Cigarette bursting bead noctilucence coating film material, and production method of cigarette bursting bead

A coating film, cigarette technology, applied in the direction of tobacco, application, e-liquid filter, etc., can solve the problems of different colors and no appearance characteristics, and achieve the effect of improving waterproof, improving solubility, and improving waterproof and moisture-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The preparation of a kind of luminous popping beads for cigarettes, the specific steps are as follows:

[0024] (1) Dissolve hydroxypropyl methylcellulose with a viscosity of 10mPa.s in pure water at a temperature of 25±5°C and stir for 0.5 hours to prepare an aqueous solution of hydroxypropylmethylcellulose, wherein the hydroxypropylmethylcellulose Base cellulose accounts for 10% by mass percent of the whole solution;

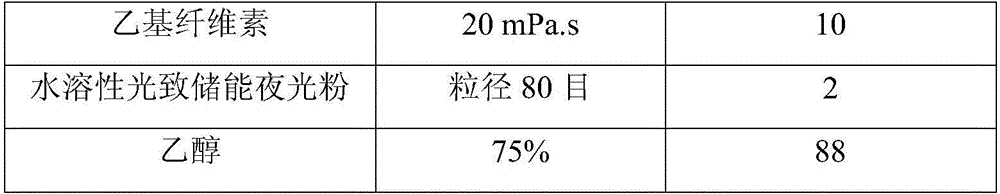

[0025] (2) Prepare the luminous powder mixed solution according to the following formula table:

[0026] Formula table of luminous powder mixed solution

[0027]

[0028]

[0029] Add all the ethyl cellulose and luminous powder in the above formula to ethanol at 25±5°C, stir for 0.5 hours to dissolve into a mixed solution of luminous powder;

[0030] (3) Mix the hydroxypropyl methylcellulose aqueous solution dissolved in step (1) with the luminous powder mixed solution prepared in step (2) according to the mass ratio of 6:4, stir f...

Embodiment 2

[0038] Embodiment 2: the preparation of a kind of luminous popping beads for cigarettes, the specific steps are as follows:

[0039] (1) Dissolve hydroxypropyl methylcellulose with a viscosity of 30mPa.s in purified water at a temperature of 25±5°C and stir for 1 hour to prepare an aqueous solution of hydroxypropylmethylcellulose, wherein the hydroxypropylmethylcellulose Base cellulose accounts for 20% by mass percent of the whole solution;

[0040] (2) Prepare the luminous powder mixed solution according to the following formula table:

[0041] Formula table of luminous powder mixed solution

[0042] Raw material type Specification parts by weight Ethyl cellulose 40mPa.s 20 Water-soluble photo-induced energy storage luminous powder Particle size 100 mesh 5 ethanol 85% 75

[0043] Add all the ethyl cellulose and luminous powder in the above formula to ethanol at 25±5°C, stir for 1 hour and dissolve to form a mixed solution of luminous...

Embodiment 3

[0052] Embodiment 3: The preparation of a kind of luminous popping beads for cigarettes, the specific steps are as follows:

[0053] (1) Dissolve hydroxypropyl methylcellulose with a viscosity of 60mPa.s in purified water at a temperature of 25±5°C and stir for 2 hours to prepare an aqueous solution of hydroxypropylmethylcellulose, wherein the hydroxypropylmethylcellulose Hydroxypropyl methylcellulose accounts for 30% by mass of the entire solution, and it is difficult to dissolve. Generally, such high-density hydroxypropyl methylcellulose is not used;

[0054] (2) Prepare the luminous powder mixed solution according to the following formula table:

[0055] Formula table of luminous powder mixed solution

[0056] Raw material type Specification parts by weight Ethyl cellulose 60mPa.s 25 Water-soluble photo-induced energy storage luminous powder Particle size 140 mesh 15 ethanol 95% 60

[0057] Add all the ethyl cellulose and luminous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com