Water-based pigment digital inkjet textile printing ink and its preparation and use method

A digital inkjet, water-based pigment technology, used in textiles and papermaking, copying/marking methods, inks, etc., can solve problems such as less than ideal washing fastness, and achieve bright color, low energy consumption, and good washing fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

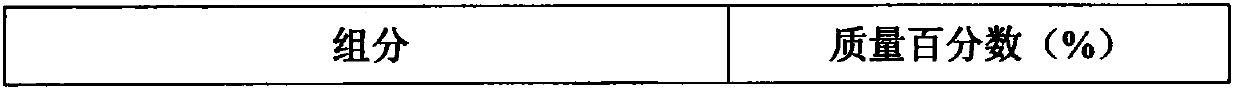

[0040] A kind of blue water-based pigment digital inkjet textile printing ink, its formula is as shown in table 1.

[0041] Table 1 Formula of blue water-based pigment digital inkjet textile printing ink:

[0042]

[0043]

[0044] Wherein, the synthetic method of described organic fluorine modified polyacrylate nanoemulsion is: 12.3g methyl methacrylate (MMA), 2.7g hexafluorobutyl methacrylate (HFBM), 0.6g emulsifier (by Xiaofan 465, sodium lauryl sulfate SDS (mixed at a mass ratio of 1:1), 0.5g of ethylene glycol dimethacrylate was added to 20g of water, stirred at a high speed of 2500rpm, and pre-emulsified for 30min to obtain monomer pre-emulsion. Then, 30 g of monomer pre-emulsion was added into the three-necked flask, the temperature was raised to 80° C., and 4 g of initiator potassium persulfate aqueous solution (concentration: 0.82%) was added to react for 30 min. Then use the dropping funnel to drop 6g initiator potassium persulfate aqueous solution (concentra...

Embodiment 2

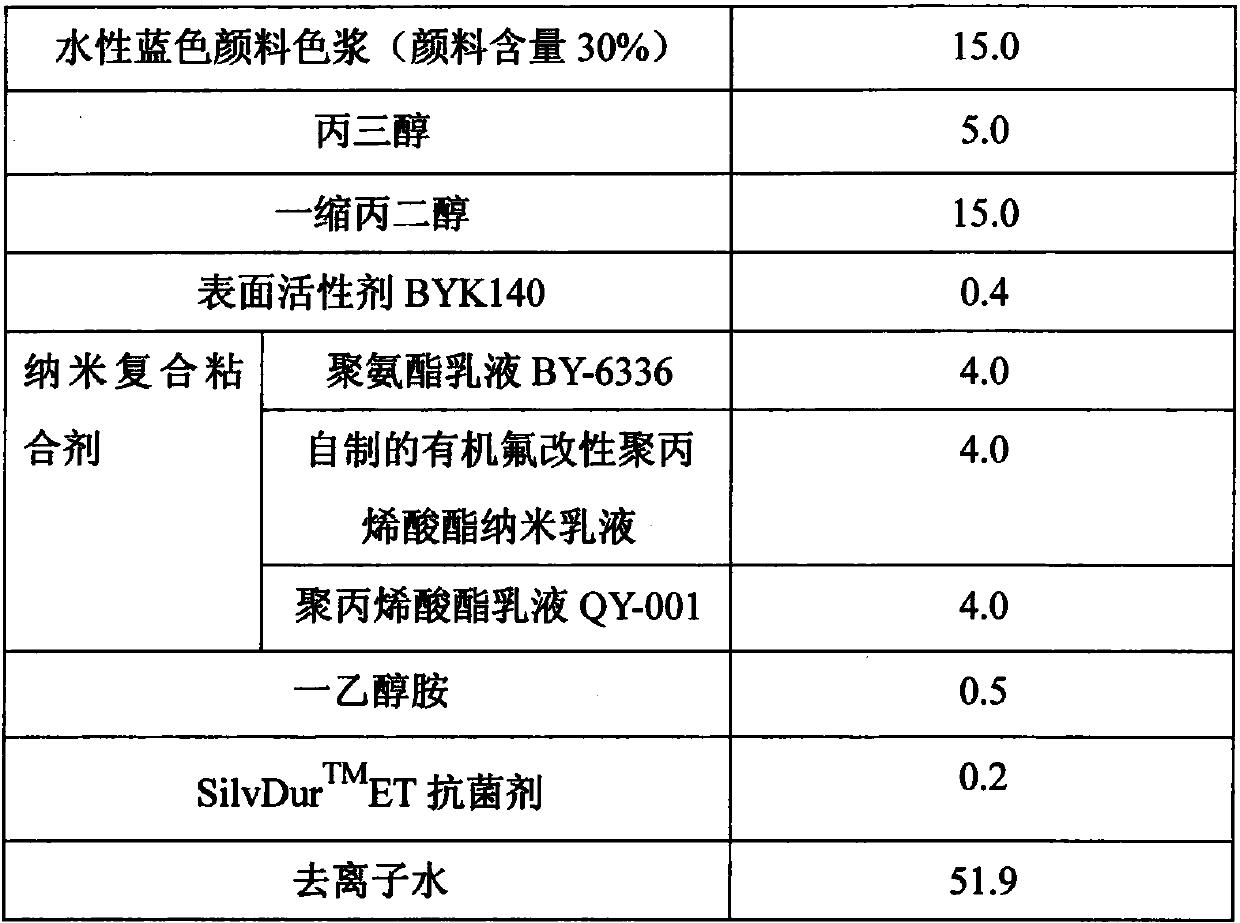

[0055] A kind of red water-based pigment digital inkjet textile printing ink, its formula is as shown in table 2.

