Crosslinkable reactive disperse dye compound and preparation and application thereof

A technology of reactive disperse dyes and disperse dyes, which is applied in the field of crosslinkable reactive disperse dye compounds and their preparation and application, can solve the problems of long printing process of mixed dyes, serious staining of dyes, poor printing hand feeling, etc., and achieve good Printing fluency, good dye compatibility, good rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

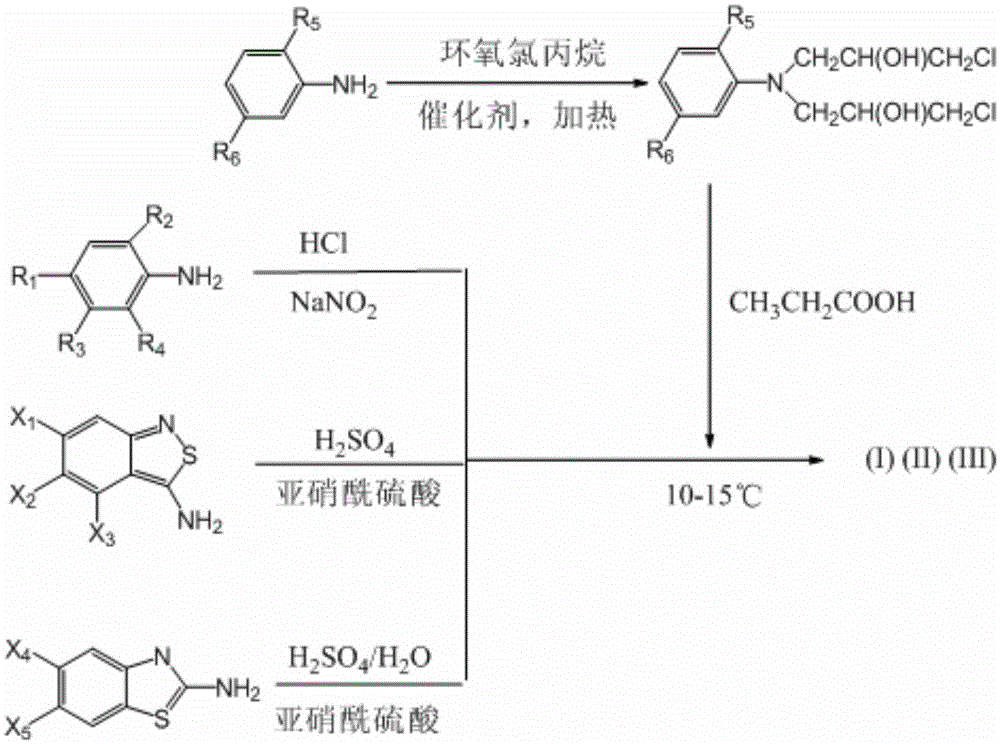

Method used

Image

Examples

Embodiment 1

[0057] Composite target:

[0058]

[0059] Raw materials include m-nitroaniline, epichlorohydrin, aniline, benzyltriethylammonium chloride, hydrochloric acid, sodium nitrite, etc.

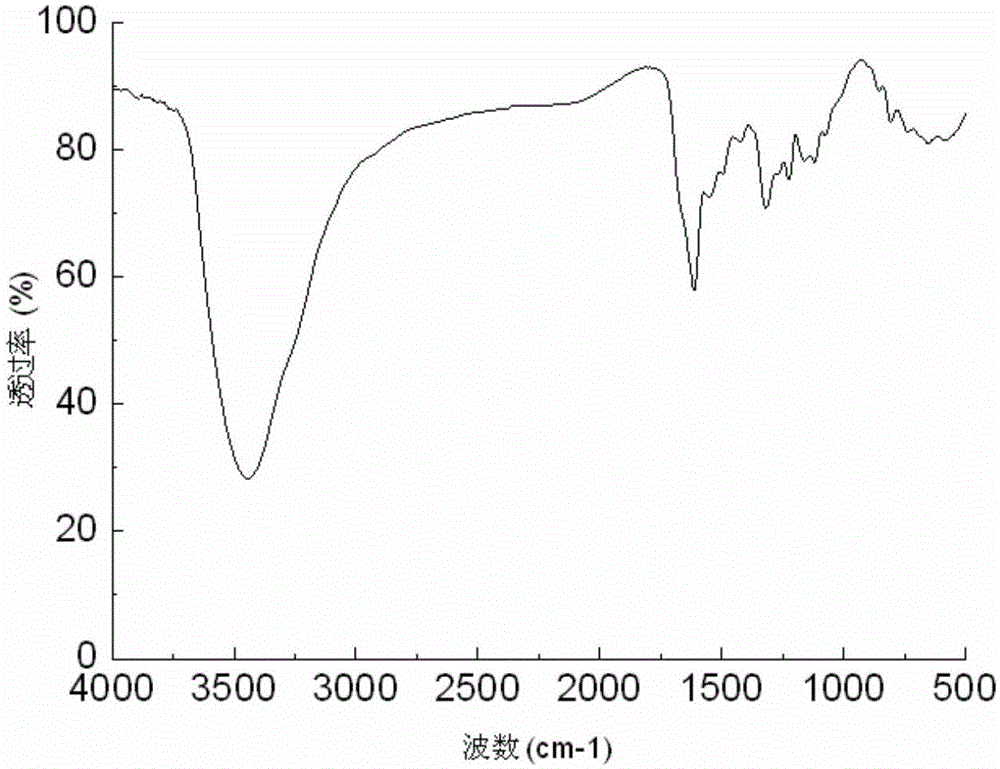

[0060] Preparation of coupling components: 148.56g of 100% epichlorohydrin, 18.63g of aniline with a purity of 100% and 0.36g of benzyltriethylammonium chloride were sequentially added into a coupling reaction kettle, and stirred until completely dissolved. After keeping the reaction at room temperature for 36 hours, the excess epichlorohydrin was evaporated by rotary evaporation, and a taupe viscous substance was formed. Add 50ml of 30% acetic acid and stir until completely dissolved for use.

