Thermoplastic elastomer for ABS jetting adhesion

A thermoplastic elastomer and thermoplastic technology, applied in the field of thermoplastic elastomer, can solve the problem of low elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

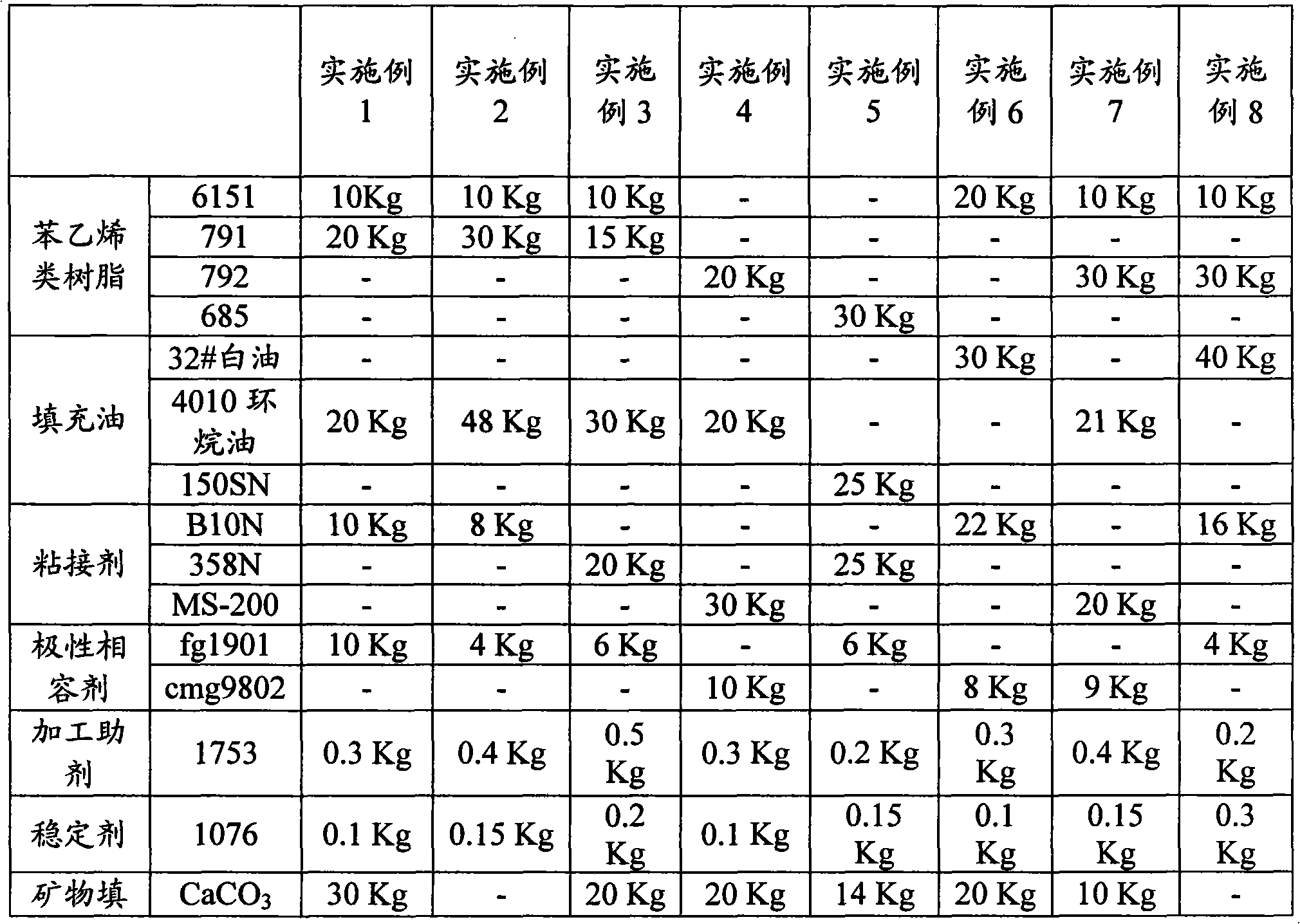

[0045] 1. Raw material ratio:

[0046]

[0047]

[0048] Among the above raw materials, styrene resin: 6151 (Taiwan Rubber, SEBS), 791 and 792 (Baling Petrochemical, SBS), 685 (Taiwan Yingquan, SBS);

[0049] Filling oil: 32# white oil (Xinjiang Karamay, white oil (that is, saturated linear paraffin oil with a flash point greater than 200 ° C)), 4010 (Xinjiang Karamay, naphthenic oil with a flash point greater than 200 ° C), 150SN (Korean Ssangyong, Saturated linear paraffin oil with a flash point greater than 200°C);

[0050] Adhesives: B10N (BASF, polyisobutylene), 358N (BASF, polystyrene-acrylonitrile), MS-200 (Nufaq, styrene-methyl methacrylate copolymer);

[0051] Compatibilizer: fg1901 (Kraton, SEBS-g-MAH), cmg9802 (Shanghai Rizhisheng, EPDM-g-MAH);

[0052] Processing aid: 1753 (Huipu, erucamide);

[0053] Stabilizer: 1076 (Ciba, hindered phenol antioxidant);

[0054]Mineral filler: CaCO 3 (Jiangsu Lida, 1250 mesh).

[0055] 2. Injection molding

[0056] We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com