Touch panel

A touch panel and touch sensing layer technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of poor visual effect of the touch panel and affecting the beauty of the touch panel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural design and manufacturing method of some embodiments of the touch panel of the present invention are described in detail below. However, it can be understood that the inventive concept provided by the present invention can be implemented in a wide variety of backgrounds. The specific implementation discussed here The examples are only used to illustrate specific ways of making and using some embodiments of the present invention, and are not intended to limit the scope of the present invention.

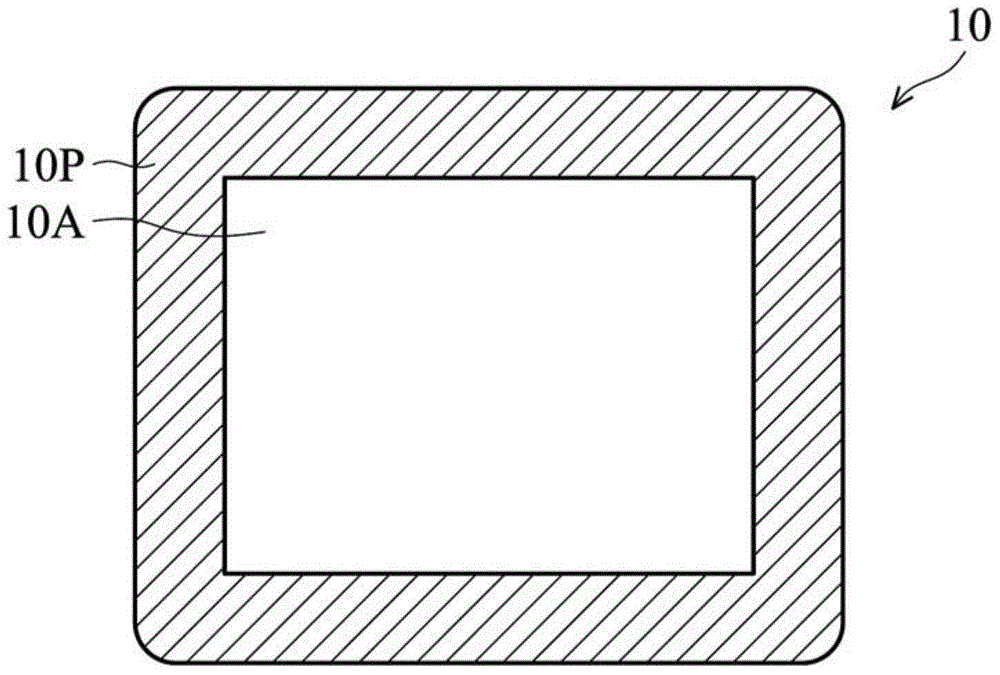

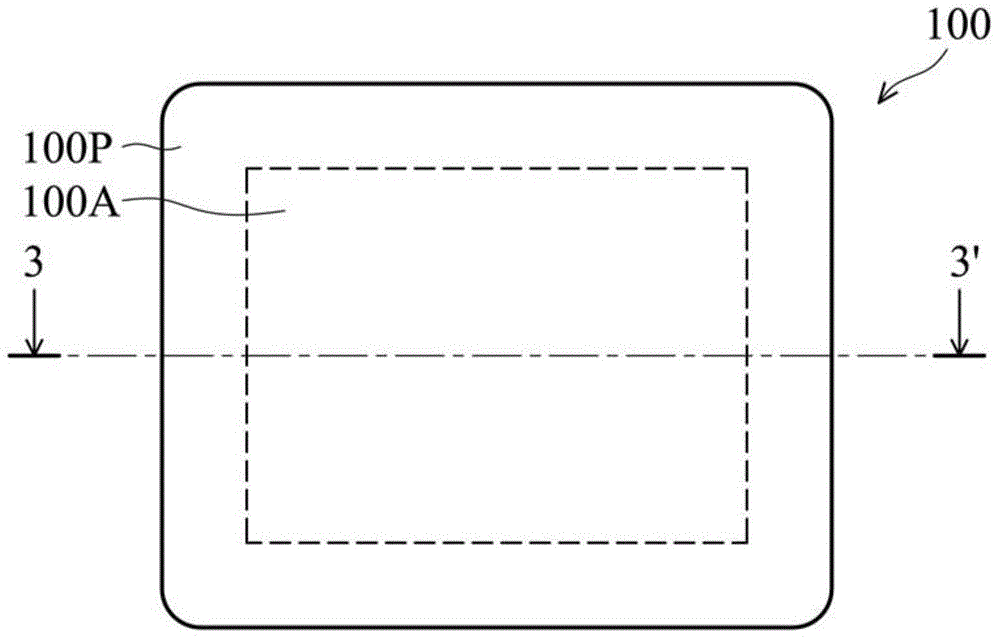

[0031] Such as figure 1 As shown, the touch panel 10 can be divided into an active area 10A and a peripheral area 10P surrounding the active area 10A. The touch sensing element is formed in the active area 10A, and the peripheral area 10P forms a decorative layer with a light-shielding effect. figure 1 A schematic plan view showing a touch panel 10 without the dielectric material layer of the present invention, since the conductive material forming the touch sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com