[0061] Diazotization reaction: Add 27.6g of 100% m-nitroaniline, 500ml of water and 50ml of 36% hydrochloric acid to the diazotization reaction kettle and heat and stir until completely dissolved. Add 47.33g of 30% sodium nitrite solution dropwise, maintain the diazotization reaction at 0-5°C and normal...

Embodiment 2

[0067] Composite target:

[0068]

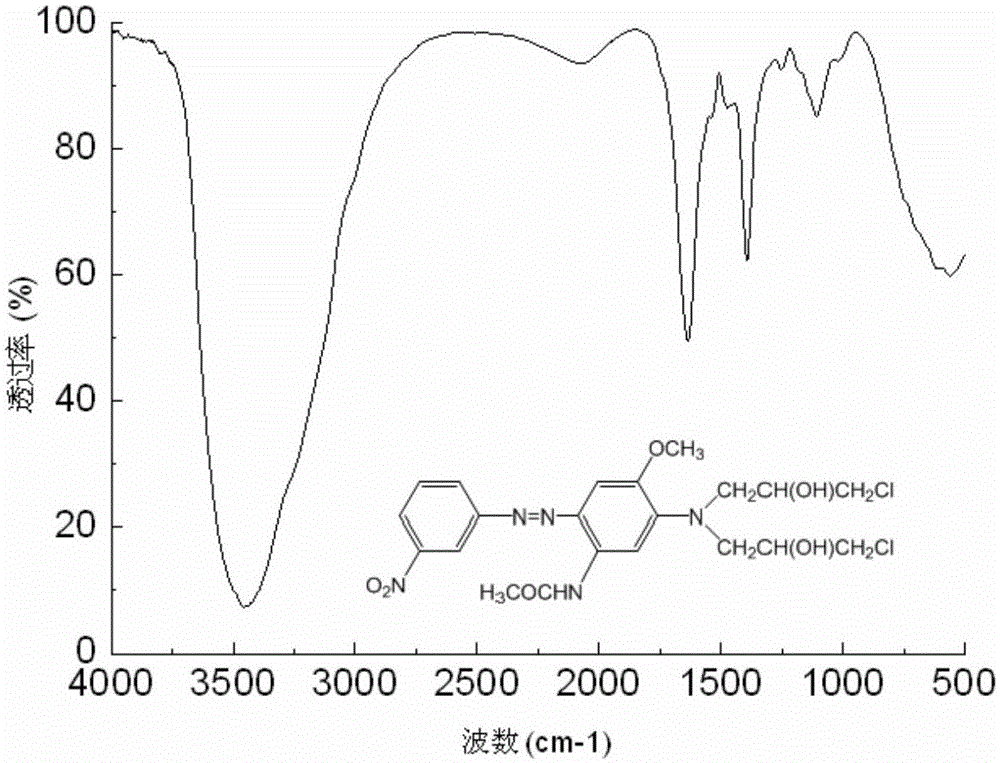

[0069] Raw materials include p-nitroaniline, epichlorohydrin, 3-amino-4-methoxyacetanilide, benzyltriethylammonium chloride, hydrochloric acid, sodium nitrite, etc.

[0070] Preparation of coupling components: Add 148.56g of 100% epichlorohydrin, 36g of 100% 3-amino-4-methoxyacetanilide and 0.72g of benzyltriethylammonium chloride in the coupling reaction kettle, Stir until completely dissolved. After keeping the reaction at room temperature for 36 hours, the excess epichlorohydrin was evaporated by rotary evaporation, and a dark gray-brown sticky substance was formed. Add 50ml of 30% acetic acid and stir until completely dissolved for use.

[0071] Diazotization reaction: Add 27.6g of 100% m-nitroaniline, 500ml of water and 50ml of 36% hydrochloric acid to the diazotization reaction kettle and heat and stir until completely dissolved. Add 47.33g of 30% sodium nitrite solution dropwise, maintain the diazotization reaction at 0-5°C and n...

Embodiment 3

[0077] Composite target:

[0078]

[0079] Raw materials include 2-bromo-4,6-dinitro-aniline, epichlorohydrin, m-acetanilide, benzyltriethylammonium chloride, sulfuric acid and nitrosyl sulfuric acid, etc.

[0080] Preparation of coupling components: 148.56g of 100% epichlorohydrin, 30g of 100% pure m-acetanilide and 0.6g of benzyltriethylammonium chloride were successively added into the coupling reaction kettle, and stirred until completely dissolved. After keeping the reaction at room temperature for 36 hours, the excess epichlorohydrin was evaporated by rotary evaporation, and a taupe viscous substance was formed. Add 50ml of 30% acetic acid and stir until completely dissolved for use.

[0081]Diazotization reaction: Add 52.404g 100% 2-bromo-4,6-dinitro-aniline and 103.6g 98% sulfuric acid to the diazotization reaction kettle in turn, stir until completely dissolved at 20-30°C, then slowly add 63.5g of 40% nitrosyl sulfuric acid, heat up to 50-55°C and keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com