Blade surface roll-polishing finishing method adopting distributed protection measure

A protective measure and finishing technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of poor processing effect of blade root, over-polishing of intake and exhaust edges, poor repeatability, etc., to achieve Effects of increasing surface integrity, improving surface texture, and reducing surface roughness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

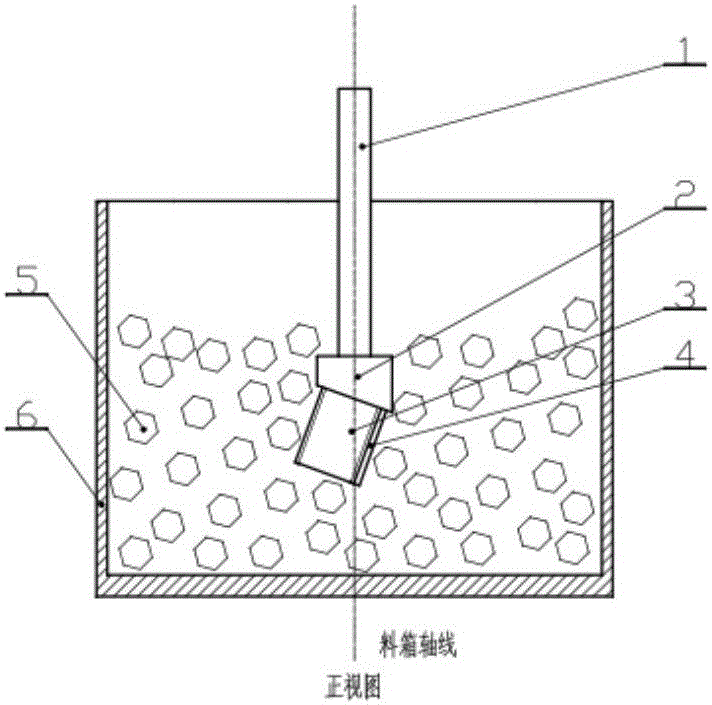

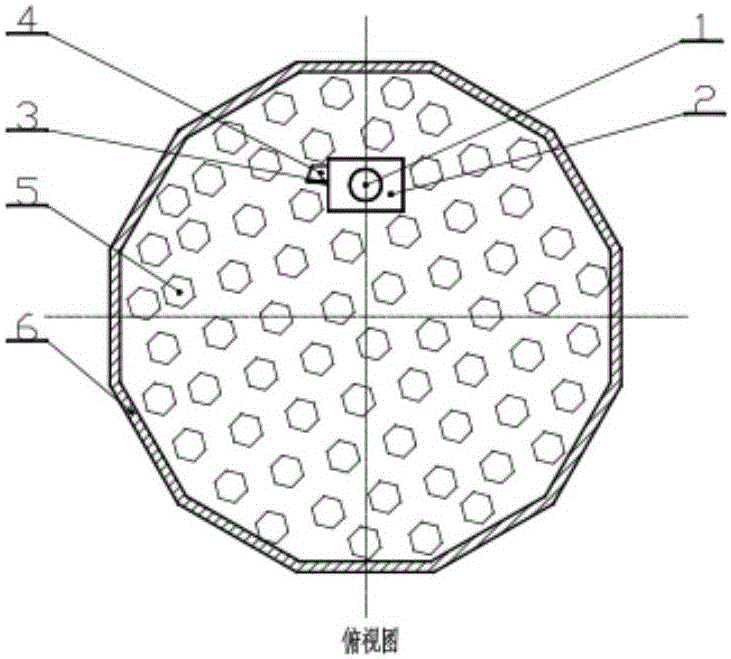

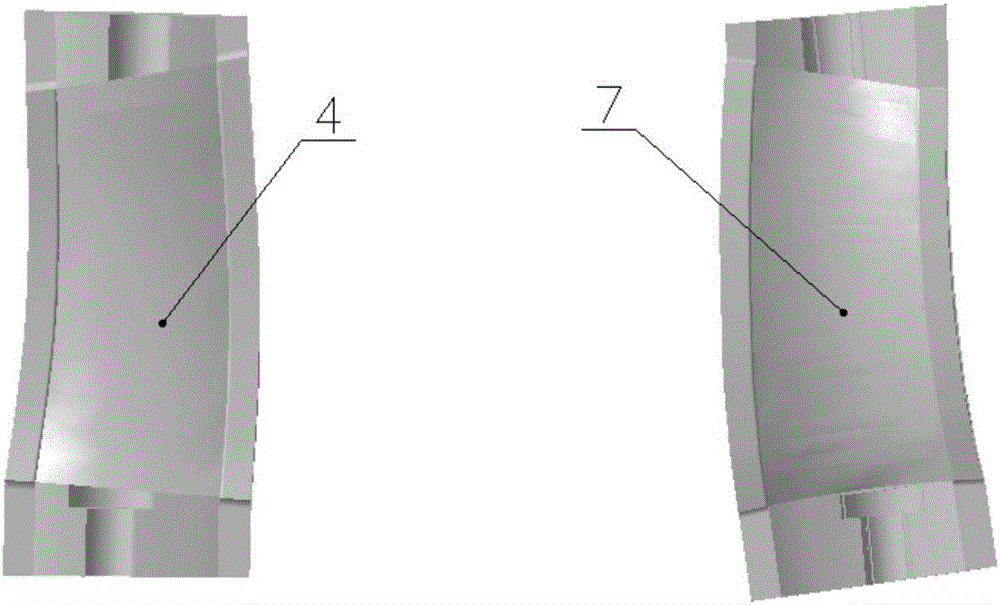

[0021] This embodiment provides a blade surface barrel polishing and finishing method using distributed protection measures, which is characterized in that: the blade 3 and the leaf pot position protection device 4 or the leaf back position protection device 7 are fixed to the clamp at a certain spatial angle 2, the clamp 2 is connected to the main shaft 1; during processing, the blade 3 is placed in the material box 6 containing the processing medium 5 (rolling polishing block, polishing liquid, etc.), and the main shaft 1 swings around its own axis , The material box 6 rotates around its own axis, so as to realize the finishing processing of the blade.

[0022] Specific processing steps:

[0023] 1) Add the processing medium 5 containing the grinding block and polishing liquid to the feed box 6. The feed box 6 rotates around its own axis, and the speed of the feed box: 46rpm.

[0024] 2) The blade pot part protection device 4 is used to protect the blades, and the blade 3 together...

Embodiment approach 2

[0039] This embodiment provides a blade surface barrel polishing and finishing method using distributed protection measures, which is characterized in that: the blade 3 and the leaf pot position protection device 4 or the leaf back position protection device 7 are fixed to the clamp at a certain spatial angle 2, the clamp 2 is connected to the main shaft 1; during processing, the blade 3 is placed in the material box 6 containing the processing medium 5 (rolling polishing block, polishing liquid, etc.), and the main shaft 1 swings around its own axis , The material box 6 rotates around its own axis, so as to realize the finishing processing of the blade.

[0040] Specific processing steps:

[0041] 1) Add the processing medium 5 containing the grinding block and polishing liquid to the material box 6. The material box 6 rotates around its own axis, and the speed of the material box: 55rpm.

[0042] 2) The blade pot part protection device 4 is used to protect the blades, and the blad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com