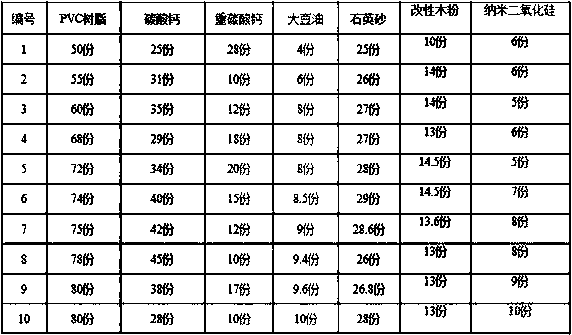

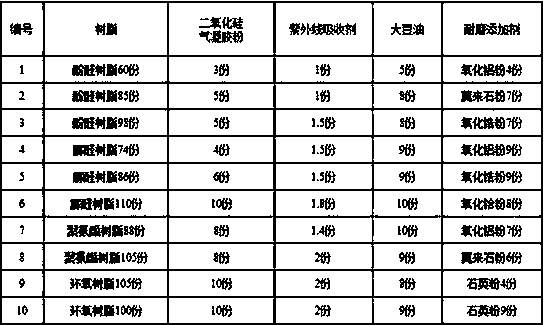

[0030] 1. Preparation of wear-resistant layer

[0031] The components and parts by weight of the wear-resistant layer are as follows:

[0032]

[0033] The silica airgel powder used in the wear-resistant layer component is a hydrophobic powder of 50-80 μm, with a specific surface area of 380m 2 / g or so, the density is 64kg / m 3 . The wear-resistant powder used has an average particle size of 25 μm. The ultraviolet absorber adopts commercially available products, such as series commodities such as phenyl o-hydroxybenzoate, 2,4-dihydroxybenzophenone.

[0034] The preparation method of the wear-resistant layer is as follows: put all the raw materials into the internal mixer for plasticization; then put the plasticized raw materials into the diffusion machine to diffuse until the raw material particles are less than 2mm, the speed of diffusion is 1500r / min, and the dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com