Low-hardness polyurethane self-skinning composition for printing rubber roll and preparation method for composition

A printing rubber roller and low-hardness technology, which is applied in the field of low-hardness polyurethane self-skinning composite materials for printing rubber rollers and its preparation, can solve the problem of insufficient contact with uneven object surfaces, failure to meet the use requirements, and increased hardness of rubber rollers, etc. problem, to achieve the effect of wide adjustable range of hardness, good impact resistance, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

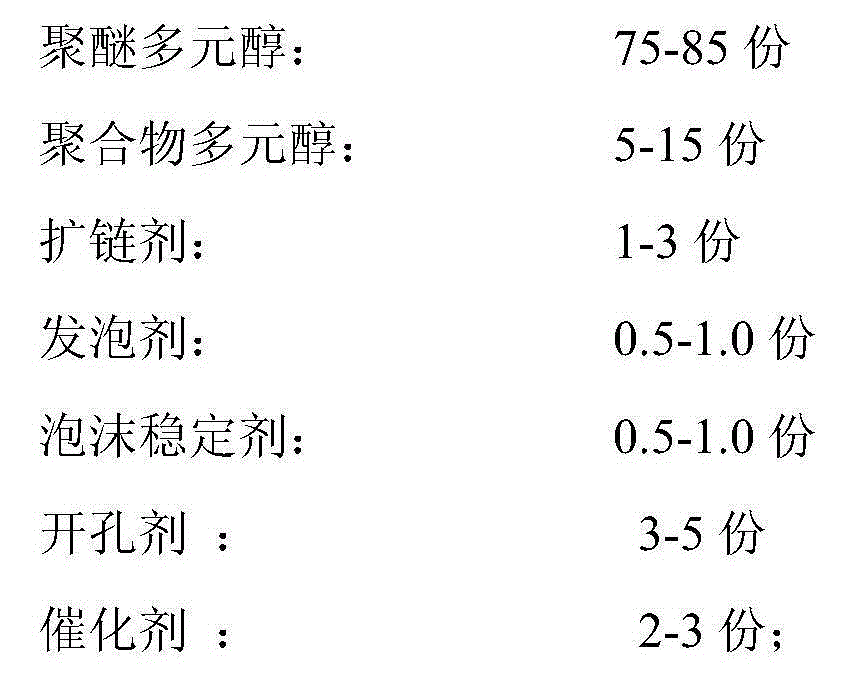

[0031] Component A is made of the following raw materials in parts by mass:

[0032]

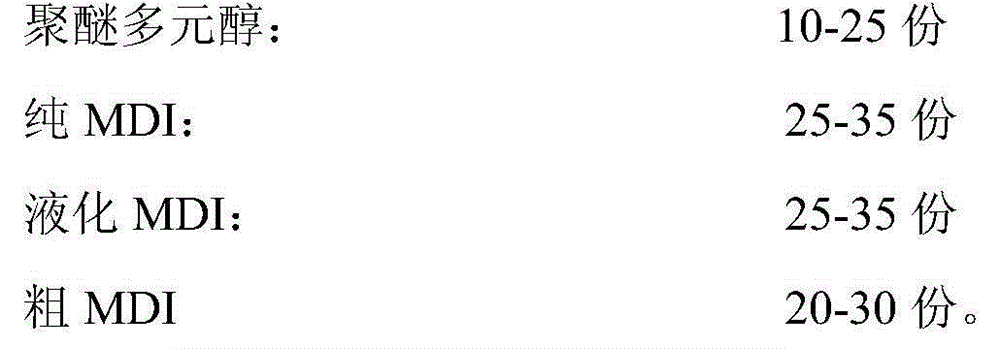

[0033] Component B is made from the following raw materials in parts by mass:

[0034]