[0056] Table 2 Red water-based pigment digital inkjet textile printing ink formula:

[0057]

[0058] The synthesis method of the described organofluorine-modified polyacrylate nanoemulsion is the same as that in Example 1.

[0059] The preparation method of described red water-based pigment digital ink-jet textile printing ink is: press each component prescription listed in table 2, at first surfactant, nanocomposite binder, humectant, pH regulator and antibacterial The agent was added into deionized water, and then stirred with a high-speed mixer for 80min at a speed of 2000-4500rad / min to make it a uniform solvent system; then red pigment paste (purchased from Cabot (China) Investment Co., Ltd.) was added Into the above solvent system, stir with a high-speed mixer at a speed of 2000 rad / min for 30 minutes to make it a uniform ink dispersion system; finally...

Embodiment 3

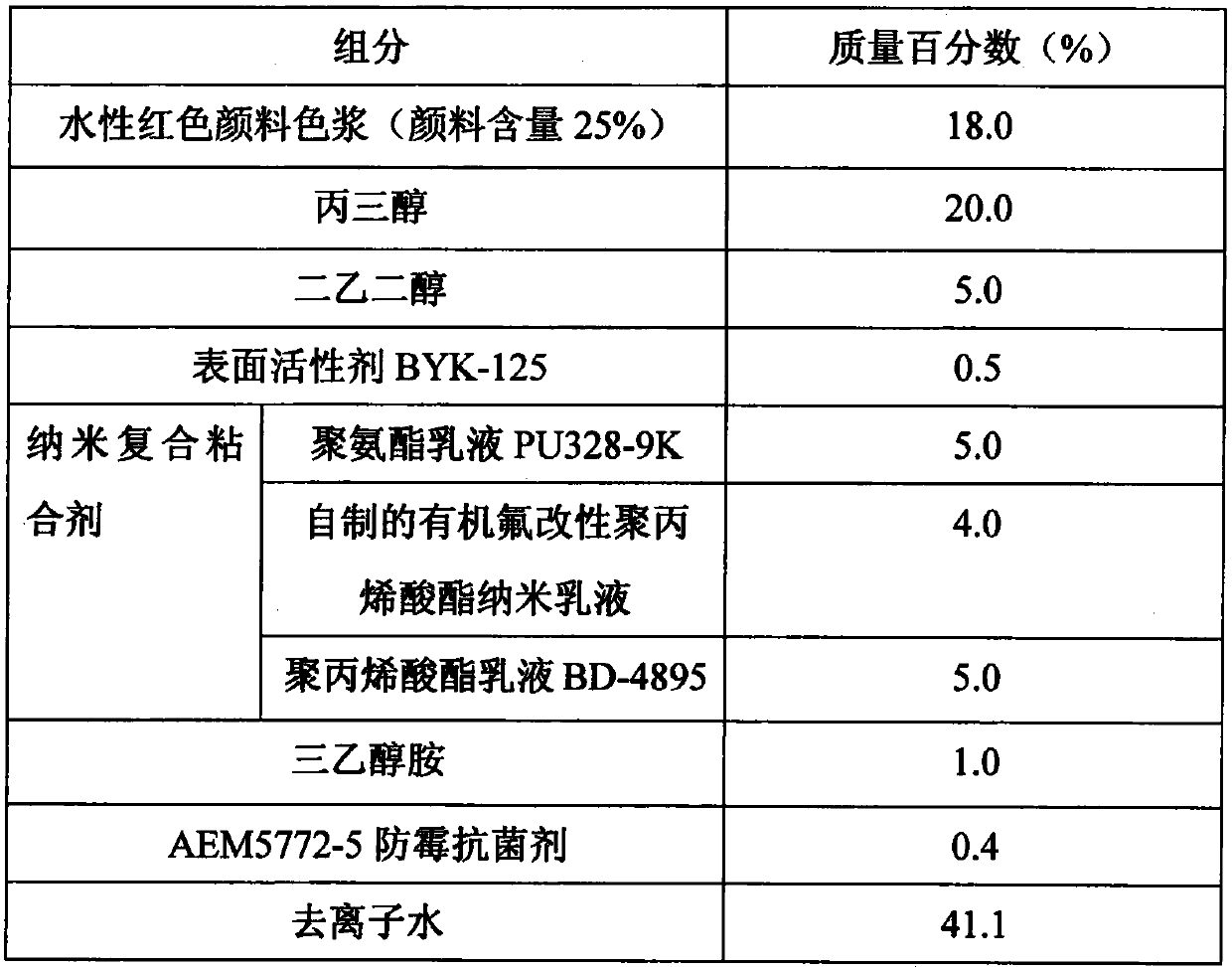

[0063] A kind of yellow water-based pigment digital inkjet textile printing ink, its formula is as shown in table 3.

[0064] Table 3 yellow water-based pigment digital inkjet textile printing ink formula:

[0065]

[0066] The synthesis method of the described organofluorine-modified polyacrylate nanoemulsion is the same as that in Example 1. The organic fluorine-modified polyacrylate nanoemulsion does not break into a film after inkjet printing on the fabric, and is distributed in the composite of the polyurethane emulsion and another polyacrylate emulsion in the form of hydrophobic nanoparticles. in the film.

[0067] The preparation method of described yellow water-based pigment digital ink-jet textile printing ink is: press each component formula listed in table 2, at first surfactant, nanocomposite binder, humectant, pH regulator and antibacterial The agent was added into deionized water, and then stirred with a high-speed mixer for 80min at a speed of 2000-4500rad / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com