Digital glazed ceramic tile and production method thereof

A production method and digital technology, applied in the field of ceramic building decoration materials, can solve the problems of single texture fixation and lag in concave-convex effect, and achieve the effect of fine concave-convex effect, fine surface texture and rich concave-convex details.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

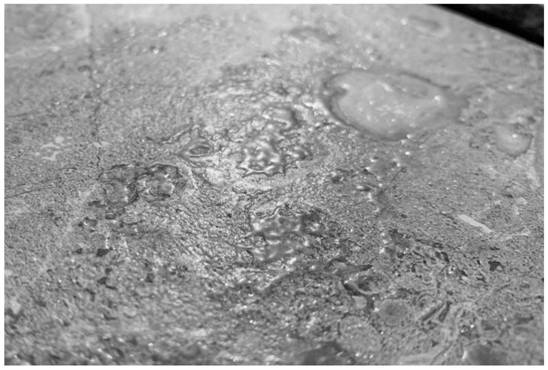

[0050] The invention discloses a digital glaze mold ceramic tile, such as figure 1 As shown, the tiles have a mold effect that is concave and convex along the grain. The tiles include a brick adobe layer, a makeup soil layer, a digital glaze layer, a surface glaze layer, an inkjet printing layer, and a digital protective glaze layer that are connected in sequence.

Embodiment 2

[0052] This embodiment discloses a method for manufacturing digital glazed tiles made of rock materials, including the following steps:

[0053] Step P1, prepare digital glaze, choose calcined kaolin 18%, quartz 10%, potassium albite feldspar 52%, barium carbonate 12%, zinc oxide 6% these five kinds of mineral raw materials and chemical raw materials to make basic glaze according to mass percentage. Then weigh 45% of basic glaze, 5% of functional resin additive (acrylic resin), 35% of ethyl acetate solvent, 13.8% of dispersant (composed of 1:5 polyacrylamine and polyvinylpyrrolidone), and suspend Agent (mixed by 0.1:5 sodium methylcellulose and ethylene glycol) 0.15%, defoamer 0.4% (polyoxyethylene polyoxypropanolamine ether), leveling agent (Hyperlev F40) 0.5% and pH adjuster (organic amine) 0.15%, and then utilize grinding and dispersing method to prepare the specific gravity at 1.43 grams / ml, the glaze ink that particle size is that D100 is equal to 0.9 microns.

[0054] S...

Embodiment 3

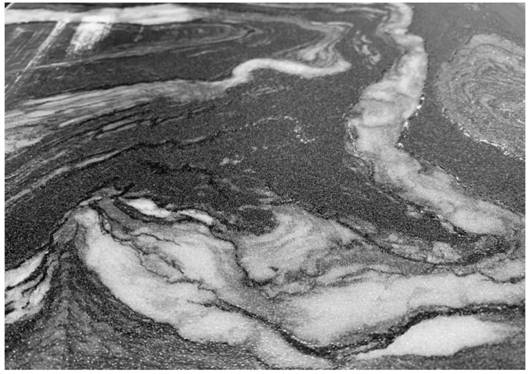

[0068] This embodiment discloses a method for manufacturing digital glazed tiles made of wood grain materials, which includes the following steps:

[0069] Step P1, prepare digital glaze, choose calcined kaolin 18%, quartz 10%, potassium albite feldspar 52%, barium carbonate 12%, zinc oxide 6% these five kinds of mineral raw materials and chemical raw materials to make basic glaze according to mass percentage. Then weigh 45% of basic glaze, 5% of functional resin additive (acrylic resin), 35% of ethyl acetate solvent, 13.8% of dispersant (composed of 1:5 polyacrylamine and polyvinylpyrrolidone), and suspend Agent (mixed by 0.1:5 sodium methylcellulose and ethylene glycol) 0.15%, defoamer 0.4% (polyoxyethylene polyoxypropanolamine ether), leveling agent (Hyperlev F40) 0.5% and pH adjuster (organic amine) 0.15%, and then utilize grinding and dispersing method to prepare the specific gravity at 1.43 grams / ml, the glaze ink that particle size is that D100 is equal to 0.9 micron. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com