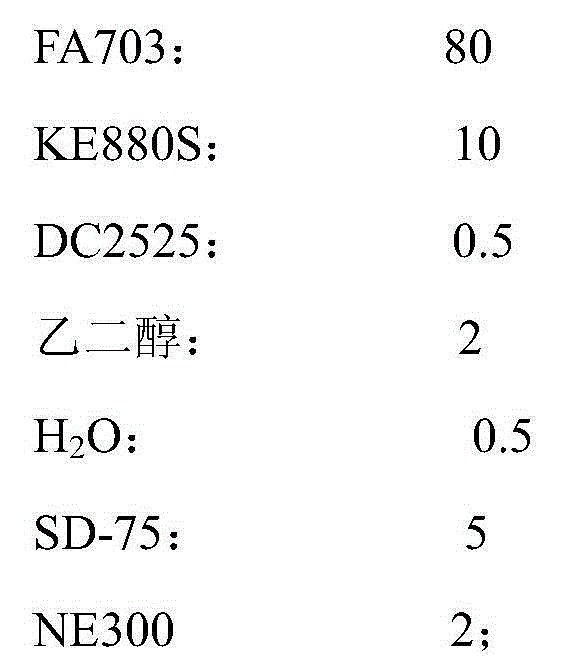

[0035] A component: Weigh 80kg of FA703, 10kg of KE880S into the reactor and stir, then add 0.5kg of DC2525, 2kg of ethylene glycol, 5kg of SD-75, 2kg of NE300, 0.5kg of H 2 O, after stirring and mixing at room temperature for 0.5 hours, the rotation speed is 50 rpm, and the product of component A is obtained.

[0036] Component B: Take 25kg KE810 and place it in a reaction kettle, raise the temperature to 110°C and dehydrate under vacuum (-0.09MPa) for 1.5 hours, then cool down to 50°C, add 25kg 44C, 25kg CD-C, heat up to 75°C and keep it warm for reaction 1 hour, then add 25kgPM200, stir for 0.5 hours, take a sample and test, the mass content of -NCO reaches 22.8±0.2%, cool down to 40°C and discharge, sealed and stored.

[0037] The required rubber roller mold is wiped with a release agent (a c...

Embodiment 2

[0040] Component A is made of the following raw materials in parts by mass:

[0041]

[0042] Component B is made from the following raw materials in parts by mass:

[0043]

[0044] Component A: Weigh 75kg of FA703, 15kg of KE880S into the reactor for stirring, then add 1.0kg of DC2525, 1kg of ethylene glycol, 4kg of SD-75, 3kg of NE300, 1.0kg of H 2 O, after stirring and mixing at room temperature for 0.5 hours, the product of component A is obtained.

[0045] Component B: Take 15kg KE810 and place it in a reaction kettle, heat up to 100°C and dehydrate under vacuum (-0.09MPa) for 2 hours, then cool down to 40°C, add 35kg 44C, 30kg CD-C, slowly heat up to 70°C and keep it warm React for 1 hour, then add 20kgPM200, stir for 0.5 hours, take a sample and test, the mass content of -NCO reaches 26.4±0.2%, cool down to 40°C, discharge, and seal for storage.

[0046] Wipe the mold release agent (conventional commercially available mold release agent) on the required rubber ...

Embodiment 3

[0049] Component A is made of the following raw materials in parts by mass:

[0050]

[0051] Component B is made from the following raw materials in parts by mass:

[0052]

[0053] Component A: Weigh 85kg of FA703, 5kg of KE880S into the reactor and stir, then add 0.7kg of DC2525, 3kg of ethylene glycol, 3kg of SD-75, 2.5kg of NE300, 0.8kg of H 2 O, after stirring and mixing at room temperature for 0.5 hours, the product of component A is obtained.

[0054]Component B: Take 20kg KE810 and place it in a reaction kettle, heat it up to 105°C and dehydrate under vacuum (-0.09MPa) for 1.8 hours, then cool down to 45°C, add 30kg 44C, 25kg CD-C, slowly heat up to 72°C and keep it warm React for 1 hour, then add 25kg PM200, stir for 0.5 hours, take a sample and test, the mass content of -NCO reaches 24.5±0.2%, cool down to 40°C and discharge, sealed and stored.

[0055] Wipe the mold release agent (conventional commercially available mold release agent) on the required rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com